Radiators not getting hot. EK System 2000 (gas). Gravity HW conversion (see photos)

What I'm working with:

- This year (2020) I bought a 1919 house, 5600 sq ft, outside of NYC. This is my first winter with it.

- Being a steam-head, at first I was very saddened to see that someone converted it to hot water

- But then with the help of someone from this forum, he explained to me it was actually a gravity hot water system. Cool! (ref: https://heatinghelp.com/systems-help-center/gravity-hot-water-heating-q-and-a/ )

- Judging by the old work piping that is still left, it looks like a commonly used Upfeed style with 2 returns (floor) and 2 supply (ceiling) (ref: https://heatinghelp.com/assets/Uploads/heating-p8-245x300.gif )

- It now has two B&G 100 pumps pushing the water now. No more tank in the attic and I can't find any mercury to play with

- Gas fired Energy Kinetics System 2000 installed in 2009

- 75 gallon domestic tank

- Mostly original cast iron plumbing. PEX used in some renovated areas (Kitchen mostly)

- 23 cast iron radiators (mostly floor mounted with covers, but also 4 wall-mounted "X-rays")

- 1 cast iron sunrad baseboard

- 5 "indirect radiators" (ref: https://heatinghelp.com/systems-help-center/indirect-hot-water-heating-q-and-a/ )

- Both B&G 100 pumps turn on with the thermostat

- Radiators are not getting hot at all. 95F according to my $10 amazon laser pointer

- The 95F temp is consistent across all radiators, and both top and bottom of radiator

- The supply's temp gauge reads 170F

- The return's temp hovers around 120-130F (reading this from the System 2000 control panel)

- Boiler never cycles

- Somehow the thermostat is eventually satisfied, it's usually at 68F but I've had it at 69/70F too

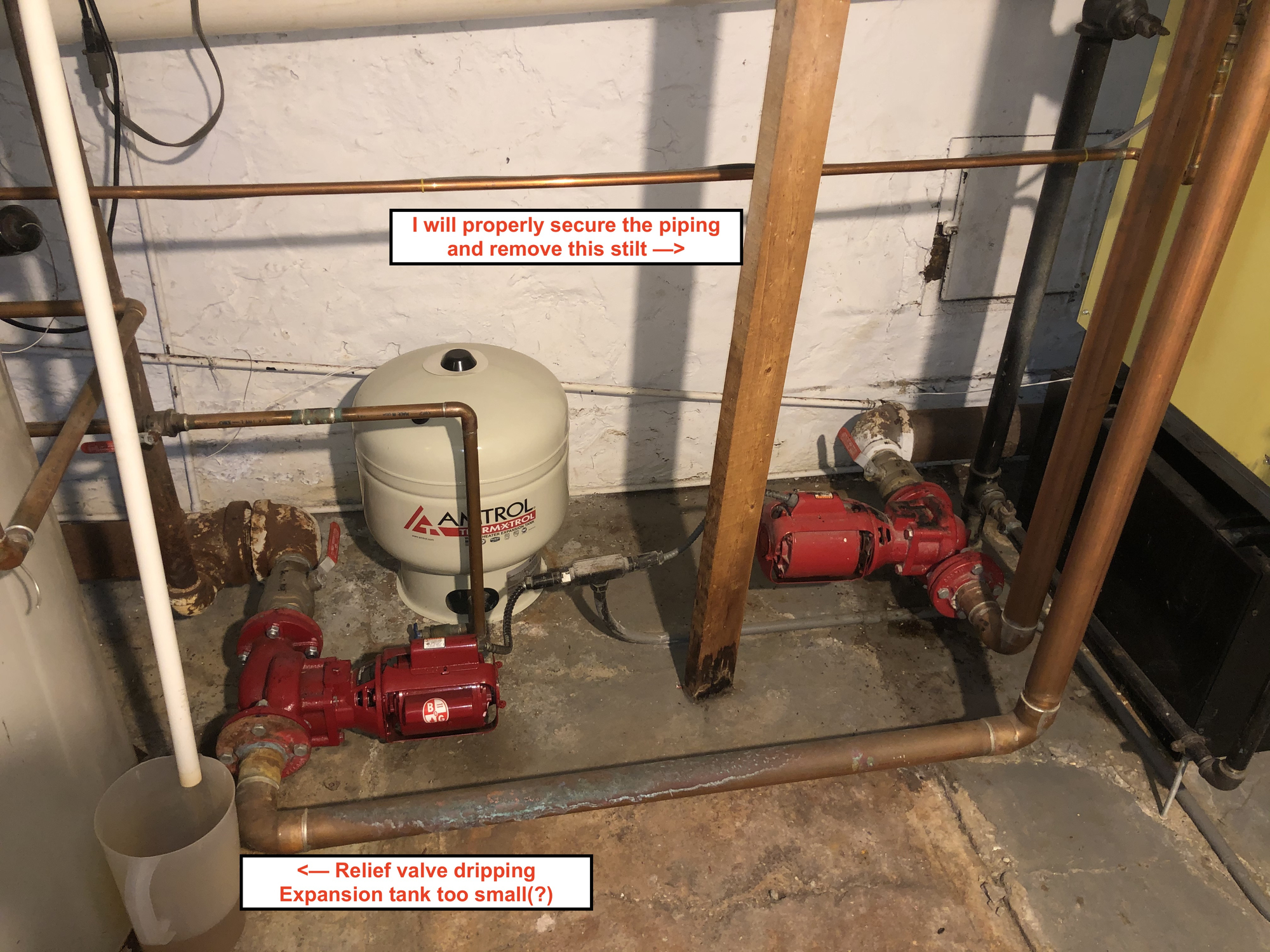

- Also, the expansion tank on this system was replaced for unknown reasons. It's now too small. Pressure reads more than 30PSI, and the relief valve is always dripping during the heating season

- The owner came on-site next day for about an hour.

- He does not frequent these forums but I won't hold it against him. I'm looking forward to working with him more.

- He decided to try something: Choked down a ball valve on the return - It was full open, now it is ~25% open

- The boiler temp gauge went from original 170F to 200-210F

- The return temp gauge went from original ~130F to 160-170F

- The boiler started to cycle about 1-2 times per hour, after 2 minutes it kicks back on

- Radiators went from original 95F to 115F. Better, but not fixed yet

- The house feels much more comfortable

- Choking the return valve any more will cause the boiler to short cycle

- For months, I couldn't understand how any of the near boiler piping worked

- The mystery was solved last night once I discovered "primary secondary pumping". The supply and return are connected with a tee, and finally now I can understand how the water [is supposed to move] in my mind's eye. (ref: https://heatinghelp.com/systems-help-center/understanding-primary-secondary-pumping/ )

- With my recent education on primary/secondary pumping, I don't think the heated water is making its way into the supply side of the secondary. (see photos). Maybe a Reverse Flow problem?

- The system loop's return side right before the tee is 80-85F (see photos)

- The system loop's supply side, right AFTER the tee, is also 80-85F (see photos)

- The boiler loop's supply is reading 110-130F (see photos), so why is the system loop still 80-85F?

Thanks everyone. Let me know what you think. I'm the HO and I can pass the info to the System 2000 tech.

Comments

-

"Also, the expansion tank on this system was replaced for unknown reasons. It's now too small. Pressure reads more than 30PSI, and the relief valve is always dripping during the heating season"

When was the tank replaced?

What is the pressure and temp when the system is cold?

What is the pressure and temp when the system is hot?

What did the tech last week say about the pressure?0 -

If that's the expansion tank sitting down between the two big red pumps... it's cute. It's also almost certainly way too small -- gravity systems with radiators have a lot of volume!

Then... what is pumping water through the secondary loop? You have to have something. How do those two big red pumps fit into the system?Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thank you @WMno57 .

Unknown, but it's a smallish town, and I actually talked to the guy that did it. He's a handyman with plumbing skills. He wasn't able to tell me why the previous HO had him do it or when. I don't think we will ever know.WMno57 said:

When was the tank replaced?

Cold: Gauge reads about 5PSI right now, at 110F. I took a photo for proof. Boiler hasn't run for hydronic heat for 8+ hours, but I'm sure it's run for domestic recentlyWMno57 said:

What is the pressure and temp when the system is cold?

What is the pressure and temp when the system is hot

Hot: Gauge will easily get up to 200-210F (when the return valve is 25% open), and personally I never saw the PSI get past the 20-25 mark. I have a chair next to the boiler and everything. The relief valve drips even when just domestic hot water is being made at ~5-10 PSI.

Anyone who sees this system says the same thing: Expansion tank is too small. I'm not sure why. So, the tech sent me a quote for a properly sized one and he says that will fix the pressure issues that cause the relief valve to blow offWMno57 said:

What did the tech last week say about the pressure?

Photo of gauge is when boiler hasn't made hydronic heat for 8+ hours, but has been making domestic hot water throughout the day.0 -

That floor tank you're looking at is plumbed into the the domestic water side of things. Now, see the photo of the boiler? There is a gray tank hanging off the right side. That's the one everyone says is too small, and is causing the pressure to be too high, and causes the relief valve to drip.Jamie Hall said:If that's the expansion tank sitting down between the two big red pumps... it's cute. It's also almost certainly way too small -- gravity systems with radiators have a lot of volume!

Take with a grain of salt (that's why I'm doing my best to upload photos): There are two B&G pumps are in the system loop. See attached photo, I drew out a diagram. There is a pump on the boiler loop, right on top of the boiler towards the rear.Jamie Hall said:

Then... what is pumping water through the secondary loop? You have to have something. How do those two big red pumps fit into the system?

(Edited image after we found there was a pump on the boiler loop) 0

0 -

You have a lot going on there and may have more than one issue.

The President of EK posted on here recently and stated that all their techs are trained. It sounds like your tech has already identified one problem and has calculated the correct size tank for your system.

Even if your handyman tank is working, those tanks have a limited lifespan. At best, your current tank is half worn out. A brand new correctly sized tank should solve that problem for the foreseeable future.

It sounds like your PRV is not seating. Not the end of the world, but the drip drip drip will have to be replaced with fresh water. Fresh water has dissolved air. The more fresh water you add, the more air you bring into the system. I would ask the tech to also replace the PRV.

Nice looking boiler!

0 -

That near boiler piping is all wrong. Thats not proper primary/secondary piping. I have no idea how that ever worked.

Two pumps on the system side? Whats pumping the boiler loop? You need someone who is familiar with hydronic heating and Energy Kinetics boilers. Where are you located?0 -

Both @clammy and I have both looked over this entire system gave our recommendations and suggestions.

Very hard to get things working properly without some type of investment.

As @SuperTech has mentioned the near boiler piping is all wrong and no where near primary/secondary piping.2 -

I was going to suggest the OP contact EK to get some dealer names so they could go out for repiping. P/S piping is in the manual. There's pictures and everything.EzzyT said:Both @clammy and I have both looked over this entire system gave our recommendations and suggestions.

Very hard to get things working properly without some type of investment.

As @SuperTech has mentioned the near boiler piping is all wrong and no where near primary/secondary piping.0 -

Thanks @EzzyT , I didn't want to drop your name as the person that explained to me that this was a gravity HW system. Very cool.EzzyT said:Both @clammy and I have both looked over this entire system gave our recommendations and suggestions.

Right.. that's why I'm here, to gather info on how/where to make an investment. I won't be able to move forward with your proposal unfortunately but I recently hooked up with the local EK tech and I am hopeful about that.EzzyT said:Very hard to get things working properly without some type of investment.

As @SuperTech has mentioned the near boiler piping is all wrong and no where near primary/secondary piping.0 -

I saw that post! That's when I called around to find a local EK techWMno57 said:

The President of EK posted on here recently and stated that all their techs are trained.

Yes, 2 on the system side.SuperTech said:That near boiler piping is all wrong. Thats not proper primary/secondary piping. I have no idea how that ever worked.

Two pumps on the system side? Whats pumping the boiler loop? You need someone who is familiar with hydronic heating and Energy Kinetics boilers. Where are you located?It appears to me that nothing is pumping the boiler loop. Which is maybe the reason why, it seems that, hot water isn't getting into the supply side. I don't think the tech caught this on the initial visit but I'm gonna point this out to him and reply back with what he says.There is a Taco Cartridge Circulator on the boiler loop (painted black, on top of boiler towards the rear)0 -

Boiler pump! The boiler isnt gravity....the system is.

Those B&G 100s are energy hogs. A gravity system should need a very small circulator, just enough to overcome the small diameter copper which was added for boiler replacement. Remember there was no pump originally.

If you had two very well respected forum members out to look at this, and are still asking in here......I don't have much to say.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!1 -

-

This is very interesting to me because in some ways our systems are identical and in other ways not.

Same:

100 years old

High mass systems

Large diameter gravity piping

B&G 100 pump(s)

Not:

Mine currently works well, and has for 70 years

My boiler is heavy cast iron, yours steel

I don't have primary / secondary

I have a single B&G 100 pump

I'm not pumping away

My plain steel compression tank lasted 70 years

Your system may be more efficient

My house is half the size and has nine radiators

At some point in the future I may buy a new boiler.

It would be interesting to hear from the EK president. Did an EK trained tech install your boiler? Does EK have any records of the install?

I would think in the cell phone age, if someone purchased an EK boiler, the installer should submit a picture of the install to EK.

At some point in the future I may buy a new boiler.

If I buy a new GMC Sierra from a dealer, General Motors will always support it. That type of support will be a requirement to win my business. Otherwise, I might as well buy my next boiler from www.supplyhouse.com or Home Depot.

HVAC businesses up and down the channel need to step up their game.0 -

I doubt EK has any information on specific jobs.0

-

I would hope they would have a record of the original purchaser's contact information, model # and serial #, in case there was a recall.

Since they should have that, maybe they should start tracking more information. Just another field in a database. It all depends on how much they wish to support their product.

How long will it be before the boiler sends an error code to the installer and manufacturer with the home's internet connection?0 -

Not sure if you realize this, and it is hard to see, but there is a boiler pump on the boiler, coming off the back.Solid_Fuel_Man said:Boiler pump! The boiler isnt gravity....the system is.

Those B&G 100s are energy hogs. A gravity system should need a very small circulator, just enough to overcome the small diameter copper which was added for boiler replacement. Remember there was no pump originally.

If you had two very well respected forum members out to look at this, and are still asking in here......I don't have much to say.

Rick1 -

So, are we correct in assuming the pipes from the boiler loop to the closely spaced tees are running at 170 degrees out, and 130 on the return? But the system piping going past the tees is only getting to 85degrees? You need to either use some flat black spray paint and paint the pipe before and after the close tees to get a good reading.Those infrared thermometers will not read a correct temperature if they are pointing at shiny pipes.

Makes me think the boiler is undersized and not able to keep up. If it is running and maintaining around 170 degrees, and the boiler does not shut off, that heat is going somewhere.

Rick0 -

I thought the same as you. Plus, EK tech was able to make one quick phone call and determined the company who purchased the system and I'm hoping he can find out more. Even though it was 11-12 years ago I called the original company and left a message.WMno57 said:I would hope they would have a record of the original purchaser's contact information, model # and serial #, in case there was a recall.

Thanks @rick in Alaska , attached is a photo of the rear of the boiler to prevent any more confusion. I didn't know what that device was but I now realize it's a pump "Taco - Cartridge Circulator". Hope I didn't throw the conversation off too much. I'll go back and edit my posts.rick in Alaska said:Not sure if you realize this, and it is hard to see, but there is a boiler pump on the boiler, coming off the back.

Rick

1 -

Good tip, I'll paint it black and get you a hopefully more accurate reading. But for now: just know that when I touch/feel around the closely spaced tee area, the system loop is just warm to the touch on both the supply and return (see photo) and I can keep my hand on it all day long. Using my touch-o-meter, there is no noticeable temp difference between supply/return. But the boiler loop is very hot at that T-fitting, I can only just quickly touch it (see photo). I have the same question as you: Where is all this heat going?rick in Alaska said:So, are we correct in assuming the pipes from the boiler loop to the closely spaced tees are running at 170 degrees out, and 130 on the return? But the system piping going past the tees is only getting to 85degrees? You need to either use some flat black spray paint and paint the pipe before and after the close tees to get a good reading.Those infrared thermometers will not read a correct temperature if they are pointing at shiny pipes.

Makes me think the boiler is undersized and not able to keep up. If it is running and maintaining around 170 degrees, and the boiler does not shut off, that heat is going somewhere.

Rick0 -

@ssa, obviously the current setup is not correct. It's not rocket science. EK offers a spec sheet for large volume systems. You just need to pull the trigger.

0 -

ok, a couple of observations.

it was installed 11 years ago so A) it always worked poorly and the previous HO was ok with the lower house temperatures. people are funny that way. this I believe is closest to the truth but I've been wrong before. or B ) it used to somehow work but now the oil burner is not working correctly as in its burning at a reduce heat output. note I'm not an oil guy so i'll stop there.

picture in the minds eye how the gravity boiler was piped. I'm thinking single zone two circuit direct return. lets say north and south circuits. the 2 floor level CI pipes where the circs are mounted are the returns that connected at the boiler base ( look at the floor. you can see where it sat. there are 2 CI pipes at ceiling height are the supplies, north and south circuits.

enter the knuckleheads. it appears the closely spaced tees are connected to only supply and one return. best I can think how the EK installer ever thought this would work would be to cross connect the house circuits in series. ie north circuits return connects to the south circuits supply and visa-versa.

the fix should be easy, it just requires redoing the near boiler piping ( which requires opening up your wallet).

properly tie the supplies together, properly tie the returns together. keep one B&G 100's as there are thousands of gravity conversions out there that use 'em. now with the EK factory piping diagram connect the closely spaced tees.0 -

The piping around the boiler needs to be redone, but you will be able to reuse one of those B&G circulators and have a spare.

This video shows the conversion of a system very similar. Note that the secondary loop (loop with red circulator) is connected to each set of supply/return pipes in parallel, and the primary loop from the boiler has a bypass valve installed. This allows you to balance the flow though the system, while adjusting how much of a load it puts on the boiler.

https://heatinghelp.com/systems-help-center/converting-from-gravity-to-pumped-flow/0 -

5600 square feet in an older home , and I can't tell from my phone but it looks like an EK-1. That boiler may be undersized, it may be possible to increase the firing rate , dont work on gas, but the oil version is only good for approximately 140, 000 but input if it is an ek10

-

huh, i thought it was oil. now i do see a gas valve.

@ssa are you on LP or natural? if nat gas, fire it up and go to your gas meter and time how long in seconds it takes to pass 1 cuft of gas and let us know. being woefully underfired or just too small of a boiler will do just what you describe

ps although it appears you've had 2 of the best out there and they also agree it ain't piped right.0 -

Beautiful. This is tremendously helpful. Thank you. I set YouTube to slow down the playback to 25% and I can see exactly what you are sayingRobert_25 said:The piping around the boiler needs to be redone, but you will be able to reuse one of those B&G circulators and have a spare.

This video shows the conversion of a system very similar. Note that the secondary loop (loop with red circulator) is connected to each set of supply/return pipes in parallel, and the primary loop from the boiler has a bypass valve installed. This allows you to balance the flow though the system, while adjusting how much of a load it puts on the boiler.

https://heatinghelp.com/systems-help-center/converting-from-gravity-to-pumped-flow/

I agree with everything you said, I can see the ghost of the original boiler (except the oil part but you corrected yourself already). And yes, I feel like the previous HO would have been OK with the low temps especially because he didn't even spend winters here. But... did the EK installer ignore that he created this problem, and just collected his payment? That's terriblech4man said:

picture in the minds eye how the gravity boiler was piped. I'm thinking single zone two circuit direct return. lets say north and south circuits. the 2 floor level CI pipes where the circs are mounted are the returns that connected at the boiler base ( look at the floor. you can see where it sat. there are 2 CI pipes at ceiling height are the supplies, north and south circuits.

enter the knuckleheads...

Natural Gas. I will do what you asked with the gas meter and reply back here with what I find, thank youch4man said:

LP or natural?

I agree. I will get this taken care of professionally ASAP. I want the system to operate properly. I'm here on this forum to get my ducks in a row (and perhaps provide you with a little entertainment as an internet problem solver). Everyone here has always been tremendously helpful. Just look a this threadHVACNUT said:@ssa, obviously the current setup is not correct. It's not rocket science. EK offers a spec sheet for large volume systems. You just need to pull the trigger.

0 -

I guess I do not see how it is piped wrong, except the closely spaced tees are too close to the elbow, which frankly, I don't think will change much. I don't believe re-piping it will solve anything.

From what I can see, there is a pump on the floor to the left that is pumping into the copper pipe, which appears to be the return, and then another pump coming out of the supply, that is pumping away from the copper pipe. I can't tell, but I assume the right side pump is pumping away from the copper pipe. I am not sure however why it would need two pumps in this case, as it looks like they are in series.

From what I am seeing, the system is doing what it is supposed to do, but the boiler is just not big enough to handle it. If there really is a 40 degree delta, that heat is being used in the system.

Rick0 -

Thank you for your posts, everyone - quite a flurry of activity!

For reference, this is an EK2 Frontier with a gas burner (up to 225,000 BTU/hr input).

In addition to the proper expansion tank, primary/secondary should definitely be used to pipe this system properly; this needs to be corrected. I talked to our tech support team and we PM'd @ssa with the correct primary/secondary drawings earlier today, but I didn't have a chance to catch up until now.

I know @EzzyT and @clammy have visited and reviewed @ssa 's installation and I have every confidence that they will propose a proper solution. I'm sure they also reviewed and traced the piping, and being on site goes a long way toward understanding and proposing the correct solution vs stitching together and tracing piping and the system overall in photos (although you did a remarkable job, @ssa !).

Also for reference, we do track every boiler serial number and the respective dealer that purchased it - all 41 years of history. If the dealer or homeowner registered the product, then we also have that information.

We are here to help if any support is needed or desired going forward.

Best,

RogerPresident

Energy Kinetics, Inc.5 -

follow where the vertical, new copper ties into the returns at floor level and the supplies at the ceiling. you can see the installer tied the left side return with the right side supply and visa versa. epic failrick in Alaska said:I guess I do not see how it is piped wrong, except the closely spaced tees are too close to the elbow, which frankly, I don't think will change much. I don't believe re-piping it will solve anything.

From what I can see, there is a pump on the floor to the left that is pumping into the copper pipe, which appears to be the return, and then another pump coming out of the supply, that is pumping away from the copper pipe. I can't tell, but I assume the right side pump is pumping away from the copper pipe. I am not sure however why it would need two pumps in this case, as it looks like they are in series.

From what I am seeing, the system is doing what it is supposed to do, but the boiler is just not big enough to handle it. If there really is a 40 degree delta, that heat is being used in the system.

Rick

0 -

Thank you Roger, I received the pm with the drawings. Your involvement in this community is very impressive to me, and it makes me happy to be an EK owner, and confident that I can get this all fixedRoger said:

We are here to help if any support is needed or desired going forward.

Best,

Roger1 -

the major problem aside from the bad p s piping ,undersized expansion tank and being over pumped is that the whole system is piped as a single loop instead of the way it should and was piped which is 2 supplies and 2 returns w supplies on one side and return s on the other not as it is which is the front of the homes return ties and feeds the supply for the rear of the home . The way it’s piped it never see the temps it should , and where the pumps are located do nothing to help anything . That whole boiler room needed some attention Include some pipe support . Peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating1 -

I just clocked the nat gas meter using the test dials. The 1/2 foot dial took 20 seconds to do 2 full rotations. Using a calculator it looks like 180 cubic feet per hour.ch4man said:if nat gas, fire it up and go to your gas meter and time how long in seconds it takes to pass 1 cuft of gas and let us know. being woefully underfired or just too small of a boiler will do just what you describe

0 -

Looks like I somehow did something to offend @ch4man already. Aw shucks. Well, thanks for your input thus far, I really appreciate your involvementch4man said:good luck. it appears your unwilling to accept the truth.

I'm out.

The truth is quite evident throughout this thread. In my initial post I said that I'm presently working with the closest EK certified tech in my area, in addition to having 2 of the best plumbers from this forum come on-site and give me their opinions and proposals to consider. I would hope this shows to anyone that I'm committed to getting the heating system working properly. It's just day by day as a new owner of a 100 year old house, with 12 other projects to manage. The reason I created this thread for advice, banter, posterity, all of the above.1 -

I under stand that completely I take offense to none of it wish you peace. I wish you luck also and hope that you don’t get led down the wrong path and not get the results your excepting or what you have paid for no? As easy as it all looks on paper it only takes a few mistakes to throw good intentions to the wind . Without the proper pipe sizing and design and installation w ease for further service and a bunch of fore thought into how the pieces fit the puzzle and being able to dial in flow well if not then its just guess work . Your piping from my memory was over sized not properly reduced ,your pumps are 100 series but w high velocity gossetts something never needed on gravity conversion just crazy the list of no gos is longer then any positives .I saw the whole system and the home and the system will never the cheapest to operate without upgrades to the building aside from the heating system . Unless the system piping is corrected you will continue to have hi bills and a terribly performing system which will never be a quick reacting system unless a secondary boiler is added to get the water temps up in some type of timely manner . You are quite lucky that a EK was installed any other cast iron or steel boiler would have been dead in the water and a pile of rust running at the both low supply water and return water temps w no low temp protection and such a hi water content system so kinda count your blessing that the EK has some built in protection . Since I was was there and seen myself I know it needs a lot of TLC not only the boiler room but threw out the system and usually there will always be the need for more improvement possible de knuckle heading and possible repair but hey that’s what goes on w old homes and old heating system ,you pay one way or another pick ur poison . Peace and good luck clammy ps never got anything in the mail ?

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating2

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements