A Little Input on Heat Loss BTU's and boiler sizing for 800sq ft project WITH PICTURES and Calcs

Hope you're all doing well. I've got a small project I'm working on and wanted to see if you'd be willing to share some input about it and see where I might be going right or wrong. Its a small very very basic 2 story structure I'm going to build up against my existing shop here in northern Arizona to contain a small living quarters and I want to put radiant floor heating in the slab, and on the 2nd floor joists. Here are the project details (the attached pictures will show all of this in the calculations too):

Placement of the doors and windows is visible on the attached (the silver building is the existing shop, the red (rusted) part is the proposed new structure):

And here are lower and upper floor plans to give you a better visual of what kind of space im heating:

For insulation, here's what I have:

Floor (R20): 4" Continuous XPS under entire 4" slab, 4" XPS at perimeter of slab

Walls (R42 at cavities, R26 at studs): 5.5" Mineral Wool inside 2x6 cavities, 2" Continuous PolyIsocyanurate rigid board & 1" XPS rigid board outside studs

Roof (R55 at cavities, R34 at rafters): 7.25" mineral wool inside 2x8 rafter cavities, 2" continuous polyisocyanurate rigid board & 2" XPS rigid board outside rafters

The existing shop is not conditioned except for a wood stove (it will have radiant tube heating or something sometime down the line) so the wall that mates up to the shop will have the same insulation as all the other exterior walls.

The temps in the winter at night usually can get down around 15 degrees, sometimes less but normally not below 15 so I calculated it with a Delta T of 55

The roof framing stops at the walls so the insulation can transition from the walls to the roof 100% continuously with no thermal bridging through framing.

Here are my issues at hand. I've been working on some basic heat load calculations and although I think I'm doing it right, I just want to see if anyone sees any red flags, or maybe im doing it completely wrong. But bear in mind, I know these are not all-encompassing calculations and there are plenty of other factors that can go into them such as thermal bridging through fasteners, etc. but I figured this would get me in the ballpark enough to come up with a good hydronic system for this structure.

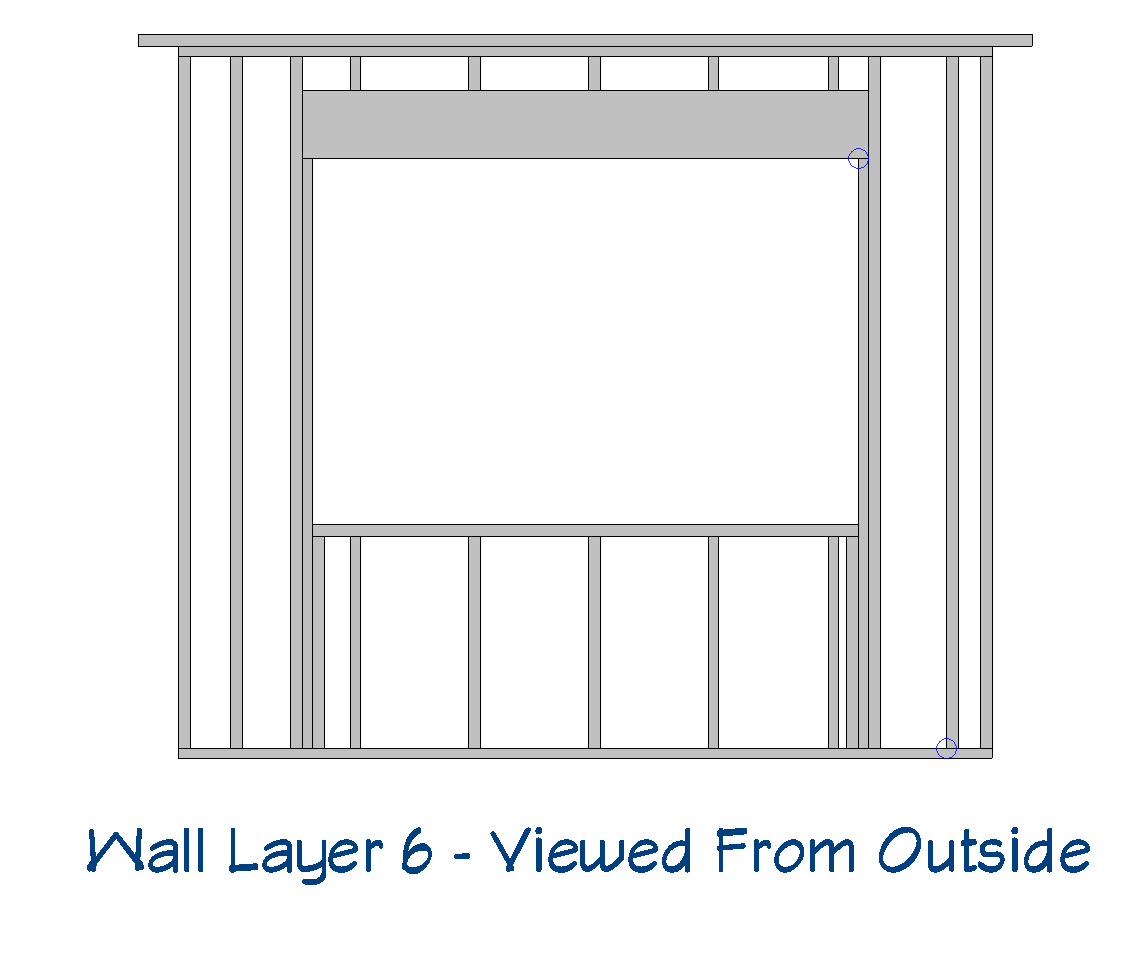

I used detail sets like these to calculate the surface area of the framing components, etc. in each wall to calculate the r-value, u-factor and BTU heat loss of each section in each wall:

Then I made some calculation sheets, which are attached as a pdf. One word of caution, the calculation for the heat loss in the slab, I'm almost certain is not correct, I've been researching how to calculate that and there is so much conflicting info on how to do it. I think it is an ongoing debate amongst experts, so don't pay attention to that one too much.

If all the rest are fairly accurate, and I will only have 11,000 BTU/hr or less of heat loss in the whole place, is there even a boiler that exists that would be suitable and efficient for this small setup?

I was thinking since the place is so small, I would only have one zone, with 4 circuits (about 200ft each circuit):

As shown in the picture, the manifold would be in the center of the building and one 200 ft circuit on one side and one on the other side (dont mind the blue vs red, I only did that to easily distinguish different circuits). The other two would be in the top floor, same arrangement except on top of joists.

Do you think 1 zone with 4 circuits would be a good setup? I want to keep it a closed loop. The domestic water supply will be separate and supplied by a tankless water heater.

Thanks for your time!! And please let me know if you think my calculations seem like they'd be sufficient for sizing a system or if its all just junk! ha

regards,

Tony

Comments

-

What are your available fuels?

How much space do you have for heating equipment?

Your calcs look pretty close. With such a small load, a small electric boiler with outdoor reset to avoid overheating would be a good solution."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

Without running all the numbers 11K for that size area sound about right, around 14 BTU/ sq ft.

That is at a design condition, so much of the heating season you will be at a portion of that, maybe 5-6K.

Small areas like that could get by with a small electric boiler, you can size them down by changing element wattage. How are your energy prices. What are your fuel options?

If you plan on heating the rest of the building perhaps size for that also.

A small combi could provide DHW and heating, a buffer tank to help with that tiny load.

A tank type boiler with 50 gallon capacity and a plate HX for DHW, HTP has some nice products based on a mod con tank.

What about cooling?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I would say your calcs are pretty close as well and would agree with Carl on the electric boiler, maybe not so much the ODR as you'd be scraping the low limit at pretty much all times anyway. One single zone would probably be fine as long as your manifolds have flowmeters and balancing valves to balance the flow between the spaces, that's how I'd do it along with a simple Electro EMB-H-5 boiler (15,000 BTU with modulation) or possibly step up to an EMB-H-7 for a little better recovery if you ever decide to run it cooler when you're not out there.-1

-

Thank you guys for your much appreciated thoughts on this. You've opened my eyes to a possibility I should've thought of a long time ago. Electric. I was so consumed with researching propane units and how I could properly size one for such a small system, given that my tankless water heater and oven/range will be on propane, the thought of using an electric boiler completely escaped me!

Available fuels at my place are propane and electric. I just installed a 400amp single phase meter box with (2) 200amp "pull-outs" to feed two separate sub-panels so electricity requirements would be no issue, and actually probably more desirable in my scenario. Not to mention, in case of a power outage, I have a generator that can power that (and plan to put a solar panel system on the roof of the shop). It would not be able to power an electric tankless on my domestic water system, which is part of the reason I went with propane for that.

I haven't yet done a cost comparison of the fuels in my area yet (I imagine electric will be more expensive) but its such a small system, I think the pros are gonna outweigh the cons. Especially since there are electric boilers with the correct load design.

The space I have for heating equipment is in that utility room on the floor plan which is 19ft x 9ft. Subtract roughly 8ft x 4ft for 1320 gallon water tank and some room for a pump and tankless water heater/80 gallon pressure tank. Should be plenty of space in there for the hydronic equipment.

I was considering a combi setup with a buffer tank like you mentioned hot rod but I think I like your ideas of an electric unit and keeping the two systems separate for simplicity sake.

Groundup I'm right with you on that setup. One zone, with just flow meters and balancing valves on manifolds is exactly what I had in mind, and that boiler you mentioned looks to be right up my alley, nothing fancy, just a simple setup.

I'll now calculate circulation pump requirements and do more research on these electric boilers, I don't know much about them, been studying LPG units, are they pretty much similar in terms of system equipment?

Also, if I'm not mistaken, a system like mine with one zone would not require a primary/secondary would it?Arizona0 -

I'll also advocate for an electric boiler. There is also the fact that generally electric boilers are less expensive to maintain than fossil fuel burning boilers. Size to your load.

Can't be sure that you will not need primary secondary piping, depends on your system flow rate. Every boiler, electric or not has a minimum flow rate, your 4 loop maniflod may only need 2 gpm, maybe even less, so just make sure that your system flow is above the minimum for your selected boiler. I would be surprised if it didn't work.0 -

https://coalpail.com/fuel-comparison-calculator-home-heating

If you use a mod con boiler plug in 90%, add you LP and electric rates to compare.

Keep in mind the electric boiler will require very little maintenance. Ideally a mod con should be cleaned and checked yearly. If you pay someone to do that the cost needs to be considered. And mod cons tend to be expensive when something fails.

Am electric boiler and a dozen PV modules Bob "hot rod" Rohr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

As far as the Electro boiler goes, it's about as simple as they come. No maintenance required, simple in/out piping, and a minimum flow rate in the H series that you'd exceed with only 2 loops piped direct. I have got hundreds of these little fellas in service and have custom built maybe 75 of them for DIY folks like yourself simply to hang on the wall and plug in. They're nearly bulletproof, made in the USA, and maintenance free. Here is one such example. An EMB-H-7 with a single zone 3 loop radiant load.

0

0 -

@hot_rod thanks for the link to the fuel comparison calculator, I ran the numbers and actually for my specific setup, its right about the same price electric vs. propane because I just found out that because my shop is zoned light commercial (even though I only use it for personal use), my local electric utility has a lower rate for it (slightly higher service charge). So that's great, and as you mentioned, when I add pv modules later on it should decrease cost even more. Being correctly sized I think it won't cycle as much as a propane unit over time either, which should improve longevity.

I do believe I read somewhere, a study that a boiler running at 25% capacity is at a very high efficiency instantaneously but longevity over time, with all the cycling, the efficiency rate is much worse in the end. Does this sound correct?

@GroundUp I am a huge fan of this setup! I've been researching these electro mini boilers, and others all day actually (well, off and on while creating the building plans and foundation detail sets). I can say that my sights are set on this particular unit (the EMB-H-5) for the reasons you stated, and the company Electro seems to really take pride in and know their stuff. My setup would need a 4 circuit manifold as I'd be running heat to the upper floor in the exact same fashion as the lower floor.

@delta T The unit I'm looking at requires a minimum of .5gpm below 144F and although I haven't run the exact numbers on my system yet, it looks like this won't be an issue

Questions:

1.) Is there a minimum BTU output for these modulating units? As @hot_rod mentioned a large portion of the heating season I will probably only have 5-6K BTU heat loss in the building.

2.) Another concern I have is heat distribution. The lower floor will be in a concrete slab while the upper floor circuit will be on wood floor joists. I suppose this might make a difference in flow requirements. Or maybe not, I'm still studying these systems, haven't gotten to the emitting part yet. Do you think the balancing valves on the manifolds will be enough to adjust these accordingly?Arizona0 -

Output of the H would be close when modulated, as they will pulse the elements based on outlet temperature. Although your heat load may only be 5k per hour, that doesn't mean the boiler has to match that load. It will run as many minutes at (X) BTU to accommodate the load and then will cycle off- same as any thermostatically controlled heating device. The flowmeters/balancing valves will be enough to balance IF the outdoor conditions are the same. As the outdoor temps change, so may the required flow rates. You could simply add zone actuators to each loop and make it a 2 zone system with 2 thermostats if it becomes an issue0

-

It is much easier to regulate the output by varying the temperature of the water, a reset type control on the boiler could accomodate that, most boilers have that function onboard.toeknee said:@hot_rod thanks for the link to the fuel comparison calculator, I ran the numbers and actually for my specific setup, its right about the same price electric vs. propane because I just found out that because my shop is zoned light commercial (even though I only use it for personal use), my local electric utility has a lower rate for it (slightly higher service charge). So that's great, and as you mentioned, when I add pv modules later on it should decrease cost even more. Being correctly sized I think it won't cycle as much as a propane unit over time either, which should improve longevity.

I do believe I read somewhere, a study that a boiler running at 25% capacity is at a very high efficiency instantaneously but longevity over time, with all the cycling, the efficiency rate is much worse in the end. Does this sound correct?

@GroundUp I am a huge fan of this setup! I've been researching these electro mini boilers, and others all day actually (well, off and on while creating the building plans and foundation detail sets). I can say that my sights are set on this particular unit (the EMB-H-5) for the reasons you stated, and the company Electro seems to really take pride in and know their stuff. My setup would need a 4 circuit manifold as I'd be running heat to the upper floor in the exact same fashion as the lower floor.

@delta T The unit I'm looking at requires a minimum of .5gpm below 144F and although I haven't run the exact numbers on my system yet, it looks like this won't be an issue

Questions:

1.) Is there a minimum BTU output for these modulating units? As @hot_rod mentioned a large portion of the heating season I will probably only have 5-6K BTU heat loss in the building.

2.) Another concern I have is heat distribution. The lower floor will be in a concrete slab while the upper floor circuit will be on wood floor joists. I suppose this might make a difference in flow requirements. Or maybe not, I'm still studying these systems, haven't gotten to the emitting part yet. Do you think the balancing valves on the manifolds will be enough to adjust these accordingly?

Adjusting heat output by changing flowrate is not very linear, temperature regulation is.

So even if the boiler is oversized for mild days, backing off the operating temperature will give you the best control, avoid overshooting, and be the most energy efficient way to run the system.

Many of the electric boilers modulate their output with triac relays so the output can be easily adjusted to match the everchanging load.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

If you haven't considered it yet, you might want to look in to radiator panels.

I've also got a low-spec heating requirement. Low enough that I'm considering using a indirect tank with an electric heating element (6kW). The coil in the indirect will be used for the area heating while the tank itself will be used for domestic hot water. NOTE: This notion was driven by input from GroundUp; based on my situation (of wanting to limit overall electrical loads (generator bound)- not wanting multiple devices, such as an electric boiler and an electric water tank, operating at the same time. If not for the DHW I'd just go with a small electric boiler for the area heating: but I'd still lean toward radiators because their response time is better vs in-floor- if you have semi-rapidly changing outdoor temps (or solar gains) then this is for sure a better way (or so I have it in my mind as being so).0

Categories

- All Categories

- 87.2K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 60 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 75 Pipe Deterioration

- 1K Plumbing

- 6.4K Radiant Heating

- 394 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 49 Job Opportunities

- 18 Recall Announcements