Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Oil Boiler - Hot water system - Overflowing out of Steam Vent

Options

wonderbeef

Member Posts: 2

in Oil Heating

Hardware:

A 2 pipe oil hot-water/steam heater system

Background:

I'm trying to get a previously abandoned house in working order. After dropping some considerable $ on servicing the system, replacing the 2 steam vents, and replacing the boiler lining, a new problem has arisen. When left alone, the boiler will fill up with water so much that the steam vent closest to the floor begins emitting water with or without the boiler on. The site gauge is full when this happens, obviously. The heating technician told me which valve to occasionally use to fill the boiler up, but I can't seem to have the boiler fill up and have hot water run throughout the house at the same time. What am I missing here? How do I have the hot water in the boiler flow throughout the house without it overflowing?

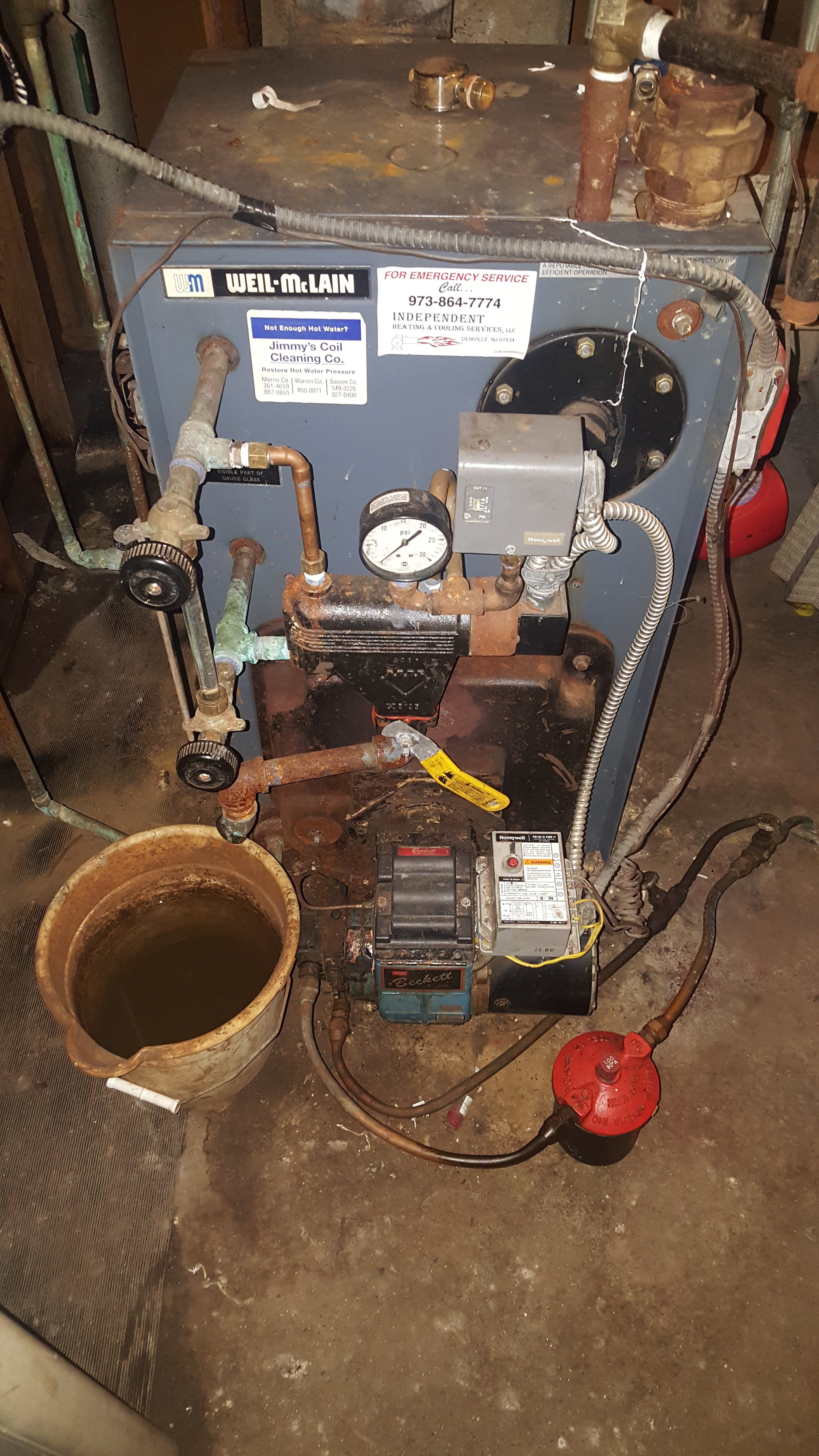

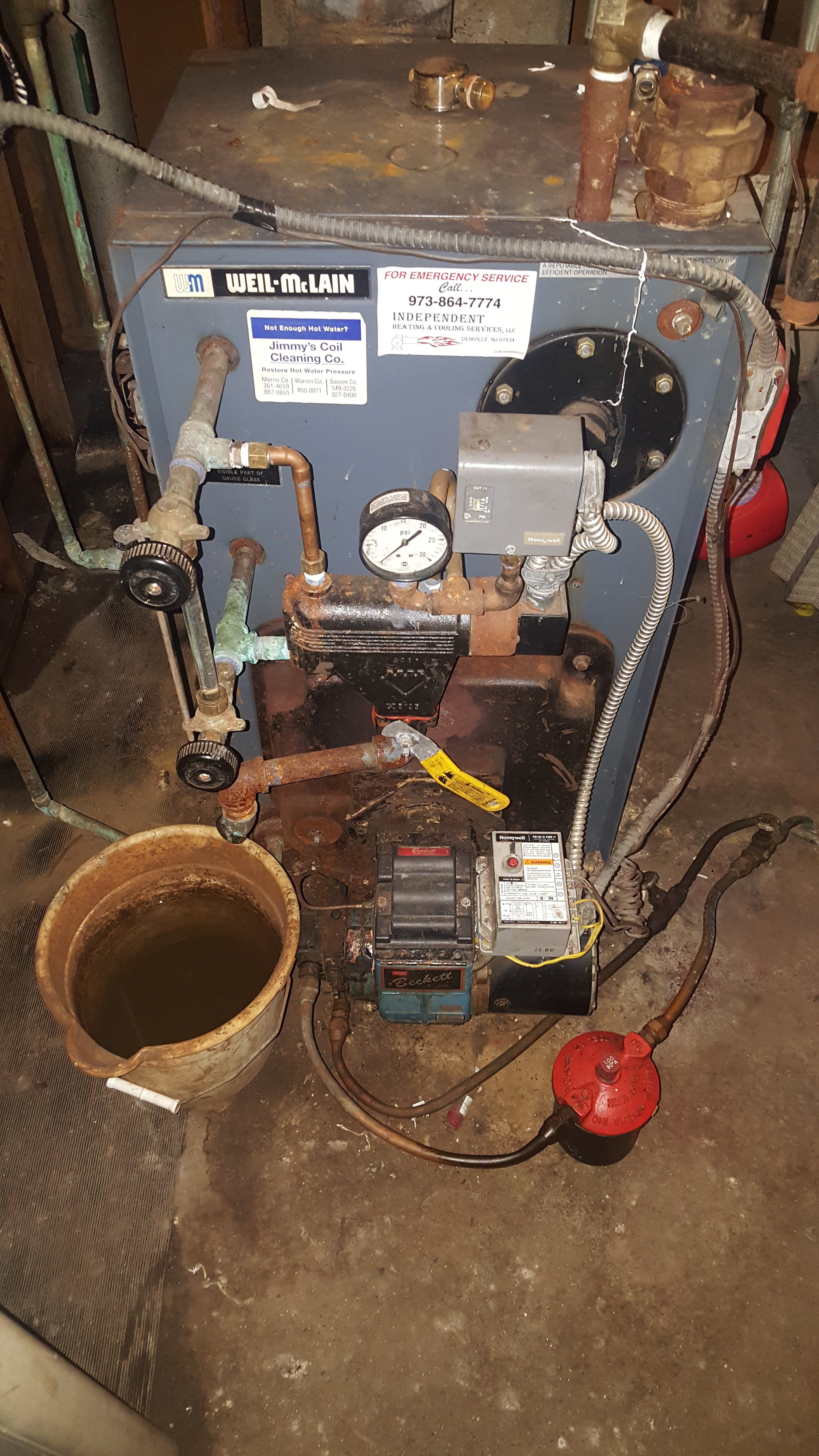

Attached are some pictures for reference

A 2 pipe oil hot-water/steam heater system

Background:

I'm trying to get a previously abandoned house in working order. After dropping some considerable $ on servicing the system, replacing the 2 steam vents, and replacing the boiler lining, a new problem has arisen. When left alone, the boiler will fill up with water so much that the steam vent closest to the floor begins emitting water with or without the boiler on. The site gauge is full when this happens, obviously. The heating technician told me which valve to occasionally use to fill the boiler up, but I can't seem to have the boiler fill up and have hot water run throughout the house at the same time. What am I missing here? How do I have the hot water in the boiler flow throughout the house without it overflowing?

Attached are some pictures for reference

0

Comments

-

Steam is supposed to flow thru the pipes to heat your house.

There is an insert coil into the boiler that will give you hot water for your faucets.

The water level should be 1/2 to 2/3 up the sight glass.

Do you have some valve letting water into the boiler, either automatically or manually?

Back up and post some more pictures so we can see all the pipes around the boiler.

PS: has this boiler been under water?0 -

I can also see the pigtail (looped pipe) that the Pressuretrol is mounted to is upside down. That will let steam hit the Pressuretrol so it may be fried. In general, that boiler doesn't look like it has been serviced/maintained in a long time. From the moisture on the floor and on that pipe that enters the boiler, there are some leaks that need attention and it looks like the two pipes that have vents on them are returns that are tied together above the water line. If you are serious about getting this house back up and running, you really need to invest a little money in a good Steam Pro to evaluate the entire system. Better now than in the dead of Winter.1

-

-

The valve to the auto feeder is off.

The bypass valve is off.

The valve on the domestic cold into the tankless coil is open.

Seems like there is a hole in the coil, filling the boiler.

If you want to double check, close the cold valve going into the coil. Drop the water level to half in the gague glass and mark the level with a pencil or a piece of tape.

Don't run the boiler overnight, and check the level in the morning.

No change = bad coil = new boiler.

Don't invest more than 50 cents into any more "repairs".

I assume the boiler is not running now because it looks like the Firomatic valve on the return is closed and that would blow the pump seal if the burner was running.1 -

I might add -- perhaps part of your confusion is that the hot water to the house comes through the coil on the side of the boiler (you can see it in one of the pictures), but the level of the water in the boiler and the site glass has nothing to do with that -- they aren't connected internally (or shouldn't be!). So there should be no problem with hot water in the house (cold, of course, if the boiler is off, but from the hot water faucets) and at the same time the water level in the boiler about half way up the gauge glass.

As has been said, close the valve to the tankless coil (I don't see one in the pictures, but there must be one somewhere), and close the feed valve to the boiler, and mark the level on the gauge glass (I use a spring clothespin). It should neither go up nor down when the boiler is off. Then, if it is stable, try opening the valve on the tankless coil. If it then goes up, you have a leak in the tankless coil. If it goes up with all the valves closed, either the tankless coil valve and the coil itself is leaking, or the feed valve is leaking. If it goes down, either the boiler or some of the piping associated with it is leaking.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Hey All,

First off, thank you for the numerous speedy replies. It's tough to describe how grateful I am that a bunch of strangers, who are experts no less, lend their time to other strangers to help them with their home.

1st question I have is, how do I identify my tankless coil? The google images didn't really look like any of mine.

As for the moisture on the ground, that came form the water leaking through the Gorton steam valve overnight after I had thought the issue was resolved. There do not appear to be any leaky points anywhere else

The issue of the pressuretrol/pigtail is quite concerning. Does this mean the boiler has no idea when to fire on and off? I'll go ahead and order a new Pressuretrol in advance. Thankfully I work for Honeywell and they aren't spinning off that product line into a new company for another year.

I will perform the suggestion of leaving the boiler off and seeing if the water level changes and report back. I think a large issue is the valve configuration is confusing to me.I can't differentiate which valve fills the boiler and which loops water through the tankless coil. Tonight more pictures will come.

Again, thank you for donating expertise.0 -

Tankless coil -- on the left side of the boiler (looking at if from the burner) towards the back there is a plate with two pipes going into it -- it's in the third picture. That's it. The valve configuration is a bit confusing, I will surely agree, and I can't look at your photos and figure out what goes to what. There may be a mixing valve on the outlet from the coil, but if that is what it is, it does look to me as though it's served its time.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@wonderbeef said: The issue of the pressuretrol/pigtail is quite concerning. Does this mean the boiler has no idea when to fire on and off? I'll go ahead and order a new Pressuretrol in advance. Thankfully I work for Honeywell and they aren't spinning off that product line into a new company for another year.

If the Pressuretrol actually is designed to shut the burner down if/when the pressure gets above the Cut-out pressure which should be around 1.5 PSI. (.5 cut-in on scale on front + 1differential on white wheel under the cover) If that Pressuretrol isn't working or if the pigtail is clogged with gunk, that device can't control the pressure and if the boiler runs long enough or is over-sized, system pressure can get way out of hand. With steam systems, you want to keep the pressure as low as possible. 1.5 to 2PSI max.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements