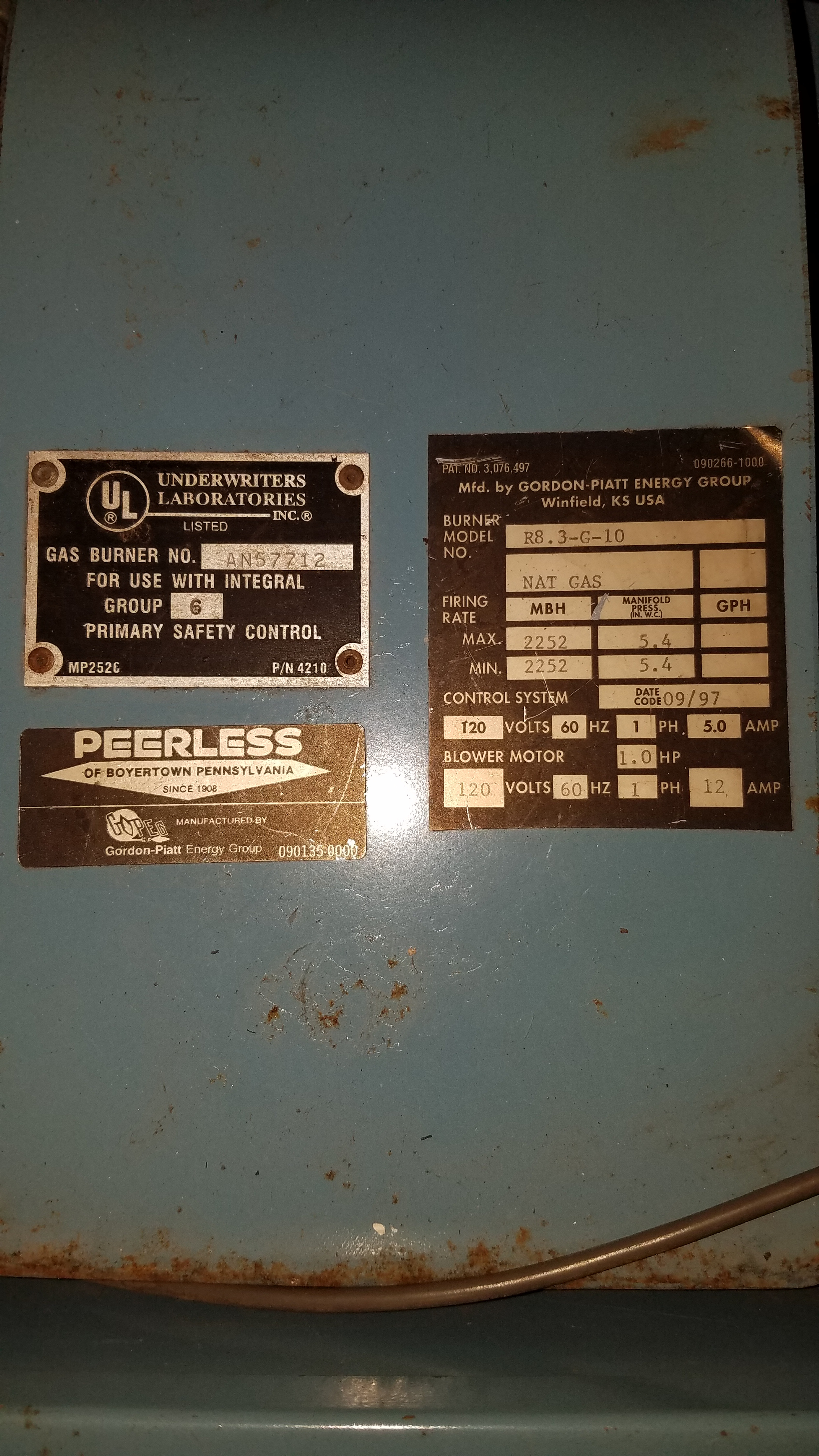

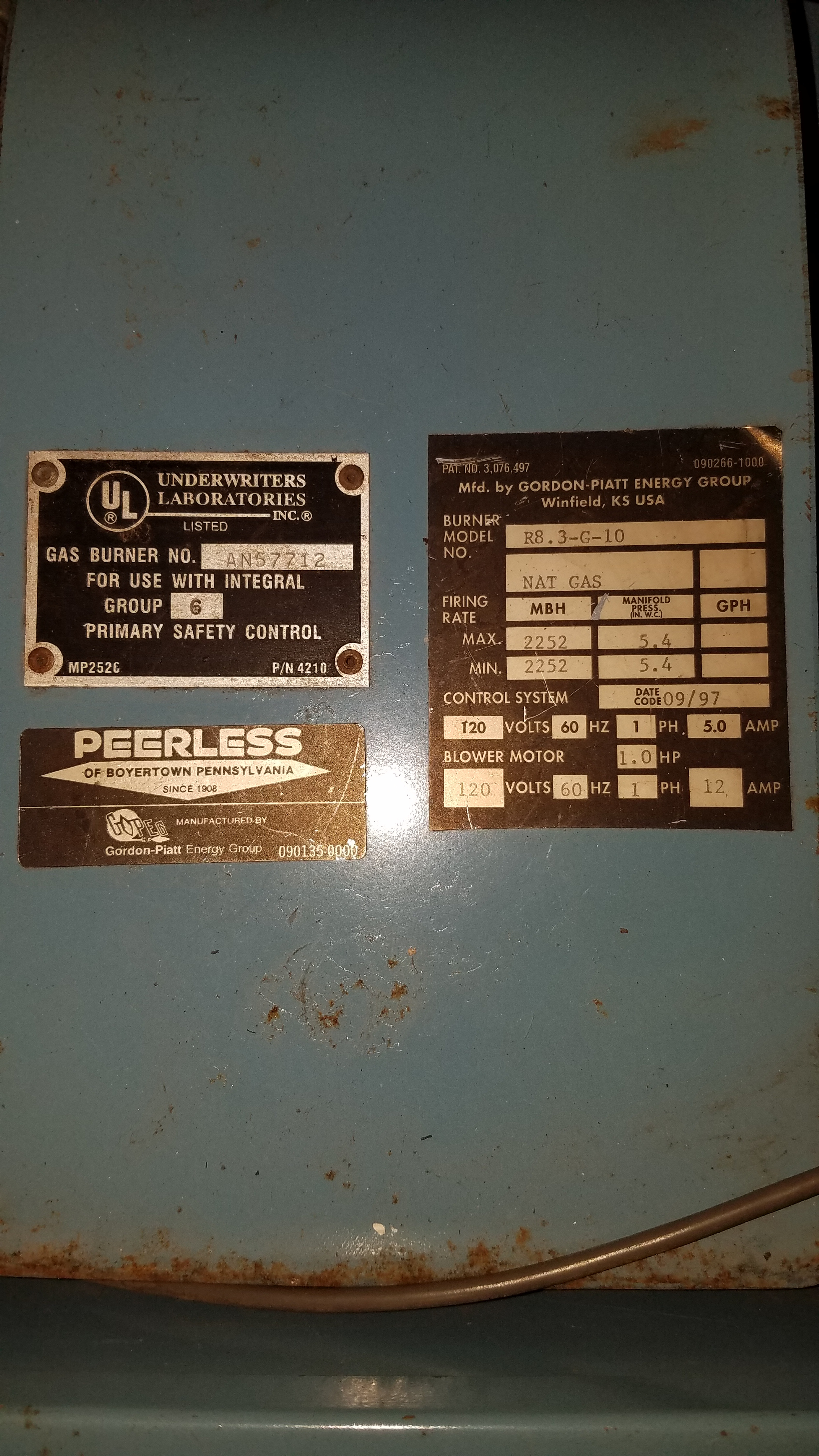

How much can this power burner be down fired?

Comments

-

If that's a Webster system and he says to run it at 5 pounds, do not let him into your boiler room.

Where are you located?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

-

@Steamhead If I were to find the right guy, is it possible to down fire that model burner and by how much?0

-

The plate only shows one firing rate & GP has been gone for many years so you may not get it down fired.Double D said:Does anyone know if it is possible to down fire this burner and by how much? I did find a local contractor who said he could downfire it but he was only able to say it would be less. He also does steam heating but I was only asking him to downfire the boiler. When I mentioned to him I would like to operate this Webster system in vapor without having the burner rapid cycle, he said I probably want to operate that system at 5lbs. that's what he does. I didn't know what to say after that and now I'm wondering if he will actually be able to do the job of downfiring.

The boiler may not be worth a new modulating burner.3 -

The gas valve is a Honeywell V4062A-1008 actuator. Is there a way to get it to low fire and will it hurt anything running it on low fire? There is also linkage across the top going to dampers.0

-

See my last post, UL rating is one firing rate.

And beyond that GP burners will burn the end of if the firing rate is too low.

I for one would not de-rate it due the UL listing as you would own it.

If it is a good boiler maybe put in a modern full modulating burner.....I/c, Wiesthaup, Power Flame, Etc.2 -

Thank you @kevinj_4, that is the answer I was looking for. The boiler itself is 22yrs old. It appears to be in good shape. The owner will need to decide what they want to do about down firing the boiler. If they chose to do nothing about it, they will need to get someone else to address the multitude of issues with the system. I'm not interested in getting into a job that will leave me chasing my tail.0

-

The V4062A comes already set up for lo-hi-lo operation. All you need to do is hook up a control to terminals 3 and 4, and have the control break the circuit when it "tells" the V4062A to go to low fire. On a steam boiler, this control would probably be a Vaporstat. I wonder why G-P would have put a V4062A instead of a single-rate V4055A on this burner if they did not want it to drop to a low-fire position?Double D said:The gas valve is a Honeywell V4062A-1008 actuator. Is there a way to get it to low fire and will it hurt anything running it on low fire? There is also linkage across the top going to dampers.

What model is the boiler, and what is the input rate shown on the boiler?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Gordon Piatt is out of business. If you can find a good commercial burner technician it can probably be down fired somewhat. You may or may not be able to run the system on low pressure without short cycling.

Many burners of that size can be run as a low fire start burner then it goes to high fire and stays there throughout the cycle

OR they can be run as a lo-hi-lo burner as @Steamhead mentioned...start on low...goes to high...returns to low (with added pressure control and wiring)

You need a good commercial burner tech with combustion testing

Weather that burner originally came with the LHL gas valve actuator...can't tell.

Do you have any of the original paperwork or wiring diagram??0 -

The V4062 also has the same date as other controls on that assembly so I assume it came that way. I was wondering the same thing but I don't know that burner well enough to know if it's ok to let it drop to low fire. I certainly wouldn't want to create the situation @kevinj_4 is talking about. By no means was I looking for something to do. The only reason I ended up there was because the local Peerless factory rep gave them my name. I took a picture of the input rate shown but you can barely read it. To me it looked like 5917sqft steam, 1,420,000btu steam.0

-

In the boiler room, all of the original paper work and wiring diagrams are there. I have only been through the manual to show the owner the 150S controller was installed too high and the normal operating water level was close to the top of the sight glass. That has already been taken care of. The boiler piping is textbook. That's something I never see.0

-

You make a good point, that burner may well have low fire start.EBEBRATT-Ed said:Gordon Piatt is out of business. If you can find a good commercial burner technician it can probably be down fired somewhat. You may or may not be able to run the system on low pressure without short cycling.

Many burners of that size can be run as a low fire start burner then it goes to high fire and stays there throughout the cycle

OR they can be run as a lo-hi-lo burner as @Steamhead mentioned...start on low...goes to high...returns to low (with added pressure control and wiring)

You need a good commercial burner tech with combustion testing

Weather that burner originally came with the LHL gas valve actuator...can't tell.

Do you have any of the original paperwork or wiring diagram??

Before any tuning to de-rate one should find the head specs to see what minimum fire can be.0 -

-

Now I'm doing what the homeowner does when they take a picture. Not stand back far enough. I assume this means Lo-Hi-Lo is ok for this boiler. Wire in a vaporstat to control High fire? I ran it for a short time on low fire. I'm sure it has spent its entire life on high fire.0

-

Here's a little more from the GP book.

I still need to do a convector survey & chase down the failed traps. All Webster and all in Dan's EDR book pages 263, 264 & 265.0 -

Do you have a picture of the dataplate on the burner? If it was meant for low/high operation, Gordon Piatt listed a minimum and maximum input on the dataplate. That is a high/low gas valve actuator.

Terminal 3 to 4 on that actuator are used to call for high fire. What is wired there? Jumper? Or does it go to a pressuretrol?

If you can get me a picture of the burner info that would help.

Connecting terminal 3 to terminal 4 makes it go to high fire. Disconnecting them makes it go to low fire. The actuator has a cam in the bottom that has to be adjusted to set low fire input. The linkages go to an air damper that has to be set properly for correct combustion.Never stop learning.0 -

This is what the data plate shows on the burner. Why would they put a lo-hi-lo actuator on it if it can't run on low? Right now it's wired for hi only. I pulled the black wire off terminal 3 and it ran on low fire.0

-

Looks like the burner was originally spec’d for on/off operation.

I am going to PM you.

I have some old GP original boiler start up forms and manuals stashed downstairs. I will dig them out and see what I can find as far as wiring.

I’m wondering if it was an on/off with low fire start (an H system)Never stop learning.0 -

@Double D go to this page in the manual. It will tell you what gas system you have in the model number at the top.

A couple of pages over from there in the materials list it will tell you exactly which actuator came with the burner from the factory.Never stop learning.0 -

I left the manual on the job. I went back and forth with taking it home. I'll look for that page when I go back.0

-

That page will tell you what gas system it was shipped with. A couple pages over will give you the original model number of the actuator it was shipped with, and further in the book it will tell you what each different gas system was.

You’re lucky they still have the original book that came with the burner! You can still download the manuals online but that burner specific info is not possible to get anymore. I collect them when I can.Never stop learning.1 -

The whole book is there. It's pretty thick.0

-

I guess they sized it the same way most do. Match what is there. Robert's Gordon Model 412 2,100,000btu.0

-

0

-

It appears this system may have had a vacuum pump. I know once a vacuum system always a vacuum system. I don't see the owner going for the idea of restoring it. It appears it's been running this way for quite some time. In the mean time, one of the zones has failed. The main this zone is on is 4" and it has a 2-1/2" zone valve on it. If I were to remove the zone and bring the main back to 4", will it help the system or would I just be wasting time?

0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements