Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

New boiler, new problem - maybe it's the LWC?

Options

JamesC in Stamford CT

Member Posts: 95

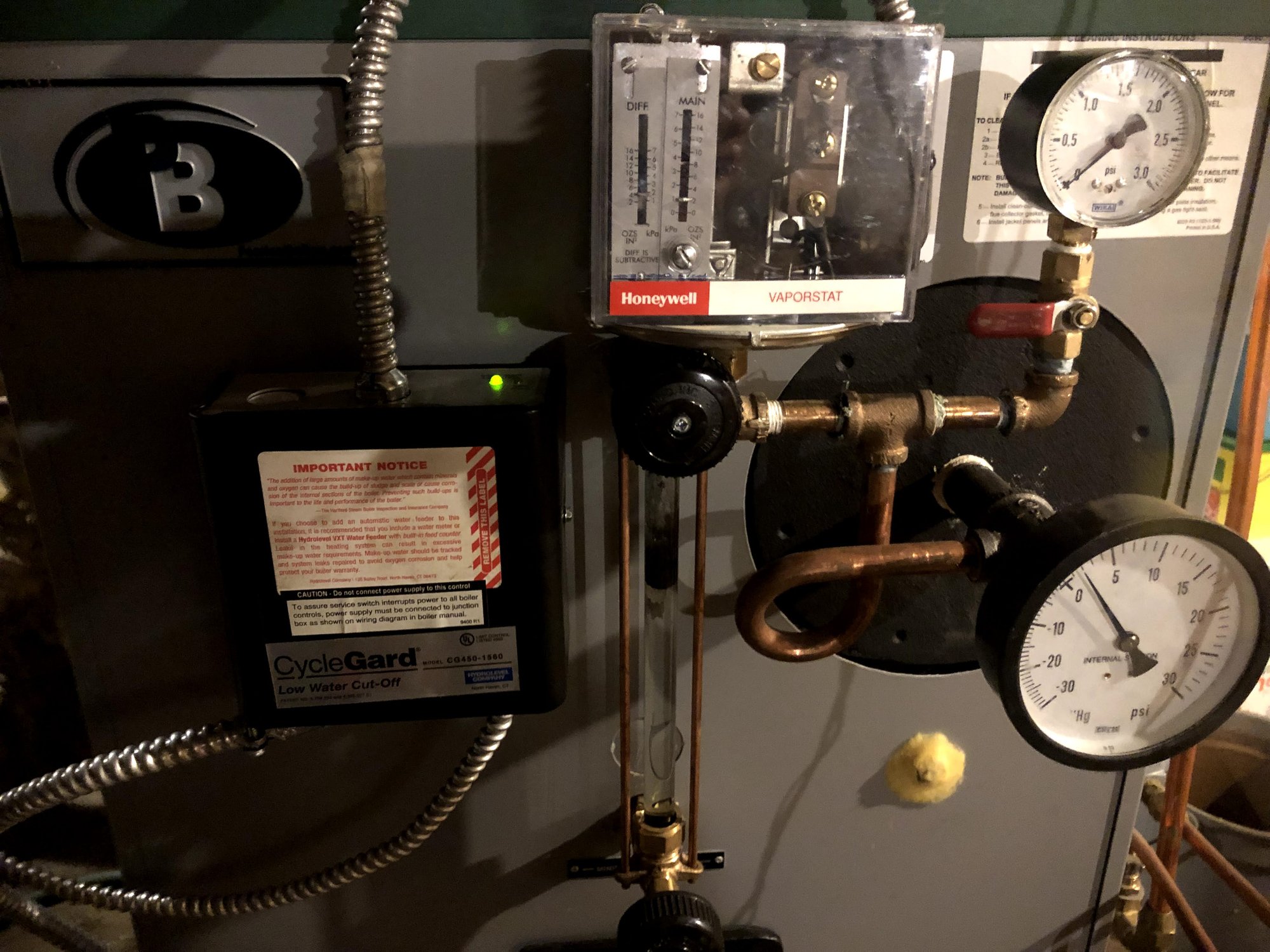

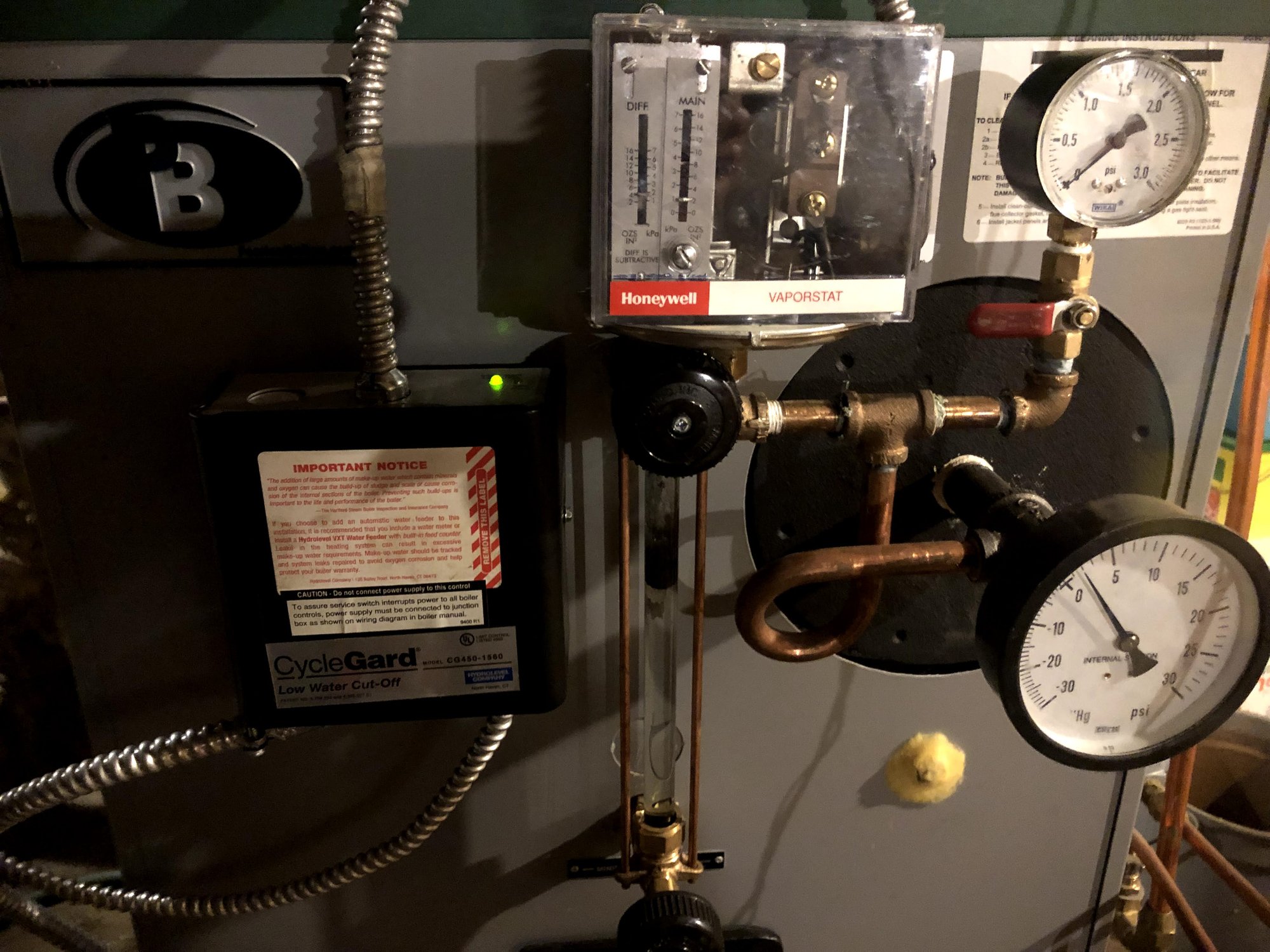

My contractor just installed a new peerless boiler for my one-pipe steam system. I used to have a float lwc. The new boiler came with a probe LWC.

I have only fired it up twice since the contractor left. The contractor is going to come back and try to trouble shoot, but i have more confidence in this Wall than i do with this contractor.

Day One: after running for 5 or 10 minutes, with steam rising through the pipes but not quite hitting most of the radiators, the green light on the lwc comes on the, and the system shuts down for about 2 or 3 minutes -- and then automatically restarts. But that lasts only a 10 to 5 minutes and then it shuts off completely and will not start. The thermostat is calling for heat, but nothing starts the burner. After 3 hours of waiting for it to fire up, I try shutting off and on the power, I try changing the thermostat low and then high again, but nothing gets it to start. I eventually gave up and set the thermostat lower than room temperature and went about my day.

Day Two: I upped the thermostats a day later, it it started! Yippee I thought, but is was a repeat of the first day. The lwc lit up green after 5 minutes, and the 3 minutes later it restarted, but that lasted only 3 minutes and then nothing.

I noticed the glass gauge was a bit dark and smokey, but it was not sludgy.

The contractor left in place and connected up the old auto feeder to the new boiler, but I have not checked to see if it is working/wired properly.

Any words of wisdom as to what to investigate?

I have only fired it up twice since the contractor left. The contractor is going to come back and try to trouble shoot, but i have more confidence in this Wall than i do with this contractor.

Day One: after running for 5 or 10 minutes, with steam rising through the pipes but not quite hitting most of the radiators, the green light on the lwc comes on the, and the system shuts down for about 2 or 3 minutes -- and then automatically restarts. But that lasts only a 10 to 5 minutes and then it shuts off completely and will not start. The thermostat is calling for heat, but nothing starts the burner. After 3 hours of waiting for it to fire up, I try shutting off and on the power, I try changing the thermostat low and then high again, but nothing gets it to start. I eventually gave up and set the thermostat lower than room temperature and went about my day.

Day Two: I upped the thermostats a day later, it it started! Yippee I thought, but is was a repeat of the first day. The lwc lit up green after 5 minutes, and the 3 minutes later it restarted, but that lasted only 3 minutes and then nothing.

I noticed the glass gauge was a bit dark and smokey, but it was not sludgy.

The contractor left in place and connected up the old auto feeder to the new boiler, but I have not checked to see if it is working/wired properly.

Any words of wisdom as to what to investigate?

0

Comments

-

Lets see some pictures of the piping above and around the boiler. Step back so we can see it.

Ask the contractor if he skimmed the boiler as required in the instruction manual.

Find the boiler manual and find the steam piping diagram in the manual and compare it to what he installed.

If he didn't follow the minimum requirements in the manual then your going to have problems

ANd most important why did you hire someone you couldn't reasonably trust?

That's a red flag for starters

He put a low pressure gauge on and the pressure looks like it is set ok (I think)

My first guess is the water is bouncing and the boiler needs skimming and cleaning0 -

You have a CycleGard (which is known around here as a PhyscoGard) for a low water cut-off. The behavior is normal. When the green light is on it is in Physco-Mode. The burner will be off for a minute or two depending on model, and the cycle will forever repeat itself at intervals that are model specific. Supposedly all for your safety. Ahem...New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

I thought Psychogard first myself, but the problem seems to a little different -- it cycles off, yes, but then the OP says it stays off. I'm thinking it is the LWCO, but skimming and maybe a dirty probe...Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

OK, it looks like it was not skimmed after it was installed. That's why all the smokiness above the waterline in the glass gauge. See pic. So I will have it skimmed and see how it works, and report back.

A few questions:

1) did I damage anything by firing it up? For instance did the little bit of steam that got through the system when it was fired send oil sent through the system, so that it might be coating the inside of the pipes further from the near boiler?

2) The boiler has an access cutout at the top, as well as an overly large cutout around the main pipe. That seems that it will let out a lot of wasted heat. Was it supposed to have been insulated and capped? (see pic)

Also see pics of near-boiler piping.

Thanks everyone!

0 -

Definitely needs skimming. The larger question (as always) is did they bother to install the skim port to enable skimming?New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com1 -

1) The first pic shows what I think is the skim port, just below the relief valve -- but I welcome comments. The second picture shows that same side of the boiler for context. I included some pictures of the other sides of the boiler too. You'll see the future connection to a domestic hot water tank, but my electric water heater's pretty new so we did not utilize the coil.

2) If the Probe is dirty from the oil, does it clean itself over time? Or can it be cleaned? Or do I need to buy a new one?

0 -

@JamesC in Stamford CT

Doubtful that the probe got dirty. It would have t have sludge on it which is unlikely in a month. Have the skim port installed and skim it. Peerless has their own instructions probably in the boiler manual.

Every new boiler needs skimming. It's a step that can't be skipped0 -

PVC on a steam relief drop??

I wonder if the vaporstat settings are too close together, maybe just separate them a little more?

The number scale is probably not accurate just like the P-trols.

Does the install manual allow only 1 riser of 2" (?) with a 2" header for that size of boiler?0 -

Would be good if the OP would post which model they have installed and we could cross reference against the manual to see if the pipe size is correct. If it's undersized that can exacerbate the problem for sure.JUGHNE said:PVC on a steam relief drop??

I wonder if the vaporstat settings are too close together, maybe just separate them a little more?

The number scale is probably not accurate just like the P-trols.

Does the install manual allow only 1 riser of 2" (?) with a 2" header for that size of boiler?

Of course that leads to the next question of whether it's sized correctly...0 -

Good comment about the piping size. I will look into that.

My immediate question is whether I have a skim port. I think the plug under the relief valve is where it is supposed to go. What should the skim port look like -- simply a horizontal pipe from where the plug is to a valve, that can be opened to allow the oily water to come out? (maybe with a 90-degree elbow own so it nicely goes into a bucket?0 -

If you have the EC boiler, the plug right under the pressure relief valve is indeed the skim tapping. You don't need a valve, to keep it simple all you really need is a 1 1/2"Ø nipple of a convenient length and a pipe cap to close it off after skimming. I would recommend a brass cap so you can take it off if it ever needs a skim again, which is only really necessary if you do more pipe work. That said, often times you need to skim more than once on a new install.0

-

I may have said "oh my god" when i saw that picture of the gauge glass with the thick layer of oil in it.0

-

Mattmia -- yes, lots of oil!

KC_Jones -- Thanks, OK, so a brass cap on a pipe, or a valve should work. Thanks! And I see now that the skim tapping is right where you said it was, per https://peerlessboilers.com/wp-content/uploads/2017/12/PB-Heat-Series-EC-Cut-Sheet-72613-8.5x11.pdf

KC_Jones and Jughne -- 2) Model is ECT0e-03-SPTL. From what I see online, it looks like a 2" pipe is what is asked for per https://peerlessboilers.com/wp-content/uploads/2019/07/ECECT3_PipingKit_CUT_0519.pdf

If anyone has a link to the installation manual, that would be great. The installer did not leave it with me.

Thanks for all your help!!!

0 -

The oil will make it surge and throw water up in to the mains.0

-

Here is the installation manual. Looks like the 3 section only requires one riser (although 2 is always better, it should be ok with one if the rest is right)

https://www.peerlessboilers.com/wp-content/uploads/2017/03/EC8000-R36_IOM_web.pdf0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements