Does cast iron boiler efficiency decrease over time?

I am wondering if over time with the aging and rusting of the boiler, the efficiency of the boiler decreases, or is the boiler still able to put out something close to the original claimed heat output?

Thank you all, and Happy Valentine's Day!

S.

Comments

-

New efficient boilers get some of their higher efficiency by having thinner castings.

I figure my Weil-Mclain number 57 has lost so much to rust over the last 70 years that it is now 120% efficient. (If the Heat Pump and eMPG people can make up numbers, then I can to).

Old boilers never die, they just rust away.5 -

-

-

Surface rust/carbon buildup on the sections, sludge and sediment buildup inside the heat exchanger, dirty/rusty burner tubes, old gas valve, etc will certainly contribute to a measureable decrease in efficiency.Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes1 -

I don't think it's oversized. It's a 1970s Weil-McLain with an input of 245K, output of 196K, and Net IBR of 170.4. It's pumped with the original 1970s Taco 110. It's connected to the home's original 1897 gravity system with cast iron radiators. The house is a 2 1/2 story brick house somewhere between 5,000 and 5,500 square feet. The attic has been insulated and there are storm windows. For an old house, it's not too leaky either.pecmsg said:Clean boiler in relatively good shape. A small %.

Bigger Question is how oversized it is?

With temps at zero degrees or just a bit below, the boiler runs continuously, producing a supply temp of 132 and a return of 119-120 degrees. When the outside temp has warmed up to 6 or 7 degrees, the boiler starts to cycle off and on. The house has stayed at a comfortable 70 degrees.

The reason I was asking the question is that I am considering replacing the almost 50 year old boiler with a Viessmann Vitocrossal CU3A rated at a max input of 199 and Net AHRI rating of 161. Watching my small cast iron boiler run non-stop at these temperatures, I'm wondering whether the Vitocrossal is going to have enough heating capacity for temps such as this.

If my old boiler is still giving me the full 196K output, but has to run continuously at these temps, I'm starting to worry that the Viessmann might not be big enough for the house. If the old boiler is actually producing something lower than what it was originally rated at, the Viessmann might be adequate.0 -

that boiler shouldn't see return water below 140°f.Shahrdad said:

With temps at zero degrees or just a bit below, the boiler runs continuously, producing a supply temp of 132 and a return of 119-120 degrees. When the outside temp has warmed up to 6 or 7 degrees, the boiler starts to cycle off and on. The house has stayed at a comfortable 70 degrees.pecmsg said:Clean boiler in relatively good shape. A small %.

Bigger Question is how oversized it is?

What are the emitters, baseboard or cast iron?

Have a accurate heat load loss performed, with those operating temperature Yes it is oversized. If it heats OK consider a condensing boiler.

0 -

The way the boiler was piped originally (no bypass loop or anything) it's been seeing return temperatures of below 130 for almost 50 years. Most of the winter, the supply is in the upper 90s and return in the 80s. The emitters are ornate cast iron radiators. I think it's a matter of time before the boiler springs a leak, as there is always a rust powder on the bottom of the boiler and in the burner tubes.pecmsg said:

that boiler shouldn't see return water below 140°f.

What are the emitters, baseboard or cast iron?

Have a accurate heat load loss performed, with those operating temperature Yes it is oversized. If it heats OK consider a condensing boiler.

The previous owner had a heat loss done before this boiler was chosen in the early 1970s. I should add that all my neighbors, many with houses half the size of mine, have boilers that are 1 1/2 times bigger than mine, and most of them are recent installations!

The Viessmann Vitocrossal I'm considering is a condensing boiler. But how can my current boiler be oversized if it has to run continuously at design temperatures of zero degrees to keep the house at 70 degrees? It's been heating the house just fine, even with these low temps. However, with outdoor temps just below zero, I have never seen a supply temp higher than 132 on my boiler.

Thanks!!

0 -

I should have continued it on that post. I was pretty much set on the Viessmann that is just slightly smaller than what I have now, but seeing my boiler operate nonstop at 0 degrees is giving me second thoughts.Youngplumber said:@pecmsg we've already had this conversation in a different post.

0 -

If zero degrees is your design temp, it seems like it's doing what it is supposed to do.

It works its butt off at zero degrees, anything above makes it work less....anything colder and it still works its butt off but can't keep the house at 70 degrees.0 -

Hey there @Shahrdad . I'm interested where you went with this. Did you go with the size you were looking at? Has it been enough? Or was it undersized? Did you get a heat load / radiation calc done? How has everything turned out?

For posterity, I'd echo most of what folks have noted here, with a caveat or "Devil's Advocate" opposing thought.

First, yes, lime, scale, or mineral deposits, and rust, can reduce heat transfer efficiency. Soot buildup can reduce both combustion efficiency and heat transfer efficiency from the other side. Burners and actuators can also degrade over time and may need maintenance or replacing. So you can lose both capacity and efficiency over time.

On the flip side, thermodynamics says heat energy has to go somewhere. So if a combustion analysis shows a high combustion efficiency, and your boiler's space isn't getting significantly hotter than it used to, well, that heat has to go somewhere ... it might be going into the water. Also, the soot can be cleaned out, and the scaling can vary significantly depending on water quality, and might even be reversed (somewhat) with some good treatment and flushing. So it's entirely possible the 50-year-old system might be operating somewhat close to its original capacity and efficiency if its been properly maintained. Rust is your biggest concern...

Still interested what you wound up doing, what kind of a reduction in bills you saw, and what impacts you saw on your space comfort.0 -

We have a similar situation in our old house with cast iron radiators and low water temps. The reason you can heat your house with 130 degree water is that you have a massive amount of radiator surface area. See this chart that tells you how many BTU's your radiators will throw off per sq ft of surface area at a given temperature. And apparently, based on your house's heat loss, you have enough radiator surface to keep up with that heat loss with the radiators at that water temp. You can use the chart to calculate for yourself how much radiator surface area you have, and from there to calculate total BTU's/hr radiated for a given water temperature.Shahrdad said:

But how can my current boiler be oversized if it has to run continuously at design temperatures of zero degrees to keep the house at 70 degrees? It's been heating the house just fine, even with these low temps. However, with outdoor temps just below zero, I have never seen a supply temp higher than 132 on my boiler.

https://www.expressradiant.ca/pdfs/product_classic_sizing_how_to.pdf

You might also be interested in this article by @RonBeck expaining why old cast-iron radiator systems tend to run at low water temps:

https://www.usboiler.net/outdoor-reset-doesnt-work.html

0 -

Hydronic heat , you size the boiler to the heat loss of what you are heating .. The larger size rads are a bonus allowing you to run the system with lower temperatures .. Condensing boilers shine on this system...

There was an error rendering this rich post.

0 -

Also, you can calculate your heat loss quite accurately if you have records from a previous winter's oil deliveries. From one month's oil consumption in mid-to-late winter, and from weather records in your area during that period, you can do the math yourself fairly easily. And it will be more accurate than any contractor estimates based on assumed R-values, etc.

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler0 -

(This comment removed. Software glitch / Double entry of same comment.)0

-

One would also want to look at run time and cycle efficiency. I suspect even brand new cast iron boilers being installed today are running down in the 70% range

When a boiler with a fixed output is connected to a multi-zoned system, the boiler short cycling drags down the efficiency. In addition the short cold run cycles shorten the life expectancy. Oversizing still runs rampant as we see here almost daily.

Modulating boilers better deal with ever changing loads

It is not just the yellow sticker on the side, or a combustion analysis showing burner efficiency that needs to be consideredBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi there, sorry I hadn't looked at this thread for a few years with work and life and everything. I still haven't done anything with my system. I was set on getting the Viessmann Vitocrossal 300 with 199 input, but I couldn't find anyone in the St. Louis area who was familiar with the boiler or had installed it. I had been worried about whether it was big enough for the house, since the professional heat loss calculation showed 186,000 BTU of heat loss, which really isn't bad for a close to 6,000 foot 130 year old house with all its original windows (storms and insulation were added). When I watched my gas intake on a 0 degree day with my old boiler running continuously, I saw 10 cubic feet of gas used every 174 seconds and the house at a comfy 70 degrees. Going by my actual gas usage, it seems like my boiler is burning 211K and putting out around 170K assuming it's still 80% efficient, which is just about 15% lower than the professional's heat-loss calculation.

Recently, I noticed insulation inside my old boiler starting to break off and fall on the flame tubes, and it has started making a banging noise a minute or two after shutting off (I think it's the casing cooling down). So I'm working on a replacement again, especially since my neighbor had to have an emergency replacement in the middle of winter. I have decided to forego Mod-Con boilers, even though my low-temp gravity system is a mod-con's dream. My better half really hates the look of steam coming off the side of the house and I'm not keen on putting a hole through my 1 1/2 foot thick masonry walls either or venting through a basement window. I know some mod-cons can be vented with appropriate vents through the chimney, but the vents have to stick a foot or two out of the top of the chimney, which is also unsightly, and getting an ice-dam 50 feet up in the midst of winter would be a disaster. Also, whatever I save on gas I'll probably end up spending on annual maintenance. And there is also the shorter life-span of the typical mod-cons compared to CI.

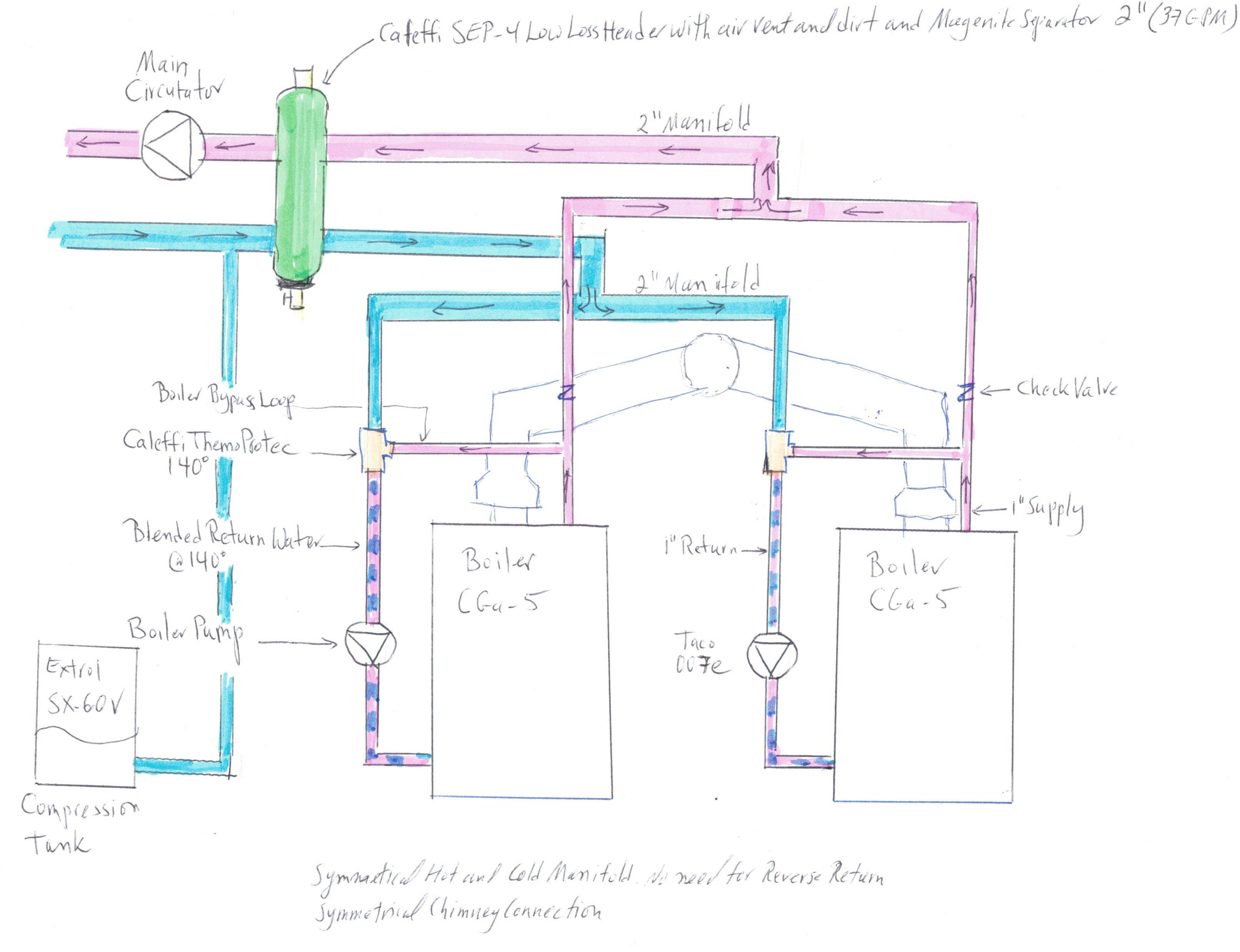

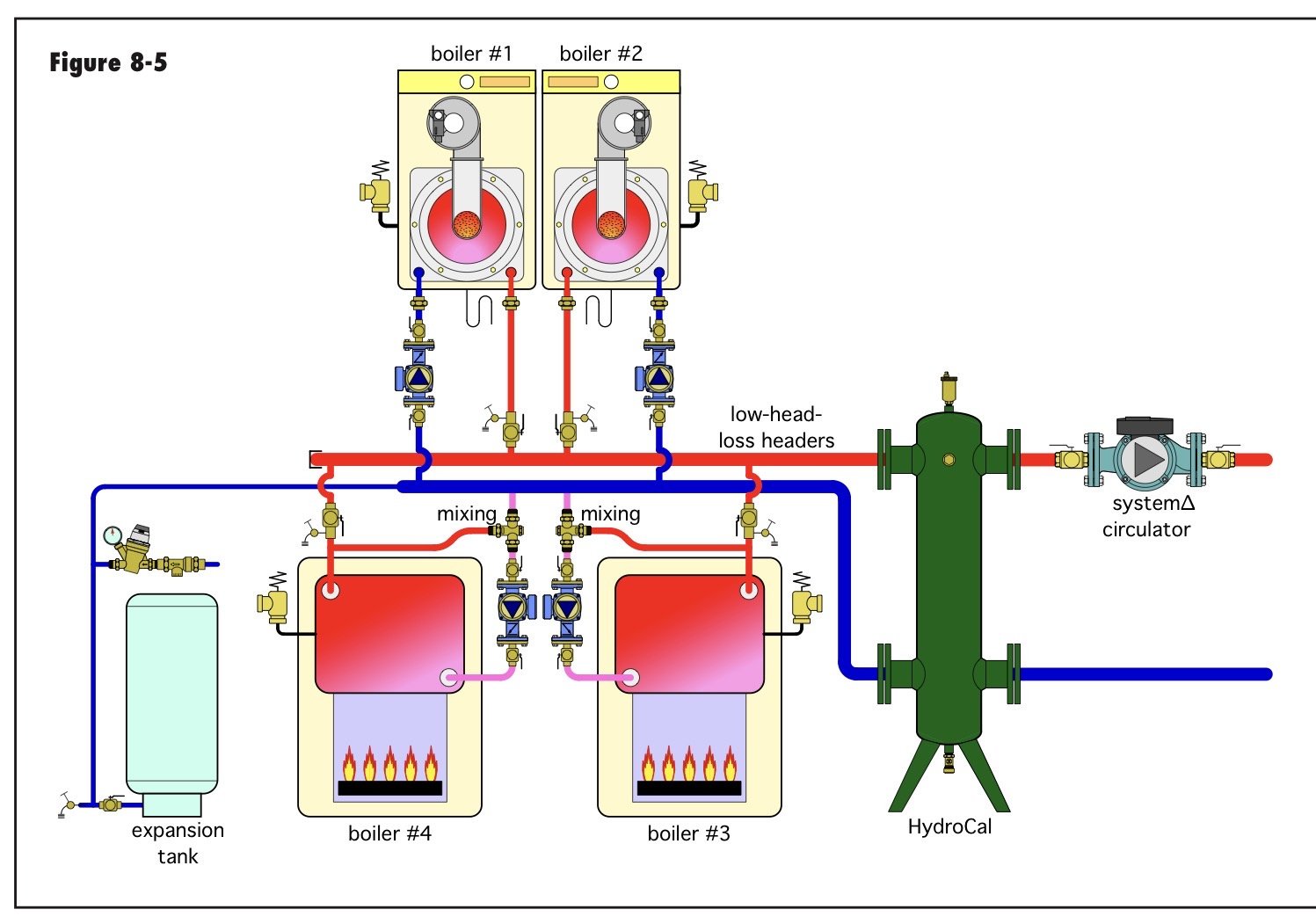

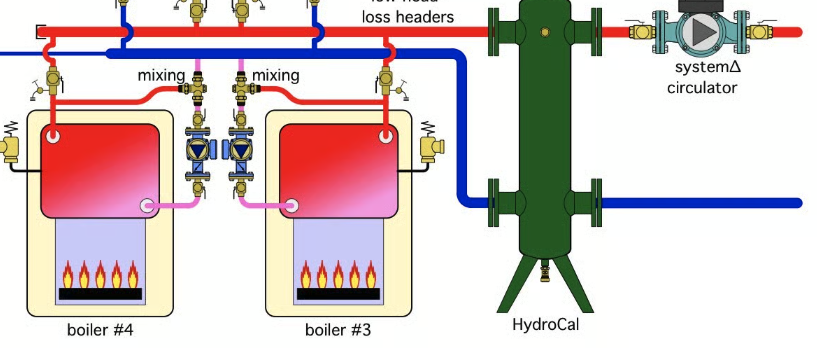

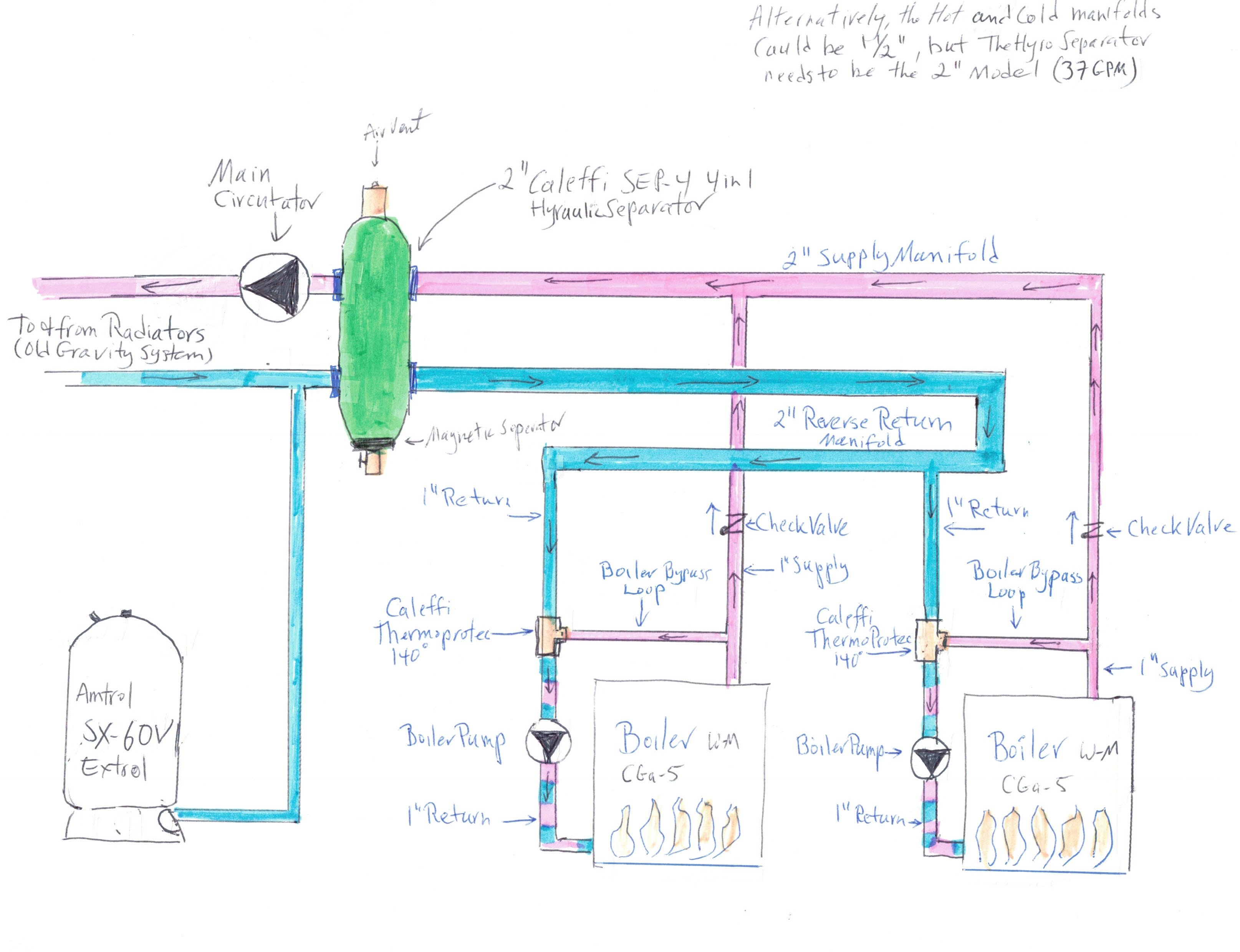

So I'm working on getting two smaller cast iron boilers of 133K input, each of which would give me about 60% of my heat needs and keep the house from freezing if one boiler fails. They can also safely share my 50' tall lined chimney. The system is slightly oversized still, but I think the next size down (100K input) is just a tad too small, especially for redundancy purposes. I'd rather pay a little extra for gas than deal with frozen pipes and water damage in an old house in case of a boiler failure in a super cold week like we had recently. I would have loved to get the Buderus boiler, but they have stopped marketing it in the US, and even though it's still available from some suppliers, I worry about support and parts in the future. So I am going to go with a WM CGa-5, which everyone seems to be quite familiar with, and I won't worry about parts and support. I just have to find a good installer to do what I envision. I have seen so many bad install jobs in my area, and I want mine done right. This is kind of what I have in mind.

0 -

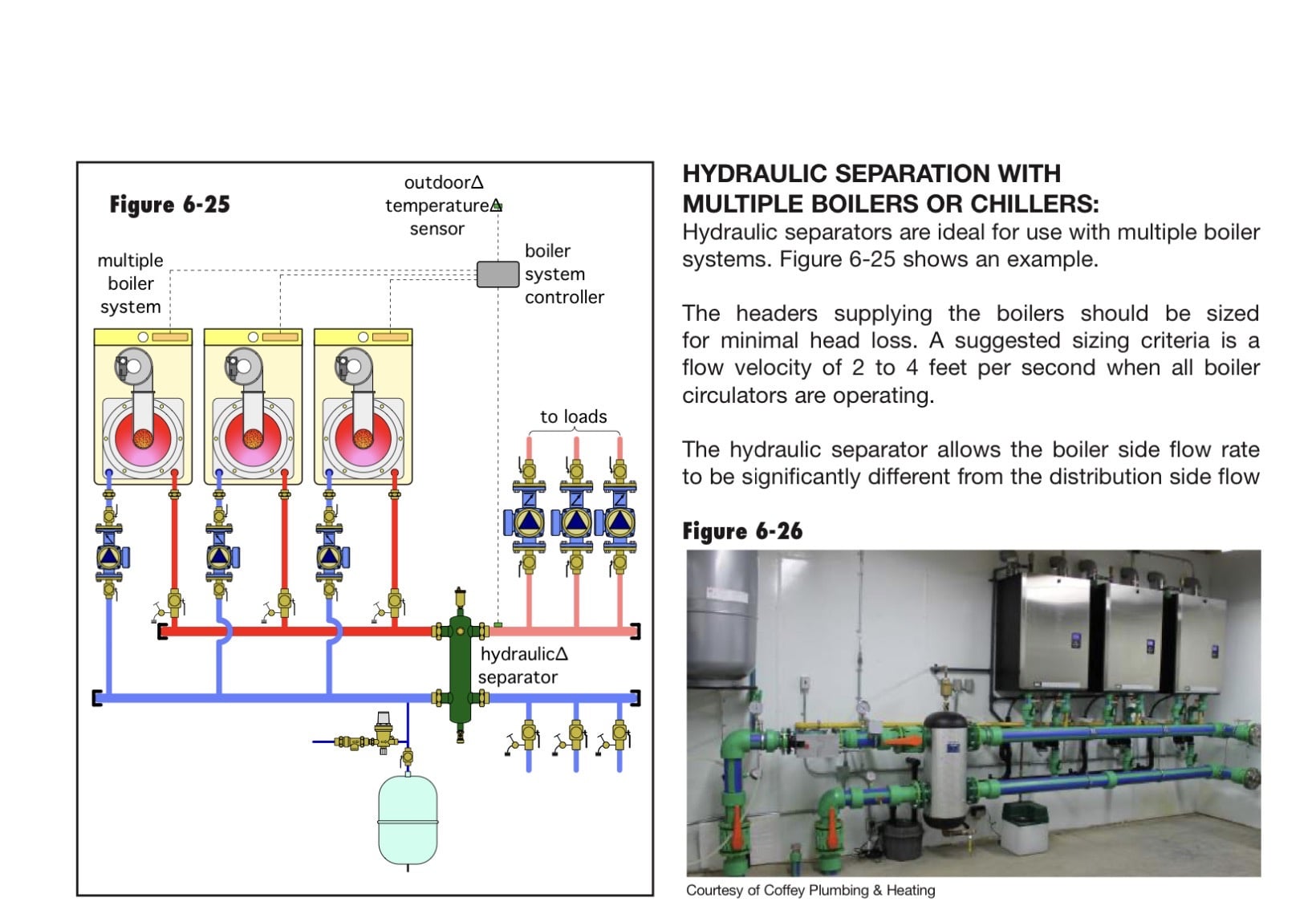

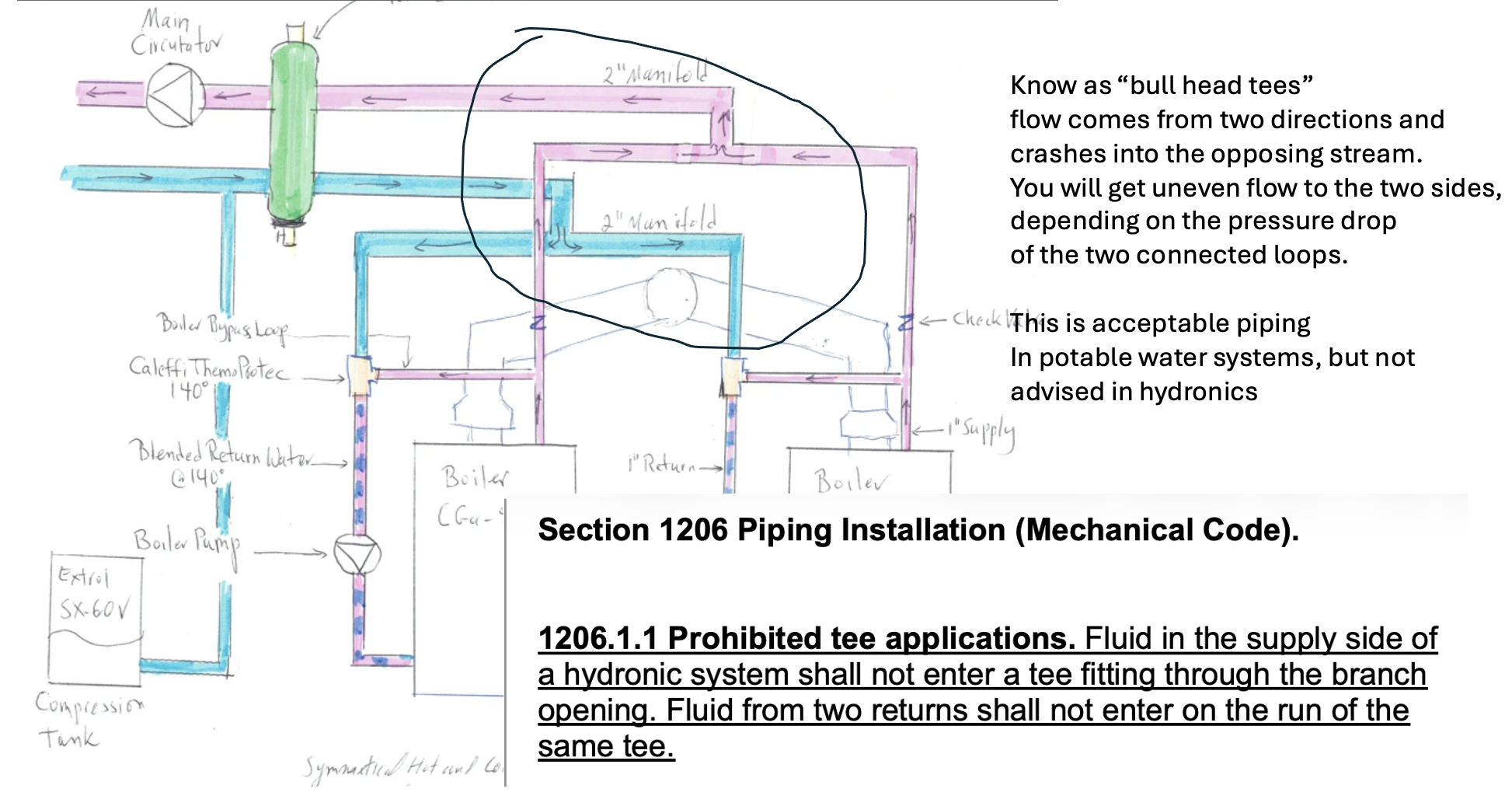

here is a good way to pipe multiple boilers to a seperator. You do not need or want to bull head, bring two flows into the run of a tee. The branches off the sep should be 2” as you show to maintain low velocity when both are flowing.

My suggestion is to run a hydronic cleaner after the installation, use good fill water, see the manuals recommend water quality. I like to add a conditioner also. It protects the metals from forming a scale which will reduce efficiency of the heat exchange.

I couldn’t talk you into a hybrid, one mod con, one conventional cast option? 🧐 1/2 of figure 8-5

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks Hot Rod! So you think my drawing is pretty sensible? Is there anything you find wrongly thought out with my drawing??

As far as a mod-con / CI combination goes, I see your point, but I don't think it would be great for my house, since my supply water never needs to rise above the low 130s on a 0 degree day with return of around 120. If my system ever required higher temps, I think adding a cast iron to mod-con would make great sense. A pure mod-con makes perfect sense as far as performance and modulation goes, especially since low temps like mine are a mod-con's dream, but there is the issue of side venting which I really want to avoid, or venting through a pipe sticking out of a chimney, which is even uglier.

And when I ran the numbers, what I would save in gas annually in STL came out only a tad above what I would spend on annual maintenance, especially on a boiler with more fragile components than a cast iron one. And then there is the shorter lifespan of mod-cons compared to CI. I think my plan has a good balance of decent performance, CI dependability and low maintenance, and redundancy in case of a single boiler failure. And if I use something like a Tekmar 294 with an outdoor sensor and an indoor sensor (or Tekmar communicating thermostat), I should be able to have outdoor reset and good comfort during the entire season, plus the peace of mind of redundancy.

To be honest, if anyone in my area were familiar with the Viessmann CU3A (as they seem to be in New England), I would even compromise on side venting, but I have to think of parts, maintenance, local expertise and all that goes with it. So for me and my area, it seems that run-of-the-mill WM cast iron boilers make sense.

A question about expansion tank: I'm looking at figure 8-5 with the combined mod-con / CI boilers. Shouldn't the expansion tank be connected somewhere very close to the Low-Loss-Header rather than at the end of the cold manifold? I think I heard you say in a couple of your talks about hydronic separation that connecting anywhere near one of the four ports of the low-loss-header makes the separator itself the Point of No Pressure Change.

One more question: My system has been running on a Taco 110, which going by my delta-t calculations is pumping just over 28 gpm through my system with decent distribution and no water noise. I would like an efficient ECM pump with a digital display that would allow me to play with different flow rates (up to 37 gpm per the SEP4). The Taco Viridian VR3452-HY1-FC1A01seems to fit the bill, though it will operate only at 50-60% of its capability. Do you have any recommendations for a circulator that would fit the bill?

0 -

Do you see the difference in your proposed piping vs the attached example? There in no need to tie the boilers together before you connect to the separator headers.

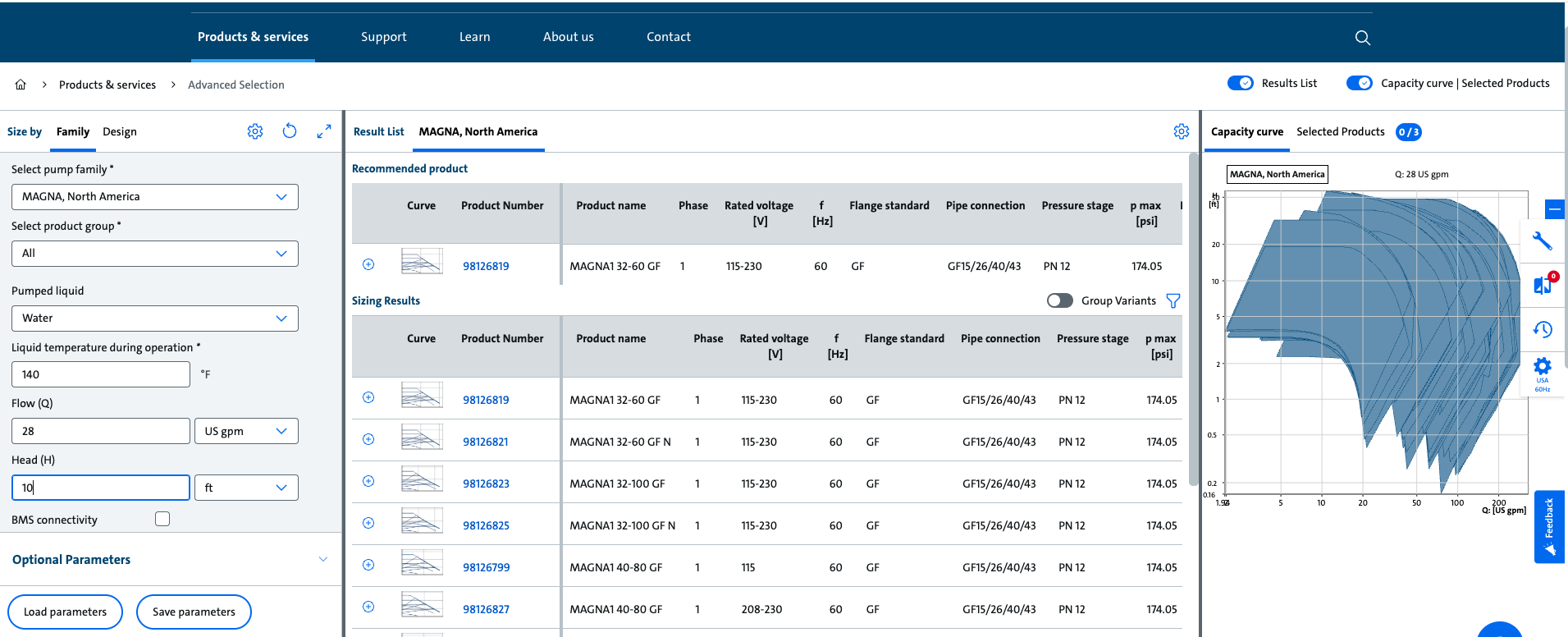

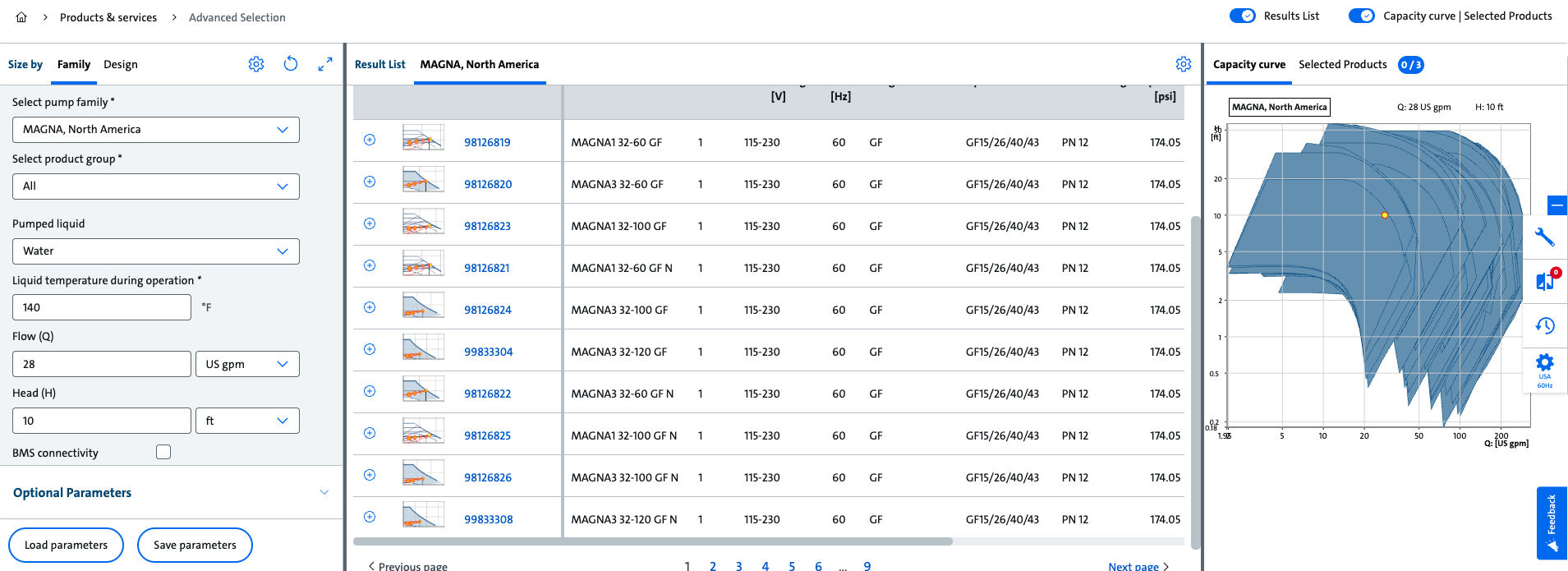

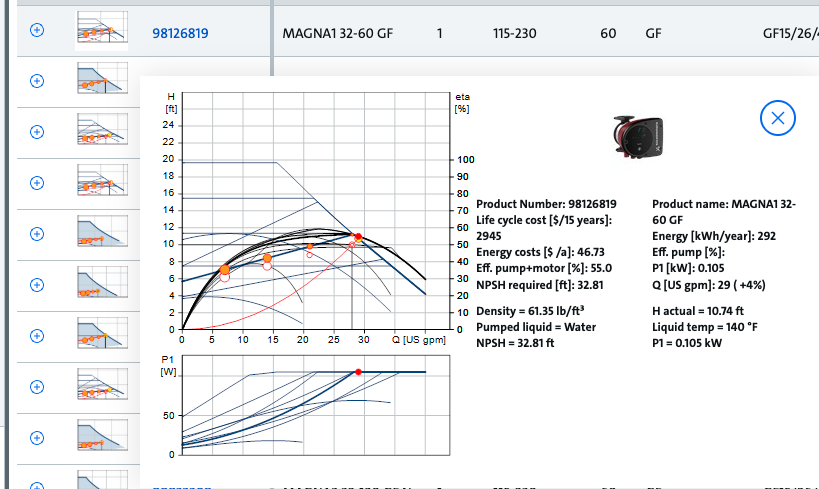

To size a pump, use one of the online calculators, pick a brand, here is a Grundfos example..

You need to know gpm, head, type and temperature of the fluid.

I used your 28 gpm, guessed at the head of 10', water at 140°?

It spits out a list of pumps, hover over a choice, the smallest Magna, and learn all about it down to operating costs.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you! I drew the diagram because if you face the boilers where the would go in my basement, the old gravity pipes would be behind you, so it kind of made sense. I thought the supplies and returns would connect to the 2" pipe and then from the center would take off and go toward the old gravity pipes. But I had no clue about the "law of the tee!"

Thanks for all the information on pumps. I had done some reading on the Magna, which claims to be magnetite resistant, though with a magnetic separator on the SEP4, I'm not sure how important that would be.

This is the previous drawing I had done, with a reverse return (though it might be overkill with 2" pipes). However, looking more closely at figure 8-5, since the boilers are mirror images of each other, they are in effect doing reverse return, though that sort of piping wouldn't be possible on a WM CI boiler.

0 -

if the boilers are close, within 5-6’ of the separator no need for the reverse return piping. Just tee them into the headers off the sep.

The two Weil boilers are 113,000 output, so 11 gpm is plenty for each, 22 gpm total. The 1-1/2” sep 4 is rated at 26 gpm.

If the system is zoned the flow on the B side would vary. But that is the whole intent of a separator, it allows various flow

1-1/2” copper is good for 11 gpm at 2 fps velocity, 22 gpm at 4 fps.

So the 2” sep might be a better choice, it’s about 30 bucks more at Supply House.

2” copper is good for 20 gpm at 2 fps, you want low flow velocity in those headers

A sep 4 covers your air, dirt, magnetic and hydraulic functions. So it does protect ECM circs from magnetite, etc.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Nice job with the sketches / hand drawings

0 -

coloring inside the lines🤓

If you can run Visio, these Caleffi stencils work nicely

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you. I think the boilers will be pretty close, but if not, I will ask them to do reverse return. I really enjoy thinking about fluid dynamics and flow behavior, so this is fascinating to me (just as it was fascinating to figure out blood flow characteristics in babies and children with heart defects when anesthetizing them for heart surgery). I started reading Dan's books almost 30 years ago and I have tried to understand my system well. And I think I have seen just about every Coffee with Caleffi and similar videos and try to educate myself. And I have also seen so to many badly done installation jobs that I've become pretty picky about how I want my own system to be done.

I decided on the 2" SEP4 since mine is a gravity system with large pipes and lots of water, and I didn't want my primary flow to be limited to 26 GPM, especially since my current Taco110 is probably putting out around 28-30, which seems to be working well. The system isn't zoned at all, and the house is always evenly heated and comfortable. I think a Taco0035e Plus should do the job nicely and will also allow me to choose how many GPM are circulated through the primary circuit. I think it'll be fun to play with the flow and different Delta-Ts and just see how the system behaves.

I spoke with the man (the previous homeowner) who took out the original giant boiler in 1975 and installed my current cast iron boiler with his buddies, and he said that when they opened the large gravity pipes, the inside of the pipes were clean as a whistle and looked brand new. And that was after 80 years of service. I'm hoping they're still looking like that!

One last thing, do you think it's ok do have the near boiler piping done with copper, assuming they would use brass fittings where they connect to the boiler and the old iron pipes, or should I have them do iron pipes? I believe they offer both. Press fittings would naturally be faster and easier, but I'd rather pay a little more and have it done well without worrying about galvanic reaction, etc.

Thanks again for all the help and all the teaching.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements