Moving from series loop finned baseboard to parallel cast iron - how to pipe?

Comments

-

@hatterasguy Thanks for the offer of the loan. Where are you geographically (NC?) I'm in SE PA.

I looked into changing the orifice and evidently my older unit has it welded in place. I need to look at the original docs that came with it to see if I can even make the change.

My installer friend said to just adjust the air to get a nice blue gas flame and tweak the over-fire draft. I'm not quite ready to tackle that anyway.

Many thanks- I'll keep you posted.

0 -

@Hatterasguy Ok - we have progress. I DID get an 0013 pump (by Friday) and I was able to order a new orifice for the EZ-Gas. Depending on how I drill it out it will either be 145K output or 130K.

Suggestions?

Also, either the propane company or my friend will set it up with a combustion analyzer so I won't be risking life and limb. Seriously though -- thank you for your concern.

I should get the 0013 in place Saturday and I hope I'll get the down-firing done next week.

0 -

@Hatterasguy Current output is 175k. Should I go to 145k or 130k? Depends on which drill bit I use.0

-

One way offers the option of trying both. The other is one and done.0

-

@paul48 Thanks for your comment. I'd like to shoot for where we think the output should be. I can redrill but it means disassembling again and scheduling installer to setup combustion and $$. Having said that I am shooting for the smaller hole (lower capacity) following advice from @Hatterasguy unless he suggests otherwise.0

-

Make sure the stack temperature stays good, if that drops too low your in trouble.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

@Hatterasguy I spoke to Carlin several times about this downfiring. Their unit can go as low as 98mbh input. With the diffuser head that my unit has installed their tech recommended to not go below 150mbh. Dropping 1 size takes it to 168mbh and 1 1/2 sizes is right around 150mbh. This gives the DOE of 130mbh (which is in between the 2 ES2 sizes). Based on my conversation with Carlin I feel pretty confident that combustion will be ok at that level.Hatterasguy said:

I am fully confident that the building will be satisfied with less than 130K on the design day. If the installer can downfire it safely to that level, please do so. Note that 130K is a significant reduction and it may be difficult to get satisfactory combustion at that level. Make sure you personally verify the CO.

This is good advice. I'll ask for before and after data and I'll take pictures. Carlin has specific levels stated for the parameters in their setup guide which I will provide to the tech.Hatterasguy said:

Have the installer measure the parameters (CO, CO2 and O2) at the current firing rate before the modification to be utilized as a basis for comparison. Any doubts............take a photo and post the results on here.

@Hatterasguy I would love to hear your comments on my other post about the flue liner.

http://forum.heatinghelp.com/discussion/160021/can-chimney-liner-be-sized-based-on-combustion-level-only#latest

0 -

@Hatterasguy Thanks again. Based on what I have learned, I think it will be oversized at 150/130 as well. If this is confirmed in practice on a design day, we know to go with the ES25.

Also - globe valves - can they be put on the return size of the loop with no difference in effect?

0 -

@Hatterasguy Thanks for researching this. This is consistent with what I understood. The only setting I changed from the defaults is the "increase response" setting that theoretically should make the speed changes happen sooner.

Did Dave Sweet talk about why the pump goes right on by the DT setting by 20 degrees before it starts to change speeds? Two calls and an email to Doug Bird at Taco and still no answer to this mystery...0 -

@Hatterasguy Speaking of Taco, I just heard from Doug Bird. He is baffled at the pump response to the temp sensors and agrees the data does not make sense. We agreed to touch base next week after the 0013 goes in to see if there is any change in performance. If not, he would like to try a different control board with a new design.0

-

@Hatterasguy So true... I was thinking about the test you described... a shorter zone should both respond faster and also not have head loss issues. I'll run that tonight since I am planning to change the pump 1st thing tomorrow. That said, the inability of the pump to change speed in response to temps seems unrelated... I should have some news tomorrow.Hatterasguy said:Well...........cannot make any conclusions until we can be sure the pump is of sufficient size for the EL. The DT will be all over the map if the pump doesn't have the capability.

Taco can't describe anything about the control algorithm. I'm considering making my own speed control but only if absolutely necessary... :-)

0 -

@Hatterasguy I actually looked at this same device last week. But I don't think it had a differential input. I figured I would have to make my own difference circuit and output a control voltage. The pumps are split capacitor types so would be easy to interface on that end. The motor control is the tricky part with AC so the Nimbus would be awesome. Are you using it on a hydronic circuit?0

-

@Hatterasguy What, no globe valves? :-)0

-

@Hatterasguy Plus an outboard controller is way cooler than a plain old valve...0

-

@Hatterasguy The plot thickens. I ran the short zone test for an hour last night and I had one critical observation - the pump is too big (I think you predicted this). There is no sweet spot for the ball valve. The SWT is going to vary by at least 20F. When it rises during a burn cycle, the DT rises and the pump speed increases and overpumps the zone. If I close the valve enough to correct this then on low speed it can't move enough water. This would not be a problem with a smaller pump. So... 0011 is too small for the long zone, too big for the short zone. No need to spend 2 hours putting the 0013 in place and bleeding the air. If I correct the long zone problem (questionable) I only make the short zone worse.

I went back and read what you said about the VR3452. I think this has the flexibility to handle my weird unbalanced system. If you concur I'm going to go that route. It's only $300 more than the 0013 and way worth it to me. As I read its capability, it will handle the unbalanced situation much better.

I can have one by Thursday. Reasonable?

0 -

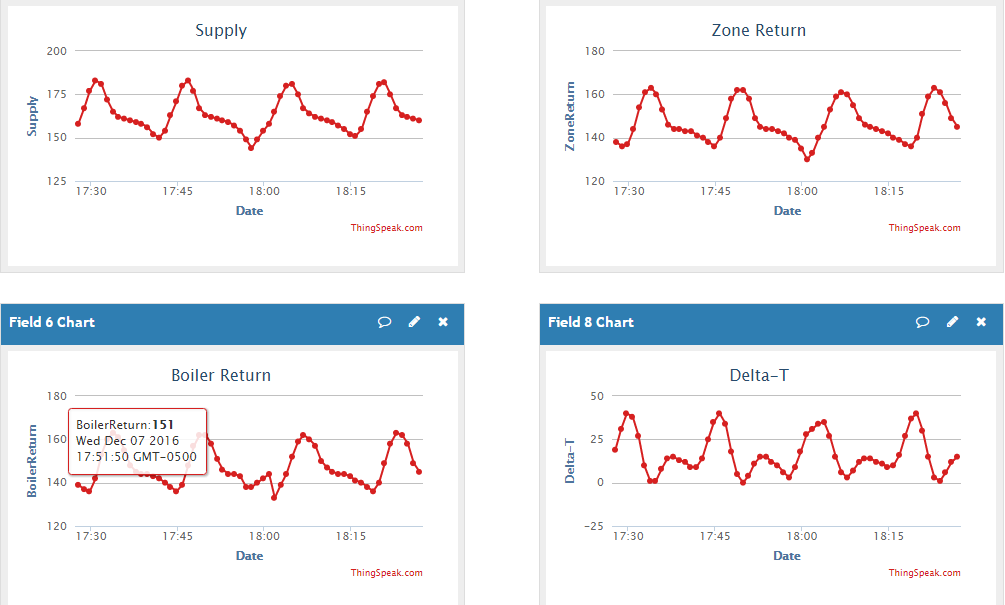

@Hatterasguy Attached is DT data from last night's "small zone" run. Does this look acceptable? Also I attached all data from a run I did this morning with 5 most likely used zones.

If you think the 3452 is even marginally better for the mixed loop sizes it's my preference since, if I understand it correctly, it will adapt to each zone and provide consistent flow. Please give me your thoughts - I am standing by with wrenches in hand...

0 -

@Hatterasguy I installed the 0013. Everything is coming up now. So far no air issues. I'll repeat the gpm test later today. Thanks.0

-

@Hatterasguy Using these constants you supplied from our earlier discussion and referring to the 1st floor long loop (120 ft BB), we have....

150F--------340 btuh/ft --------40,800

160F--------408 btuh/ft --------48,960

170F--------459 btuh/ft --------55,080

180F --------519 btuh/ft--------62,280

At 170F we can get by with 5.5 gpm which is what I now get (almost) from the faster circ. So we're within striking distance of supplying the long first floor zone (and way better than what was there for years).

The DT still fluctuates from 0-50 averaging about 25. It stays pretty steady until the boiler fires and then because the boiler is oversized and the SWT has such a steep slope, the DT rises sharply. Just to remove that somewhat, I set the boiler diff to 40F (140-180F) so we had some longer cycles to observe the DT.

You can see in the graph that during the longer off times the DT is getting reasonable. I feel pretty good that a boiler with a lower firing rate will help this even more.

How does this look?

0 -

That's nice to hear - I agree. I could never analyze this system without this data. I designed and built the unit last winter. It runs on an Arduino microprocessor for data aquisition and display and uses another microprocessor to send data to the cloud every 60 secs via WiFi. It has 7 temp inputs - 3 for heat - SWT, Zone RWT and BLR RWT. 4 more are used for DHW data (Tank, Hot, Mix, Return). It also handles the time of day "on/off" control of DHW demand and actively controls DHW recirculation. Picture provided below...Hatterasguy said:Those graphs look fine. They really are excellent to view the system in real time.

1 -

Nice screen/keypad. Is it custom, or an off-the-shelf piece?0

-

@ratio I just used standard stuff available in the hobbyist marketplace. The box was the biggest ticket item at $14.0

-

@Hatterasguy I set the diff back to 20. Tomorrow I'll run all zones in "recovery " mode and see how the data looks. Thanks for the guidance.0

-

I'm not ready to conclude this yet. When I see how slowly the speed logic responds I don't think we can blame the pumping power itself. I was aware of how much faster the building recovered this morning which I think can be attributed to simply moving more water.Hatterasguy said:@Hatterasguy I don't have much confidence that a 0013 VDT pump will improve the performance. The pump response is simply too slow to manage the climb of the boiler from LL to HL.

I have some ideas on how to take over the speed control since I already know the deltaT. When I get some time I will set up a circuit which will allow me to select the speed manually and I will see how much improvement I can make in the DT. If it's decent, the next step would be to automate the response.

0 -

@Hatterasguy The 0013 IS a VDT pump. I guess I am saying that I don't think the DT algorithm is very good. Take a look at this graph of the 1st floor long zone running. Instead of the DT varying widely from 0 to 50F, as it has been, you will see that it stays much better centered, and hangs around between 12F and 40F.

You'll laugh when I tell you how I got this to behave better. Starting at 9:15, I took the sensors off the pump and created my own fake DT values. I watched the displayed DT, watched the pump speed, and I varied my "fake" DT to better match the speed with the size, direction and slope of the DT.

So if in the first attempt it's that much better, I think its realistic to think I can come up with an automated way to control the speed.

But I really need to do some more productive (non-boiler) work! So until I get the downfiring done (so far no tech has agreed to set it for me), I think I'll just let things be as they are. I hope I can get somebody out here this week, or I may just have to buy my own analyzer...

Thanks again for your ideas and advice.

0 -

@Hatterasguy Thank you. If you should come across a PSC motor speed control that takes a control input, I'd be interested. It would be much more effective to have the algorithm actually control the speed, rather than just pretend to be a sensor.

It's like trying to steer a car from the backseat with a rope tied to the steering wheel.

0 -

-

@SWEI Thanks. This is perfect but I don't see how to get a few of these for lab use. Do you know?0

-

No minimum for your first order -- call them up and give them a credit card. I'd suggest the J-box version unless you have an existing enclosure with space available.

Be aware that your turndown will be limited compared to a VVF.0 -

@Hatterasguy If the appointment is kept I'll have the boiler running at 150K input by this afternoon. I'll be interested to see how the DT looks. In the meantime I ordered a Nimbus and I'm working on my own algorithm a bit in my spare time. A few questions:

1. I can make the algorithm aware of which zones are calling. That way I can modify the responsiveness. I have to think that through some more. Would this be valuable do you think?

2. Also, just to clarify circulator operation... if the long zone which requires overcoming more head loss is running at max flow, and one of the smaller zones opens it does not affect the flow in the long zone, correct? This plays into #1 since the response adjustment needs to hinge on either (a) the sum of the length of all open zones, or (b) just the longest open zone. I think it's (b).

3. Is there any reason to conclude that the 0013 does not provide any benefit? I don't see any change to the short cycling nor to the DT. I did measure the flow rate to be somewhat better in the worst zone so that may be a reason to keep it. The globe valves are on their way. It occurred to me that I could also add one to the longest zone in case I needed to throttle the 0013 system wide.

4. I have ordered "proper thermowells" as you called them. They have a 1/2" NPT outer thread. I was planning to use 1.25" x 1.25" x .5" tees and place one thermowell in each tee. Do I need to be concerned that it will impede flow? There will be two back to back on the supply and the same on the return.

0 -

@Hatterasguy Thank you. There are 6 zones in total -

69mbh, length = 270 ft

29mbh, length = 250ft

32mbh, length = 120ft*

15mbh, length = 60*

15mbh, length = 120*

15mbh, length = 100*

Total = 175mbh (raw numbers at 560 btu/ft)

*estimated length - I will get better measurements.

Does this shed any more light?

0 -

@Hatterasguy Gotcha. I ordered 6 valves so if they ever get here I'll get them put in.

The downfiring is done and set up. Dropped firing rate from 203 to 155. The boiler is obviously quieter. Rise time is still pretty short - so far I don't see longer run times. Tomorrow AM I'll do a 6 zone full recovery and check duty cycle. Right now the supply is ranging from 150 to 180 (actual temps considering over/under shoot). Leave it here for the recovery test?0 -

@Hatterasguy 190F for the setting or 190F as the actual high temp? (it overshoots 5 deg).0

-

@Hatterasguy will do and will report. Actual stack temp dropped from 325 to 300 due to the downfiring. Concern? Flue liner is only a few weeks away.0

-

@Hatterasguy Ok - second liner quote is coming next week and then I will pull the trigger as soon as contractor can be available.

Also - here is live data with only the long zone open.

Not great DT, but better and looks like an average of about 20... This boiler is now a 155mbh input and the ES2-5 is about 10% smaller at 140 so I presume this can only improve...

0 -

@Hatterasguy Take a look at this - I finally decided to run the 0013 on high only to see how much heat I could get out of the boiler. I think it performs way better than VDT mode. Check out the graph - the DT is no worse than in VDT mode - slightly better actually. And the run cycles are longer. I'm thinking get the Nimbus installed and find an optimal single speed. Am I looking at this correctly? I'll try the all-zone recovery tomorrow AM and then Friday I'll do the same on high speed only to compare.

High speed:

VDT mode:

I should add that the area around the boiler is not as hot when on high speed only - less standby loss...?

Also I can open up the diff to extend run time if needed...

0 -

@Hatterasguy Ok - new data! This is quite interesting. I attached a graph of a full recovery this morning (all 6 zones). It was 30 degrees ODT. I opened up all 6 zones and watched it - the boiler ran 33 minutes, shut off for 4 minutes, and then came back on. It was just about to shut off again when I realized the 2nd floor zone had no hot water flowing. Despite the end switch closing the zone valve was stuck shut so I opened it manually. Of course this dropped the RWT and the boiler had to work to overcome it. I let it run all together 65 minutes and it was only off that one time - so 61 min on out of 65 total min = 94% duty cycle. This sure suggests to me we don't want to drop the size much more - right? DT looked really good as you will see. The 0013 is a keeper. Obviously we had a lower average SWT than you wanted because there was no overshoot and we only reached HL once. It was set to 185/165 and if it were higher the boiler may not have shut off at all.

This really puts a spotlight on how problematic this one primary zone is when using only 40% of the boiler capacity. It forces such a short cycling problem I think everything else is downstream of that. One thing I could do is to add more baseboard. This is not as bad as it sounds since the installer left whole long sections of enclosure with only pipe running through them - rather than drill through the floor and run it below. I can just replace the pipe with element. Obviously I would split the zone in this case to get more btus moving at the max flow rate. Also I am planning to blow the dust out of the existing fins.

The tech that set up my downfire yesterday was pushing a mod/con. I explained to him that the relative benefit of the "con" is pretty limited with the low mass fin tubing - he was skeptical. But the "mod" part could be beneficial in adjusting the capacity to the zoning load. I really wanted to avoid an overly complex product but do you think I should reconsider? I would keeps the temps pretty high anyway considering the finned emitters.

Sorry about the long post - lots happening here. Also, I made my wife wait to take a shower so the DHW demand did not influence the recovery profile. But in sizing the unit I will need to consider the btu requirement of the indirect tank (which I plan to replace). Also - only 1 zone (closest, small) satisfied during the 65 minutes. The 1st floor zone was coming up from 63F to 68F and was at 65F after the test. It hit 68F at the 1:45:00 mark - so more emitter might not be a bad thing?

0 -

@weekendguy, Being a data junkie, I have been following this thread with interest due to the plethora of great data you have been collecting from your system.

Fin tube baseboard, when properly sized for low supply water temperatures, will allow a mod-con boiler to run at condensing temps. The critical part is to have an accurate room-by-room heat loss calculation and an accurate emitter survey. Also, running a deep setback (more that a couple of degrees) on a mod-con can be problematic.weekendguy said:

The tech that set up my downfire yesterday was pushing a mod/con. I explained to him that the relative benefit of the "con" is pretty limited with the low mass fin tubing - he was skeptical. But the "mod" part could be beneficial in adjusting the capacity to the zoning load. I really wanted to avoid an overly complex product but do you think I should reconsider? I would keeps the temps pretty high anyway considering the finned emitters.

As an example of what can be done with low mass fin tube baseboard, at an ODT of 32F, my system runs a SWT of 106F (Loch WHN055 assuming 93% efficiency at 20% fire is 10,230 BTU/hr, through 95 feet of baseboard is about 110 BTU/hr per foot). It can take up to 4 hours to recover a 2 degree setback.Hydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg0 -

Another thing I've wondered about off and on as your thread has progressed, is if it would make any sense to run your long zone off the more powerful pump, and run your short zones using a separate, smaller pump.Hydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg0 -

@brewbeer We sure can spend alot of time thinking about our heat, huh?

The guy yesterday asked me why I built a controller and why I log several points of data to the cloud every minute. I really didn't have a rational answer (if you have to ask...). Data junkie pretty well captures it. I guess you just have to be slightly obsessed with your boiler.

The guy yesterday asked me why I built a controller and why I log several points of data to the cloud every minute. I really didn't have a rational answer (if you have to ask...). Data junkie pretty well captures it. I guess you just have to be slightly obsessed with your boiler.

Anyway, thanks for your comments. Your system is quite impressive and I would love to see it up close sometime. If I were starting from scratch I'd want to have some major conversations about it. But I'm at the point where I can't really do my whole system over without an unjustifiable major expense and I'm past the age where I can put 30 hrs of work into my house on a weekend. So I'm just trying to right some of the wrongs and get the overall fuel usage a bit better controlled. This is all with the thought that a new boiler is right around the corner for me. I'd rather put in a new one proactively than wait for the current one to start to leak.

I started this thread thinking about possibly changing out the finned tubing for cast iron but the cost is just a non-starter. Hatterasguy has been helping me analyze this data to try to make the best of the situation. As you probably noted, we now can see the impact of reducing the input from about 200K to about 150K. The cycles seem much better and FINALLY I am seeing a respectable DeltaT when several zones are calling. It's only been a day but It seems like a good move. The boiler was built to be 245K and is now running at 150K. Yes, this was oversized...

Regarding multiple circs - I have thought about that as well - there are 2 fairly long zones (270 & 250 ft) that would probably do well on the big circ. But Hatterasguy has convinced me that as long as I balance the head of the smaller zones that they should work fine on the single circ. I ordered really nice globe valves for balancing but they're backordered and I probably won't get them until the end of the month. Then I can tweak the balance and I'll assess if the single circ solution is workable.

The way we use the house (our 4 kids are gone mostly) is that we heat the first floor primarily - that's the one long zone that tries to put out 65mbh if the flow will enable it. Clearly the length of the zone and the amount of baseboard has been an issue over the years. The main problem now is that when this zone is calling alone, which is probably 80% of the time, the boiler wants to make way more btus than the zone can emit. This makes for serious short cycling. The bigger circ definitely helped but not enough. I'm thinking of adding 20% more BB and splitting the zone to help with this issue - looking for opinions on that.

I was actually thinking of adding a storage tank to store heating zone water - this would act as a buffer and allow the zones to draw what they need and also provide the boiler a place to put a bunch of btus on a 15 min running cycle. There may be dozens of reasons why this won't help but I haven't completely ruled it out. I don't think the tank would need a heat exchanger -it could just be in/out storage. I'm curious what @Hatterasguy thinks since he seems to have a direct line to the Roman God of Boilers (is that Lochinvarius?, Buderius?). No, wait - it's Uticas!

No, wait - it's Uticas!

Seriously, if there were such a thing as a "mod" without the "con" I would be interested, Allowing the boiler to only fire at the needed rate would solve the short cycling problems, assuming the controls can effectively communicate the system needs to the boiler. I know you have baseboard working at low temps but you must have lots of it. I think with my situation I'd want to keep water at 155 minimum to create sufficient temp differential to make convection happen. At lower temps I just watch the RWT come back at the same temp as the SWT - I know the btus are not getting out.

So a mod/con that I can keep from condensing might be an option - I honestly am not up to speed on them enough to know at this point. Can you set hi/low limits between 155 and 185?

Thanks for your help. I started reading Dan's books close to 20 years ago and this site with guys like you and Hatterasguy just helps me extend that knowledge. It's awesome!

0 -

Mod-Cons can fire up to 180F and down to below 90F or so for spaceheating water depending on your ODR curve or without ODR sensor- via direct hi/low limits.

But, from what I've read- they use the condensate to 'wash down' the HX, so running in non-condensing mode exclusively might be damaging? Probably best to run this by one of the mod-con manufactures for their opinion...0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements