Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

1 Gallon Per Day Makeup Water, But No Visible Leaks in Mains?

Options

cubicacres

Member Posts: 360

We noticed our VXT Hydrolevel water meter indicating we're using about a gallon per day of added water the past few weeks, but didn't see any leaks in the basement mains like we had at two unions on the drop-header last year after the new WMC EG-75 boiler install. We just finished a skim to help with the low-water cut-off stopping our Tekmar 279 too early. Any thoughts on where water leaks tend to occur more frequently from what you've seen? All the mains & many of the risers are fiberglass insulated & we didn't see any obvious leaks yet. We're guessing someone has a leak near their radiator supply valve and hasn't noticed it yet if it drips down the riser hole or something?

0

Comments

-

Check the radiator supply valves and air vents. On the valves, pay particular attention to the packing nuts. If you can spin the handle with little or no effort, the packing nut needs tightening or repacking.

The water is probably escaping as steam, which won't necessarily leave a mark.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

You're probably not leaking water. You're leaking steam.

Just as bad. Find and change the bad vents. A mirror helps.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com1 -

-

-

Flood the boiler and check for leaks under it....If none ....then run the boiler for a good while and go thru the system with a good young ear and listen....Use a bright flash light and look around....If this is has occurred over a period of time it may be spitting valves and packing nuts...If it is just all of a sudden then I would be looking at the possibility of a decent leak1

-

Thanks. Would leaving some tissue paper on the radiator supply values or using an IR thermometer when steam is moving to the radiators help identify steam leaks?0

-

The meter started going up a few weeks ago near the begining of the heating season. Our returns are dry until they drop to a short wet return next to the boiler.

The vents are all 14 months old or newer (all new Hoffman vari-vents with last year's install, less a few larger Gorton & Maid-o-mist Jacobus vents on the far rads).

Now that we did the skim last week and our water meter is reading 100 since installation last November, is there a history of water usage you've noticed eats different boilers? The old one had visible rust/corrosion problems for sure. We read that over 180F, the dissolved oxygen levels are low, so would that suggest a gallon a day to a 180F degree nearly full boiler wouldn't be as bad as when it was added below 180F? Curious about how many gallons equate with shorter life (every 20 gallons is about year of life lost, etc? Not sure is anyone's observed rates of decay or not).0 -

could be a pipe leak in a wall cavity too.gwgillplumbingandheating.com

Serving Cleveland's eastern suburbs from Cleveland Heights down to Cuyahoga Falls.0 -

They still need to be checked. They can fail quickly. Especially if pressure too high, or steam wet. Check the radiator valves as well.cubicacres said:

The vents are all 14 months old or newer

I always find a nice letter to tenants explaining how vents work and encouraging them to report steam leaks to be of great help.

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Check the Chimney.0

-

We checked the chimney tonight, and no visible smoke while the boiler was running. We saw the water meter was the same as 4-5 days ago, so maybe the makeup water has stopped after our 90 minute, 29 gallon skim last week? We also got our steam established using the Tekmar down to 9 minutes today from 12 compared last week pre-skim. Established at 125F, with a 15 degree lockout differential-the condensate took 6 minutes to return.

Is it possible the makeup water was due to wet steam & needing a skim and not a steam or water leak? We can check the radiator vents & supply valves as well, but if the water meter stays the same, does this narrow it down for us?0 -

Hi can you post a picture of the boiler and near boiler piping...The reason I ask is as a general rule when I had my business and one called me for a ongoing issue the first thing I did was look at the install....And work from there....more often than not I had to say the boiler is not piped correctly so any repair started after the piping was corrected....Some liked to hear it others gave the blank stare and figured you were a thief,looking for work.....Any body in my area looking for work has issues, I know guys that turn away as much work as they take on....Anyway snap a picture0

-

-

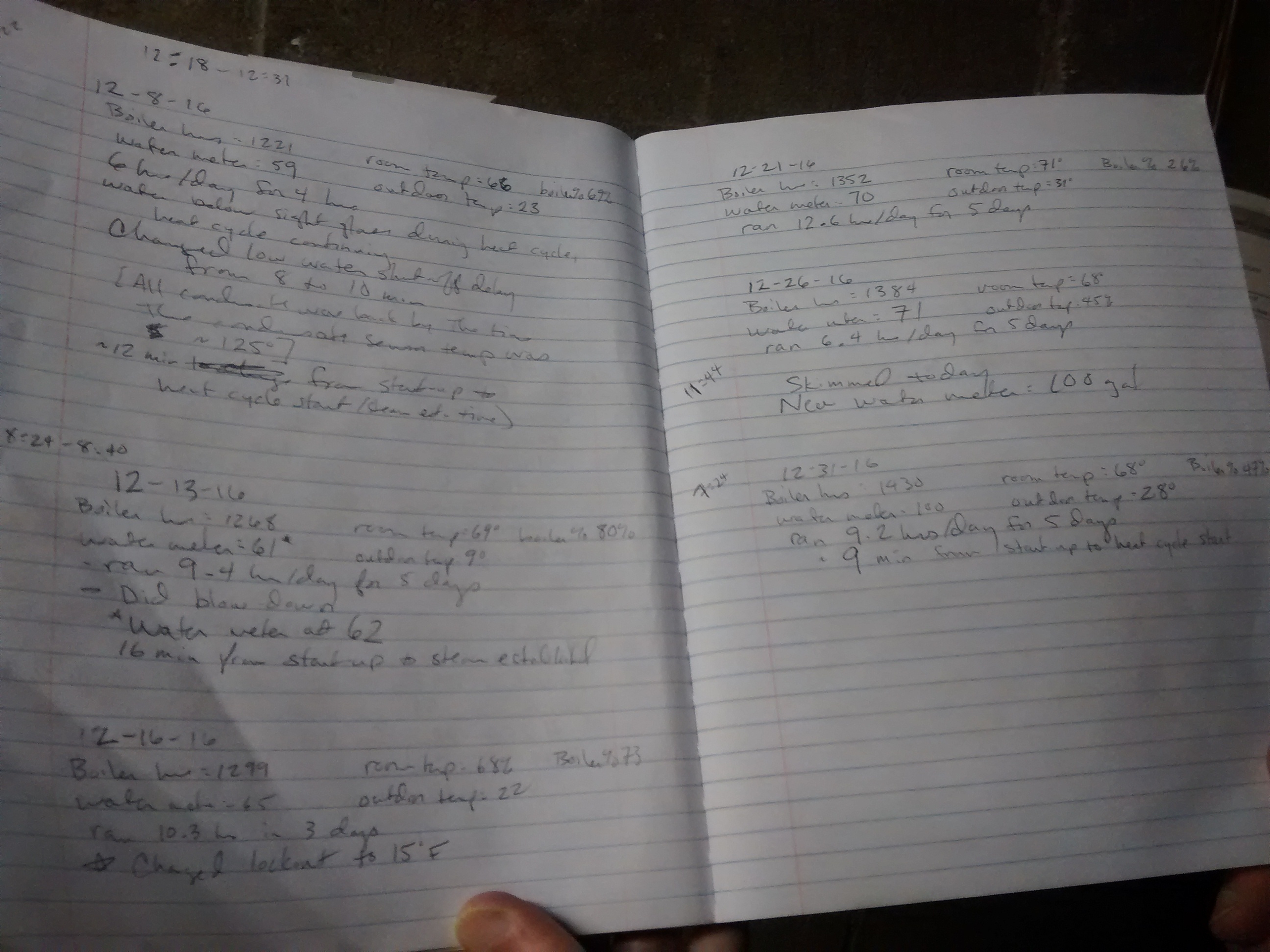

Also, our weekly or so log book with the settings is attatched in the pic. It was running at 47% last week after the skim. With condensate returning around 123F last time we checked, would setting the lockout around 120F be preferred?

We wanted to give it plenty of time (123F temp in this case) since we don't have a timer to return to minimize new street water. We notice the condensate returns about 5 minutes after a low-water shut off instead of using the 10 min. feeding delay on the VXT-24 water feeder most times.

Using the Tekmar's lockout differential to wait longer between firings allows the pipes to cool more, heat to dissipate in the rooms more, and theoretically reduces run times each day, saving energy per our assumptions.

But sometimes Tekmar says the lockout is only to allow enough time to return the condensate, not to gain efficiencies using residual heat & delaying a new heating cycle with cooler pipes. So far the room has been within 2 degrees of our 68F target this past month, so we feel we're doing pretty well as far as the indoor sensor is concerned (no tennant complaints either

But when it starts up several minutes later with a higher lockout differential each time, it needs to re-heat those pipes and is there any efficiency gained overall for lower energy use over a season? We were wondering about this "using already produced residual heat vs. re-heating the pipes again" situation.

0 -

2 more pictures for good measure from before insulation was added. Our wet returns are just a few inches right next to the boiler as shown in the 2nd photo.

0 -

As mentioned above a cold/cool mirror works.

I have a FLIR TG 165 which will "see" steam going into the ambient air. It takes some practice and more patience but it does work.

I recall a posting some time back that someone used a soil moisture indicator (house plant type) to probe insulation looking for dampness.

The few elusive leaks I have found surprised me for the amount of make up water they were actually requiring......loose union.....plug in a cracked CI fitting.0 -

Last year I noticed my water usage creeping up and couldn't find anything obvious. I put some newspaper under the boiler to see if something showed up. The next day I found one piece wet paper under the boiler drain valve. i only leaked under pressure and it was dripping onto a cinder block.

When I looked at the block I realized it was darker then the other cinder blocks that were under the boiler feet. That block was acting like a sponge and feeding the drips into the cellar floor without any telltale stains.

I fixed that by tightening up the bonnet on that valve.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Bad news..we checked the water meter after a week of cold days and saw it went up by another 7 gallons this week after our skim. We did use 2 large old gorton D radiator vents around the same weeks the water increase started in November, so we suspect that could be related. Haven't examined all the tennant's radiators yet, but the front hall was louder & had a constant white noise machine sound, so we might replace it with a new maid-o-mist and see if that changes the water intake level after a few days.0

-

No no on the maid o mist....What's the size is the radiator....Height sections columns ? We will help you pick one0

-

hall radiator is 40sq ft, 9,600 btu per our charts.0

-

Is that the radiator right inside the main entrance door?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

Yes, that's the hallway radiator. We noticed it making noise yesterday and realized we used the old (prior boiler) gorton D's on that one & 2 others just behind it on the long 2in loop to be split. The last 4 radiators on that long loop now have either an (old) gorton D or new maid-o-mist large D size vents (hallway,#2 BR, #2 small kitchen wall rad=gortons, #4 2nd fl BR=maid-o-mist), which seemed to reduce the steam established time by about 2-3 minutes before we swapped them in Nov. (around when the water use started increasing to 1 gal/day).

Our last 4 radiators with those large vents going back from the end of the long slowest 2in line to be split are: Front hallway-5 section column style 40sq ft or 9,600btu radiator, 1st fl BR unit #2 column style 25 sq ft or 6,000 btu rad, 1st fl BR kitchen wall-mounted smaller rad 9sq ft or 2,160 btu, 2nd fl unit #4 BR column style 9,600 btu rad.

Why are the larger rad vents (gorton & maid-om-mist/jacobus size D's) bad at the end of the slow, long main loop if they seem to help the longer line catch up to the other 2 loops by 2-3 min? If we swap them with the smaller hoffman veri-vents that are on all the other rads, would this prove if they are leaking our 1 gal/day water?0 -

We noticed it used 4 gallons of new water yesterday! Looking back at the log the past 14 months, 0-5 hrs of boiler run time has about 1/20 gal/day water use, 5-10 about 1/4, 10-15 about 1 gal, and yesterdays 16 hrs run time was a record & used a record 4 gallons of new water. The tekmar 279 showed a 63% boiler percentage for this recent cycle, if that means anything.

After swapping the front hall C size gorton radiator vent to a smaller new hoffman 1A vari-vent, our tennants in unit 1 mentioned for 2 months they've been adjusting their bedroom rad vent since it kept spitting & wouldn't close, along with a steam bubbling leak form the smaller bathroom radiator supply valve. We'll replace the BR vent tomorrow and resarach how to replace that bathroom supply valve or tighten the packing nut. We hope the wet steam pre-skim last week was why our energy use was so high, and these leaks are why our water use was so high. If this fix doesn't do it, we'll be moving on to the next possibility. Just curious, if we're at 111 gallons since install in Nov. 2015, how much new water can boilers handle (10, 100, 1,000 gallons before rusting out?)0 -

Man, I'd fire up the boiler an walk through all the units. Btw, what's your op pressure? This can be why vents are failing.0

-

And pop in a few Steamaster tablets every few days until you figure this out.0

-

With our pressuretroll 0-30 gauge, not sure about pressure. I think cut-in as low as the troll can go (.5 or 1?) with cut-off at 2 or 3 psi. Do the steamaster tabs scavenge oxygen?0

-

Your psi might be too high now too ... Those Honeywell trols are horribly inaccurate. If venting is good, any 1 or 2 pipe steam should be able to operate on oz of pressures, not pounds... all you need is to overcome pipes friction to the end of farthest radiator. I have a book somewhere - with adequate venting, pressure drop is ~1oz per 50 ft on a 2'' pipe, if memory serves me...cubicacres said:With our pressuretroll 0-30 gauge, not sure about pressure. I think cut-in as low as the troll can go (.5 or 1?) with cut-off at 2 or 3 psi. Do the steamaster tabs scavenge oxygen?

Many people use vaprostats, although it is double the price of the the trol. See www.supplyhouse.com if you don't have a local relationship with the supplier. This may be what changed since the last install: more inaccurate trol, and that higher PSI will definitely use more fuel.

I know before all my venting was good, I had to push, oh, 2-2.5 psi or so to get the last rad hot. Now, even with one zone closed off (essentially making the boiler oversized), all rads still get hot before pressure rises and cuts off about 8oz... Actually, I jacked it to about 9.6 recently to see how it behaves with cycling... Vaporstat will not let you go above 1 psi, so you always work on figuring out venting to get system balanced. Higher pressures waste a lot of fuel.

Back to water: yes, Steamaster does exactly that, scavenges o2, but also gets the TDS down to virtually nothing. Someone here (I think it was BobC on one of my questions) said that with Steamaster tablets he gets something like 5 ppm TDS. Anyhow, if you are doing so much makeup water, pop a few of these in and do it every few days depending on how much water you lose. It is color coded - you'll know when it's purple in the sight glass. If you want to geek out, look up your municipality water report and look at chlorides levels. I read one of the guy's here replaced a boiler that was eaten up after a few years, with chlorides in 35-45ppm range. For bad water, you want to look into water treatment for sure.

If I were you, finding out where is the water going would be my first priority... This much water loss is not normal. I have a float type condensate feeder motor switch and this thing needs blow-downs weekly, so there is naturally more make-up for me. I have no idea how much fresh water this brings in - but I just installed water meter and water 5 micron filter for the boiler, so soon I will know. I also plan on starting to use Steamaster. I estimate wasting about 2-3-4 galons/week on this blowdown on a boiler whch holds 40 gallons of water, and plus another 35-40 in the condensate return tank. For me, there is no going around this so I am probably getting between 8-16 gals/month of fresh water because I have to blow down this float thingy. This means, my water turns over about once a heating season, so I assume boilers should be able to do at least that.

Hope this helps!0 -

Thanks. We'd like to use a 0-3psi vaporstat to see the actual pressure ranges. Do the steamaster tablets pop into to the skim port or are they inserted another way?0

-

I saw supplyhouse had a vaportstat controller, is buying one of these and a 0-3 psi gauge the way to go? We have 2 pressuretroll boxes now.0

-

Before you go adding a Vaporstat I would highly recommend you start with a good low pressure gauge. As was said the pressure is actually a function of boiler size and venting. If you are building pressure there is the possibility you don't have enough venting or the boiler is oversized or both. Having followed most of your posts during this project I doubt you are oversized.

The pressure isn't the boiler making pressure, it's the air in the system pushing back on the expanding steam that makes the pressure. A boiler makes steam it doesn't exactly make pressure. If the boiler was open to atmosphere it would just dump all it's steam and never make any meaningful pressure. This is what you are trying to get close to with venting, as if the boiler wasn't connected to any piping. There is piping resistance that must be overcome, but this won't account for pounds of pressure on a system like yours.0 -

Remember what I suggested (and reposted on your other thread) Stay focused on finding and fixing the water leaks first. With the kind of water loss you have, I can't imagine their is any way to determine you need to lower the pressure and besides that, a Pressuretrol and/or Vaporstat should be an upper limit switch, not an operating control. The Thermostat should be the boiler's on/off control. Adding more gadgets to the mix only adds to the confusion about what is going on with the system during a time when you are trying to resolve problems. Add the bells and whistles after the problems have been resolved. That way, if the system acts differently, you will know what One change you made that most likely effected that new behavior.cubicacres said:I saw supplyhouse had a vaportstat controller, is buying one of these and a 0-3 psi gauge the way to go? We have 2 pressuretroll boxes now.

1 -

I may have been confusing here in my replies, trying to describe my system to compare and make a point. Sorry if I'm causing confusion.

I'm going to second @Fred, and reiterate what he and others have said: first find where all the water is going. Forget steamaster tabs, forget anything else... 4 gal/day is not normal by any stretch. Find and fix leaks first.

It can be:

- rads dripping at valves

- vents not closing and spitting both steam and water

- hidden drips inside walls...

I've seen it all on my system alone. You have to find the leak first. And definitely don't expect tenants to report issues. They won't until they are cold first.

You have to walk through every apt and look at:

- every rad, left to right, top to bottom

- Touch or look below any unions on the shut-off valve and the rad (those can loosen or crack if overtightened),

- look at the valve bonnet (the valve stem comes up through it, right where packing nut is, seam between valve body and the bonnet),

- look at the packing nut

- put a mirror against the vent and wait for a while. Steam will fog the mirror. Hot air escaping won't. (you said you replaced some or all of these recently - this may not be an issue, but it may be so check anyway!)

- Run your hand below the rad and see if any is moist wet between sections - this will be hard to detect with a hot rad, so get a mirror and a flash light, or use your phone camera as a mirror and look closely for any small water, It may be small enough to dry right away against the hot radiator, but it's a leak nonetheless. You can try using spray bottle and bubble solution (and spray on anything suspect). Any steam escaping will make bubbles.

- look for stains on the floor under rads

- look for any dry rot on the floor where rad riser comes up through the floor - this will be a tell-tell even if the rad looks dry that it gets moisture.

Any of these can have a small leak that is just small enough to run down pipe and evaporate against the heated pipe, and will not show up as a drip anywhere, but it's still losing water nonetheless. It will be obvious as it will look like an old water stain.

- look any exposed piping and exposed couplers the same way, look for water stains under on them

- look on the ceiling on floors below the upstairs rad for discoloring paint and water stains

- look at the ceiling where the pipes disappear into ceiling/wall and look for water stains on the ceiling below pipes

- look for bubbling plaster and bubbling paint anywhere below where the pipes and rads may be...

- look under the pipe covers (like the one rusted on your picture).

This will be like chasing a leak in the gas line, if you ever had the pleasure to do this. You might have to touch and physically look at any joint between to pipes, use a scope camera to get inside walls and inspect hidden pipes...

Hopefully, it will be something quite obvious. But you must walk through every unit and inspect. Any jurisdiction will give you 24 hour notice exemption if there is an emergency. Broken boiler would be classified as that. Inform your tenants, make a note, go knocking and enter. I would not delay this.

Then, after you are no longer making up new water, look for venting and all other issues.0 -

Thanks-we'll start this. The bubble solution can detect steam as well as gas leaks? Is there anything else that could detect steam/water leaks other than us observing it and seeing past moisture contact points?0

-

If you use a small mirror and hold it close to the stem/pipe/fitting, it will fog up if steam hits it.cubicacres said:Thanks-we'll start this. The bubble solution can detect steam as well as gas leaks? Is there anything else that could detect steam/water leaks other than us observing it and seeing past moisture contact points?

0 -

> @cubicacres said:

> Thanks-we'll start this. The bubble solution can detect steam as well as gas leaks? Is there anything else that could detect steam/water leaks other than us observing it and seeing past moisture contact points?

Anything escaping a joint should bubble up with bubble solution. If you ever obaerved a gas line leaking, those are running at about 4 oz and show up quite well!0 -

We are also getting a fair amount of water loss from our system, was there ever any resolution to this?0

-

@NYCDave , might want to start a new thread.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements