Trio boiler / Beckett afg bang at startup

https://www.youtube.com/watch?v=W5TW7BIRrhw

https://www.youtube.com/watch?v=W5TW7BIRrhwThanks for any and all help!!

Comments

-

Are you at or below the MFG recommended firing rate? 1.20 nozzle at 160 psi=1.52 gph. I can't read your rating plate.

Could be electrode settings, igniter going bad oil supply problem.

To me in the video it seems to light instantly but hard.

If i couldn't find anything after rechecking all adjustments and combustion test I would reduce the firing rate with a smaller nozzle (like 1.00) retest the combustion and see if that helps1 -

I forget at moment mfr and location is 2hrs away. However I double check electrodes, new nozzle and all adjustments. Has a 15/15 pre post purge. FYI this is a completely new system I installed in a new home. I have called Rep and waiting for reply. He is also the one that spec’d 160lbs on that nozzle. This is a three past high silicone, low mast unit with a AFG M tube with conic shield tube. One of my thoughts is to under fire with a 1.0 60B. Just need to get stack to 335/350 degrees. That’s so much for your input. Updates to follow.0

-

-

I think it’s too much combustion air. What was your excess air number and net stack temp?

What’s the model number?

Are you sure that model wants -.02 over the fire? Triple passes usually want zero to positive, and some want zero at the breech or test port.

Draft and excess air will affect your stack temperature more than nozzle size.

1.20 @ 160psi is 1.52 gph.

There was an error rendering this rich post.

3 -

Net stack is 353. I forget excess air at moment. If these trio’s have a Riello then they are positive. All numbers I am using or tuning to are provided by the factory rep. But I do agree this is over fired at this point as far as I’m concerned. I do have call into rep to review video and advise or stop at location. Will update0

-

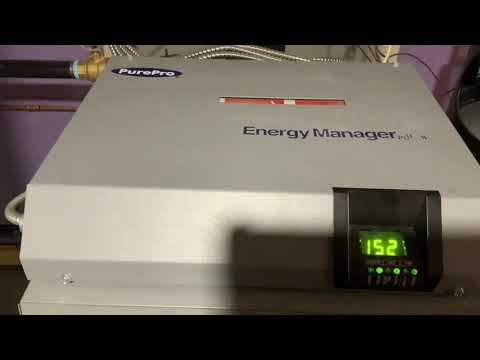

Sorry….model PROP3 By FW Webb Purepro Trio0

-

@gchevm

Something seems off here. The PROP3 only has a max input of 105,000 btu/hour which is .75gph achieved with a .60 70B with a pump pressure of 160. That's what the boiler manual attached says. Are you sure it is a PROP3?2 -

A prop3, afg, has a .60x70B nozzle, 160 psi, +.02 over fire draft.

Page 19

https://fwwebbimage.fwwebb.com/ProductInfo/FWWebbP3P8Boiler10517Manual.pdf

Edit: @EBEBRATT-Ed beat me to it. But note positive over fire draft.

There was an error rendering this rich post.

0 -

I don't see anything listed at 1.20 GPH.

I don't see anything listed at 1.20 GPH.

0 -

This is the same as the Solaia boilers. Here's what happened when we found one over-fired not long ago:

https://forum.heatinghelp.com/discussion/164295/over-fired-3-pass-boilerAll Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I don’t know how I missed it and why they specd and sent me at burner but that’s the info I need. This is definitely over fired and a .6 makes sense but I believe to low for this home. May need slight step up. Going to take this to rep and FWWebb commercial sales designer. Thanks again so much will update0

-

Where did you get this app? Looks great!STEVEusaPA said:I think it’s too much combustion air. What was your excess air number and net stack temp?

What’s the model number?

Are you sure that model wants -.02 over the fire? Triple passes usually want zero to positive, and some want zero at the breech or test port.

Draft and excess air will affect your stack temperature more than nozzle size.

1.20 @ 160psi is 1.52 gph. 0

0 -

Already looked at charts and monitored fuel usage. Net stack is 353. I forget excess air at moment. If these trio’s have a Riello then they are positive. All numbers I am using or tuning to are provided by the factory rep. But I do agree this is over fired at this point as far as I’m concerned. I do have call into rep to review video and advise or stop at location. Will update and thank you0

-

I made it myself. It's made with the same database program I did the Heat Loss app.Robert O'Brien said:

Where did you get this app? Looks great!

The program (FileMaker) is free on IOS devices (iPad, iPhone). But to use it on a desktop you'd have to buy the database program (or use a trial version).

Either way I could send you, or anyone the file. I offered up this on here Alan's FB page a few times, almost no takers..

Adding on a circulator sizing component in my spare time. Just a lot of data entry to build all pipe types/sizing.

There was an error rendering this rich post.

2 -

Did you do a heat-loss calculation on the house?gchevm said:I don’t know how I missed it and why they specd and sent me at burner but that’s the info I need. This is definitely over fired and a .6 makes sense but I believe to low for this home. May need slight step up. Going to take this to rep and FWWebb commercial sales designer. Thanks again so much will update

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

I’d love to have it!!STEVEusaPA said:Where did you get this app? Looks great!

I made it myself. It's made with the same database program I did the Heat Loss app. The program (FileMaker) is free on IOS devices (iPad, iPhone). But to use it on a desktop you'd have to buy the database program (or use a trial version). Either way I could send you, or anyone the file. I offered up this on here Alan's FB page a few times, almost no takers..

Adding on a circulator sizing component in my spare time. Just a lot of data entry to build all pipe types/sizing.

0

Adding on a circulator sizing component in my spare time. Just a lot of data entry to build all pipe types/sizing.

0 -

I’ll send it over to you tomorrow on FB messenger.

Edit: Sent...There was an error rendering this rich post.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements