Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

couple general questions on radiant heat functions

Options

ahreno

Member Posts: 5

I just finished installing my radiant floor heat myself. i understand most of it but have a couple random questions. I live in bum **** no where so hiring someone competent isn't really an option.

I have a navien NCB 210e as the boiler/DHW, used these valves (3,5,6 loop). and the preassembled kits (PMP and ZDM from radiantec

first issue i'm having is that one zone all of a sudden stops pumping. i'm guessing its still purging air, i'm going to redo my fill/purge today. I ran it for four or so hours yesterday and everything worked fine, left for 4 hours and came back and one zone wasn't pumping. low water i believe. I reread the fill instructions and will do it over. i didn't really do it exactly right the first time. (i had my drain hose hooked up in a different spot etc).

second question is... the zones all have flow meters... is there a standard flow rate i want to see through them?

third... is there a standard temperature the hot water heater should be set at? i have concrete floors throughout. currently it's set at 110°. the supply temp at the manifolds was around 90° and return around 60... the slab is cold, but it seemed to be heating up.

fourth... and i'm guessing this ties in with the second question. two of my zones have a 3 speed grundfos. how do i know which speed to set them to?

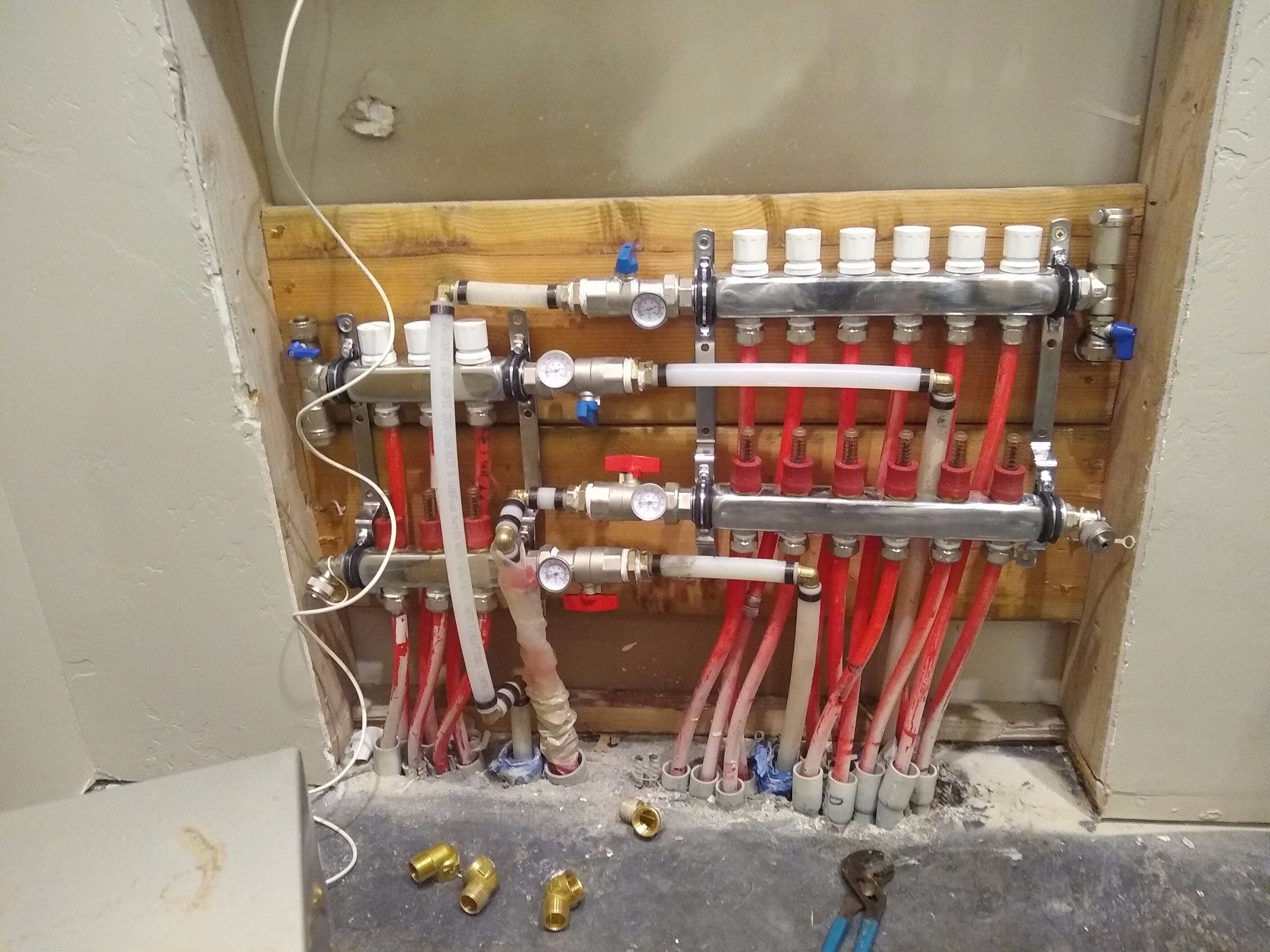

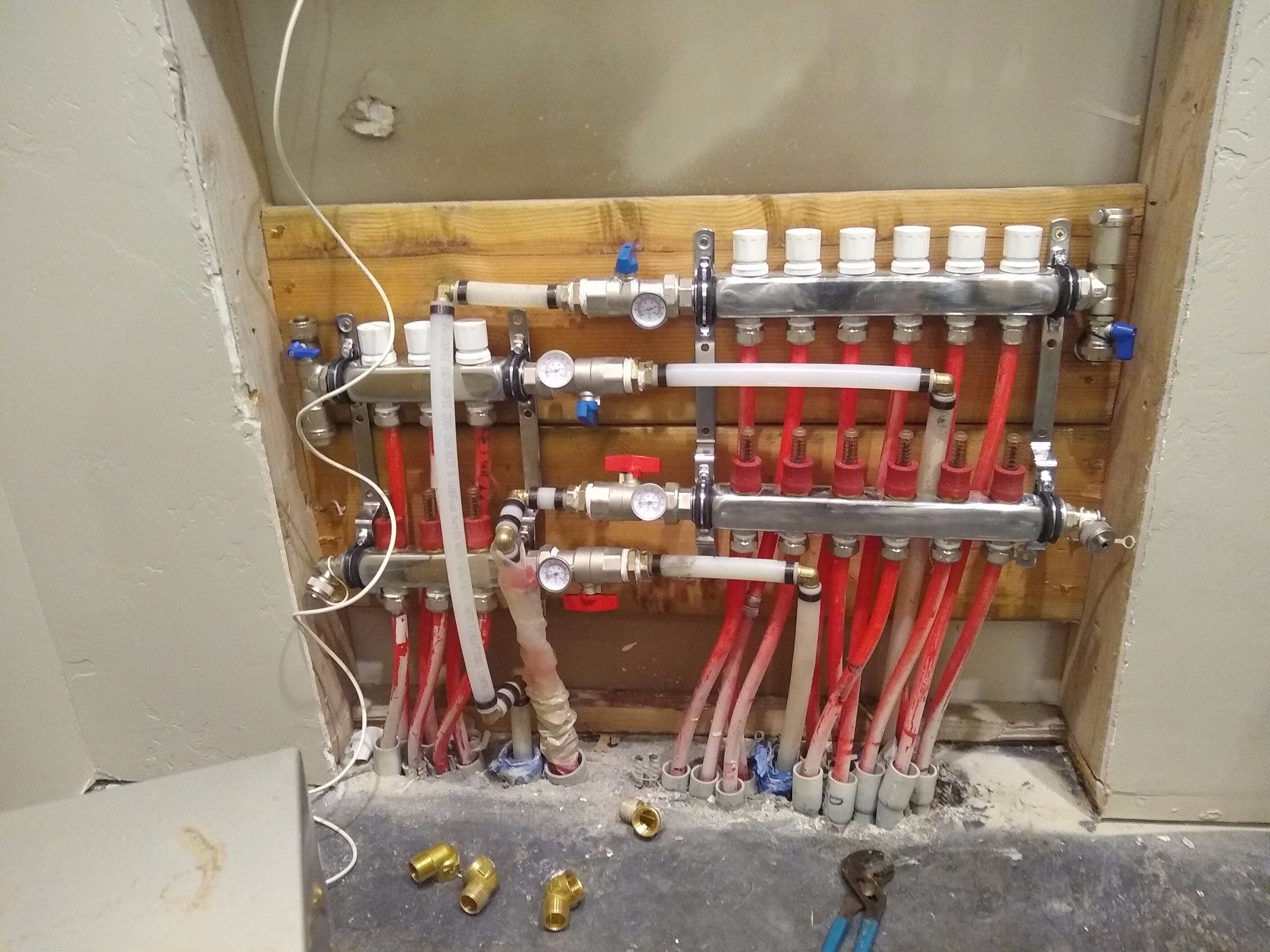

here's a couple shots of my work. Before this, i had never sweated a copper pipe in my life. The plumber that hooked up the DHW wanted $ for materials (I spent $ish tops) and 42 hours of labor to hook up manifolds and supply side. I did it in under 20 which included redoing a bunch of their work which was a maze and in the way. hows it look? few things i'd have liked to do differently (how the cpvc drain is run, how the plumber has some of the domestic water hooked into the copper..)

I have a navien NCB 210e as the boiler/DHW, used these valves (3,5,6 loop). and the preassembled kits (PMP and ZDM from radiantec

first issue i'm having is that one zone all of a sudden stops pumping. i'm guessing its still purging air, i'm going to redo my fill/purge today. I ran it for four or so hours yesterday and everything worked fine, left for 4 hours and came back and one zone wasn't pumping. low water i believe. I reread the fill instructions and will do it over. i didn't really do it exactly right the first time. (i had my drain hose hooked up in a different spot etc).

second question is... the zones all have flow meters... is there a standard flow rate i want to see through them?

third... is there a standard temperature the hot water heater should be set at? i have concrete floors throughout. currently it's set at 110°. the supply temp at the manifolds was around 90° and return around 60... the slab is cold, but it seemed to be heating up.

fourth... and i'm guessing this ties in with the second question. two of my zones have a 3 speed grundfos. how do i know which speed to set them to?

here's a couple shots of my work. Before this, i had never sweated a copper pipe in my life. The plumber that hooked up the DHW wanted $ for materials (I spent $ish tops) and 42 hours of labor to hook up manifolds and supply side. I did it in under 20 which included redoing a bunch of their work which was a maze and in the way. hows it look? few things i'd have liked to do differently (how the cpvc drain is run, how the plumber has some of the domestic water hooked into the copper..)

0

Comments

-

maybe you missed some air the first time ?

or,

maybe you're pulling air in thru the Watts, esp if all 3 circs call, are those caps turned down tight?

and what's the fitting to the right of Watts?

another air vent ? pulling in ?known to beat dead horses0 -

I don't see your fill valve in the picture, so it is hard to advise on purging.

I would expect you would be able to balance at about .75 gpm per loop.

You want to go as low as you can for peak efficiency and comfort. If the boiler is capable of outdoor reset, install the sensor and set it up. Somewhere in the 105-120 degree range should work on your coldest day. It just depends on the insulation (particularly under the slab) as well as tubing design.

Yup, the pump speed depends on the loop lengths and design flow.

Workmanship looks nice. It is hard to follow the design with the partial pictures.

We don't discuss pricing here. Keep in mind that the contractor would have travel time, callback time, insurance,rent payments ,vehicles, and other burdens that you do not. Nothing wrong with DIY, just be careful not to bash the folks you are asking advice from "If you can't explain it simply, you don't understand it well enough"

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein-1 -

the little caps on the top of the air purger? no, i read that those had to be on loose to let air out. to the right of that is a pressure release valve.neilc said:maybe you missed some air the first time ?

or,

maybe you're pulling air in thru the Watts, esp if all 3 circs call, are those caps turned down tight?

and what's the fitting to the right of Watts?

another air vent ? pulling in ?

fill valve is "top left" hose bib.

not sure what outdoor reset is. it does have an outside temp sensor that of course the plumber decided to just leave on top of the unit. He also made me do my own drain lines.

definitely not complaining about his hourly rate, it was more than fair, it was the amount of hours he quoted. i even asked if it would take significantly less if we could adjust the price knowing that it wouldnt take anywhere near 40+ hours.

i also haven't hooked up the replacement water line to the navien yet so maybe thats the issue. the plumber has some big **** valve in the way that i haven't been able to figure out how to route around it. going to have a pro come figure that out i guess.

0 -

yeah but I'm thinking air is getting pulled in, instead of expelled out, when all those circs turn on.

I might be wrong.

known to beat dead horses0 -

He is pumping away from the xtank. That’s good.

0 -

I know, pumping away, I see that,

but he's pulling between the tank,

and in my mind I see air sneaking in there,

and that you would want Watts after the circ(s).

i'm having troubles over this one.known to beat dead horses0 -

It can be tricky removing air from a system with a hose fill rather than automatic fill valve. As air leaves, the pressure drops.

I assume you are closing the ball valve between the purge hose bibs and putting water in one side and letting it out the other? Opening the radiant zones one at a time to force the air out?

A purge pump setup with a 5 gallon bucket would be more efficient but you can probably get it done without."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

ah,

what do we have for system pressure ?known to beat dead horses0 -

so, i flushed each valve independently for probably 10 minutes today, i'm thinking thats going to solve everything. there was a leak that appeared on one of the loops where it connected to the manifold.

i ran it for a while and it worked fine, turned it off for over night just in case.

also, maybe its worth mentioning, maybe not but the PMP (preassembled section of hose bib, shutoff, hosebib, air bleeder, pressure valve) was designed to be fed from left to right but the instructions made it sound like it was ok to run it right to left as well. the only difference i can see now is that when filling the water from the garden hose would go through the air bleeder before going through the system vs going through the air bleeder on the tail end of the loop. it definitely makes more sense but is it worth desoldering at this point.

0 -

For the system to run correctly, you need check valves on the zone circs. With checks in place you will not be able to reverse flow."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

yeah, there's check valves above the shut offs on each circulating pump. i mean i literally rotated the PMP 180°.

you can see from radiantec's install manual that the flow goes left to right (water heater > hose bib > shutoff > hosebib > air purge > pressure relief > check valves > circs

it also says:

i was a bit unclear since the second sentence talks about un/resoldering. i didn't know if that meant i had unsolder everything and rebuild it so its in the same order, just opposite direction

0 -

Just to confirm put water in with the left drain valve and out on the right. Purge one zone, one loop (1/2" pex) at a time. Close all other zones and loops. Is there a arrow of direction of flow on the air separator? The piece to the right of the air vent looks like a pressure gauge and a pressure relief is that correct?1

-

it worked today as i expected. granted it only had to run about 4-5 hours to get up to temp. i think i'm goood to go. i wasnt really trying to troubleshoot in this thread (but thanks for all the info anyway) i was more just trying to figure out what i should all know about the system... what sort of flow rate i want, what to set the three speed pumps to etc.

DZoro, you are correct and no, no flow arrow on air separator.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements