Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Getting oil fired steam boiler replaced. Future maintenance tips appreciated.

Options

burbsfurnace

Member Posts: 3

I’m working with a buddy who does hvac and is doing the swap, im helping him with whatever I can.

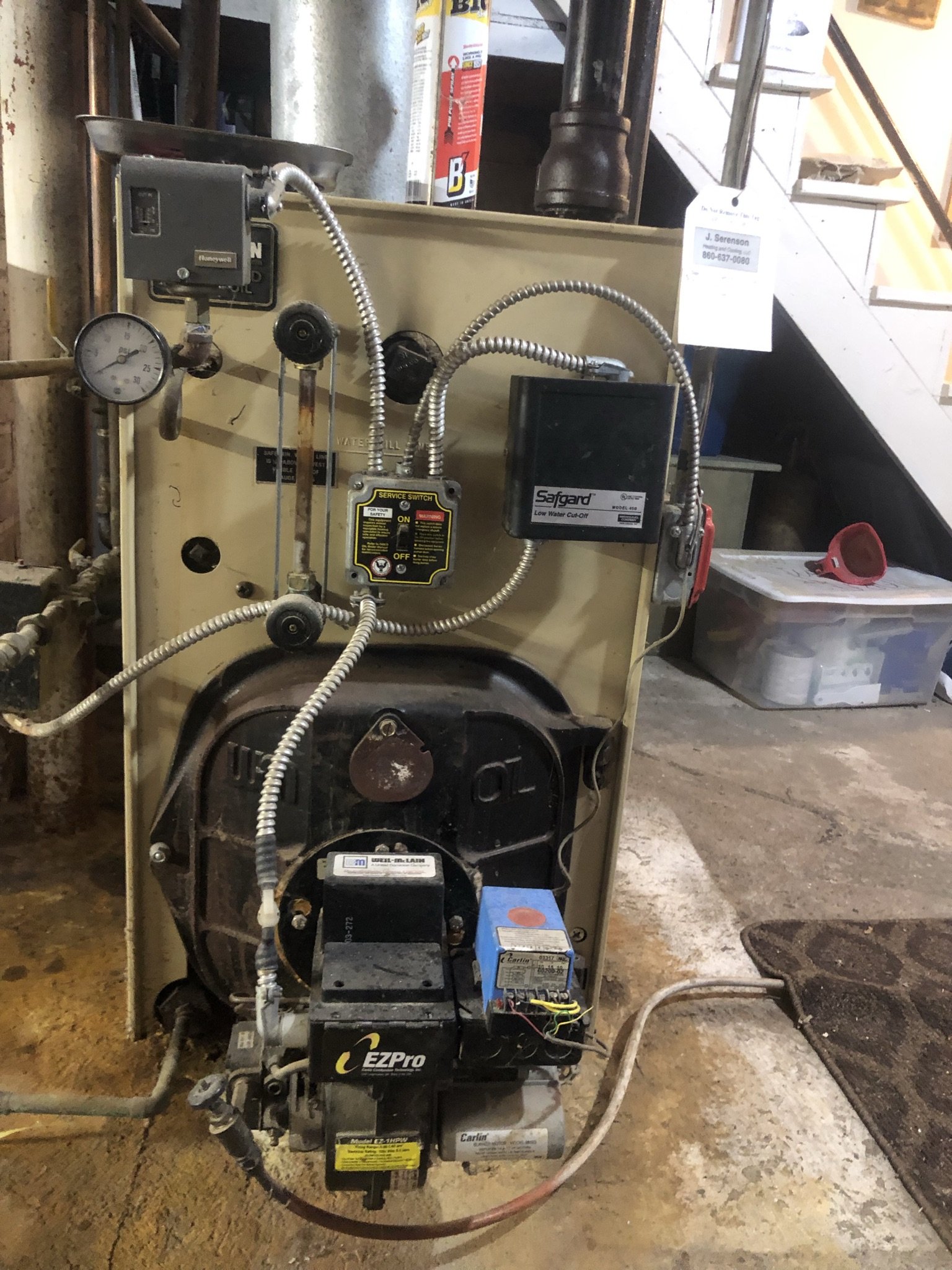

I’m working with a buddy who does hvac and is doing the swap, im helping him with whatever I can. The old boiler rotted out internally and it’s about 18 years old. It only purpose is for heat we have an electric hot water heater. It’s a well McLain SG0-4 and we’re replacing it with the same exact unit. Got a single pipe going to each radiator in the house. We’re doing a new VTX auto water feeder and burner. And replacing all the vents on the radiators and the 2 main vents on the pipes in the basement. We will be reusing some piping and replacing what didn’t crack loose. The Hartford loop is still in tact and will be reused.

I joined here in hopes of gaining a better understanding of the system so I can repair minor things if needed on my own. And also because frankly I should know what’s going in my basement and for early warning signs of a bigger problem.

So with a new boiler I believe you are supposed to skim it for assembly oils and my new boiler has a port for it which were going to put a valve on. What is the process for skimming? Are you firing up the boiler first or skimming it cold? Is it obvious when you can stop skimming by the water condition?

I was told by a few people it’s a good idea to flush the low water cut off. Or something in the low water cut off every 7-14 days when it’s running. Anyone have a photo or vid on how to do it?

I was also told to flush the return line since it’s disconnected. However I’m a bit lost as to how I would do that with my current setup. I get it that all systems look a little different. I’ve attached a few pictures of the old boiler….any chance someone here can give me a clue on flushing the return. Do I need to add valves anywhere?

I was also told to flush the return line since it’s disconnected. However I’m a bit lost as to how I would do that with my current setup. I get it that all systems look a little different. I’ve attached a few pictures of the old boiler….any chance someone here can give me a clue on flushing the return. Do I need to add valves anywhere?

Asides from what I mentioned any advice on preventative maintenance and things to look out for with a new oil steam boiler would be appreciated. Oh yeah we’re on well water too. We have a neutralizer, softener and iron filter as well.

Thanks all

0

Comments

-

Um. Hope that the new boiler is properly sized -- a like for like swap isn't necessarily correct.

But -- the piping in the pictures looks pretty good.

18 years is a decent life for a boiler.

Now maintenance. The type of low water cutoff which you have there really doesn't need much maintenance. Not a bad idea to remove the probe once in a while -- like at most yearly -- and clean it, but that's about it. No need to blow it down (that applies to float type LWCOs, not what you have).

During installation its a very good idea to flush any return lines which are below the water line. In most cases, though, it's easier said than done. Unless someone got nice and put Ts rather than elbows at the ends, about all you can do is use a hose to run water into the accessible ends and let it flow out.

Skimming is a must. It's not at all hard to do. Raise the boiler water level so water just trickles out the skim port -- you don't want a flood -- and then run the boiler just hard enough (you'll have to turn it off and on) to just barely simmer. You don't want it to boil, but it needs to simmer. And wait. Keep adding water now and then to just keep a nice little flow going. At first you will probably see some oil, then probably some more, on the water, but eventually -- and it may take hours -- the water will be pretty clear. But it's not obvious... and someone has to be there and pay attention to how hard it's simmering.

You also need to make sure that you adjust the combustion with the proper instruments. New burners will be close, but it's not plug and play.

Once all that is done, the number one maintenance in my view is to keep track of how much water you have to add from time to time and, if it's more than a gallon or two a month (if that) find and fix any leaks.

Once a year you need to have the fire side of the boiler cleaned and the filters on the oil cleaned and perhaps -- most likely -- a new nozzle and readjust the combustion.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

-

Sorry can you elaborate a bit. I’m not familiar with what a HW zone is?Robert O'Brien said:No black pipe on pop safety valve and I'd use a coil for the HW zone to isolate it0 -

Sorry can you elaborate a bit. I’m not familiar with what a HW zone is?burbsfurnace said:Robert O'Brien said:No black pipe on pop safety valve and I'd use a coil for the HW zone to isolate it

A hot water zone is a heating zone which uses the same boiler as the steam system. There are several ways to pipe them -- but I don't think you have one.

And now I'm curious, @Robert O'Brien . If not black iron pipe on the safety valve connections, what would you use? And why? How would you connect it to the boiler?Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

That reducing tee with the nipple and plug on the main closer to the chimney really should be removed and replaced with a regular ell or dripped down to a wet return. It is a place for condensate to collect and steam to encounter the condensate and collapse and cause water hammer.

Look at the manual for that boiler and make sure that the header and riser sizes are at least what the manual calls for and that there isn't a second tapping under the jacket that you are supposed to use with steam.

A hot water loop is a loop made using a circulator that circulates the water in the boiler as hot water to heat some other zone with hot water rather than steam like a basement or an indirect hot water heater. It looks like there is a hot water loop connected to that boiler.0 -

Ahhh okay yeah there was something in past connected to that boiler but is no longer there it’s been capped off since I bought the house.mattmia2 said:That reducing tee with the nipple and plug on the main closer to the chimney really should be removed and replaced with a regular ell or dripped down to a wet return. It is a place for condensate to collect and steam to encounter the condensate and collapse and cause water hammer. Look at the manual for that boiler and make sure that the header and riser sizes are at least what the manual calls for and that there isn't a second tapping under the jacket that you are supposed to use with steam. A hot water loop is a loop made using a circulator that circulates the water in the boiler as hot water to heat some other zone with hot water rather than steam like a basement or an indirect hot water heater. It looks like there is a hot water loop connected to that boiler.0 -

If you haven't bought the boiler yet, I'd measure all the rads and make sure what you have is proper, steam boilers are notorious for being oversized.

Second, I wouldn't reuse what you have, well I wouldn't reuse it as you seem to plan on doing.

That capped off elbow is the end of the previous header. I'd abandon most of the existing piping ang go back into that nice high original header. Then reconnect the equalizer (the capped elbow) and return piping. Not sure why the previous installer didn't do that. The only detail I can't make out is how the end of that old header is set up. If the end is a tee, that isn't the most desirable set up, should be a tee for the system, then a nipple, then an elbow down like the header you have.

Also, the mains are supposed to connect to the boiler header individually, not like yours is currently, that's another influence into my suggestion of using that original header.

You want to get the details right, it will make the difference between loving the system and wanting to blow it up with some C4.1 -

As mentioned, measure the rads and the connected piping to find the EDR. You'll probably find you only need an SGO-3.

When you know what size boiler, download the installation manual beforehand and and follow their piping diagram exactly. No exceptions.

What burner are you planning on using?

It will pay to have a qualified tech set up the burner properly and do a combustion test. At the same time sign up for a 24/7 service agreement.

P.S. We've got the "before" pics. So you have no choice but to post "after" pics. Make us proud of you.0 -

burbsfurnace said:

The old boiler rotted out internally and it’s about 18 years old.

Oh yeah we’re on well water too. We have a neutralizer, softener

Jamie (and everyone else) missed the fact that you have a water softener.Jamie Hall said:

18 years is a decent life for a boiler.

Water softeners are BAD for boilers. Hard water is better than softened by sodium ion exchange water for boilers. De-mineralized water is even better yet.

Sodium is inversely soluble in relation to temperature. It will stay in solution and cause corrosion. Calcium and magnesium will come out of solution at boiler temperatures and coat the insides of your boiler. Sounds bad, but it's not. Minerals out of solution do not cause corrosion. The scale is not as big a problem as sodium staying in solution and causing corrosion.

Water softeners are good for water heaters, washing machines, and dishwashers. Lower temperatures and the water is constantly replaced. Boilers operate at higher temperatures and water is not replaced, but recirculated. Therefore, sodium is bad, and calcium and/or magnesium are a lesser evil.

2 -

A hot water zone is a heating zone which uses the same boiler as the steam system. There are several ways to pipe them -- but I don't think you have one.Jamie Hall said:

Sorry can you elaborate a bit. I’m not familiar with what a HW zone is?burbsfurnace said:Robert O'Brien said:No black pipe on pop safety valve and I'd use a coil for the HW zone to isolate it

And now I'm curious, @Robert O'Brien . If not black iron pipe on the safety valve connections, what would you use? And why? How would you connect it to the boiler?

On the blow off, not the boiler side. Should be copper or brass, ferrous metals can and will rust the blow off shut.0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements