Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Children's home pump and heating system

Nollag

Member Posts: 2

Hi all,

I have a problem with a pump. It's a cold winter here in Ukraine so any help would appreciated ... I'll describe the system first, sorry i don't have access to a pc right now so i can't send a sketch.

... I'll describe the system first, sorry i don't have access to a pc right now so i can't send a sketch.

We have four pumps, a solid wood burner in the boiler house and two buildings to heat. The house heating circulation pump and the hot water pump are run automatically by a control panel. The school has a pump that has to be manually switched on for the heating. And the boiler house has a large back up pump that we switch on if the burner starts to overheat in a power cut.... It's powerful enough to pump water to the house and to the school.... The burner should really have an n.o. valve and a secondary water circuit to dissipate heat in a power cut but it doesn't so we have to power a generator to stop overheating.

So here's the story

The circulation pump for the house has stopped working. Apparently it's nine years old and has been noising for the last year. It's buzzing and heating up but not pumping. I twisted the shaft manually but it didn't kick in, so it's not the capacitor i imagine. Do you think it's completely banjaxed or how would you work out if a fix is possible?

I vented it a couple of weeks back but this didn't affect the noise. Also we already have a back up battery and inverter that i recently connected to the pump to keep the house heated in a power cut. I hope it's just a coincidence that the pump finally gave up after three power cuts this week. I wired it via a relay that switches between the utility power from the controller and the inverter power. Problem is i could only get one old USSR cooker relay here, which sparked once and tripped the circuit breaker when the utility power came back on. I think it's possible a bad switch in the relay meant that both inverter and utility power were being fed at the same time to the pump. However this was two weeks ago and the pump had been working since.

So, i don't have a background in plumbing but I'm sure i can follow any advice given. I'll follow up with the specs of the pump in question. Also i want to redesign the system but that's an idea for another day. Thanking you...

Thanking you...

I have a problem with a pump. It's a cold winter here in Ukraine so any help would appreciated

We have four pumps, a solid wood burner in the boiler house and two buildings to heat. The house heating circulation pump and the hot water pump are run automatically by a control panel. The school has a pump that has to be manually switched on for the heating. And the boiler house has a large back up pump that we switch on if the burner starts to overheat in a power cut.... It's powerful enough to pump water to the house and to the school.... The burner should really have an n.o. valve and a secondary water circuit to dissipate heat in a power cut but it doesn't so we have to power a generator to stop overheating.

So here's the story

The circulation pump for the house has stopped working. Apparently it's nine years old and has been noising for the last year. It's buzzing and heating up but not pumping. I twisted the shaft manually but it didn't kick in, so it's not the capacitor i imagine. Do you think it's completely banjaxed or how would you work out if a fix is possible?

I vented it a couple of weeks back but this didn't affect the noise. Also we already have a back up battery and inverter that i recently connected to the pump to keep the house heated in a power cut. I hope it's just a coincidence that the pump finally gave up after three power cuts this week. I wired it via a relay that switches between the utility power from the controller and the inverter power. Problem is i could only get one old USSR cooker relay here, which sparked once and tripped the circuit breaker when the utility power came back on. I think it's possible a bad switch in the relay meant that both inverter and utility power were being fed at the same time to the pump. However this was two weeks ago and the pump had been working since.

So, i don't have a background in plumbing but I'm sure i can follow any advice given. I'll follow up with the specs of the pump in question. Also i want to redesign the system but that's an idea for another day.

0

Comments

-

-

@Paul48 's advice is good -- presuming that you can actually find another pump. I imagine that they are not that common.

In the meantime. You mentioned that you can twist the shaft manually. Does that mean that it spins relatively freely, or that it does turn but you have to exert a fair amount of force? A pump shaft should spin pretty easily.

If the shaft spins pretty easily, the problem probably is in the motor -- and from your mention of buzzing and heating up, I'm going to make a wild guess that there may be a damaged winding in the motor. Can you find another motor somewhere and substitute that and see if that works?

Your relay idea is fundamentally sound, but with one note: there are two kinds of really contact sets. One breaks one set of contacts before it makes the other set. The other makes one set of contacts, and then breaks the other set. You description sounds like the latter, and that -- however briefly -- you did have both the mains power and the standby power hooked up. That will lead to fireworks; hopefully the circuit breaker tripped before it did anything more than fireworks. You need to find a relay -- if you can -- which breaks the one set of contacts before it makes the other set.

Keep posting -- we'll help as much as we can.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England-1 -

Thanks for your replies, I'm hunting for a replacement to fit the space at the moment.

@Jamie Hall the shaft spins OK, its a little heavy to get moving but doesn't feel stuck or anything.

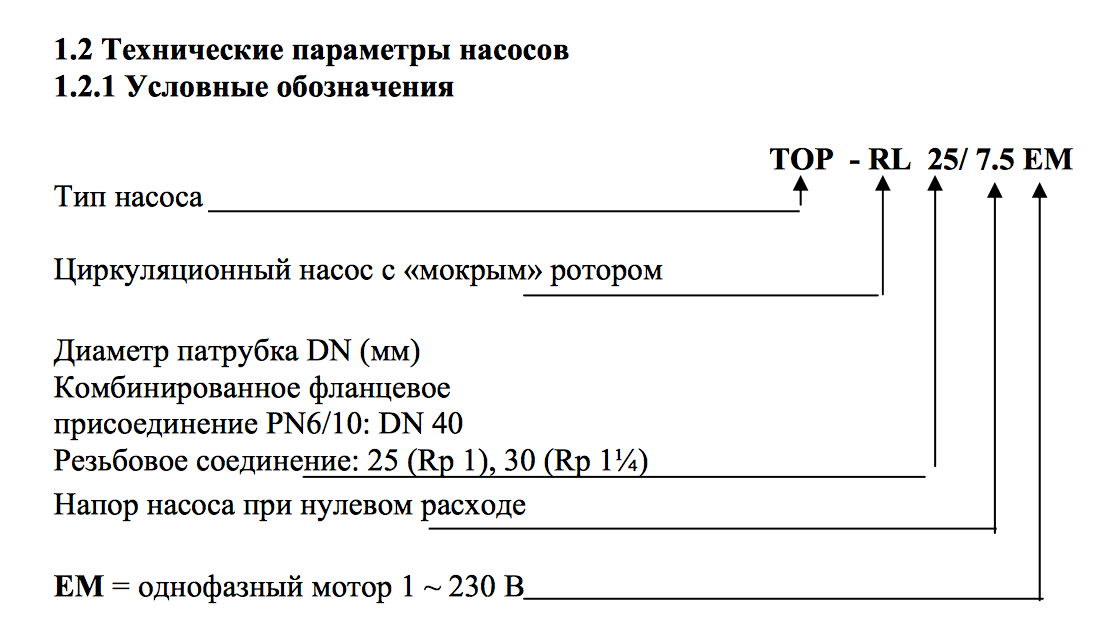

The pump is a wilo top rl 30 7.5. we have another for the hot water with the same model number, except it ends in 6.5. The union connections top and bottom are the same but unfortunately the motor housing dims are different so i can't just swap over the motor. I'd swap the whole unit but i don't want to undo any piping as it's an old enough system that's rusted and i dont want to risk anything.

@Jamie Hall can i ask, you mentioned about relay closing times. I'm looking at a Finder relay type 40.51 http://www.finder-relays.net/en/finder-relays-series-40.pdf

It mentions operating time 7ms with release time of three. Would this delay suffice for switching between utility power and inverter power for the pump?0 -

It is often easier to remove the motor with the two, or four allen both and replace just that, instead of finding the exact same body style complete pump. it is not uncommon for pump manufacturers to supply OEM pumps with specific connections.

In Wilo language the model numbers indicate the pump performance and dimensions of the body. That looks to be a common 80W circulator.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If this is a non pressurized wood boiler, it is considered an open system, and no ferrous components should be in that hydronic circuit. They will rust shut.

ME0

Categories

- All Categories

- 87.1K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 59 Biomass

- 427 Carbon Monoxide Awareness

- 117 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 111 Geothermal

- 163 Indoor-Air Quality

- 3.7K Oil Heating

- 72 Pipe Deterioration

- 1K Plumbing

- 6.4K Radiant Heating

- 393 Solar

- 15.5K Strictly Steam

- 3.4K Thermostats and Controls

- 55 Water Quality

- 51 Industry Classes

- 49 Job Opportunities

- 18 Recall Announcements