hydronic walls-newbie here

After much reading of archives & other research. I've made a decision.

I've decided I'd like to fully explore the various options of heating my entire house via a system inside of the walls.

Not baseboard.

To keep on subject, I've already decided not to do it via the floors or ceilings, less maybe the bathroom floor, there's plenty written here about hydronic floor heat, so we don't need to discuss that option. The layout of the house, the square footage, existing floors & ceiling height are all issues I've already taken into consideration in my decision.

There's not a whole lot of people writing about doing their walls, outside of their bathrooms, so here I am, because I want to do the entire house this way. This just isn't done in my area, but doesn't mean it shouldn't be.

The house:

Small house, apx 800 sq ft total, balloon framed, mostly gutted to the studs.

3 rooms & bath on 1st floor apx 576 sq ft, w/ a 1 room attic. Has small full basement & also a crawl space under the additions.

Location: South Western Pennsylvania, rural.

I will be heating with oil, no natural gas access.

There are painfully few actual 'professionals' around my area, in hvac or plumbing, though there are plenty of hacks hard selling poorly designed 'systems'. I'm done with people trying to sell me, and am looking to the science of it.

Everyone I've spoken to in my area seems to think they know how to do it, but after reading for the past year, I realize this is not the case.

Most I've spoken to still oversize boilers & NONE have heard of heating via the walls, aside from placing a radiator on it, or doing baseboard heating. No one uses outdoor resets. Most have tried to sell me on staple up under floor heating, under my 2 inches of wood floor, and use some of the worst practices I've read about.

My goal here is to educate myself on what I can do, what it is I need to do, & then to do it properly.

I will be doing the 'grunt work' myself -insulating the walls, installing the pex etc., & will eventually find a *real professional* to do the rest-boiler/manifolds/resets.

The good news is that I LOVE doing this type of work, & am very mechanically inclined.

Previously, with the help of Desco Energy, I DIY'd 95% of my present house's forced air system, top to bottom,

so I'm no stranger to the math/science or technical side, or the labor involved. I had a lot of fun doing it.

The system works wonderfully for what it is, which is forced air.

Due to a traumatic brain injury & resulting damage, I now have issues regulating/maintaining my own body heat & staying warm, or even getting comfortable in cold temperatures. It is a rare condition & a total pain in the behind.

There's not much I can do aside from controlling my direct environment, which is my intention.

The slightest drafts make for a miserable experience, and destabilize me, causing me a lot of 'down time' just trying to get warm. I can feel the cold from the walls sucking the heat from my body, despite the heat being 78 degrees, it bakes most people out of here. I get chilled from the drafts due to the return air, which causes me to turn up my heat. I've tweaked my present system to the max. I dress in multiple layers from September til May.

I do realize that 99.9% of people will never deal with this to the extent that I do. I want to make my 'new' home as comfortable as possible-for me, dealing with my medical issues. That means--no more forced air & warm walls!

So far, I'm thinking I'd like to do the system 1/2 way up the walls, or possibly, 3' up the walls, and doing some type of wainscoting.

Most of my ceilings are 7'6".

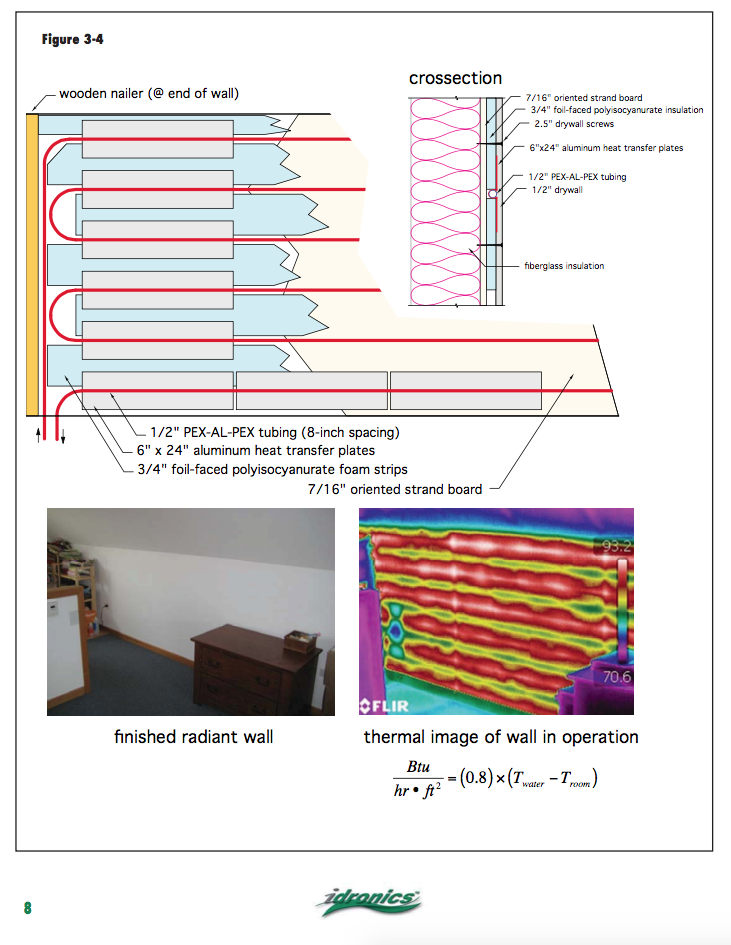

I'd like to do the exterior walls, after air sealing, then filling the stud bays with roxul & covering the studs with an inch or two of rigid foam board, to mediate thermal bridging, possibly foil faced, taped & vapor barriered.

I considered poly-iso, but have also read that it loses it's R value over time especially in cold conditions, so another type of foam board will be used over the studs.

After that is all done, I'd place the pex system over that, & the finish walls.

I'm not incredibly concerned about the issue of having the pex in the walls and nailing. I'll make story boards & take pics & proper precautions. Most everything on my walls is mounted over the 4' mark. I'm not planning on selling the house, but if I ever do, the plans will all be clearly documented for the next person.

I have been looking at warm board & some of the 'similar' products that might make it easier to install, but am not sure if that is the best product to use due to cut outs & sizing for windows, doors, & electrical.

I do really like what I've read about warmboard for transferring & distributing heat.

Taking into consideration windows , doors & electrical, with the limited sizes of warmboard panels, it might be too much waste to use warmboard for the walls, due to all of the necessary cut outs.

I'd still like to get the most efficient heat distribution using heat transfer plates & it seems this can be done, if I am guided by the right people.

So I have been looking at the aluminum heat transfer plates, Uponor/Wirsbo products, and a few others.

Being that it's the walls & not the floor, I actually feel I have more options. I'm not limited on my flooring choices, which I like to change out with the seasons. I like having more bare floors in spring/summer & roll out heavy wool rugs & pad in the winter, when I spend most of my time indoors.

Now is the beginning of the planning stage. I'd love to learn what it is I need to know about the installation process for the plumbing aspect of this & figure out the most efficient way to design it, & find an actual professional to install the boiler & associated goodies that allow the system to run properly, & hopefully I can find that through someone here.

This place has some really knowledgeable people & I've enjoyed reading here.

It has already saved me from having a poorly designed & inefficient system installed.

Thanks Much!

-Paulo Coelho

Comments

-

Pretty simple installation with transfer plates. I have installed them both horizontally and vertically. The U fins work best, if you have access from being the C fins work also.

This small vertical application is in a tiny home I'm building.

There are a number of remade wood panel systems, depends on how many windows, etc that are in the way.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

"Pretty simple installation with transfer plates"

Ahhhh--What a beautiful way to start.

Thanks hot rod-

There is relief in knowing I am finally in the right place.

I'm so tired of hearing how difficult/impossible/ridiculous this project will be.

It's all very straight forward physics & some new toys, tools & products I get to play with.

What book are those pics from? would you kindly link to it?

I've been wanting to read some more, was not sure what books to read. I'm looking for material that focuses on walls.

I know I will be limited on boiler/heater options since I will be using oil.

Suggestions?

Which type of drywall/cement board/wall board/plaster board or wall covering makes a better substrate over top of the pex?

I'm also open to different options as well-ceramic/z-brick/stone/metal-I've considered these depending on their effect/function-& they'd be an 'extra protection' over the wall.

It's an open canvas & I'm more interested in function as opposed to looks & am certainly not opposed to an industrial or rustic look.

Actually, I'm leaning towards metal for a 'wainscotting' more than anything & am curious how a layer of sheet metal over top might affect it's function.

LOL I find drywall pretty boring & metal would certainly deter nailing

"The Universe Always Conspires to Help the Dreamer"

-Paulo Coelho0 -

You are correct, this really does need to be done right. ODR-controlled mixing for sure, and quite likely a buffer tank.catia1313 said:I will be heating with oil, no natural gas access.

I'd like to do the exterior walls, after air sealing, then filling the stud bays with roxul & covering the studs with an inch or two of rigid foam board, to mediate thermal bridging, possibly foil faced, taped & vapor barriered.

See if you can find an insulation contractor who does wet-sprayed cellulose. It's quite a bit less expensive than mineral wool and does a better job of air sealing. You can apply it with the plates in place or install them afterwards.

Radiant Engineering can make plates in pretty much any length you want. Saves a lot of time on walls.

Here are some shots of a job where we used ThemoFin C plates on lightweight steel studs.

0 -

It's been a while since I've done radiant walls.

Roth panel was my preferred method.

Insulated backing, aluminum face with standard tube spacing, 2 sizes. Worked well on a good number of projects. Regards, Gary0 -

SWEI said:

You are correct, this really does need to be done right. ODR-controlled mixing for sure, and quite likely a buffer tank.catia1313 said:I will be heating with oil, no natural gas access.

I'd like to do the exterior walls, after air sealing, then filling the stud bays with roxul & covering the studs with an inch or two of rigid foam board, to mediate thermal bridging, possibly foil faced, taped & vapor barriered.

I've done one like over wood studs that with plywood in between.

It worked very well, simple to install.

I would recommend reading anything you can by Robert Bean regarding Mean Radiant Temps (MRT).

By the sounds of your sensitivities, paying close attention to these variation will be the key to comfort.

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

I like the metal idea. That small wall I showed will cover with a piece of mirror finish 430 stainless. A local shop will break it to wrap around the end of the wall into the shower lip.catia1313 said:"Pretty simple installation with transfer plates"

Ahhhh--What a beautiful way to start.

Thanks hot rod-

There is relief in knowing I am finally in the right place.

I'm so tired of hearing how difficult/impossible/ridiculous this project will be.

It's all very straight forward physics & some new toys, tools & products I get to play with.

What book are those pics from? would you kindly link to it?

I've been wanting to read some more, was not sure what books to read. I'm looking for material that focuses on walls.

I know I will be limited on boiler/heater options since I will be using oil.

Suggestions?

Which type of drywall/cement board/wall board/plaster board or wall covering makes a better substrate over top of the pex?

I'm also open to different options as well-ceramic/z-brick/stone/metal-I've considered these depending on their effect/function-& they'd be an 'extra protection' over the wall.

It's an open canvas & I'm more interested in function as opposed to looks & am certainly not opposed to an industrial or rustic look.

Actually, I'm leaning towards metal for a 'wainscotting' more than anything & am curious how a layer of sheet metal over top might affect it's function.

LOL I find drywall pretty boring & metal would certainly deter nailing

I like the 430 as to will hold magnets for clothes hooks. The mirror finish will make the space seem larger.

I agree with ODR or constant circulation to limit wide temperature swings. The wide temperature swings can cause expansion noise with large metal panels.

Use pex al pex as it doesn't move in the plates as much and the bends stay put.

Not much on the design, 3/8 pex keep the loops 200' or less. 1/2 pex 250 or less.

Capco Energy in Woburn, MA has their entire counter are warmed with radiant wall. They sell several brands of the wood pre-grooved systems if you don't want to build your own with furring strips. Depends on how much hands on you want to commit to a home built system. They would do a system design for you.

Radiant walls can run around 110 for about twice the output of floors limited to 85°. Fast response time, easy to retro fit.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

SWEI-That project is really interesting. The pics are great.

I hadn't considered the C plates. Do you have a specific reason or preference for the C plates over the U plates?

What did you use to cut the studs-a fine tool or something else?

"The Universe Always Conspires to Help the Dreamer"

-Paulo Coelho0 -

catia1313 said:

SWEI-That project is really interesting. The pics are great.

I hadn't considered the C plates. Do you have a specific reason or preference for the C plates over the U plates?

What did you use to cut the studs-a fine tool or something else?

What about the integrity of the metal stud when you notch them? I suppose screwing the sheetrock puts some strength back into them?

Depending on the r value of the wall covering you have more conduction to the metal studs.

I think the U fin would be a cleaner, simpler option? Also the metal studs would need a thermal break or air space behind as they too will be a conductor, or transfer plate.

If you end up doing a lot, a palm nailer with a hard plastic tip makes easy work of tube installation. Hammers or mallets tend to bend or distort the plates if you are not careful.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks!catia1313 said:SWEI-That project is really interesting. The pics are great.

I hadn't considered the C plates. Do you have a specific reason or preference for the C plates over the U plates?

ThermoFin U would have been far easier. We bought eight foot plates from Watts and were not aware at the time that Radiant Engineering was the OEM (or that they made high performance U-plates.)What did you use to cut the studs-a fine tool or something else?

That was our second revision of the process -- two cuts with aviation snips followed by a steel stud punch (designed for cutting conduit holes.)

0 -

I'd like to see a thermo image of a light weight steel stud radiant wall application. I see it as beneficial for heat spread to the emitter surface.0

-

Lemme get over there on a cold morning with my FLIR...0

-

I think it may prove interesting.0

-

The studs get pretty squirrelly as soon as you cut/punch them. Once they're pop-riveted to the plates, the assembly becomes quite rigid. This is a high-traffic area in a hotel, so we covered the bottom 5 feet or so with metal lath and topped with stucco scratch coat. Above that is drywalled, then the entire wall is troweled and textured using a mixture of lime mud, drywall compound and concrete bonder. Finish is an ongoing process with many coats of lime wash.hot rod said:What about the integrity of the metal stud when you notch them? I suppose screwing the sheetrock puts some strength back into them?

the metal studs would need a thermal break or air space behind as they too will be a conductor, or transfer plate.

The photos don't show it very clearly, but there is a gap (ranging from about 1/16" to 1/2") between the steel studs and the hollow clay tile exterior wall. The new walls were stood up plumb and true and secured, then gaps were filled with cellulose.If you end up doing a lot, a palm nailer with a hard plastic tip makes easy work of tube installation.

We made a black walnut anvil for the Milwaukee M12 palm nailer and tried it on that job. It gave out halfway through so we reverted to mallets. The new one is UHMW PE and should hold up better.

0 -

Have palm nailer and will take that advice

pex al pex --agreed.

What effect do you think the metal wainscoting can have on top of the pex with aluminum plates?

I would think it'd heat up faster, but not hold as long.

Not sure what the positives/negatives might be.

Bear with me here,

I was wondering about the mass & how this might affect the function--would it function more like fin tube which doesn't do well at low temps?

I'm out of my element, so sorry if it's a dumb question, but it seems to me that if I am running low temps & transfer the heat too fast, it's gonna affect something, or do the metal plates somehow take care of that? Better to ask ahead LOL.

ODR is a definite, from everything I've read, I can't understand why people don't just get them in the 1st place-especially here, where one day it's -6 and the next it's 50 & nose dives again with the polar vortex.

So what is the main difference between the C plates & the U plates?

Aren't some types of aluminum better than others-I think I read that here-extruded is better?

Anyone know why? or is it a noise factor only?

"The Universe Always Conspires to Help the Dreamer"

-Paulo Coelho0 -

These are done using the technique SWEI described with radiant plates. We used plywood strips behind the plates.

The first pic was a false front cabinets with way hot water temps. The owner asked for it against my better judgement.

The other is a drywall wall being used to offset the cooling effect of the large windows. The primary heat is in floor radiant.The windows have automated reflective shades that are rolled down.

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

It's mainly about the tube fit. It needs to be a snug connection to transfer and also keep the tube from creeping.

The thin flashing gauge would "oil can" make that popping sound that an old oil can does. It would drive people bonkers.

You see here the importance of the fit and holding power. I would not scrimp in this area. See the gap in these graphite brand, not good.

I like the Roth panels also, but they would need ply backing, they are very thin under the tube. Easy to install and great aluminum transfer. A shot of the Roth panels in my tiny home.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

Wow-I am completely shocked at the difference in temperature between those plates, that is a LOT of degrees of difference. There will be NO skimping on plates.

Good to know about the tin canning--were you referring to using metal as wainscotting or to using plates that are too thin or both???

You used stainless in that one application-what is happening with that? Do you have a gauge that you wouldn't go less than?

Also am curious-how many sq ft is your tiny house?

My house is not 'tiny' but it is a definitely a very small footprint-the entire 1st floor is actually well under the 576 sq ft.

I just gave the outside foundation measurement (slightly less than 24'x24').

I didn't account for walls & stairs, chimney- I'm about 475 sq ft on 1st floor inside taking that into consideration, which will be my 'greatroom', 1 bedroom, bath & kitchen.

Heating source Question:

Since I will be using oil for heating fuel, it appears I am limited in options. I don't think there is an oil boiler made small enough, & a boiler isn't appropriate for low temp heating anyway correct?

I believe I may also have an issue finding an oil fired hot water heater small enough. Thoughts?

Question about pex al pex expansion-or any pex expansion:

If the pex is so tightly fitted in those plates-where is the expansion taking place?

"The Universe Always Conspires to Help the Dreamer"

-Paulo Coelho0 -

What are your LPG prices like there? A fire-tube mod/con boiler comes with all the controls you need and can be direct-pumped.catia1313 said:Heating source Question:

Since I will be using oil for heating fuel, it appears I am limited in options. I don't think there is an oil boiler made small enough, & a boiler isn't appropriate for low temp heating anyway correct?

I believe I may also have an issue finding an oil fired hot water heater small enough.

If oil truly is your best option, I would choose the smallest three-pass boiler I could find and use a buffer tank (possibly a reverse indirect) and an ODR-controllerd mixing valve.Question about pex al pex expansion-or any pex expansion:

With good quality plates and full ODR we have not had noise issues.

If the pex is so tightly fitted in those plates-where is the expansion taking place?

If you do use PEX-Al-PEX, make sure the OD is compatible with the plates you choose.0 -

Expansion of the metal siding will be an issue, as Kurt suggested run it constant circ or outdoor reset to minimize temperature swings. A company near me still stamps metal ceiling tiles, I'm anxious to travel up and see what they have for scratch and dents.catia1313 said:Wow-I am completely shocked at the difference in temperature between those plates, that is a LOT of degrees of difference. There will be NO skimping on plates.

Good to know about the tin canning--were you referring to using metal as wainscotting or to using plates that are too thin or both???

You used stainless in that one application-what is happening with that? Do you have a gauge that you wouldn't go less than?

Also am curious-how many sq ft is your tiny house?

My house is not 'tiny' but it is a definitely a very small footprint-the entire 1st floor is actually well under the 576 sq ft.

I just gave the outside foundation measurement (slightly less than 24'x24').

I didn't account for walls & stairs, chimney- I'm about 475 sq ft on 1st floor inside taking that into consideration, which will be my 'greatroom', 1 bedroom, bath & kitchen.

Heating source Question:

Since I will be using oil for heating fuel, it appears I am limited in options. I don't think there is an oil boiler made small enough, & a boiler isn't appropriate for low temp heating anyway correct?

I believe I may also have an issue finding an oil fired hot water heater small enough. Thoughts?

Question about pex al pex expansion-or any pex expansion:

If the pex is so tightly fitted in those plates-where is the expansion taking place?

Interesting on my tiny 160 sq ft and a 5700BTU/ hr heat load, I don't have enough open floor to cover that load,with cabinets fiberglass shower, etc. That is why I'm adding the small radiant wall section.

Be sure to subtract out any cabinets of furnishings the will not allow the radiant panel to "see" the space.

I think there is a time and place for a small electric boiler or heater for low load jobs. My tiny has a 1650W, 120V 6 gallon electric tank.

Small, readily available and easy to change to upgrade elements. A digital setpoint control runs it at a 15∆, wall t stat turns on the 6 gallon tank, pump runs constantly.

I know a contractor that uses these small diesel boilers for small oil fired applications, if you really want to be creative

\

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 52 Job Opportunities

- 19 Recall Announcements