Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Monoflo Discrepancy

Options

HydroNiCK

Member Posts: 186

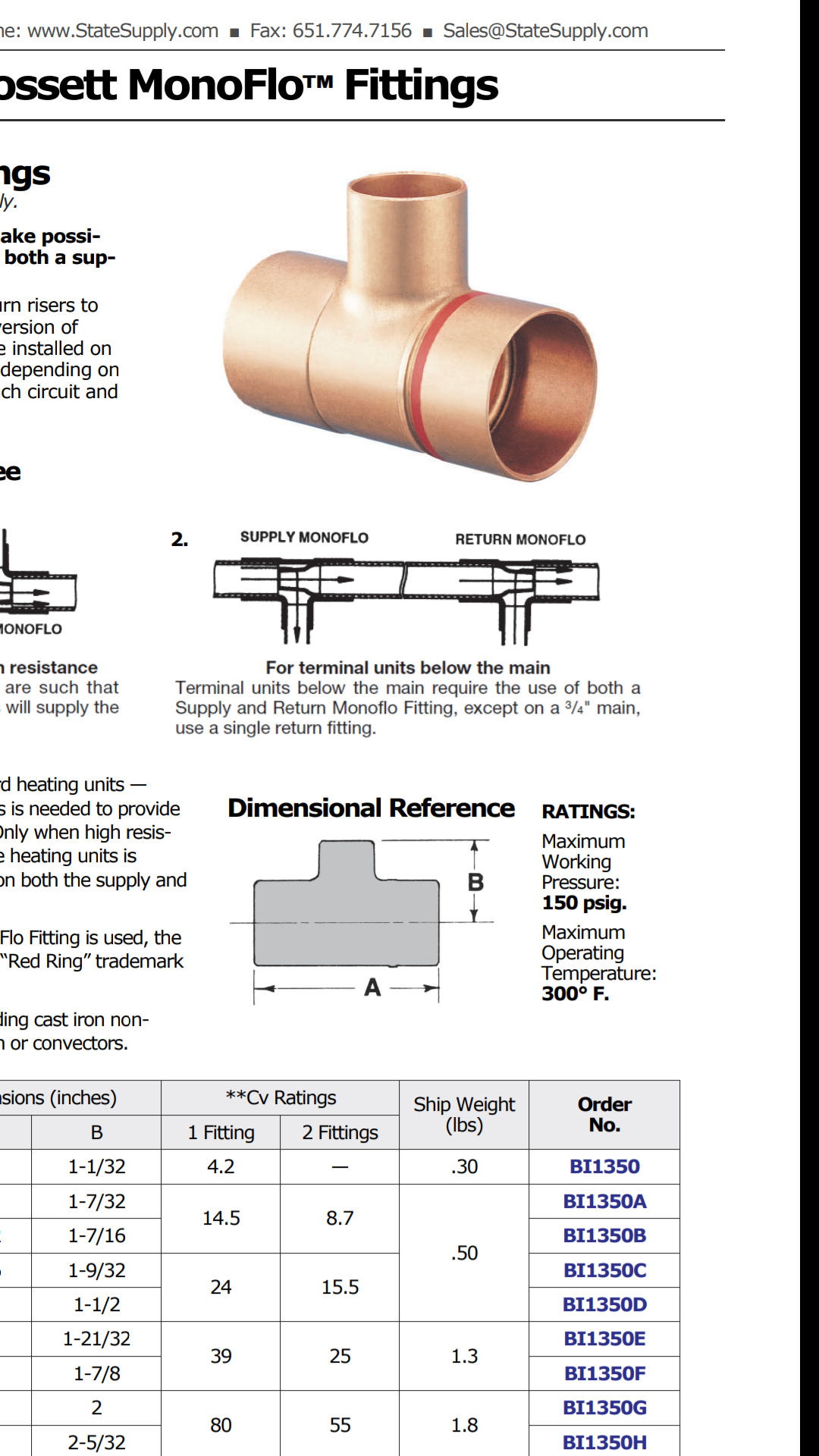

I am going to be re-piping a finished basement do to a slab leak. Its a split level house with baseboard throughout the zone except for one convector in the entryway foyer . The zone requires 23,000 btus. Do to the layout of the room a series loop may not work out. I am leaning towards a pex manifold with 5/8 pex al pex or a monoflo system. I was brushing up on diverter tees and began confusing myself. I was thinking about cutting a supply loop of 5/8 pex al pex into the ceiling and down feeding 1/2" risers using monoflo tees to supply 3/4 baseboard. However, I feel that is probably not correct. Should I be using a 3/4 supply loop instead? Would going from 5/8"to 1/2" to 3/4" baseboard be to gradual of a resistance change? Reading Bell and Gossett's 1949 manual added to my confusion when I saw this:

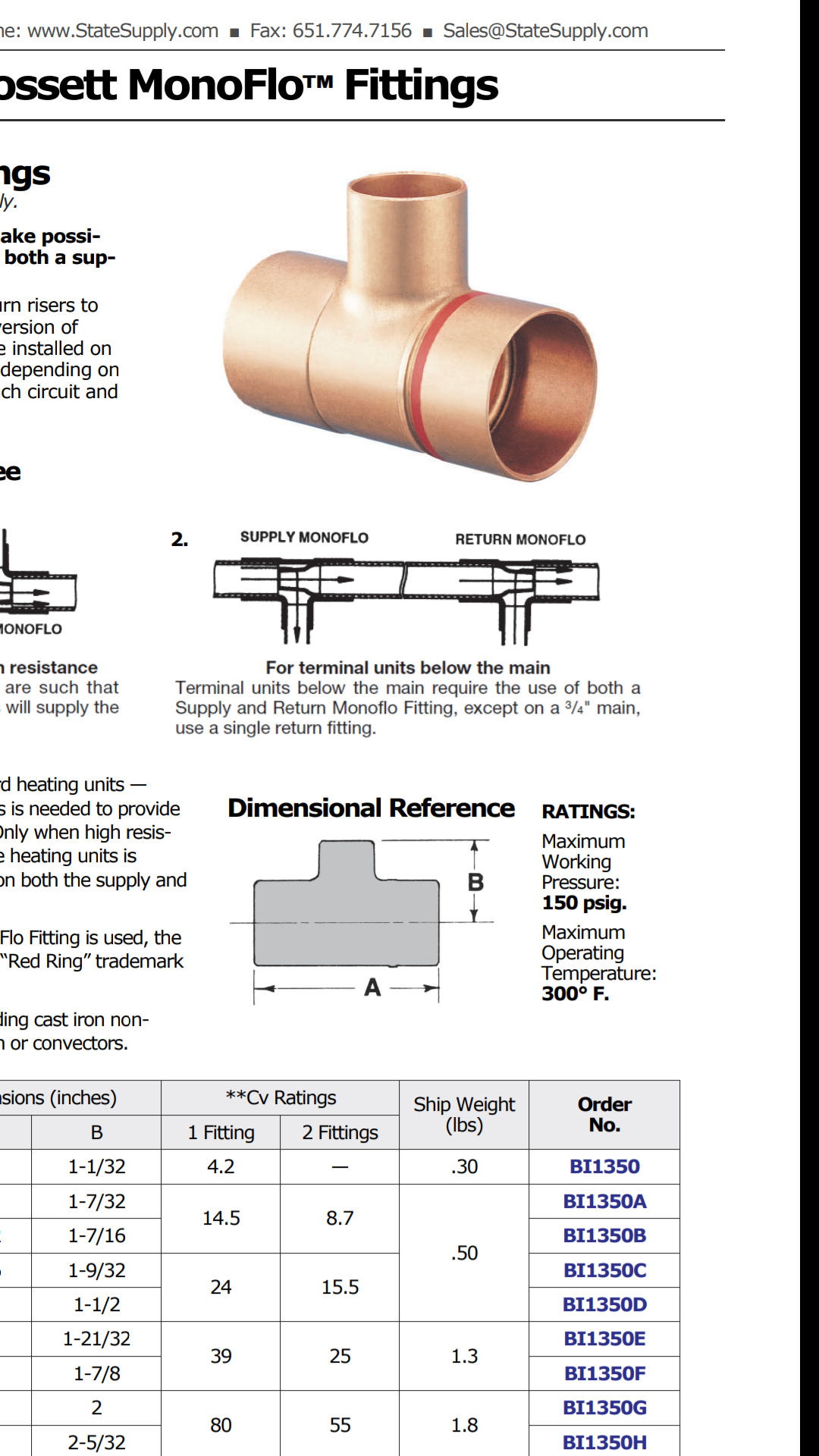

Then I read their current literature which said this:

Why does the 1949 manual say to use two tees and the recent guide says to only use one tee on the return only if the main is 3/4"?

Thanks for your help,

-Nick

Then I read their current literature which said this:

Why does the 1949 manual say to use two tees and the recent guide says to only use one tee on the return only if the main is 3/4"?

Thanks for your help,

-Nick

0

Comments

-

Standard procedure has always been to use two monoflows if the radiation is below the main. If you go monoflow use 3/4 tubing or pex for the main because your not going to get 5/8 monoflow tees. 1/2" for the branches. If you use 1 monoflow keep al the branches as short and direct as possible. Also make sure to space the supply and return tees far enough apart. You need some pressure drop to move the water through the radiation

0 -

I have never designed a single pipe diverter tee system from scratch, there are a number of steps involved. Modern Hydronic Heating third edition, chapter 11 walks you through some 16 steps. It has all to do with the flow resistance in the loop and circuits.

heat load of each circuit.

SWT and temperature ∆ for the circuit.

AWT for the emitter to size for correct output.

flow rate required for each circuit from above calculations

tube size based on required flow rate and heat output at emitter.

placement of circuits and emitters.

drawing of entire system to calculate pipe and fittings pressure drop.

determine hydraulic resistance of each component and circuit piping.

circulator selection based on all above calculations.

remember to consider the temperature drop thru each emitter and piping in between each.

Or the trial and error method . Bob "hot rod" Rohr

. Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

My 1950's era house was piped with the mains at 1 1/4" steel pipe, and risers with 1/2" steel pipe and uses monoflow T's for just the supply to the cast iron baseboard radiators on both 1st and 2nd floor. Works like a charm - and I like the simplicity of only needing 1 circulating pump for the entire system (except my mod con has its own internal circulator and we now use a Low Loss header to interface the boiler with the main system).

Not sure if that helps or not... But, that's how the dead men did it.

If I was building new I'd favor going with a similar monoflow system. Perhaps it could be split into 2 zones.

My advice is to work the math on the CV's for the piping, elbows, radiators, and monoflow T's to be sure it works - up front.

Have a great day,

Perry1 -

Can you run the return in the baseboard?

There was an error rendering this rich post.

0 -

> @STEVEusaPA said:

> Can you run the return in the baseboard?

I would if i could run the supplies to the baseboard in series through the walls. Or if i use a pex manifold in the ceiling.0 -

You can run the supply and return wherever you want. The only issue is it's not just the circulator that pushes the water through the baseboard.....flow is determined by the size and length of the branches and the pressure drop between the standard tee and the mono flow tee and the flow in the main.

To get more pressure drop between the tees you move the tees farther apart. With baseboard the rule of thumb is the tees should be place as far apart as the length of the baseboard. And the tees should be at least 18" away from any elbows in the nmain0 -

I understand, but do to the layout of the baseboard and walls a series loop is not going to work. You would run the return on top of the supply in a series loop. However I can do that if I were to pipe to a manifold in the ceiling. My question is why do those two documents say different things? Based on your experience have you used one monoflo tee on the return or one on supply and return when the main is down feeding the baseboard. 3/4 main feeding 1/2" risers piped to 3/4 baseboard. The new spec sheet says use one on the return. However I find that hard to trust if the length of baseboard is longer than the height of the riser.EBEBRATT-Ed said:You can run the supply and return wherever you want. The only issue is it's not just the circulator that pushes the water through the baseboard.....flow is determined by the size and length of the branches and the pressure drop between the standard tee and the mono flow tee and the flow in the main.

To get more pressure drop between the tees you move the tees farther apart. With baseboard the rule of thumb is the tees should be place as far apart as the length of the baseboard. And the tees should be at least 18" away from any elbows in the nmain0 -

On the discrepancy. You are looking at two different rules of thumb -- and like most rules of thumb, sometimes they work just fine and sometimes they don't.

To understand monoflow systems, you absolutely have to start with the hydraulic of the flows. The system works, when it does, because the monoflow T or Ts, as the case may be, cause just enough head loss and pressure differential in the main pipe to force some flow through the radiation pipe. The downstream one creates a slight low pressure zone at the side inlet, helping flow from the radiation. The upstream one -- oriented the other way -- produces a slight high pressure zone at the radiator outlet, again, helping flow to the radiation. If one gets the number of Ts right (one or two) and the pipe sizes right, you get the right amount of flow through the radiation -- and the right amount through the main line.

If at first you don't succeed, try again...Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Example: assume the system is off and the water is cold. On a call for heat the boiler and circulator start. The main starts to heat up and water starts flowing. Because cold water is heavier (more dense) than hot water the cold water wants to stay in the baseboard below the main it's heavier than the hot water in the main. It requires more pressure drop to get it moving. I would use two mono flow tees with the radiation below the main. I can't see it causing an issue.0

-

A monoflo piped with 3/4 pex really isn't any better than a plain old series loop. Just harder to purge!

Think about it, monoflo is a series/parallel hybrid. Not all the water must pass through each radiation, but the last radiation gets cooler water due to all the radiation before it.

Monoflo works well with 1-1/4 primary pipe and higher flows. Its kind of outdated in our ECM circulator world now. It really makes for a larger high flow low head circ like the old B&G series 100s or the equivalent Taco 0010. That same loop could now be run with an ECM of your choice with 1/8 the wattage and be series looped or split into two separate loops of series and piped with PEX.Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements