Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Hot Water Radiant Floor Piping

Options

zkt4

Member Posts: 2

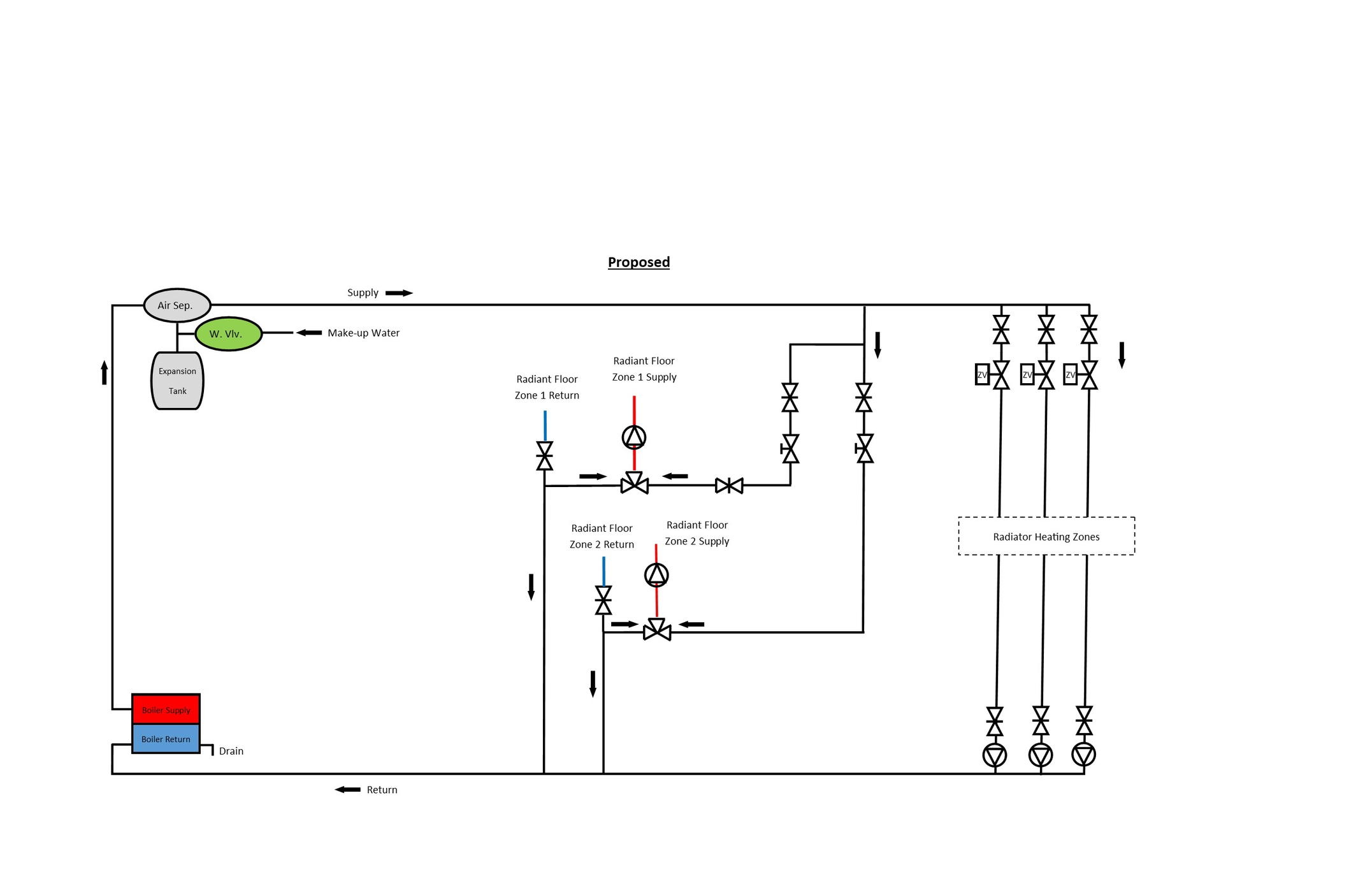

Hello, I am trying to make heads or tails of my current heating system in the house I recently purchased. It is an oil furnace system with 3 radiator zones and 2 radiant floor zones. Here is the current layout:

This layout to me is incorrect, as the radiant floor zones pull the heating water from the return, and I don't see a clear loop for return water to the boiler from the radiant floor zones.

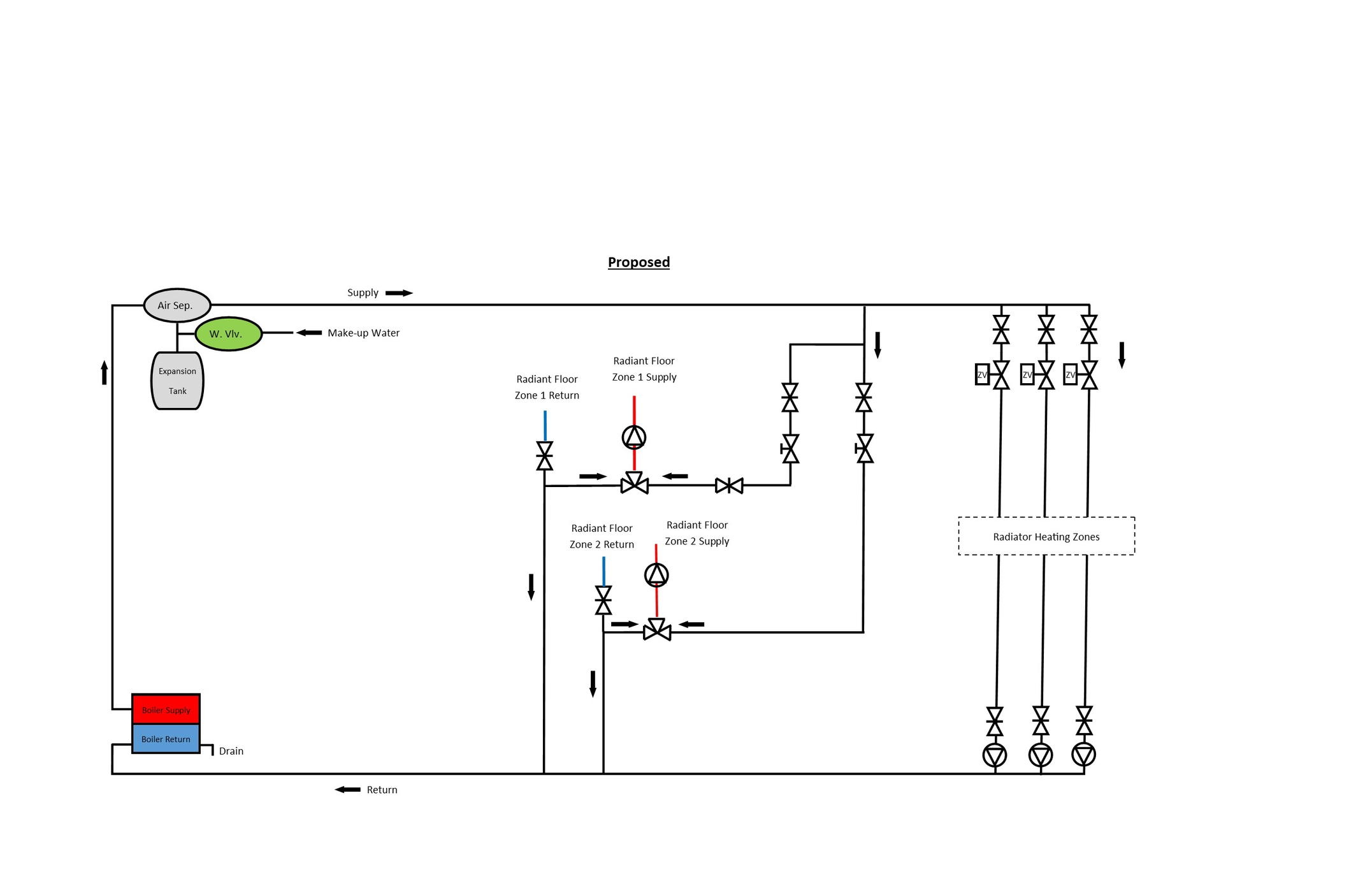

Here is how I am proposing to redo the piping:

Basically I want to relocate the radian heat returns to the other side of the mixing valves and have the "tee" on the return side instead of the supply side.

I am looking for a sanity check. Will my proposed solution work or am I missing something? I am not a professional, just a homeowner with no prior experience working with radiant floor systems.

To me the proposed solution will allow supply and return water to mix by way of the mixing valves and also allow return water to the boiler. Thanks in advance for any insights.

This layout to me is incorrect, as the radiant floor zones pull the heating water from the return, and I don't see a clear loop for return water to the boiler from the radiant floor zones.

Here is how I am proposing to redo the piping:

Basically I want to relocate the radian heat returns to the other side of the mixing valves and have the "tee" on the return side instead of the supply side.

I am looking for a sanity check. Will my proposed solution work or am I missing something? I am not a professional, just a homeowner with no prior experience working with radiant floor systems.

To me the proposed solution will allow supply and return water to mix by way of the mixing valves and also allow return water to the boiler. Thanks in advance for any insights.

0

Comments

-

With cast iron rads and radiant, you might want to add a return temperature protection valve, like this.

Take off the high temperature loop first, then mix valve for radiant.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for your reply hot rod.

My system does not have a boiler circulator pump as shown in your diagram, nor a 3 way valve on the boiler loop.

2 of the radiator zones are baseboard fin tube radiators.

1 zone (basement) has cast iron radiators.

What is your concern with return temperature? What do I need to protect? My intent is to use the mixing valves (Taco with temp gauge on mix port) to limit the supply temp to the radiant floors to 120-140 degrees with 180 supply.0 -

Watch when the boiler first fires up, monitor the temperature at the return connection to the boiler. Within 10 minutes that needs to be at least 130F. If not the boiler and flue piping will experience corrosion from the condensing going on.

A valve that regulates how much supply flow goes to the system, and a portion back to the boiler to keep that return temperature up.

In some cases, if the boiler is oversized, it may get up to speed just fine.

Two ways to know, watch it run a few times at cold start, cold day under a good load, or crunch the numbers, determine the heat load on design day, and compare to boiler output.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements