Radiant heat, modulating boilers & constant circulation questions

My LoopCAD drawing claims a required heat output of 31 k btu. I have an ~1,800 sq/ft ranch- above ground floor is 1k sq/ft and partial below ground (walkout) is 850 + garage. I am in the process of renovating 75% of the home so I am trying to air seal it (closed cell spray foam) and provide proper insulation to make this the most efficient install as I can get it to be.

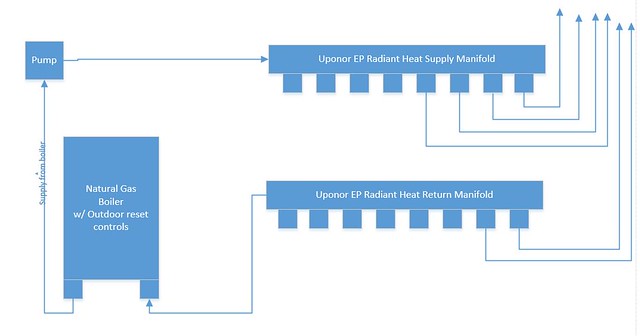

Currently I have Uponor 1/2" HE-PEX installed with a suspended pipe design using clips (more below).

Products I have purchased:

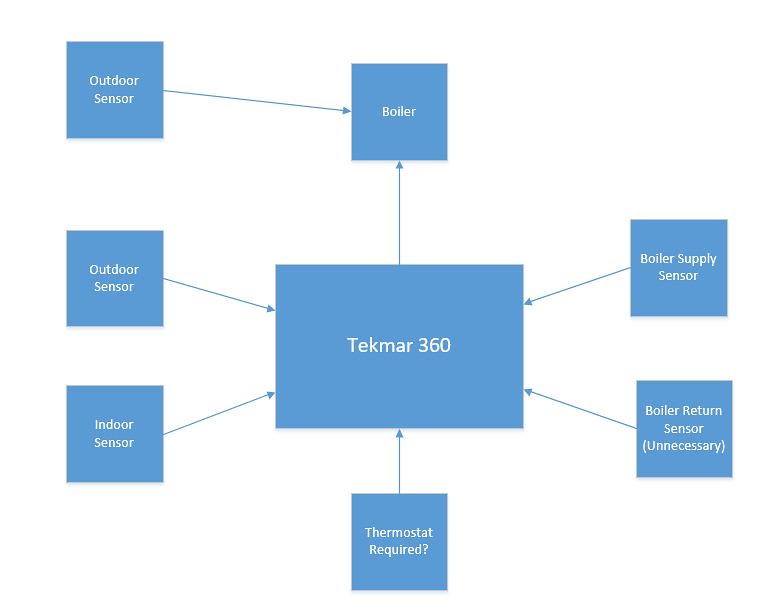

-Tekmar 360 Control with outdoor & indoor sensors

-Uponor EP manifold- 10 ports total

-Thin metal 4 ft. eBay heat spreader plates (4" wide), about 400 of them

-Grundfos 15-55F pump

Pictures of my piping design & control strategy are below.

I have a few questions:

1. I was told that doing the thin heat plates would be superior to a suspended tube design. Is this correct?

2. LoopCAD tells me that I should use 3/4" pipe to supply the manifolds due to an estimated flow of 3 GPM. If I make the radiant heat system the primary boiler loop is restriction of flow bad for the boiler? If I change to 1" or 1.25" primary piping is the lack of pressure bad for the manifolds? Maybe the solution is to make a 3/4" bypass with ball valve?

3. My control concept is to have the Boiler ODR determine the temperature of water to produce and the Tekmar to determine the calls for heat and fire the boiler based off feedback from the indoor sensors. Also this will prevent the boiler from short cycling (I believe?). Can I just jump the thermostat terminals on the Tekmar or should I connect them to my Nest Thermostat and use it as a high heat cutoff by setting it to say 75 when my Tekmar indoor desired temp is 70?

4. Recommendations on boilers? My plumber had me leaning towards a Navien unit and I would do a separate wall mounted on-demand water heater too. I've also looked into Bosch gas burners recently too.

5. Is a fully modulating boiler built to run 24/7 without input from my Tekmar or a thermostat but just operating off of an ODR control? I feel like this would be the simplest setup?

Comments

-

An "extruded"plate under floor design will out perform a suspended tube. However plated over the top is even better..not thin plates.

Be aware of floor covering r values which will reduce output, and response time of the panel.

Most mod/ cons come with onboard controls. Some can have up to 3 different temp zones plus DHW priority. So pay close attention to your boiler selections capabilities out of the box. Think carefully about control needs not price.

0 -

When you select the right boiler based on heat loss, and control strategy. Follow the boilers manufactures piping diagram.

3/4" copper pipe will deliver 45 kbtu at 2-4 fps

1" 72kbtu

1 1/4" 145k

1 1/2" 225k0 -

Why would you use a dedicated on-demand water heater for domestic hot water, instead of an indirect tank fired by the boiler?

31,000 btu heat loss indicates a small boiler is in order. NHB-55?Hydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg1 -

I agree with the above recommendations.

I am not sure why you are considering a mixing controller for a modulating, condensing boiler. It is more efficient and simpler to just modulate the boiler to the target temp.

Tekmar has other products that will handle that if the boiler you choose does not have the capability.

Your question about pipe sizing will be partially dictated by the boiler selection.

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Thank you for all the replies! I'll do my best to respond, but it seems that this all comes down to boiler selection (controls, piping and DHW). Could you guys recommend a few NG boilers that would work for my situation?

At first I was looking at a Navien combi-boiler, but learned that they do not modulate as low as the dedicated Navien boilers.Brewbeer said:Why would you use a dedicated on-demand water heater for domestic hot water, instead of an indirect tank fired by the boiler?

Opting for on demand instead of tank is really an issue of space. Why would a tank be preferred over a on-demand heater that can provide adequate temp raise & flow?

Are you saying thin plates will be LESS effective than suspended tube? My understanding from my reading online tests and the ASME study on heat transfer plates was (best to worst):Gordy said:An "extruded"plate under floor design will out perform a suspended tube. However plated over the top is even better..not thin plates.

tube in slab > warmboard style subfloor panels > extrude underfloor plates > thin underfloor plates > suspended tube > staple up

I was not planning on utilizing the mixing portion of the controller. The control was really purchased to prevent short cycling and the indoor feedback feature for the ODR curve. I only purchased the 360 > the 260 because I got a great deal on a new old stock unit ($200).Zman said:

I am not sure why you are considering a mixing controller for a modulating, condensing boiler. It is more efficient and simpler to just modulate the boiler to the target temp.

Tekmar has other products that will handle that if the boiler you choose does not have the capability.

I purchased this secondary control (instead of only utilizing the Navien's onboard ODR) because I was told by Navien's tech support that jumping the boiler thermostat terminals (instead of connecting a thermostat) would result in the boiler short cycling itself and I needed a control that would prevent that.

I had assumed the Navien ODR would modulate the boiler and the Tekmar would attempt to provide heat demand for the house (taking the place of a thermostat). Am I over complicating this and should just connect my Nest?0 -

The 360 is a mixing controller. It is also capable of basic on/off boiler control. I don't see how you will integrate it with a modulating boiler.

I would suggest looking into the firetube designed boilers like triangle tube, lochinvar whn and others. I would not consider anything other than a stainless heat exchanger."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

An indirect tank doesn't require separate gas line or separate venting, doesn't require regular annual maintenance, doesn't have sensitive moving parts to fail, and will have better high and low flow rate performance.doooglasss said:

At first I was looking at a Navien combi-boiler, but learned that they do not modulate as low as the dedicated Navien boilers.

Opting for on demand instead of tank is really an issue of space. Why would a tank be preferred over a on-demand heater that can provide adequate temp raise & flow?

And here is the video: https://youtube.com/watch?v=vffdymvjluk

Hydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg1 -

I always shudder when I hear light weight plates.

If you are going Mod/con the goal is designing an emitter system that uses the lowest awt possible. This promotes more time in condensing mode which takes you from upper 80's efficiency to mid 90s. Suspended tube, or staple up is a bad choice to achieve this. Will they heat the space? Yes, but at a hit to efficiency. You have a clean chalk board use it well.0 -

My issue is cost. The extrude plates are substantially more money (~$2,800 vs ~$500 I spent).Gordy said:I always shudder when I hear light weight plates.

If you are going Mod/con the goal is designing an emitter system that uses the lowest awt possible. This promotes more time in condensing mode which takes you from upper 80's efficiency to mid 90s. Suspended tube, or staple up is a bad choice to achieve this. Will they heat the space? Yes, but at a hit to efficiency. You have a clean chalk board use it well.

Do the thin plates work better than a suspended tube design?0 -

First, define light weight?doooglasss said:

My issue is cost. The extrude plates are substantially more money (~$2,800 vs ~$500 I spent).Gordy said:I always shudder when I hear light weight plates.

If you are going Mod/con the goal is designing an emitter system that uses the lowest awt possible. This promotes more time in condensing mode which takes you from upper 80's efficiency to mid 90s. Suspended tube, or staple up is a bad choice to achieve this. Will they heat the space? Yes, but at a hit to efficiency. You have a clean chalk board use it well.

Do the thin plates work better than a suspended tube design?

There were some made with thin flashing gauge material, forget those. They would make all sorts of noise when the heat hit them and poor heat transfer from tube to aluminum.

There is also a "lite" version of the popular, and original ThermoFin out of Bozeman, called ThinFin C. ThinFin is 3.5" wide instead of 4" and a .050 compared to .0625.

But the thick extrusion at the tube is the key to a quality transfer plate, that is the same on both.

I suspect most of the radiant companies buy that product.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

A plated install works better yes. However as @hot rod mentioned the key is how well the plate fits the tube, and how well it fits to the underside of the floor. Thin plates promote noise.

Conduction is king. Water to the tube, tube to the plate, and plate to the floor. Any gaps in that chain decrease output, and efficiency.

0 -

Here is what it looks like

Suspended tube, old Wirsbo method

Wirsbo in ThermoFin, even the screws become heat transfer mechanism

The last pic shows from closest

Warmboard

ThermoFin with copper tube, notice where tube is pulled from slot to make connections

Wirsbo in ThermoFin

Suspended tube

Staple up rubber Onix (with heat transfer staples

The left hand side of each has berber carpet, no pad . Same supply temperature, same flow rate.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It looks like the onix is the best at transferring heat to the plates. What are the 5 different types in the first picture? All wirsbo?

TaylorServing Northern Maine HVAC & Controls. I burn wood, it smells good!0 -

Copper in plates was the best output. Warm board was great also, but 12" OC shows some striping. Floor covering helps smooth out some stripping.

Notice on the Warmboard where I roistered through the aluminum. It cuts the heat transfer right out.

Suspended and staple up Onix were the bottom two performers.

With staple up Onix, the staples become the best transfer "medium". Bob "hot rod" Rohr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

HR, mind if I borrow those photos for educational purposes? VERY graphic.

Thanks for all you do for our industry.

ME0 -

Regarding the boiler controls:

I think you are over complicating this. As far as I know, the Tekmar 360 can't modulate a boiler. The boiler would still rely on its internal target setpoint to adjust the firing rate. The boiler target and the tekmar target would generally not be in sync and this would be counterproductive to the efficiency of the system.0 -

Sure, the RPA helped fund that project.Mark Eatherton said:HR, mind if I borrow those photos for educational purposes? VERY graphic.

Thanks for all you do for our industry.

ME

I have close up of the individual panels also. I'll find the original disc for best clarity.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Oh, I was confused as to which was which. Was that soft copper in extruded aluminum plates for the winner?Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

-

It was rigid type M copper. I crimped pex on the ends to make the connections to the manifold. You can see where I pulled the copper out of the groove a small amount to make the crimp connection. Once tight tube to aluminum conduction is compromised, the heat transfer goes away quickly.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements