Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Anyone can help service Amana HTM heating in San Jose area?

Options

billtang

Member Posts: 10

The house has Amana HTM with outdoor heating unit ERGW0012, with indoor water tank EGWH0040B. The hot surface igniter is 767A-369 (may be 10 years old but appears OK); the control is Fenwall Triton 2465H 600-003. The system cannot maintain heating:

1. Heat exchange motor turns on

2. Ignition turns on after about 45 seconds.

3. Gas comes on runs for approx 40-20 secs (initially longer but goes shorter after a few cycles)

4. Gas turns off but heat exchange motor stays on

5. After 45 seconds, repeats cycle of turning on Gas (goes to step 3). During the whole time, the heat exchange motor stays on.

6. After a few cycles, the ignition control goes into lockout.

bill 408 507 8865

1. Heat exchange motor turns on

2. Ignition turns on after about 45 seconds.

3. Gas comes on runs for approx 40-20 secs (initially longer but goes shorter after a few cycles)

4. Gas turns off but heat exchange motor stays on

5. After 45 seconds, repeats cycle of turning on Gas (goes to step 3). During the whole time, the heat exchange motor stays on.

6. After a few cycles, the ignition control goes into lockout.

bill 408 507 8865

0

Comments

-

clean the flame sensor (?)

what's the lockout code say ?

got manual ?known to beat dead horses0 -

The gas comes on, but do the burners ignite? All of them, smoothly from the igniter across to the flame sensor.

If it's doing all that, try removing and lightly clean the flame sensor with some Brillo or SOS pad.0 -

Thanks for the suggestions. The manual has a diagram (attached).

When there is call for heat:

1. Heat exchange motor turns on

2. After about 45 seconds, there is a click which appears to turn on ignition

3. After about 1 or two seconds, gas comes on and the flame is maintained for approx 20-40 secs (initially longer but goes shorter after a few cycles).

4. There is a click that the gas appears to turn off. There is no flame. But heat exchange circulation motor stays on. Fenwall ignition control appears light once (indicating control?)

5. After about 45 seconds, it repeats cycle of turning on Ignitor, and after 1 second the gas (goes through step, 2, 3, 4 again). During the whole time, the heat exchange circulation motor stays on.

6. After a few cycles, the ignition control goes into lockout. There is no longer ignitor click or the gas. Only the heat exchange circulation motor is running. The Fenwall ignition control led flash three times on lockout.

7. I have to turn off the electrical switch to power off the unit and wait for a few minutes to reset the lockout. Then the system repeats from step 1.

It does not appear there is any flame sensing rod other than the hot surface ignitor (767A-369). I suppose the hot surface ignitor provides flame sensing? Maybe I should order a new ignitor and try it.

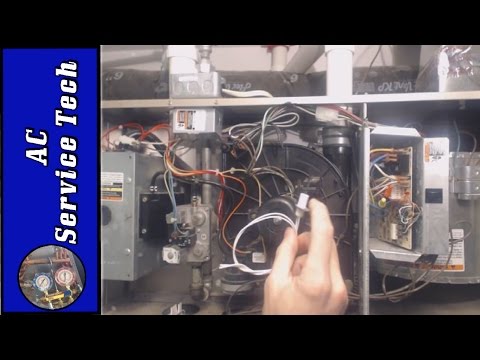

Pictures:

diagram, outdoor burner, indoor heating blower, water tank. The heat exchange (ethylene glycol heat exchange solution circulates from burner to indoor blower and water tank). Inside the outdoor burner there is ignition control (fenwall), heat exchange solution circulation pump, and gas heating.

0 -

That unit has been obsolete for about 25 years. And it was fraught with problems when it was on the market. I would be amazed if the heat transfer module is not shot.

You would be better off in the long run getting rid of it now, rather than throwing money at it.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

If a new hot surface ignitor does not fix it then that is the most I would put into it.

I took one of these systems out about 20 years ago.

It had the HTM inside of one of the 2 air handlers.

A new Mod Con boiler now feeds the existing coils in the 2 air handlers and the indirect water heater.

I had a basement to work with and plenty of room.

Your laundry room looks tight.

Do you have room for a small wall hung boiler?1 -

apparently you've never seen one of these unicornsHVACNUT said:The gas comes on, but do the burners ignite? All of them, smoothly from the igniter across to the flame sensor.

If it's doing all that, try removing and lightly clean the flame sensor with some Brillo or SOS pad.0 -

Prepurge.....igniter heats up........ignition.........flame stays on, but then goes out. I'd say the Fenwall ICM loses the flame signal and shuts down the unit. Replace the Fenwall ICM.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Combo HSI and flame sensors had issues years ago. Rheem came out with those and within months were providing free flame sensor rods with info on connecting them to the HSI.

I didn't see how something that gets that nasty/burnt looking could reliably conduct milliamps. They will still glow and light but lose the conductive properties. IMO

I would start with the HSI, about the least expensive fix.

Unless there is a pressure switch with plugged hoses etc.

Door interlock....limit switches and of course the often overlooked good ground connection to ICM from burner.0 -

Thanks for all the feedback, and especially for the voice message to suggest replacing fenwall. Sorry I missed your call.

I swapped the hot surface ignitor. It now seems to work for much longer without too frequent lock up. As this appears promising, I am still waiting for a new ignitor and may put it in once it arrives next week.

After the hot surface ignitor lights the flame, it becomes the sensor. I actually couldn't find much difference between the one swapped out and the one I put in in appearance other than it looks old. (picture attached.) I saw on one video that the resistance should be between 40-90ohms. The one I swapped out is at 130ohm cold so I guess this messes up the flame sensing. Cleaning the ignitor by sanding with dollar bill does not affect the resistance much.

Another thing I noticed is that there is air in the heat exchange pipe so I bleeded it through the air bleed valve, which is at the highest point in the heat exchange pipe:

I suppose with air in the pipe, some limit is tripping the ignition control causing it to cycle when the heat exchange solution becomes too hot.

The manual says to recharge through plug on the module plug. Unfortunately, this one is rusted shut; I don't want to risk opening it and accidentally cracking something. I supposed the air bleed valve achieves the same purpose. Ideally, I would like to drain the refill the heat exchange solution but I simply filled the expansion tank for now. (manual page images attached):

This Amana HTM is indeed a dinosaur. I don't know how long it will last. The indoor unit and the water tank together occupies space of 32 in by 60 in. If the air blower and water tank are to go, there needs to be a replacement furnace and water heater (regular 50 gal). And there is no vent to the roof on top. Any suggestions on replacement furnace and water heater (regular 50 gal)? The air conditioning unit would have to go as well as it is currently integrated with the air blower, which serves both heating and cooling.

0 -

The videos on hot surface ignitor.

The worn ones look ok but may fail to provide sufficient flame sensing: https://www.youtube.com/watch?v=pcnlpMzYgcs

https://www.youtube.com/watch?v=pcnlpMzYgcs

Also another one on testing the resistance of hot surface ignitor: https://www.youtube.com/watch?v=FunjhjWk98w 0

https://www.youtube.com/watch?v=FunjhjWk98w 0 -

As I mentioned above, a small wall mount Mod Con boiler can supply heated water to your existing air handler and also your water heater tank. All can stay and be reused, including the AC.

The only vent would be the boiler out thru the wall, typically.0 -

Thanks for suggesting Mod Con.

For this house, the indoor water tank and air blower are both more than 20 years old. I don't know if they would be able to last the life of a Mod Con boiler ; I wonder if it is less headache to just swap out this integrated system to separate water heater and funance units.0 -

In your case, probably so. There's no real advantage to having a boiler when all it's doing is supplying a forced air unit.billtang said:Thanks for suggesting Mod Con.

For this house, the indoor water tank and air blower are both more than 20 years old. I don't know if they would be able to last the life of a Mod Con boiler ; I wonder if it is less headache to just swap out this integrated system to separate water heater and funance units.

A properly sized, high efficiency gas furnace and a/c would serve you just as well and be less up front costs.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Hi, just read the complete thread and coincidentally have just returned from helping with an HTM system that was installed in 1982. It sounds like your controller is not sensing flame properly, the ground circuit between combustion chamber and controller must be perfect or the unit will ignite and then turn off within about 40 seconds (or intermittently). In this case I built a short one piece harness with soldered connectors to run from the combustion chamber (HTM unit) base to the metal cabinet and the controller ground connections, had no more flame sensing problems. Otherwise, I recommended to the owner that the least expensive total replacement solution was to replace the complete system with a condensing 95% efficient natural gas hot air furnace (appx 70,000 BTU) and a condensing tankless water heater (there is no chimney at their home). Installing another boiler system as a previous poster has already stated, would be a very expensive way to make hot air. The temperatures lately in Edmonton, AB (Canada) have been lately in the -30C range and this Amana HTM system is still performing extremely well.0

-

WOW -- I put one of these in my first house ...mid 80's. Can't believe that heat transfer module is still alive. Mine was the inside model with indirect and AC on top. When these things came out there was nothing that could touch the efficiency -- NG was expensive. Typically, in the north east the ones with the indirect tank failed sooner as they were operating all the time. They were able make endless hot water and they ran very hot -- so the air from heating coil furnace was toasty ... they had a preheater that cooled the exhaust and condensed. Unfortunately the intake was from the room and any contaminates would eat the HTM -- so I was told.

They were very touchy with the igniter and dirty contacts. They also used a special glycol/fluid. (Amana Transfer fluid).

Amana bought me two replacement HTMs .. and more than a few igniters Also -- one of the fluid pumps .... mine lasted 20+ years. I replaced it with a carrier infinity furnance/AC. NG tank WH. The HTM got to be around $500.00

The HTM would burn through the case -- your looks very clean.. amazing.

0 -

Interesting thread. What a strange system. I've never seen or heard about these before. I have a strong dislike of anything with a flame sensing hot surface igniter. I'm glad I haven't had to deal with any of these on a service call, my first question for the owner would be "what the hell is that thing?"

Now that I jinxed myself I'll probably be dealing with one of these antiquated dinosaurs this week.0 -

Super -- it was basically a donut cylinder. Induced flame w/jacket of glycol. looked like a big coffee can. Heat up was very quick -pump would start the cycle of glycol through the heat exchanger. It was the first I had seen with PVC exhaust -- York's answer at the time was a system using an ICE outside. I had a big old house and it cut my fuel bill more than 1/2 going from oil to gas. The indirect was an add on (expensive) -- can't remember the reason for the OP's system with the HTM outside. It was very well made -- also had a water connection that ran a wash of the exhaust exchanger after each cycle. I also added the Amana AC0

-

I converted one these systems some years ago.

The house had 2 air handlers/AC's.

It had an indirect DHW tank with internal heat exchanger.

One of the AH had the HTM inside of it.

A mod con boiler was installed with 3 Zones.

DHW, and 1 for each AH hot water coil.

The only added major item was the Modcon boiler.

As far as I know the only thing changed since then has been the indirect tank which developed a leak.

We had plenty of floor space available.

Your room looks to be a tight fit.

Considering your climate, would it be possible to install a wall mount Modcon outside that is enclosed in it's own insulated rain tight cabinet with piping thru the wall to existing components?

Just an idea. FWIW0

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 121 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 115 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.8K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements