Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Ductless Mini-Split Lineset Location Question (Exterior or Interior)

Options

jb9

Member Posts: 104

Hello,

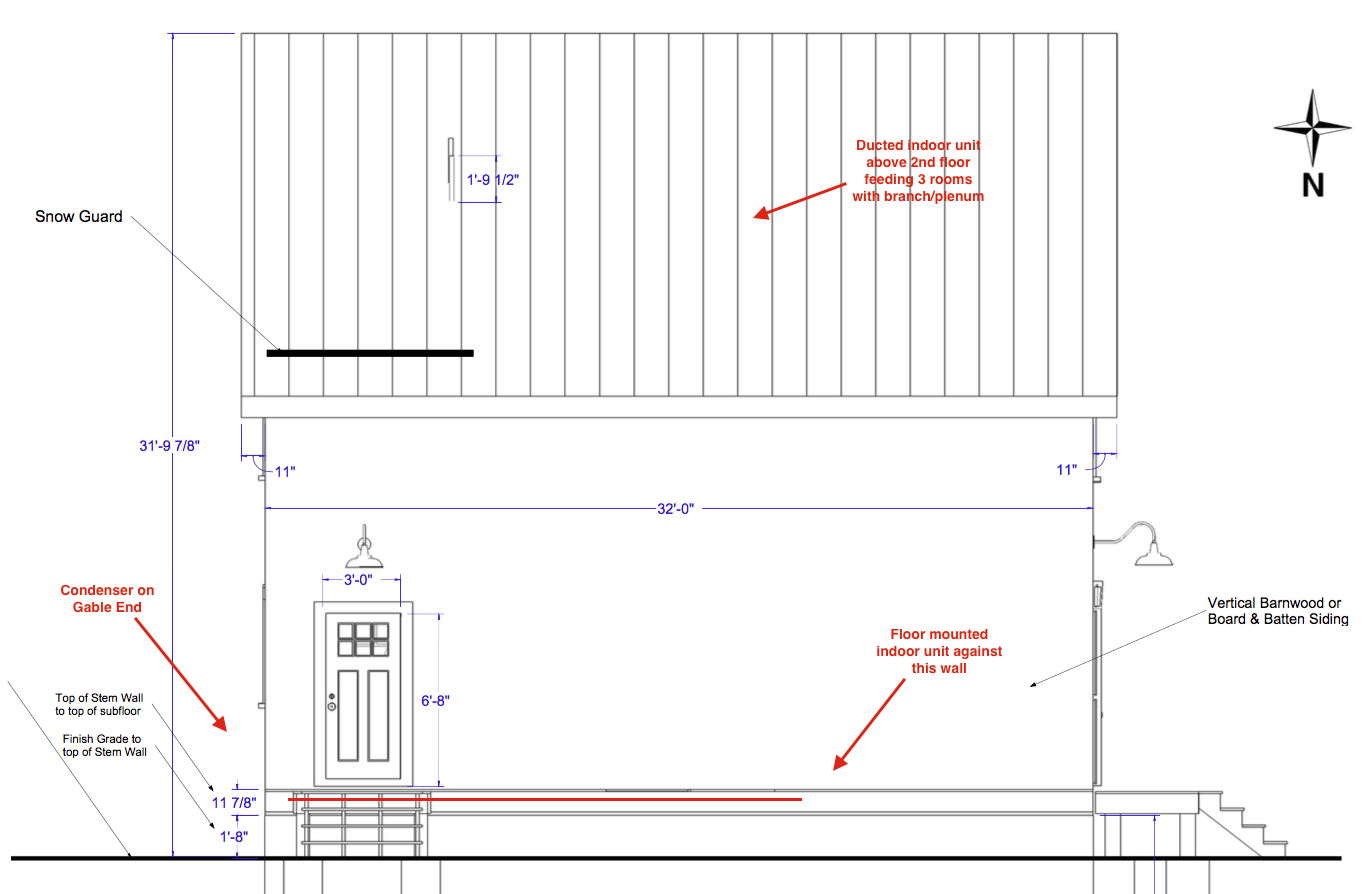

I am finishing up my building plans and was curious to hear how a pro might run the linesets from this condenser location. I have snow at my location so I am definitely going to have the unit high enough to avoid snow and placed on the gable end to avoid the dreaded roof slide. I'm thinking I might be better off running the linesets on the interior and then bringing one of them up through the 1st floor (conventionally framed deck) to a floor mounted unit shown in the attached rendering. 2nd floor will have a ducted unit. I am OK with exterior or interior placement of the linesets but I was curious if there are pros and cons of either approach. This is the north elevation of the house which does not face the street so it shouldn't impact curb appeal.

Any thoughts are appreciated. I have learned a great deal from the pros here. Thanks.

I am finishing up my building plans and was curious to hear how a pro might run the linesets from this condenser location. I have snow at my location so I am definitely going to have the unit high enough to avoid snow and placed on the gable end to avoid the dreaded roof slide. I'm thinking I might be better off running the linesets on the interior and then bringing one of them up through the 1st floor (conventionally framed deck) to a floor mounted unit shown in the attached rendering. 2nd floor will have a ducted unit. I am OK with exterior or interior placement of the linesets but I was curious if there are pros and cons of either approach. This is the north elevation of the house which does not face the street so it shouldn't impact curb appeal.

Any thoughts are appreciated. I have learned a great deal from the pros here. Thanks.

0

Comments

-

IIWM, I would run the linesets in the basement. Even the 2nd floor set up inside a stud wall or closet corner if that lines up, build a chase around it and be sure to install guard plates at all plate penetrations.

Also would run the condensate drain the same route and bring out to daylight thru the rim joist as soon as possible. Visible condensate

dripping is a good indicator of operation and you then know where it is dripping to.

What if any, so you have for back up heat? If you are in serious snow area then it must be serious cold area also.

Mini heat pumps just will not deliver at low temps for cold climate. IMO

0 -

Thanks JUGHNE. I was looking at the cross-section of the linesets to see how much space they consume. I do have a service cavity up to the 2nd floor that I think I could use to reach that upstairs unit. I do think the basement will work for the 1st floor unit. One stupid question though... Does a minisplit in heating mode generate the same amount of condensate as a minisplit in cooling mode? I see that I should be able to bundle the condensate drain tubing with the linesets so your idea makes a lot of sense. I will be in somewhat close proximity to the plumbing so perhaps I could put a P-trap. Could I even use a reservoir in the basement? Just curious about the condensate line freezing up if I run it to daylight.0

-

One more dumb question...

Will I need a branch box with 1 outdoor unit + 2 indoor units?0 -

No condensate should be produced in heating mode...cooling only.

No trap on the drains....they are built into the inside coil. Do not double trap.

Condensate lined must not be connected directly to drain lines...an air gap is needed or you may have sewer gas. I like them to go outside so you can back flush with garden hose and visibly see what is coming out.

I use 3/4" sch 40 PVC pipe. If a 90 is needed I use an electrical PVC sweep 90. You want no sharp 90's. I use either the sweep 90 or 2 45 ells with at least 4" of pipe between them.0 -

Thanks JUGHNE. I have been looking at linesets that will come with the unit. Are there any guidelines for the number of bends that are acceptable? I know there is a max length I will need to watch out for. Also, it looks like with one outdoor unit and two indoor units, I will need a branch box but probably not a line separator. Where do folks typically run their branch boxes? I presume I will try and locate my branch box near the logical location that my two linesets will split. I still haven't decided on Mitsu, Fujitsu or Daikin but I assume each mfg will have the accessory parts for this job.

Thanks for following this thread.0 -

Some manufacturers also call for a minimum lengh. Excess should be coiled horizontally. Looks like you have room in the basement or crawl space if needed.

Of your 3 choices, only the Mitsubishi City Multi needs a branch box with multiple heads.

The City Multi, and similar by others, allow heat and cool at the same time. $$$$.

On a standard ductless, the outdoor unit will come with ports for 3 heads to run seperately. Cap off the 3rd.

Also, to get to the attic, you can run the line set and drain through Slim Duct on the exterior. A much neater alternative to leader pipe.0 -

Another small note: some Multi head Mini units must have a minimum number of heads connected and their valves opened before operating.

I believe it is because of the amount of refrigerant stored in the unit for shipping. You must have at least 2 line sets opened to relocate that gas out of the outdoor coil, other wise the unit would appear to be overcharged.0 -

Thanks HVACNUT and JUGHNE. I did some more research and saw that the multizone units have multiple sets of liquid/suction ports so I won't need a branch box after all. Good to know. I think I will have a good chance to try and run the linesets inside if possible. With the floor mounted and wall-mounted units, is it standard on these units to have that 12"-14" of copper leader line coming from the unit to be connected to the lineset as opposed to the ports on the side of the outdoor units? Can those leaders be put in a bender and sent in a 90 to below the floor (if I went with a floor mounted unit)? If I kept the linesets inside, I will need to run the lineset inside the envelope and send it into the basement. All the videos I have seen show the linesets protruding through an exterior wall.0

-

Most I have used have bending spring on the lines.

They would work going thru or inside of standard 2 x 4 walls.

Probably work going down on the floor model.

How many rooms are upstairs that you need a ducted system?

Most of my installs were on 10" thick walls, so I cut the tubes short, silver soldered longer tails that my bending springs would fit over.

Then solder again with flares used only at outside unit.0 -

Some mini split wall tumors have a spring already installed on the flare stubs—Mitsubishi's Mr. Slim comes to mind.

And while I have run more than a bit of linehide, I personally try to hide the lineset as much as possible. In the walls, in the basement, in the eaves or soffit, as long as you take care with the insulation it should be fine.

0 -

The "tails" on the heads give you the option of left or right exit. On the wall mount, if you swing the tail out, you can make the flare connections outside. If not, a second person is needed to hold the head while you make the flare connections, then mount it on the bracket.

Some units even have perforated knockouts on the cover if there's a need to have exposed lines inside along the wall before you can penetrate.1 -

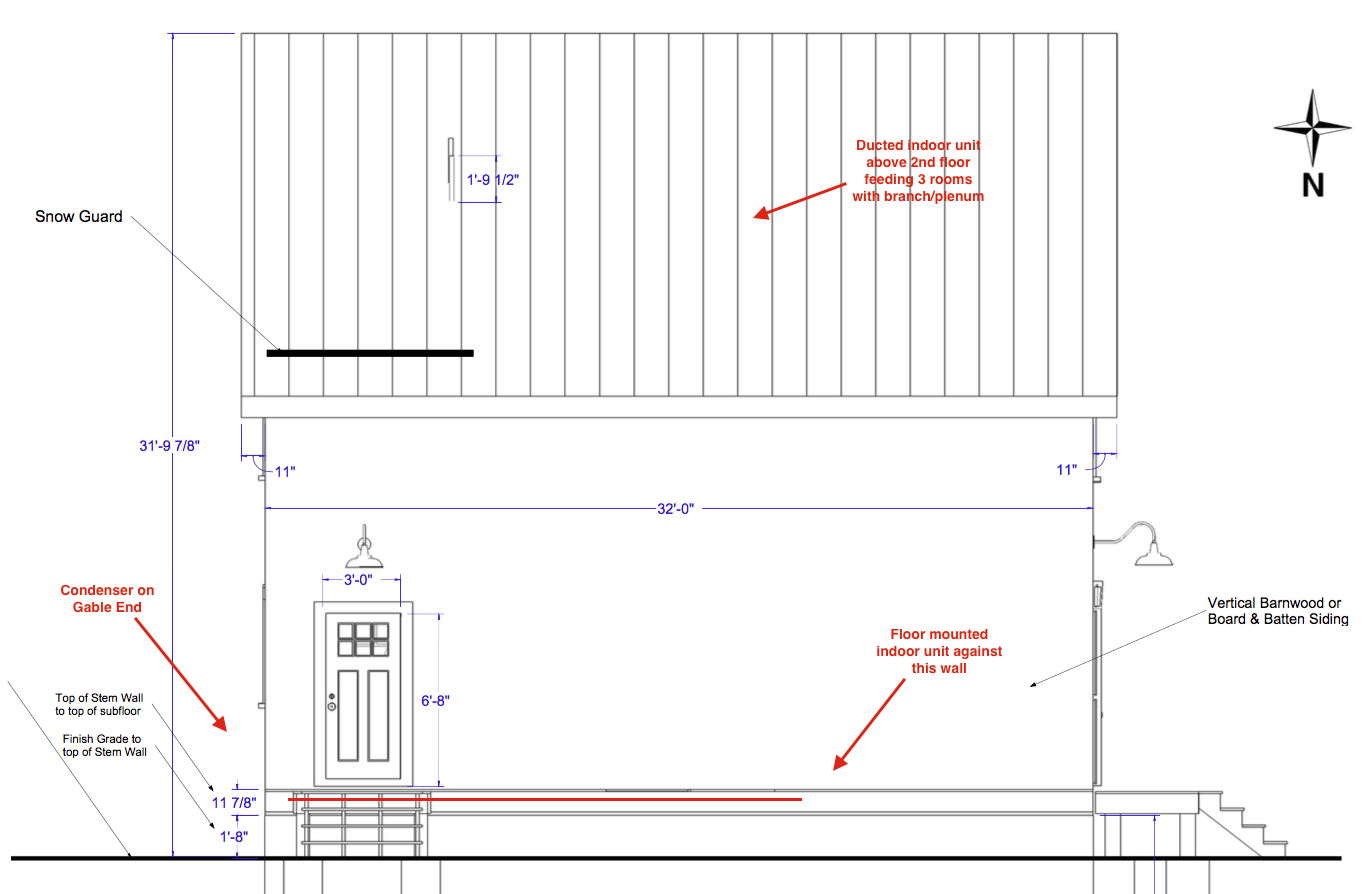

The upstairs concealed head will serve 3 bedrooms with very short runs of duct work since static pressure is limited in the unit. Here is a viewport into my model that shows service cavity possibilities and the two main exterior and interior options for the linesets. The orange one is more or less the exterior run option and the blue one is the interior run option. Hopefully this gives folks a better view of the building mechanicals and floorplan. I annotated the blue and orange lines so they aren't exact of course.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements