Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Will a Danfoss ESBE VTC thermic valve used to control return temp lock up the system flow?

Options

weekendguy

Member Posts: 181

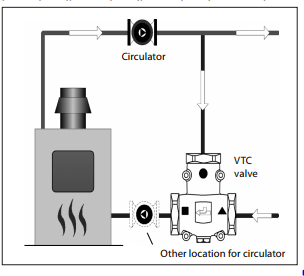

I have had an ESBE VTC sitting on my shelf for at least a year because I'm not sure it will do what I need. Since I am replacing the boiler in the next few months I have it penciled in to the new design. Before I go ahead I hope someone with experience can explain its operation - maybe I'm just reading the literature wrong. Here is my concern - if I have this sitting on the return side with a 122F element installed, it seems on the surface (and from the docs) that it will be open as long as the return water is >= 122F. It opens slowly across a 18F range so at 140F is fully open. When it's not open it will be in bypass where the system return water is blocked and it bypasses the supply back to the boiler return (is this correct? wouldn't this cause short cycling?) I just don't understand is how this valve works in a real-life system. I have 6 zones - all finned BB. If one gets turned on that's been off for a while, the return water can be, let's say 100F. So if that's the only zone open for some reason, how does the valve ever open? It will stay in bypass until warmer water arrives, but the warmer water can't get there because it's blocked by the cold water ahead of in the return line. It's like a lock up. What am I missing?

0

Comments

-

No, it's sensing temp at the mix port which means once the boiler gets 122* the valve will begin to mix return water from the system. When it senses 140*, it will be fully open to the system.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

@Ironman

Thanks for the comment. Help me understand. I attached a snip of the diagram from Danfoss.

Which one is the mix port? The left one entering the boiler? So as long as the boiler supply is 122F it begins to allow some system return water in? Is this example right: if the system return were 112F and the boiler was making 132F water, the valve would sense the average temp from its thermal mass and begin to open. So if the system return is very cold like 80F (this happens) how would it ever open?

Sorry I'm not getting this - when I called them the guy said "maybe you should put a small bypass around it so it doesn't lock up. - that way eventually warmer return water will arrive".

This just made me question its operation even more.

0 -

The valve doesn't "lock up". It's always open to one or both ports coming into it. The left port is the mix port in the diagram. It's so simple that you're missing it: it's a mixing valve; 2 ports in, one port out. A diverter valve is one port in, two ports out.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

@Hatterasguy Thanks for jumping in. This is similar to the discussion I had with the Danfoss guy where he suggested some minimum flow using a bypass. So I'm not sure if this will work for me.0

-

@Ironman For me to think about this as a mixing valve, I have to also recognize that it can be 100% closed to both entry ports. So whats happens when the valve is 100% closed to the system return water and can't open? What changes to cause it to open?0

-

It can NEVER be closed to both ports. It can only be closed to EITHER, not both.

Imagine a Y with a diverter gate in it. The gate can only be closed to one branch in the wye when it's fully open to the other branch. Or it can be anywhere in between allowing flow from both.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

@ironman @Hatterasguy When I look at this valve the element is right in the middle so I think it's sensing the thermal mass of the device itself rather than any port. I guess therefore that boiler water coming through the bypass will begin to average out the temperature and it will essentially modulate. I would be fine with just using it if the Danfoss guy hadn't started talking about bypassing it...0

-

@ironman I didn't mean 100% closed to both ports at the same time - I mean either could be closed fully. Sorry I was not more clear.0

-

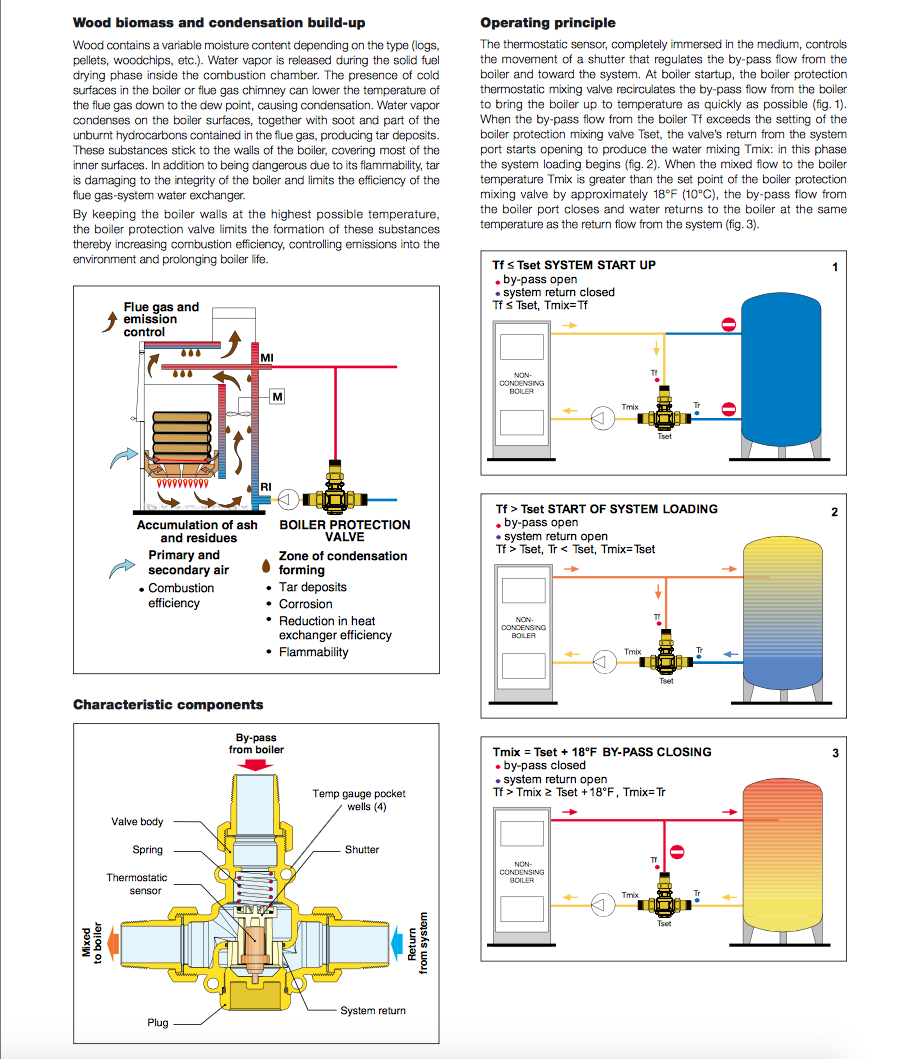

Some of those ESBE valves require a balance valve to "force" them to operate properly.

The 280 Caleffi, for example has a 100% shut off, designed specifically for the return protection application, no balance valve requires to make it operate properly.

Do they have a tech brochure like this to show and explain the operation?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot rod That is nice literature. The Danfoss literature is more primitive and harder to understand (I suspect you know that :-)) I have the ESBE because it was recommended on The Wall once otherwise I would look at the Caleffi. The designs are very similar as far as I can see mechanically. Thanks for commenting.0

-

There was someone over at the wood heat site that had more specifics on that valve. He may have been a dealer or Danfoss rep? Maybe you can search past posts over there.

Important to know about that 18° differential. I started with a 140° on my system. I found that the wood boiler control was starting to rev down before the bypass was closed completely. It has a variable speed inducer fan on the gasification.

A 115° plus 18° works ideal for bypass closure at 133° return at boiler.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot rod The lowest temp option I have with the ESBE is 122F-140F which seems a bit high but I'll see how it works.0

-

@hot rod - 'Some of those ESBE valves require a balance valve to "force" them to operate properly.' Do you know which ESBE valves require a bypass?

@weekendguy - I've been thinking of installing an ESBE valve for a while now so I would be interested to hear how it works for you. My CI boiler has a 110F minimum recommended return temperature so I put in a system bypass to help with this, but a thermostatic valve like the ESBE or Caleffi looks like a much better option for me.0 -

If you keep digging at the Danfoss site, you can find installation info. It looks like the smaller, basic valve requires a balance valve, instructions here.

http://products.danfoss.us/productrange/heatingsolutions/hydronic-comfort-controls/esbe-valves-actuators-controls/thermostatic-boiler-protection-valve/#/

Looks like the bigger series works without a balance.

Probably best to find a Danfoss rep to get clear on which valve you need.

I like the brass body version the we (Caleffi) offers. We looked at the other brands and designed for a simple, serviceable, long lasting design.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot rod Sorry about the delay - I just looked back at this thread. Thanks for your comments. The one I have is the VTC500 and I'm glad you conclude that it should work without a bypass valve.0

-

First, thank you @Hatterasguy and @hot rod for your advice.

Maybe I'm just dense here, but I'm still having doubts about using a thermic bypass valve. The installation is in a few days. Boiler is Burnham ES25 (cast iron). The system will run at 170F with a 30F diff (nominal) which means that 140F water will be entering the distribution piping (all finned BB). With a 20F delta-T, that means commonly 120F return water in every normal on/off cycle.

The lowest temp element I can get is 122F (for the Danfoss ESBE). That means that in every cycle, this valve will be completely closed at the end of the "off" cycle, stopping system flow, and causing the boiler to short cycle. Yes, I know that eventually it will warm up and open somewhat but it's fully closed at a temp which is higher than a common return temp. Seems like this will guarantee that system flow starts and stops during a call for heat. I know I can run the system at a higher temp but at some point that eliminates the need for the boiler protection valve and sacrifices efficiency. I know that the building can handle a design day with 157F average temp and I'm trying to minimize distribution loss.

If I scrap the valve, I'll see 70F water entering the boiler when a cold zone opens up. Burnham says this can take 110F return water. Will 70F be a problem? Gotta be lots of CI boilers out there without a high tech protection valve...

Anybody run into this issue?

0 -

You are way overthinking this, the valve does work as advertised, & your boiler will be much happier with the valve. The valve does NOT cause my boiler to short cycle.

TimWinter Park, CO & Arvada, CO0 -

Thanks for your comment, Tim. I may be overthinking it, and I am sure the valve works as intended, but I'm not sure a 122F valve is the best choice considering the temps of my system. Maybe you can help me understand this better - am I wrong that 120F return water will cease to flow if the valve needs 122F+ to come out of bypass? I also see that in the boiler installation diagram there is no discussion of boiler protection and I'm wondering if I should just leave it out. The Burnham rep told me the unit can handle a 80F Delta-T. I'm also toying with scrapping the Danfoss and trying to find the Caleffi 280 with the 115F element....

0 -

"am I wrong that 120F return water will cease to flow if the valve needs 122F+ to come out of bypass?"

no, you are basically correct, but the boiler does not take long to heat up the boiler loop to 122, then the valve 'starts' to open, only letting enough 122 water out to the load, BUT, the valve never lets the boiler go under temp by modulating (limiting) the amount of heated water delivered to the load, & only letting a controlled amount of cold water back into the boiler loop. Just like the t-stat in your car, tried & proven.

HR would be your source on the caleffi, but I believe the concept is similar.

good luck!Winter Park, CO & Arvada, CO0 -

@weekendguy, I have the same boiler and thanks for your postings concerning this valve. I would like to install this valve (or the Danfoss version) sometime before the next heating season. My only concern is should the thermostatic element fail, then would the valve be closed to the system with water circulating only in the boiler loop? That would be bad if the system was unattended during a cold spell.

Eric0 -

If you look at how the Caleffi valve works, it has an 18 degree differential. So if you chose the 120 element once the return goes to 138, the bypass is off 100%

I ended up with a 115 element as the 130 was allowing my wood boiler to rev down the fan too soon

The 115 + 18= 133, ideal for anti condensation operation for wood or most any other boiler

I'm not sure if your valve operates the same way, a tech brochure should indicate the operationBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot rod Thank you. That's my understanding of how the Danfoss ESBE works as well. I just wish they had the lower temp element. If I could do it again I'd get the 280. I think I'll go ahead and install the ESBE since that's all I have at hand and if I need to switch it up to the 280 down the road I will do that.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements