Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

zoning with a pump

Options

larryjbjr

Member Posts: 69

For what it's worth, I think I'm starting to get this hydronic heating thing. It seems that my idea of pushing as much water thru the system as I could was not a good idea. So...

I'm looking to put my upstairs on a separate zone than the ground floor. I recently replaced the circulation pump on my system. So, I have an extra pump sitting around that works. Only thing is, it does 17 gpm. But, I don't think I need that much for my upstairs zone. I have 2 kick space heaters that the specs are at 3 gpm, and a cast iron radiator that I'm not sure what the recommended gpm is.

So, two questions for now.

1. What is the recommended gpm for a cast iron radiator?

2. If my pump is rated at 17 gpm, but I only need around 10 gpm, what would happen?

I'm looking to put my upstairs on a separate zone than the ground floor. I recently replaced the circulation pump on my system. So, I have an extra pump sitting around that works. Only thing is, it does 17 gpm. But, I don't think I need that much for my upstairs zone. I have 2 kick space heaters that the specs are at 3 gpm, and a cast iron radiator that I'm not sure what the recommended gpm is.

So, two questions for now.

1. What is the recommended gpm for a cast iron radiator?

2. If my pump is rated at 17 gpm, but I only need around 10 gpm, what would happen?

0

Comments

-

I am not sure what the 17gpm is referring to. Is that the max or is optimal flow for this circ?

You want to size the circ so that it is running in the middle part of it's range.

The required flow rate is related to the btus you are trying to move. BTU/hr = GPM x delta t x 500.

Example:

If you are trying to move 50,000 BTU/hr with a delta of 20 degrees, that would be 5 gpm

Another consideration is the size of the piping. With copper, between 2-4 fps is recommended. With pex you can safely go to 5 or 6 fps."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Zman

The 17 gpm is what the pump is rated at. Max 17gpm. It's a Grundfos UP15-42F. I'm assuming that, since it is a single speed pump, it pushes 17 gpm all the time.

I've done some reading on caleffi.com and saw that there is something called laminar effect that if you push water too fast thru an emitter that you actually have less heat transfer. So, I'm worried that if I hook this system up and it is pushing 17 gpm all the time, then I will get the laminar effect thing.

As for BTUs, at 3 gpm and 140 deg water my kick space heaters should be putting out just under 6k btu. Which is fine for my rooms are only around 175 sq ft each. I don't know what my radiator is rated for. But it's in the hallway. I have another room, the spare bedroom, which I haven't yet found a way to run a pex up to yet so it has no heat. I'm figuring if I need to heat it I'll use an electric heater.

For what it's worth, I have 2 Beacon Morris K84 kick space heaters.

My upstairs is only around 600 sq ft, so with the 2 kick space heaters and the radiator I should be fine. I am feeding the 2 kick space heaters with a 3/4" pex that splits into two 1/2" pex. The radiator is fed with a 1/2" pex.

So, am I wrong in my thinking that there is an ideal flow rate for radiators?0 -

No. There is a pump curve that will relate the the flow rate to the pressure drop. The 17 GPM is if the pump were pumping against no resistance at all. That will never be the case, there is friction generated by the water as it moves through the system, this manifests as a pressure drop and will lower the GPM that is actually moving. Pressure drop or 'head' is typically measured in ft of water column. 2.31 ft of head=1 psi. Do not confuse head pressure (in ft) with vertical height. The vertical height has no bearing on the pump's operation in a closed system like yours.larryjbjr said:Zman

The 17 gpm is what the pump is rated at. Max 17gpm. It's a Grundfos UP15-42F. I'm assuming that, since it is a single speed pump, it pushes 17 gpm all the time.

That being said, that pump will work fine, do as Hattersguy says and you will be set, though I will add, that once the rads are warm and you make an adjustment on the valve, wait a few minutes for the temps to equalize before you make another adjustment. I will emphasize what was said above, DO NOT USE A BALL VALVE!!! You MUST use a globe valve for this, ball valves are not designed in a way that makes them conducive to this type of adjustment. Essentially what you are doing with the globe valve is adding head (resistance) to move the operating point of the pump up its curve and lower the flow rate to the desired point (20 delta t should be ideal for your set up).

Here is a pump curve for that pump. Ideally you will want to run the pump in the center of its curve. You can see that the more head you are fighting, the lower the flow rate will be. The graph is in metric units, if you want to convert here are the relevant factors:

m^3/hr to GPM, multiply by 4.4

m of head to ft of head multiply by 3.28

http://product-selection.grundfos.com/product-detail.product-detail.html?custid=GMA&productnumber=59896171&qcid=147917176

0 -

@delta T

Now, that's interesting. I'm learning a lot from this.

So, if my calculations are correct, I figured my longest run to be 160 ' of pex and copper. I've heard somewhere on here to take that, multiply times 1.5 then multiply times .04 to get total head. That would give me about 10.8 feet of head. Looking at that pump curve would that give me only 3 gpm?

If so then that's not nearly enough....0 -

That is an old 'rule of thumb' formula, it tends to overestimate by quite a bit. The only way to actually find out is to measure every length of pipe, count every fitting, convert all your fittings into equivalent lengths of pipe, add it all up, determine your ideal flow rate, and you can figure out exactly what the pump is operating at. keep in mind that 3 GPM will deliver 30,000 btuh at a 20 degree delta T, that may well be more than enough. You would be surprised at how little flow you actually need. When you say radiator, I assume you mean a cast iron radiator. Can you post a picture of it? We can then determine what the output would be for that at 140 and tell you what flow rate you actually need.0

-

This one.

It measures 34" long, 21" tall, 5.5" thick.0 -

The "fast and dirty" calculation you are referring to, is applied after you know the required flow, and have sized the piping accordingly. Use an EDR chart to figure the btu output of your cast radiator. Those emitters, in series, pose other problems.0

-

"I've done some reading on caleffi.com and saw that there is something called laminar effect that if you push water too fast thru an emitter that you actually have less heat transfer. So, I'm worried that if I hook this system up and it is pushing 17 gpm all the time, then I will get the laminar effect thing. "

Larry, you have it backwards .

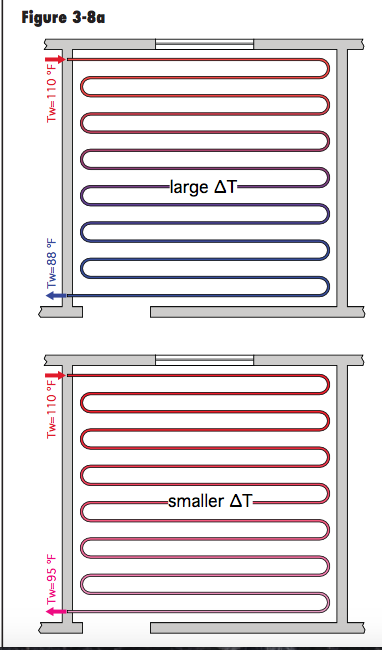

There was an error rendering this rich post.

1 -

> @bob said:

> "I've done some reading on caleffi.com and saw that there is something called laminar effect that if you push water too fast thru an emitter that you actually have less heat transfer. So, I'm worried that if I hook this system up and it is pushing 17 gpm all the time, then I will get the laminar effect thing. "

>

> Larry, you have it backwards .

Ok. How's that?0 -

The faster the flow through a heat emitter the more heat.

Turbulent not laminar flow transfer more heat from the fluid to the heat emitter surface. This is true for radiant loops, fin tube, air handler, radiators, any heat emitter.

Read Idronics 16 for more detail, on pump selection.

http://www.caleffi.com/sites/default/files/coll_attach_file/idronics_16_na_0.pdf

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok, I seem to be losing my mind....

I am certain I read on one of the idronics that laminar flow is when you push the water too fast... in my mind I can even see where on the page it was at. But, after searching thru every idronics I can not find it.

So, I'm wrong then? So, can you push fluid too fast thru an emitter? I mean, can you push so fast that it hinders heat transfer? Or...?

0 -

We talk about flow velocity and heat transfer in Idronics 16 and more about heat transfer in Idronics 12.

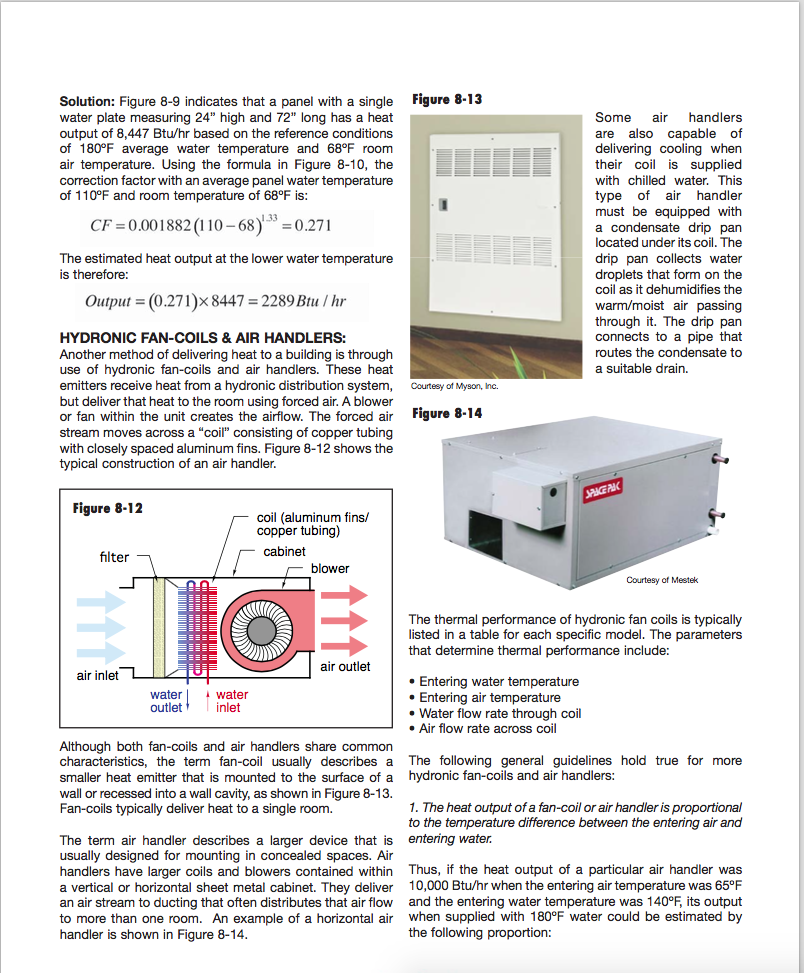

With any heat emitter designed for a pumped flow, increasing the flow rate will increase heat output.

We show examples with radiant slabs, fin tube and fan coils i Idronics 12 Hydronic Fundamentals.

As this fan coil graph shows, at some point the juice is no longer worth the squeeze. The additional pumping power to get small increases in output may not be worth it.

Generally the flow rate we design around is limited more by velocity. In 2" and smaller we suggest 2-4 fps, maybe 5 in pex tube with smooth wall.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 52 Job Opportunities

- 18 Recall Announcements