Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Burnham KV74 poor DHW after upgrades

Options

doooglasss

Member Posts: 18

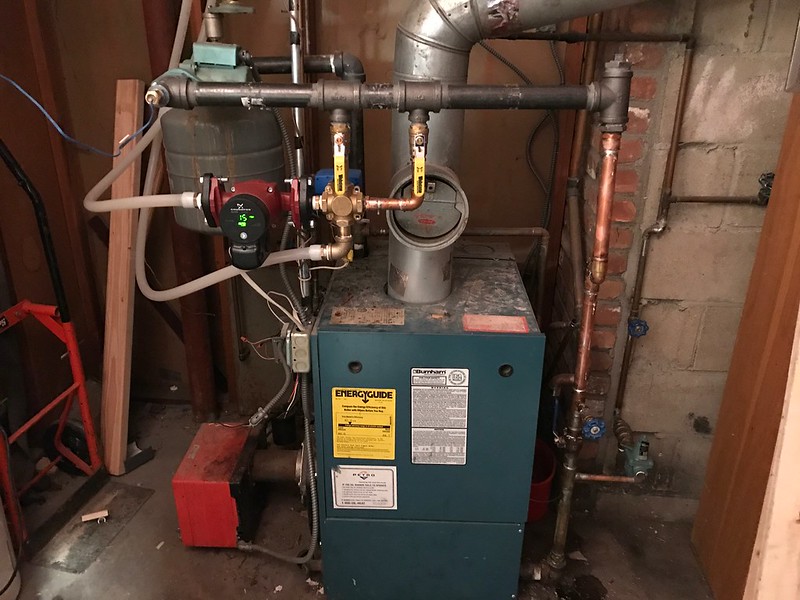

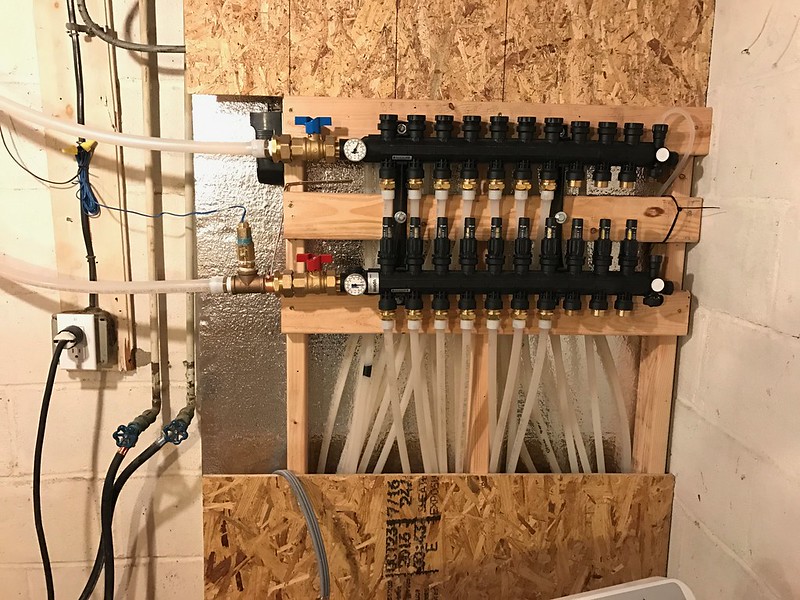

I have a Burnham KV74, oil fired with on-demand DHW. Previously my house was setup with radiators and the boiler operated off of it's aquastat which overshot nearly all the time to 220' F. I just cut that system out, installed a suspended tube radiant heat setup with a primary/secondary boiler configuration using a 4-way Tekmar motorized valve controlled by a Tekmar 360.

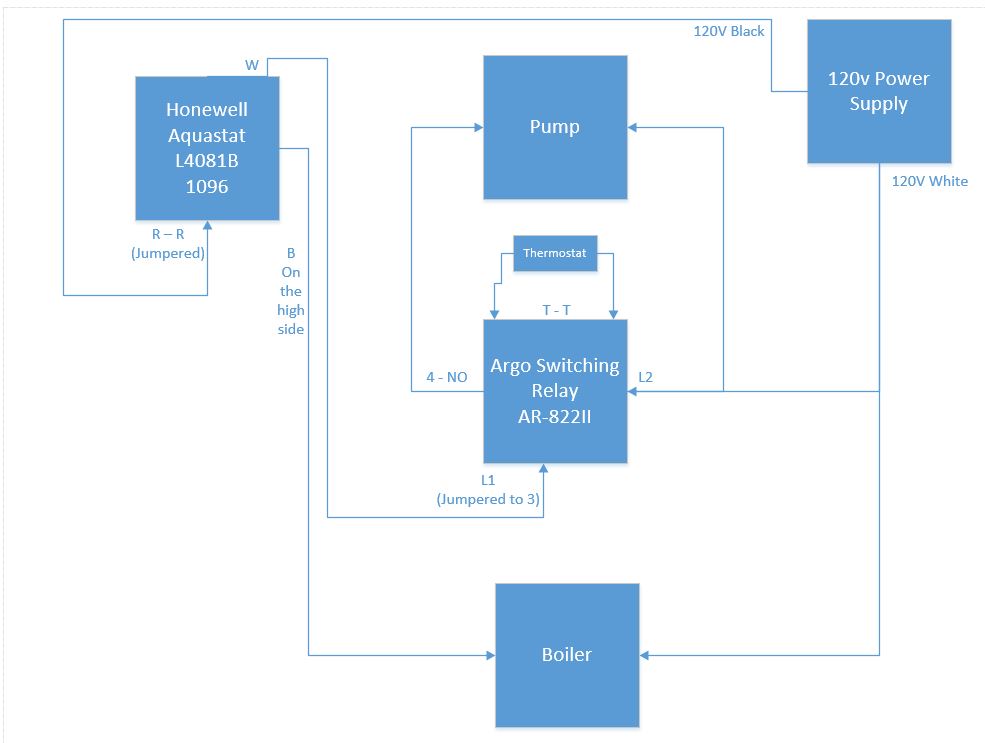

In my current configuration the Tekmar is the only boiler control. The side mounted Honeywell aquastat has been completely disconnected. The 360 sends boiler-on signal to the T-T terminals on a Argo AR822-II relay which then fires the burner. The primary and secondary pumps both are running in constant circulation. The 360 is programmed to maintain a minimum boiler temperature of 140'.

The GREAT news is my new heating system is heating the home very comfortably and efficiently running ~120' supply and 110-115' return temps.

I'm just a homeowner/nerd and might not fully understand how DHW on-demand works. All I know is that the DHW performance was mediocre at best before and is crap now- I'm sure because the boiler is running at a colder temp.

Long term I'm planning to buy a natural gas water tank and eventually when the money allows a natural gas burner. Is there anything that I can do now to improve DHW performance? Unfortunately I am probably weeks away from being able to install any gas utilities because I have to go through the permit/inspection process for a new gas install (no current NG appliances are in the home).

Any advice is appreciated!

In my current configuration the Tekmar is the only boiler control. The side mounted Honeywell aquastat has been completely disconnected. The 360 sends boiler-on signal to the T-T terminals on a Argo AR822-II relay which then fires the burner. The primary and secondary pumps both are running in constant circulation. The 360 is programmed to maintain a minimum boiler temperature of 140'.

The GREAT news is my new heating system is heating the home very comfortably and efficiently running ~120' supply and 110-115' return temps.

I'm just a homeowner/nerd and might not fully understand how DHW on-demand works. All I know is that the DHW performance was mediocre at best before and is crap now- I'm sure because the boiler is running at a colder temp.

Long term I'm planning to buy a natural gas water tank and eventually when the money allows a natural gas burner. Is there anything that I can do now to improve DHW performance? Unfortunately I am probably weeks away from being able to install any gas utilities because I have to go through the permit/inspection process for a new gas install (no current NG appliances are in the home).

Any advice is appreciated!

0

Comments

-

The tekmar is designed to keep the boiler at 140 to prevent condensation during the heat cycle only. I suspect your boiler goes cold when the heating load is satisfied.

The on demand function on that boiler is a coil with the domestic water running through it submerged in the boiler water. The hot water in the boiler jacket heats the DHW indirectly. Cold boiler=cold hot water.

Every system can get by with a different minimum temp and still have hot water.

Your old aquastat probably had a hot setting for the heat call and an idle temp so you would always have hot water.

With some creative wiring and maybe a new aquastat you should be able to get it working.

Post some more details and maybe pictures showing the wiring setup."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Thanks for the reply. I thought the Tekmar would maintain a minimum water temp, but it looks like you were correct-- NY outside temps went up tonight and the thermostat stopped calling for a mixing demand. House is plenty warm but boiler was at 93' when I went down there to look and probably would keep dropping unless I kicked it on. That can't be good for a cast iron boiler.

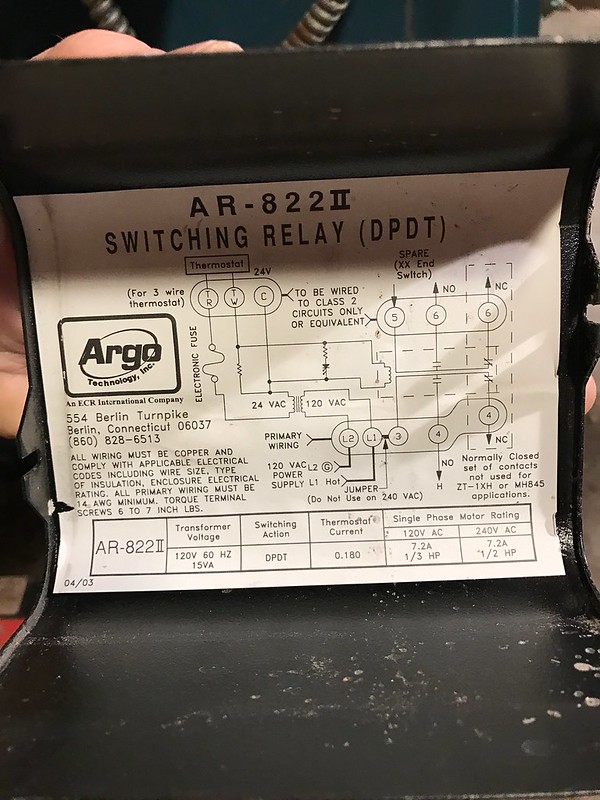

So I have the following mounted to the boiler:

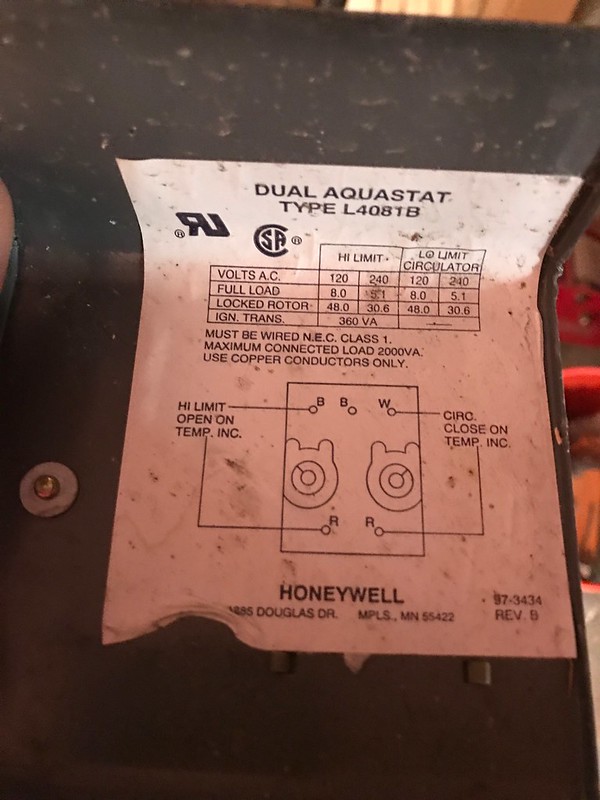

Dual Aquastat Type L4081B

Argo AR-822 II switching relay (DPDT)

Current wiring:

Tekmar boiler demand > T-T Terminals on Argo

Power 120v > Argo L2 & L1

Argo 4 NO & L2 > burner element

I think I'm going to have to change the Tekmar supply sensor to a return sensor so I can have the aquastat also fire the boiler to maintain a minimum temperature in the boiler.

EDIT:

If I'm understanding correctly the Aquastat has a normally open circuit for the low temp sensor that closes R & W terminals on the right hand side. If I set the aquastat for 140 (and test it) then connect the R&W terminals to T-T on the Argo relay the aqua stat should fire the boiler if it drops below 140. Above 140 the terminals should open and if the tekmar requires a higher supply temp than 140 it will fire the boiler or if the tekmar senses the return temp of my secondary circuit will bring the boiler below 140 it will also fire the boiler.

I have to move the tekmar boiler supply sensor to the return side

Is this correct? Should I be implementing some type of high-limit control?0 -

0

0 -

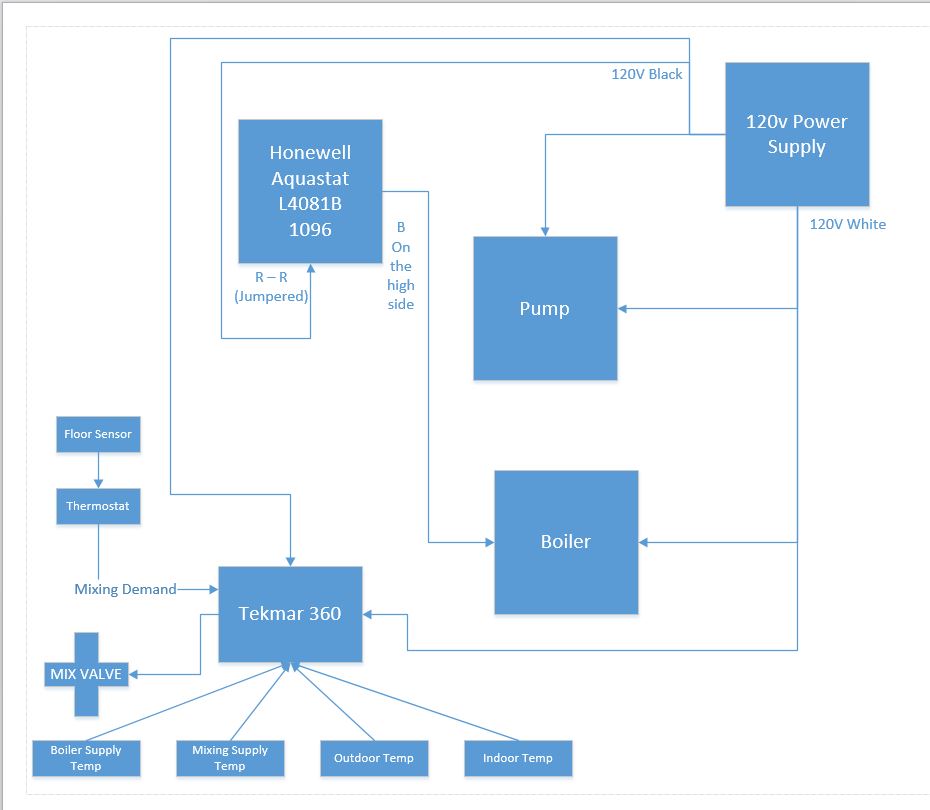

What you have makes me more than a little nervous.

The boiler aquastat has a high limit switch that prevents the boiler from running away.The tekmar does not.

I would recommend getting the boiler control wiring back to the way Burnham had it wired. If the aquastat was bad replace it with a new one.

The 360 is a mixing controller, not a boiler controller. Once the boiler is wired the way it used to be, the boiler will control itself and will have to be always on to satisfy the DHW.

The 360, in your case does not even need to be connected to the boiler. It will just pull hot water off the already hot boiler to heat the floors.

I would put the 360's sensor on the return side of the boiler. It will tell the mixing valve to pull less water from the boiler when the temp drops below 140. This will prevent boiler condensation.

One more thing, please don't run 120 power like that. Mc cable with proper connections is not hard to work with and makes for a much safer installation. The romex wire going through unprotected sharp metal holes is a hazard."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

That makes sense since I realized I don't have a high limit control right now.

Tekmar's manual recommends leaving the primary circuit pump on full time- is that OK if I reconnect the aquastat to fire the boiler?

The tekmar boiler demand should still be connected to the T-T terminals I would think?0 -

The boiler circ needs to be on if the boiler is firing and if there is a heat call (sometimes you have a heat call and the boiler is not firing). Leaving it on all the time would be less brain damage than figuring out how to make it run under those conditions.

Normally you would connect the tekmar to the T-T terminals. In your case you will have those jumpered to keep the boiler always hot.

You can probably run the boiler at 160 degrees and keep everything happy. It will be a bit of trial and error."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

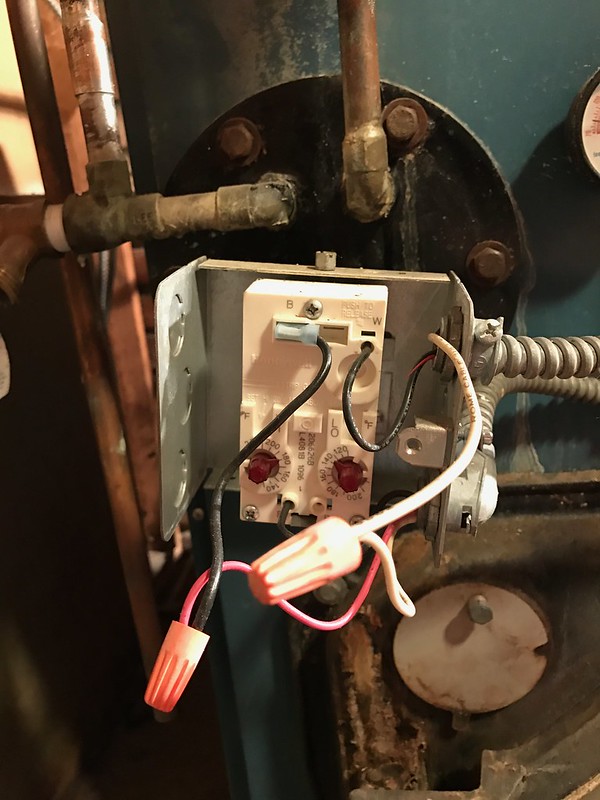

Okay so I think I just finally got this correct.

Both pumps are always on.

Tekmar is not connected to the boiler at all

120v power white > boiler white

120v power black > Aquastat high side B terminal

Aquastat high side R terminal > boiler black

With the aquastat high setting knob set to 135' the boiler fires at 150' and stops firing at 170'. After it climbs to ~180' on it's own.

EDIT: Just saw it stop firing at 160' after pushing the high limit control down as far as it would go.

Since my control is a Honeywell L4081B-1096 it looks like it only has a single temp setting with a differential (drops x degrees below it fires the boiler, reaches x degrees above and it turns the boiler off. There is a low setting but it is just to turn the pump on and off I think.

Link to manual

I really appreciate all your help (and I'm glad I didn't have any catastrophic effects while I was running the wrong way). If you could reassure me I did this correctly that would be great!0 -

I think I would let the 360 control the radiant circulator. No need to have it running in the summer.

Do you have anything that shows how the boiler was wired to begin with. A schematic on the cover or a manual online.

The functionality of the argo unit is pretty generic. How it integrates with the aquastat and the burner is what you need to check."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Original wiring:

Current wiring: 0

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements