Webster type R

I'm looking for some help on a Webster type R system . We installed a gas boiler 2 years ago. System has been banging off and on since the day of install. Went out to the job site last week and spent 2 hours there and never heard anything. Complete silence. Homeowner says it bangs at least twice a day on mild days and about 7 times a day on cold days. The boiler has a pressuretrol on it and the standard pressure gauge. I watched the gauge and it never got above 1 psig. I know it needs a vapor stat and a gauge that reads 0 to 16 oz. I'm pretty certain that the distance from the underside of the Webster boiler return trap is not 4 to 6 inches to the water line of the boiler. I'm going back to the job to measure it, but it could be as much as 10 to 12". Knowing that 1 psig at the boiler raises the water 30 inches in the return ....would mean that the water might not rise up into the boiler return trap to activate it? We installed a No. 76 Hoffman air vent on Webster vent trap. Also is the "H" dimension that critical? Could I just lower the the boiler return trap instead of raising the boiler? That would increase the "H" dimension(listed in Warren Webster Type R book) Says "H" dimension is dependent on square feet of radiation. And also my service tech removed the guts of one of the traps on the end of the steam main where it drops down for the wet return about a year ago and it quite it up for awhile. We hadn't a clue what we were hooking our boiler into. This is my first encounter with this type of system. Any help would be Greatly appreciated!

Comments

-

Change the vent on the vent trap- vacuum can cause water to be held up in the system, which can cause banging. I'd use a Gorton #2 since this is a "B" dimension, and we don't know if the float inside the vent trap still works.

Are the end-of-main traps thermostatic (same as the radiator traps) or larger than that? Post some pics if you're not sure.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I ordered the Gorton #2 vent. Also ordered a ounce gauge and a vaporstat. Gonna set it at 8 oz. Will take pics of the end-of-main traps when we go over to install vent, vaporstat, and gauge. Thank you Steamhead.0

-

@Rabbit02 , I am a homeowner with a Webster "R" system. Just last month I had my boiler replaced. My system has all of its original equipment including check ball on the vent trap. Venting of the trap is unaltered from original. The new water line is 27" below the bottom of the return trap which is much more than the 4" - 6" originally specified and my system makes no noise at all so that may not be your problem. I installed a Dwyer Capsuhelic 0-6 inch WC gauge on my system and it is running at just 3-4" WC so I don't think the return trap will every be called on to function. I don't even know if it does function. My crossover traps between the ends of my mains and my dry returns are the same Webster 512H traps installed on all the radiators. Once you removed the guts from your crossover trap you let steam into the dry return which is not good, I can't imagine that it helped the system unless it had failed closed and main was not venting. I replaced all of my trap elements in the system with B and J cage units 10 years ago when I purchased the house.1

-

thank you for the input EricBaisch. I came to the conclusion that the crossover trap that got the guts removed from it is going to be replaced with a new F&T trap. I ordered a Watts WFT-15 . I know now that it needs to be in the system. After I posted the initial post I realized that the return trap may never have to operate if the pressure is low enough and it would be fine. I was concerned the install was improper, but now I know the distance is okay.0

-

Not an F&T! That's not what is needed!!!! Use a regular radiator trap, please. That's what was there, and that's what's meant to be there. An F&T has a very different function.Rabbit02 said:thank you for the input EricBaisch. I came to the conclusion that the crossover trap that got the guts removed from it is going to be replaced with a new F&T trap. I ordered a Watts WFT-15 . I know now that it needs to be in the system. After I posted the initial post I realized that the return trap may never have to operate if the pressure is low enough and it would be fine. I was concerned the install was improper, but now I know the distance is okay.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

At the ends of my mains condensation drops down to my wet returns and the air is vented thru to the dry return so only a thermostatic trap is needed. The float part of the trap you are planning on installing is handled by the wet return so if the system you are working on is laid out the same way I am not sure that you will not need the "F" part of the "FT" trap. I guess it would not hurt thought.1

-

so just a radiator trap. no float needed. What's there doesn't look like this at all, but I understand.0 -

What specific trap do you recommend? Can I use Hoffman brand? I know it has to do with connected radiation. Input btu is 225,000 . Boiler is capable of heating 183,000 btu's (Net IBR rating)of connected radiation and it splits off with 2 equal headers, so I would guess its roughly 90,0000 btu's per side. Only replacing one of the two traps so... 90,000/240 = 375 square feet of radiation.0

-

@Rabbit02 , @Steamhead can probably answer trap recommendations better but replacing innards of existing housing might be easiest. Here is a picture of the end of one of my mains. Steam main drops unobstructed down to the wet return and another pipe comes off the top of the main and thru a thermostatic trap to the dry return for venting the air from the main to the dry return. Capacity just needs to handle the air in the steam main on startup. You might see a couple of valves in the picture that shut off some lines heading underground to my detached garage so don't let them confuse you.

0 -

@EricBaisch 's photo is of a completely typical crossover trap. As you can see, it is piped so that all it handles is air, and that is as it should be. Most radiator traps can handle all the air you need to handle.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Take a pic of your trap and post it here, along with the piping connecting the trap to the system. Also measure the length and diameter of your steam mains. Then we can give you an answer that means something.Rabbit02 said:What specific trap do you recommend? Can I use Hoffman brand? I know it has to do with connected radiation. Input btu is 225,000 . Boiler is capable of heating 183,000 btu's (Net IBR rating)of connected radiation and it splits off with 2 equal headers, so I would guess its roughly 90,0000 btu's per side. Only replacing one of the two traps so... 90,000/240 = 375 square feet of radiation.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

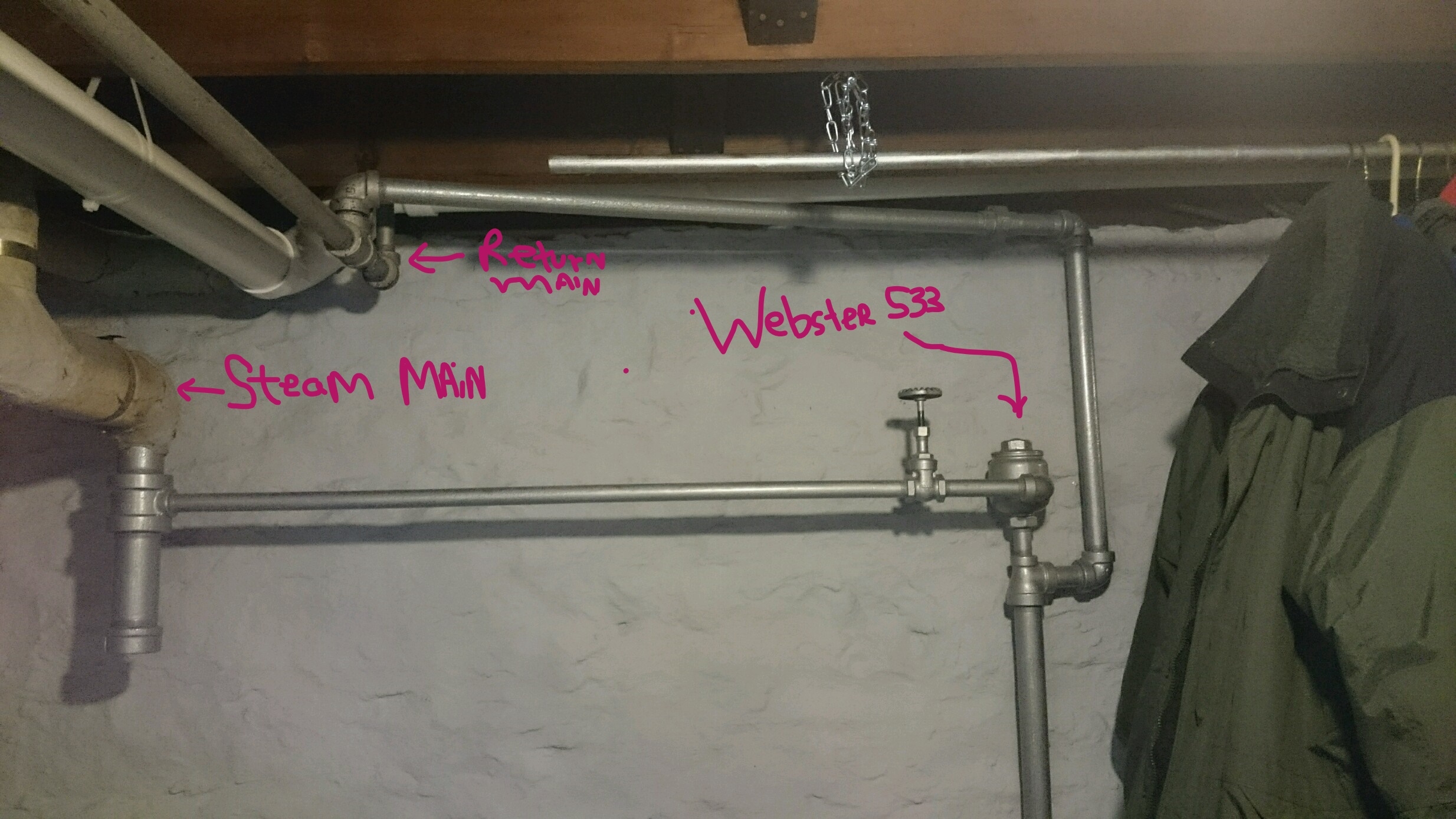

Ok , here's the info. It is Webster 533H trap. I installed a new cage assembly in it. Installed vaporstat and ounce gauge. I measured the distance from the boiler water line to the boiler return trap and it is was 18 inches. I installed the Gorton# 2 vent. Set the vaporstat at 8 ounces. We couldn't get the boiler to stay on for more than 15 seconds before the vaporstat was kicking it off at 8 ounces. Cranked the vaporstat up to 15 oz. System ran close to 10 oz. Lots of air coming from the Gorton#2 for awhile then it quit. Water level in the boiler went down and kicked off on low water cut-off after about 20 minutes of solid running. Heard air coming from the Gorton #2 when boiler shut off.(sucking air?) Cycled it back on and went out on pressure 2 times before finally staying on and running close to 12 oz. We had the thermostat jumped out, a constant call for heat. The boiler return trap was cool to the touch during operation. I took the lower plug out of the boiler return trap during operation to see if any water was in it. It was dry. After watching it stay on for about 20 minutes it cycled off on low water again and after about 3 minutes a bang came from the pipes at the boiler. Felt the boiler return trap and it was so hot you couldn't keep your hand on it. I came to the conclusion the banging was coming from the boiler return trap letting steam go thru it when the boiler shut off. We removed the boiler return trap altogether to see if this fixed the problem. We capped the 3 lines off that were attached to it. We tore it apart. It can be re-installed, needs new gaskets. It was dry and rusty. Did not look like it had seen any water in awhile. I ran the system with boiler return trap off, operating pressure a little higher, around 14 oz. Cycled it and heard no banging. I'm not too confident its fixed. I also used my infared camera to compare the two end-of-the- main radiator traps and they both looked the same. Sorry for writing a book here! Why is my pressure so high? Please take a look at pics.. a penny for your thoughts?0

-

-

-

another pic of end of the main 533 trap. This is the one we put the new cage assembly in. Lowest pipe in pic is the cast sewer main

0 -

-

-

@Rabbit02 , based on my own Webster R system and my posting and replies from the pros here I would guess that your problem now is the boiler needs skimming. When my boiler was first installed it seemed to run OK for a couple of days and then as time progressed steam would not travel down one of the two mains and boiler pressure increased to 1 or 2 psi and steam started to be forced down the Hartford loop into the return. That would certainly cause the water in the boiler go down as condensate could not return. Solution was to skim for 3-4 hours after which the boiler pressure returned to the condition of not registering on 0-30 psi gauge. Several days would pass and increased pressure condition would return and I would skim for a few hours again. This repeated several times. I have now installed a 0-6 inch WC gauge and system has been running for a month at a constant 2.5 inch WC which is less than 1/10 psi. It is very interesting to see you got the return trap opened. I have been considering trying to get mine open to have a look inside but with tentative wrenching on the bolts they did not yield. It would be nice to have a sight glass installed where I just have plugs so function could be confirmed.-1

-

Thank you. I was thinking the same thing. Boiler needs cleaned. But I think customer is running out of patience. Its going to be difficult to convince to clean it. $$$0

-

Mmmmmmm........ being a homeowner and also a curious person at this point you have so much invested in learning about this system you could skim the boiler at the same time you worked to put the return trap back together and install it at no additional charge to the customer and consider your time ($$$) spent as a good investment in educating yourself about a Webster Type R system plus regain patience from the customer.0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements