Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

How close to the boiler can you put insulation?

Options

david_and_heather

Member Posts: 32

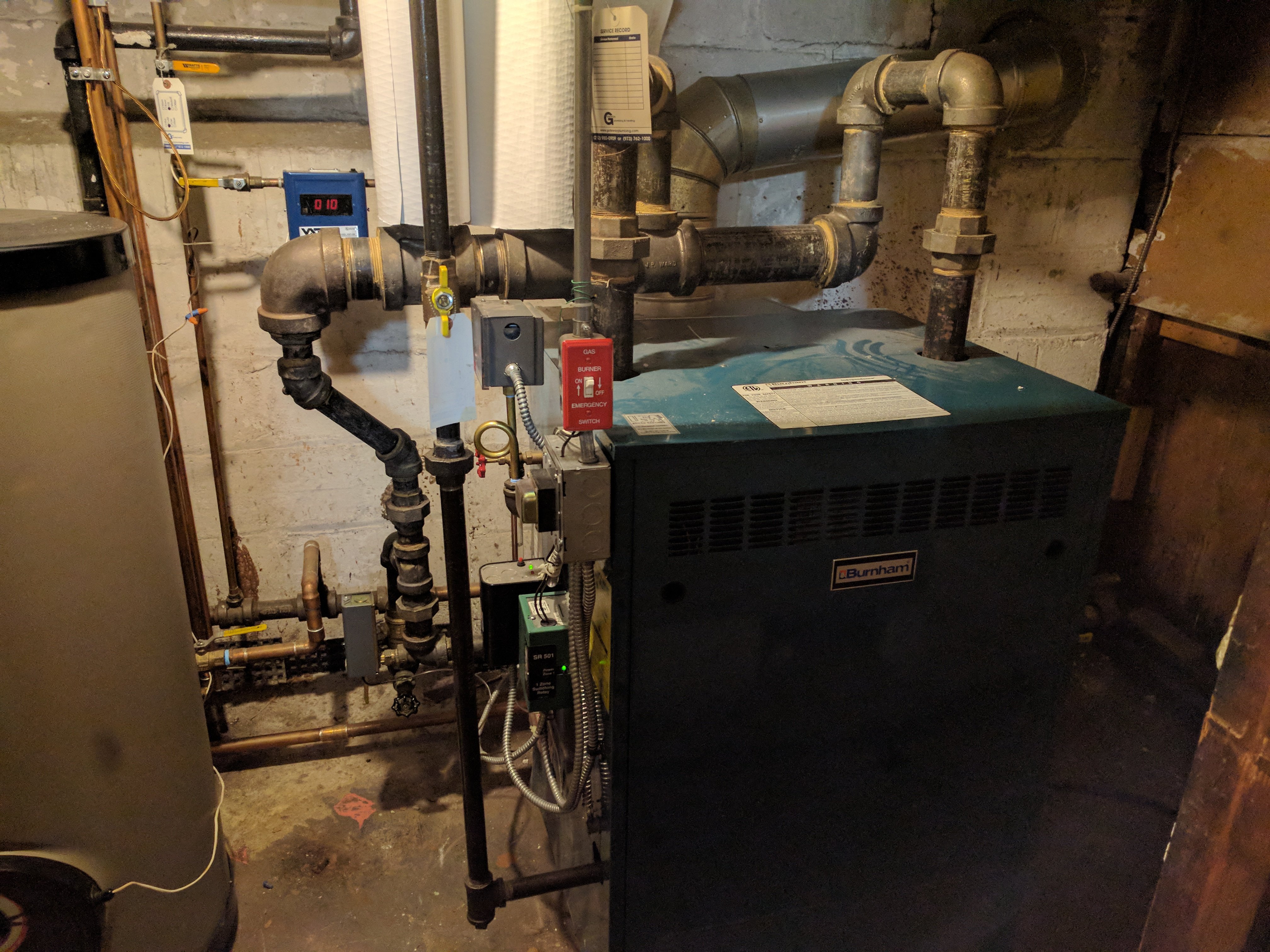

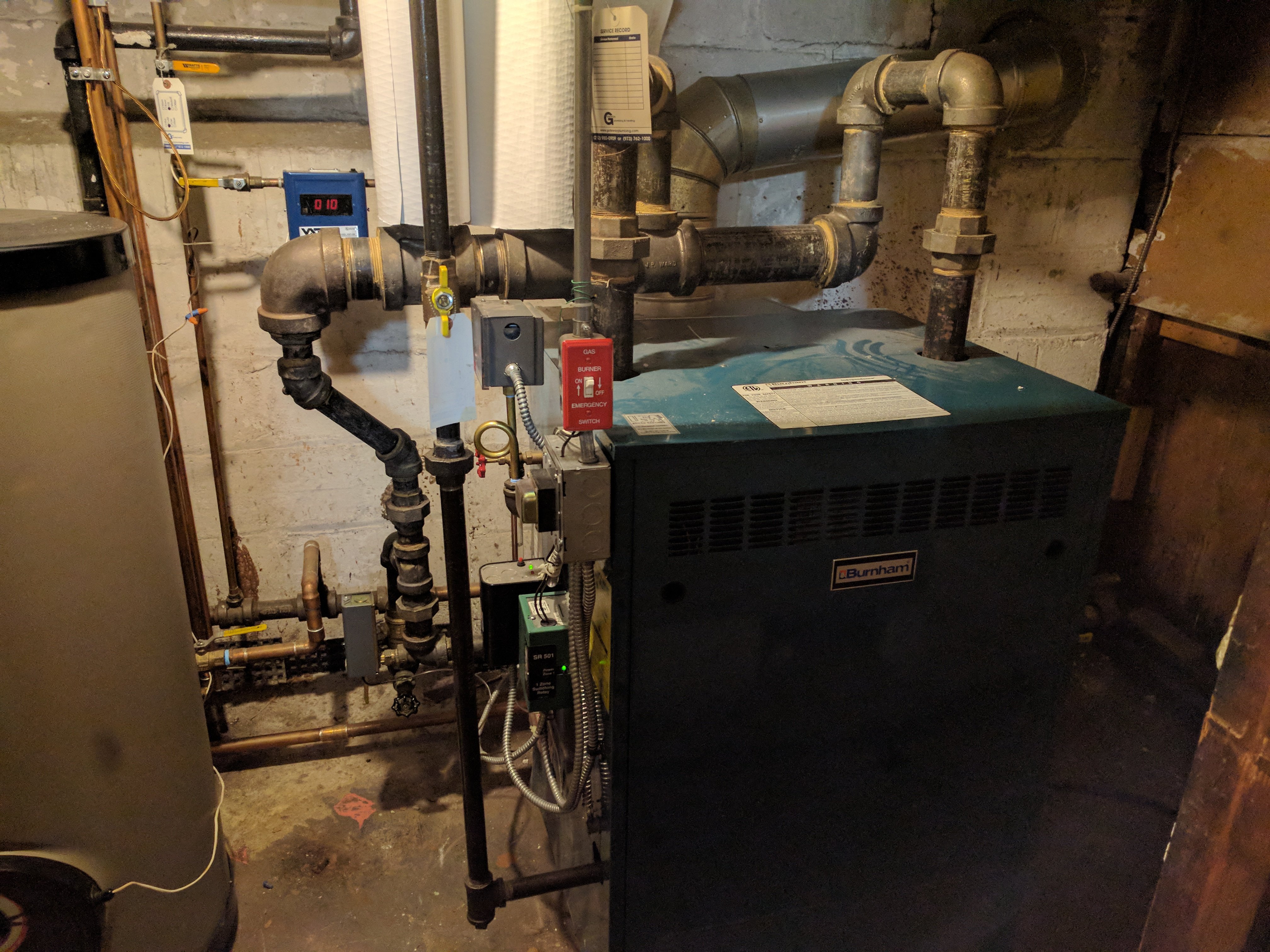

My boiler set up is in the photo below. Can I run insulation all the way to where the steam pipes leave the boiler, or no? What about the part on the left that goes down to the water line? I'm worried about if there is a flammability issue or other issue in going all the way to the edge.

Follow up question. We are considering converting our basement to a bedroom, and would like to isolate the boiler room and its associated noise. Assuming I can insulate all of the pipe, would it be reasonable to vent in outside air for combustion, thus eliminating the need for registers into the rest of the basement (as we have now)?

Follow-follow up question: if it is reasonable to would be prudent to use outside air for the furnace, is there a reasonable way to duct it directly to the combustion chamber, rather than into the room? (Running ductwork is reasonable. Replacing the boiler is not.)

Follow up question. We are considering converting our basement to a bedroom, and would like to isolate the boiler room and its associated noise. Assuming I can insulate all of the pipe, would it be reasonable to vent in outside air for combustion, thus eliminating the need for registers into the rest of the basement (as we have now)?

Follow-follow up question: if it is reasonable to would be prudent to use outside air for the furnace, is there a reasonable way to duct it directly to the combustion chamber, rather than into the room? (Running ductwork is reasonable. Replacing the boiler is not.)

0

Comments

-

Assuming that you are using fiberglass insulation, you can -- and should -- go all the way to the boiler. It is ever reaches temperature which will damage fiberglass, you have much bigger problems...

And yes, you can close the boiler room off from the house completely. However, in that event you must follow code in regards to how much combustion air must be provided by exterior venting (and if its through ductwork, the construction and sizing of the ductwork). One rule is 1 square inch of ventilation opening per 3,000 BTU rated burner input -- but codes and calculations vary widely.

Unless the burner system is designed specifically to use ducted in air (some are), MacGyvering the burner to do that is not a good idea.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

In addition to what @Jamie Hall mentioned I would recommend installing a duct with a motorized air damper in it. This will prevent cold air entry into the boiler room when the boiler is off. Boiler off=damper closed. Boiler on= damper open and "proven open" with an auxillary switch before the burner fires1

-

I would just use a fan in the can sized accordingly....codes do vary, you may need a mechanical permit ,if in my area...A general rule is 50 cubic ft per 1 k btu...as you know it’s not something to take lightly...If People or pets are sleeping in the basement it would really be a big concern to me JMO0

-

The "fan in a can" will put a smaller hole to the outside cold air than the louvers and produce less leakage when not in use.

Call for heat turns the fan on bringing air in. Proven air flow then allows the boiler to fire. Fan/can does make some noise, another brand "Tjernlund" is a little quieter IMO.

You are in effect turning this into a cold room. IIWM I would insulate the inside walls and ceiling for heat loss and sound.

Then there are building codes......do you have egress in the basement for the new bedroom?0 -

Thank you all! This is super helpful. The insulation that I've been using is the fiberglass kind with the self-sealing paper liner around it. So I should use the kind that doesn't have any paper?

The bedroom work would be a major renovation -- gutting the basement, removing asbestos, adding an egress, adding main vents, soundproofing the floor. I probably should have made that clear so as not to get anyone nervous, LOL! In my experience, it's much better to have investigated many possibilities before talking to architects and GCs. They're not as invested in your project as you are, and often don't think of some of the more interesting / beautiful / cost-effective solutions out there.0 -

Risers are looking a little short. Are you having any issues with your system?Homeowner, Entrepreneur, Mechanic, Electrician,

"The toes you step on today are connected to the butt you'll have to kiss tomorrow". ---Vincent "Buddy" Cianci0 -

Nope, it works beautifully. The only problem I have is hissing coming from all the radiators coming off one of the pipes, which is the result of a bad main vent that can't be replaced without some surgery. We are going to move that main vent somewhere smarter when we gut the basement.0

-

My old Burnham v75 had it's header about 12" above the water line and never gave me a problem, the 3 feet between that low header and the steam main probably helped some.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements