Two zones never reaching temp

We moved into our new house about a year ago and it's been great but I've been having issues with our radiant heat. Each zone has a manual thermostat - think of those old school mercury balanced types. I don't think I have any issues with the thermostats.

I have a 5 zones system with an electric boiler that has its own 200 amp system. I've noticed this winter that two zones are constantly calling. My home is well insulated, being one of those concrete and styrofoam builds.

Details about the two zones.

Both zones are on the same sending line. Most of my zones are on one return, including the two zones I'm talking about.

One of the two zones is the longest / furthest away from the boiler, going to the opposite side of my home (my bedroom). The other is the closest - just going up a floor right above.

I have a 3 speed pump that doesn't seem to make a difference if I set it to low med or high - other than water hammering issues while on high. Zone valves open and close and are one year old.

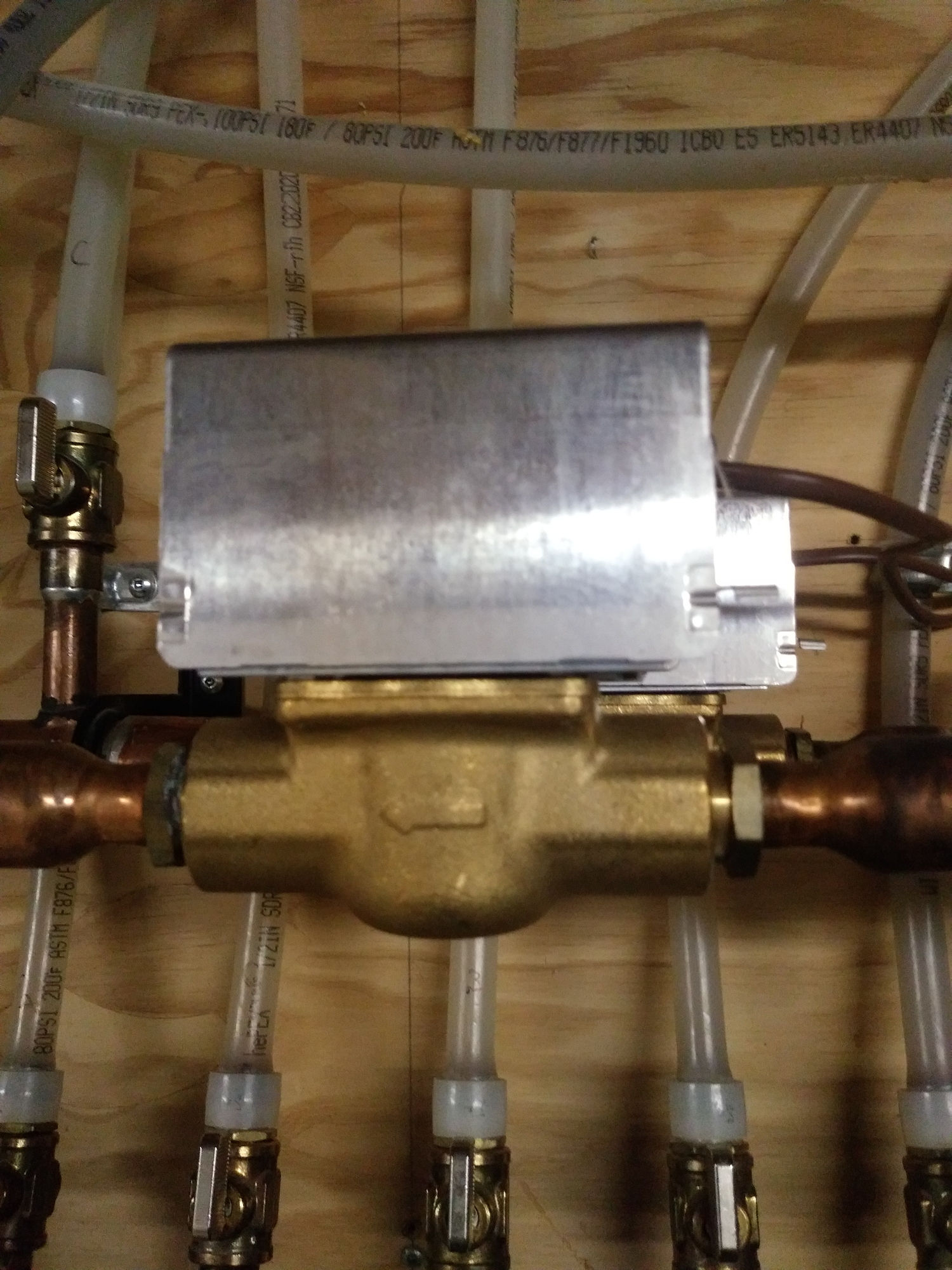

Photo of system- issue zones are top left in front of the 3 valve manifold.

up

upI'm stuck on what is causing these rooms from getting up to temp.

Comments

-

Do the two rooms in question have carpet on the floor?

What temperature is the water going to your zones?0 -

Here's a better pic of the whole system.

0

0 -

Can you determine the length of the tubing of the various loops? That tubing will have length markings I can't remember if it is every 2' or 5', probably a 5 digit number where the last digits change.

Measuring the supply and return temps with an inexpensive IR gun will give you clues to what is going on as well."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

If you turn off all other zones will it catch up?

Was a design done to indicate required gpm.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

A 26-99 is a serious circulator. Have you tried changing the speed?

It would be helpful if you could measure the temperature of the piping going to and from the two zones in question.

Do the rooms in these two zones have a lot of glass or anything else that would make the heat load high compared to the rest of the house?

0 -

Yes there is glass. I wouldn't say it's more than the rest of the house. The whole house has a lot of windows. Those rooms without this problem have large windows. So my hunch is it's not strictly an insulation issue.Robert_25 said:A 26-99 is a serious circulator. Have you tried changing the speed? It would be helpful if you could measure the temperature of the piping going to and from the two zones in question. Do the rooms in these two zones have a lot of glass or anything else that would make the heat load high compared to the rest of the house?

I've tried changing the speeds but I don't see a change. Just tried having it on high all day today.0 -

Yeah, if you don’t have enough heat emitter it may not be possible to pump your way out of the problem.

Some data collection would help, temperatures on the loops, even that without knowing flow will not tell the entire story, could be a kinked tube, for example.

The best place to start is a heat load calculation for the underperforming rooms. It that number comes In much above 25 btu per foot, radiant alone may not cut it.

Use the load calculator at Slantfin to get some numbers.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I will certainly get started with measuring temps.hot_rod said:Yeah, if you don’t have enough heat emitter it may not be possible to pump your way out of the problem. Some data collection would help, temperatures on the loops, even that without knowing flow will not tell the entire story, could be a kinked tube, for example. The best place to start is a heat load calculation for the underperforming rooms. It that number comes In much above 25 btu per foot, radiant alone may not cut it. Use the load calculator at Slantfin to get some numbers.

Is it possible that turning up the temp in the boiler would resolve this?0 -

https://www.slantfin.com/slantfin-heat-loss-calculator/

There is a limit to how hot you run the floors. 82ish is about the high side of what is a comfortable floor surface temperature.

Consider buying an infrared point and shoot thermometer. You could read the tube and floor temperatures and collect some need data.

Are these bedrooms? Beds, throw rugs, furniture all can limit the floors ability to meet the load.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I will certainly get started with measuring temps.lefe34 said:hot_rod said:Yeah, if you don’t have enough heat emitter it may not be possible to pump your way out of the problem.

Some data collection would help, temperatures on the loops, even that without knowing flow will not tell the entire story, could be a kinked tube, for example.

The best place to start is a heat load calculation for the underperforming rooms. It that number comes In much above 25 btu per foot, radiant alone may not cut it.

Use the load calculator at Slantfin to get some numbers.

Is it possible that turning up the temp in the boiler would resolve this?

Yes, it might be that simple...but in doing so you do not want to make the floors in other areas of of the home uncomfortably warm.0 -

Ok, got myself a temp gun to get some reading. I've also played around with upping the boiler temp to 120 from 110.

Tonight I'll get some floor reading but the reading I did from the send and return lines were close in temp. However, this morning I was checking other lines and I found my living room has an issue.

One of the lines off that zone isn't heating up. I know heat is getting to it, as the copper is hot but the line is much cooler. Plus the other line that's on the same zone is hot

Any ideas?

Mike0 -

With any parallel system with manifolds what is important to make sure it connections are reverse return to equalize the pressure drop across each loop ... The first on the supply the last on the return .. Looking at the pipe setup with the manifolds heading down below , The left 4 loops zone are overly favored over the right zone . The right zone is teed to the rear in the supply and the returns are the last to return .. I really can't read the marking on the Pex but if they are grouped together then reverse return was neglected .. To repair I would move the returns . The right side furtherest supply loops return should be attached to the port closest to the circulator and work your way down .....

There was an error rendering this rich post.

0 -

Would a balanced manifold resolve this too? I was thinking of putting one as the return side and just balance the flow from there. Would that help?Big Ed_4 said:With any parallel system with manifolds what is important to make sure it connections are reverse return to equalize the pressure drop across each loop ... The first on the supply the last on the return .. Looking at the pipe setup with the manifolds heading down below , The left 4 loops zone are overly favored over the right zone . The right zone is teed to the rear in the supply and the returns are the last to return .. I really can't read the marking on the Pex but if they are grouped together then reverse return was neglected .. To repair I would move the returns . The right side furtherest supply loops return should be attached to the port closest to the circulator and work your way down .....

0 -

I like them to fine-tune , I never added one to correct the problem . I would find it easier to move pipes around ...

There was an error rendering this rich post.

0 -

Here's some more updates.

Put the boiler temp back to 110. Bedroom zone sending temps are 94 ( it is hard to get a consistent temp reading) and return temps are 84. Three zones we're open when I took the readings - the two zones that this thread is about and our living room. This morning it's 8.3f (-13C). Floor temps in the master bedroom was 71.

0

0 -

Any thoughts on my temp readings?hot_rod said:https://www.slantfin.com/slantfin-heat-loss-calculator/ There is a limit to how hot you run the floors. 82ish is about the high side of what is a comfortable floor surface temperature. Consider buying an infrared point and shoot thermometer. You could read the tube and floor temperatures and collect some need data. Are these bedrooms? Beds, throw rugs, furniture all can limit the floors ability to meet the load.0 -

when you refer to the zones being open are you referring to the thermostats are calling for heat or the actual zone valves themselves are open?

has it ever heated?

can you hear the pumps for the zones not working running?

finally is there valves that allow you to bleed the possible air in the lines that could be causing the problems.0 -

Any thoughts on what that might look like for this system? I'm hoping to bring some ideas to the discussion with the heating company that installed the system here but I want to go in with a good idea of what 'should be done'.Youngplumber said:You should be getting the same temp to every zone if you have all radiant floors. I agree with @Big Ed_4. Your piping is not ideal. You could try messing with the balancing but then you'd be choking the other zones. Better to get that pulled in a more dustributave way.

I appreciate the advice,

Mike0 -

If the return pipe between the circulator and the return manifold were piped to the right side of the manifold, or other side it would give you reverse return and keep the loops organized together ...

Picture a ladder it was the way I was taught , The left rail is the supply and the right side is the return . And the rungs are the parallel heating loops . What you have , the supply and the return connected to the bottom of the rails . The first rung would be the shortest distance back to the boiler and the top rung the longest distance back to the boiler, The flow of water works off the pressure drop caused by the circulator . The first rung would have the greatest measure of pressure drop and the top rung would have the lowest measure of pressure drop . The first rung would have the greatest flow and the top the least flow

If we change either the supply or the return , and take one of them from the bottom of the rail to the top , it will equalize the pressure drop across the manifold .... Every rung will be equal , distance , pressure drop and flow ....

The manifold with the flow adjustment can be used to fine tune the resistance of each loop . Some loops could be longer and some may take more or tighter bends than others . Not to fix the primary problem ....

There was an error rendering this rich post.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements