Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

In-floor advice

Options

JAndre

Member Posts: 3

I'm brand new to the forum and in need of some advice on my in-floor heating system. really need to make sure the pumps are correct for the flow. Any help would be appreciated.

I have a home that is new construction just north of Minneapolis MN.

The system is two zones, one in the basement and one in the lower garage. 1000 square feet and 900 square feet. Each zone has 4 loops at 300ft each (1/2" tubing). 2" rigid foam was installed along the footings, a vapor barrier, foil faced bubble insulation (foil side up) then 2" rigid foam; tubing was stabled down to the foam. basement pad is 3" and lower garage is 4". I helped with the rough in on the tubing, manifolds are 1" and have adjustable flow valves and gauges.

The boiler location is 15' away from the manifold location

The gentleman that helped with the layout and design unfortunately passed away last weekend, I have a pile of parts and a system left to finish.

I have no issue doing the work to complete the install, just want to make sure its right.

Here's what I have.

2 gal expansion tank

(2) 1" mixing valves 70-180*

(1) single zone switching relay

(1) 3 zone switching relay

(2) 007 w/ifc taco pump w/hardware

(1) 007 standard taco pump w/hardware

(1) hydro smart 120 boiler

(2) thermostats

(1) purge T

(1) air valve

(various ball valves for install)

(40ft) 1" copper with various fittings

(2) additional 2 loop manifolds and 600' of 1/2 pex for future install under first floor tiled areas.

I'm sure I have to pick up more items, I just need to make sure the pumps are correct.

What he had described to me was identical to the hydro smart integration panel (that's what he used as a reference for me) main panel with one pump by the boiler and the other two pumps by the manifolds.

Like this.

I have a home that is new construction just north of Minneapolis MN.

The system is two zones, one in the basement and one in the lower garage. 1000 square feet and 900 square feet. Each zone has 4 loops at 300ft each (1/2" tubing). 2" rigid foam was installed along the footings, a vapor barrier, foil faced bubble insulation (foil side up) then 2" rigid foam; tubing was stabled down to the foam. basement pad is 3" and lower garage is 4". I helped with the rough in on the tubing, manifolds are 1" and have adjustable flow valves and gauges.

The boiler location is 15' away from the manifold location

The gentleman that helped with the layout and design unfortunately passed away last weekend, I have a pile of parts and a system left to finish.

I have no issue doing the work to complete the install, just want to make sure its right.

Here's what I have.

2 gal expansion tank

(2) 1" mixing valves 70-180*

(1) single zone switching relay

(1) 3 zone switching relay

(2) 007 w/ifc taco pump w/hardware

(1) 007 standard taco pump w/hardware

(1) hydro smart 120 boiler

(2) thermostats

(1) purge T

(1) air valve

(various ball valves for install)

(40ft) 1" copper with various fittings

(2) additional 2 loop manifolds and 600' of 1/2 pex for future install under first floor tiled areas.

I'm sure I have to pick up more items, I just need to make sure the pumps are correct.

What he had described to me was identical to the hydro smart integration panel (that's what he used as a reference for me) main panel with one pump by the boiler and the other two pumps by the manifolds.

Like this.

0

Comments

-

What are you using for a boiler? How are you heating the upper floor(s)?Hydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg0 -

The house has forced air through out and I was planning on installing the additional loops under the tiled areas of the first floor. The boiler is a hydro smart 120 NG boiler.

Just not sure if the 007 pumps are sufficient.

Thanks0 -

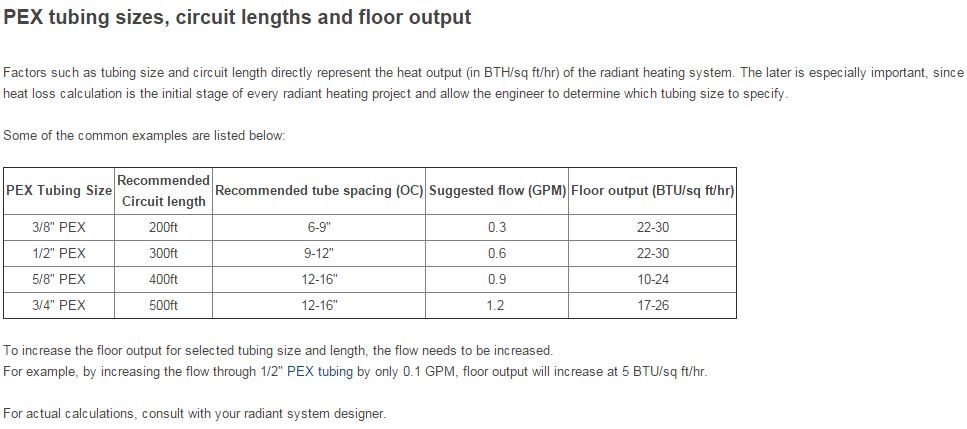

To run the numbers, find out from the PEX manufacturer what the pressure drop is for your PEX, and then take a look at this: pexuniverse.com/content/how-size-circulator-pump

Hydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg0 -

Some of this reads like stereo instructions.

The data supplied is pressure drop (psi per 100ft)

.51@ .5 GPM = 1.173 ft head

1.70 @ 1 GPM = 3.91 ft head

5.30 @ 2 GPM = 12.19 ft head

11 @ 3 GPM = 25.3 ft head

looking at the example, the recommended flow for 1/2 @ 300' its .6 GPM. .6 x 4 loops would be 2.4 GPM total for that manifold. It also states 24 -30 BTU per sq ft. At 1000sq ft for the large zone at 30 would be 3 GPM (by the example on the link) or .75 GPM per loop.

Although the PSi equation isn't linear, doing the math @ 300ft the head would be 4.27 @ .6 GPM

Or 5.382 @ .75 GPM

By this math the 007 pump should work, unless I screwed this up completely.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 19 Recall Announcements