Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

how's the near boiler piping ?

coelcanth

Member Posts: 89

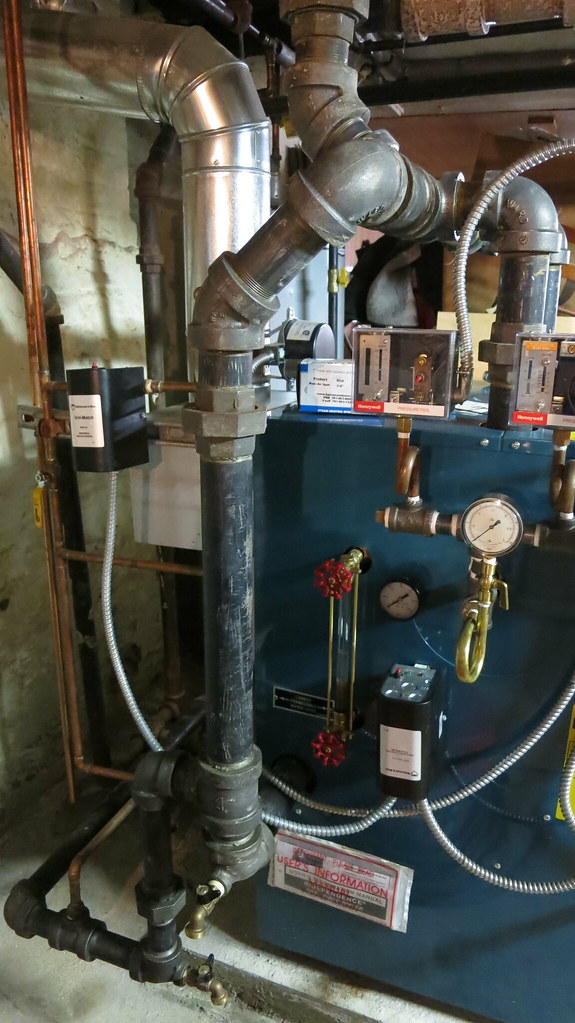

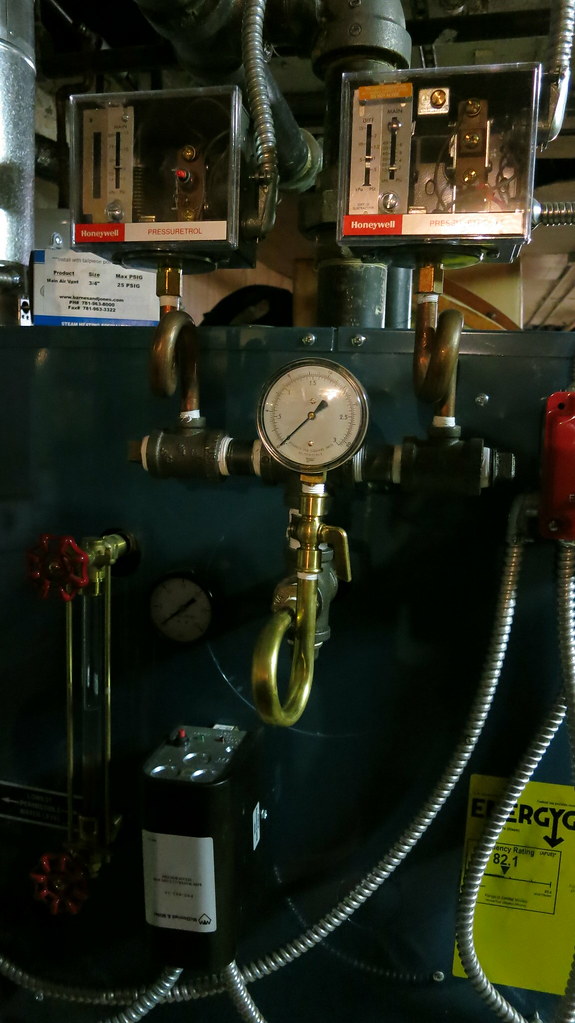

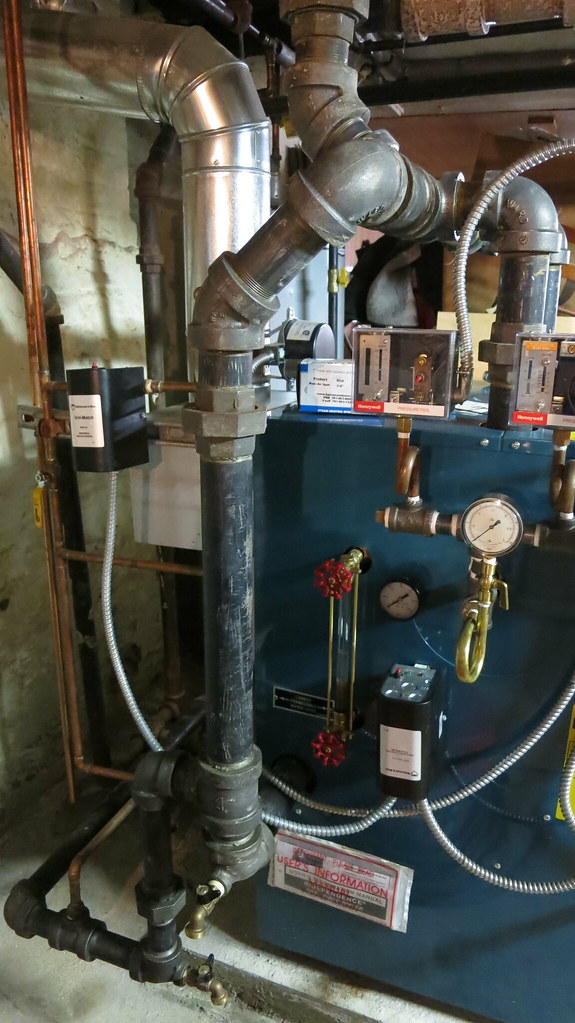

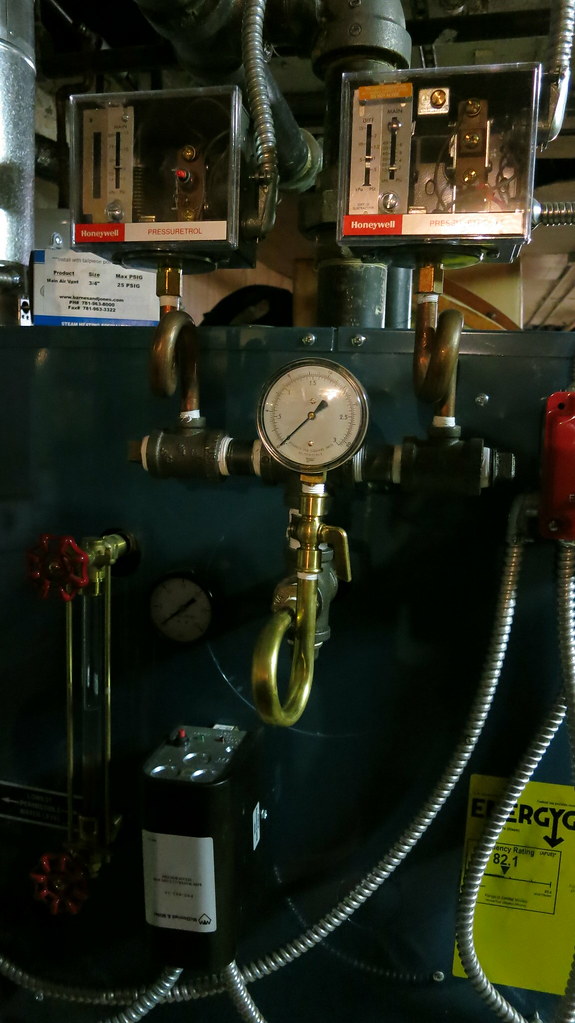

we hired a local shop to replace our 40+? year old boiler this past year. this is what we got...

i feel like these Young Men followed the manual pretty closely, but maybe lacked a little extra problem solving ability when it came to tying into the old steam mains.

the new header is just about 24" above the waterline, and is bushed with a single riser from 2"->3" into a remnant of the old header, which is plugged at the front. from here the 2" mains (first and second floor) tee off and then each split again with 1.5" reducer tees (front and rear of the house).

i think now i've learned it would've been better (or at least cleaner) to remove the old header section entirely and bring the two main risers into the new (perhaps a drop) header separately. it would be tricky to work so close to the ceiling however...

but I'm not really sure if the extra runs of horizontal pipe and the bushing as installed now are much of a problem.

even though the boiler is oversized (450sqft of steam for about 315 EDR, another mistake of the Young Men) it never seems to build more than a couple ounces of pressure. i added four B&J Big Mouth vents for the end of each main and and swapped around many radiator vents and now things are running quietly and balanced... second floor main still fills with steam a little bit faster than the first but heat throughout the house is very even, especially after adjusting the anticipator on the single old T87 thermostat..

i guess now my main goals are maintaining the system in good order and trying to improve efficiency wherever possible.

i feel like these Young Men followed the manual pretty closely, but maybe lacked a little extra problem solving ability when it came to tying into the old steam mains.

the new header is just about 24" above the waterline, and is bushed with a single riser from 2"->3" into a remnant of the old header, which is plugged at the front. from here the 2" mains (first and second floor) tee off and then each split again with 1.5" reducer tees (front and rear of the house).

i think now i've learned it would've been better (or at least cleaner) to remove the old header section entirely and bring the two main risers into the new (perhaps a drop) header separately. it would be tricky to work so close to the ceiling however...

but I'm not really sure if the extra runs of horizontal pipe and the bushing as installed now are much of a problem.

even though the boiler is oversized (450sqft of steam for about 315 EDR, another mistake of the Young Men) it never seems to build more than a couple ounces of pressure. i added four B&J Big Mouth vents for the end of each main and and swapped around many radiator vents and now things are running quietly and balanced... second floor main still fills with steam a little bit faster than the first but heat throughout the house is very even, especially after adjusting the anticipator on the single old T87 thermostat..

i guess now my main goals are maintaining the system in good order and trying to improve efficiency wherever possible.

1

Comments

-

Each of those mains should have dropped down and tied into the header. Hard to tell from your pictures but that dead end also looks like a potential to hold water. Everything looks pitched down and water will pool in that dead end. When the weather gets colder and the boiler runs longer, you may get some hammer.1

-

After/if you correct any piping causing hammer, insulate the near boiler piping and mains, which will help0

-

-

this is actually the second heating season with our new boiler and it's been close to silent.

i do plan to add insulation, but might wait until i decide whether to redo any piping...

i will double check the pitch of those near boiler pipes but there's not much room for adjustments.

if i do end up bringing the mains into the header with separate risers, and/or do a drop header, what might be the gains ?

would drier steam or less restricted condensate return lead to more efficiency or is it mostly just insurance against water hammer ?

thanks for the advice0 -

The biggest benefit is a more balanced distribution of steam into each main, and, the "mostly silent" will likely become silent if the noise is coming from the area of that dead end pipe0

-

-

that valve is just what i had on hand instead of a regular coupler.. but it serves the same purpose...

the system itself is only not silent because i can hear some creaking and heat expansion type noises.. no hammer at all..

i've checked the pitch on the horizontal non-header pipes and they seem close..

one thing that's true is that the mains do not heat at the exact same rate, but still get hot at the vents within about one minute of each other..

i think i now recognize the real cause for this though; the dry returns run separately for about eight feet before one stops and ties into the one next to it with a tee.. above the water line..

i think the steam is backfilling through this siamesed return and closing the vent on one main while the steam direct from the boiler actually has about two feet longer to travel before hitting it.

oh well, i guess the Dead Men didn't always get things right..

all that said, the system is quiet and balanced with each room between two floors to within half a degree F and within 15 minutes of a call for heat... so i am content

next step for achieving maximum efficiency will be some quality insulation in the basement

thanks for the advice0

Categories

- All Categories

- 86.7K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 56 Biomass

- 423 Carbon Monoxide Awareness

- 104 Chimneys & Flues

- 2K Domestic Hot Water

- 5.6K Gas Heating

- 103 Geothermal

- 158 Indoor-Air Quality

- 3.5K Oil Heating

- 68 Pipe Deterioration

- 938 Plumbing

- 6.2K Radiant Heating

- 385 Solar

- 15.3K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 43 Industry Classes

- 47 Job Opportunities

- 18 Recall Announcements