Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Dunkirk High Efficiency Boiler Issues

Options

EAnderson

Member Posts: 5

Hi, my 1914 build house was recently renovated, all new wiring, plumbing, and heating. We are having issues with the heating system. We had a high efficiency Dunkirk boiler and boilermate installed. It has not been used frequently over the past two months (length of life) due to a warm summer and fall, but recently we had a lockout alarm ( A06 Safety Relay error). The system shut down and we had to have out contractor return to service it. He told us a pump blew because we had the heat turned on in a room and it could not meet the demand. This explanation puzzled me as all heating controls were definitely off. The alarm has not occurred again, though. Now we are dealing with a frequent loud knocking. It seem to occur when the heat system is running, dishwasher running, washing machine is running, or any combination running every few hours. Once again, the contractor came to repair it, but it was a day when the boiler didn't have a demand to run anything - heat, dishwasher, or washing machine. The service man then proceeded to turn the boiler switch on and off about a dozen times and kept pulling a valve open and closed to replicate the noise. I confirmed the noise sounded similar to the valve lever being pulled to the close position abruptly while the boiler was running. Since then, he has said there is nothing wrong with the boiler and we will have to live with the knocking. Does anyone have any insight into this? This knocking actually is able to wake us up in the middle of the night two stories up .... Any help would be greatly appreciated. Thanks.

0

Comments

-

First, your service man is clueless. Second, you'll need to find a COMPETENT tech that's familiar with the equipment. Third, the pump didn't "blow" from being turned on too long: they're designed to run 24/7 if necessary. Fourth, the knocking could be from any number of issues including: steam flashing in the boiler's heat exchanger or an improperly installed zone valve. It could also be something that may be resolved in the boiler programming. There are too many possibilities and no where near enough info to attempt a diagnosis from an Internet post.

I would recommend that you try the contractor locator on this site or contact Utica tech support for a contractor recommendation.

If you'll post some pics of the boiler and its near piping and controls, we may be able to get a better idea of what's happening.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Ill be able to post pictures in a few hours. thanks!0

-

Here are photos of the system:

0 -

-

I see several possible issues.

What size is the boiler (btu rating or model number)?

As kcopp asked, was the internal check valve removed from the circulator?

What's the model number on the Taco circulator? It looks like an 011. If so, it could be too much circulator when only one zone is calling.

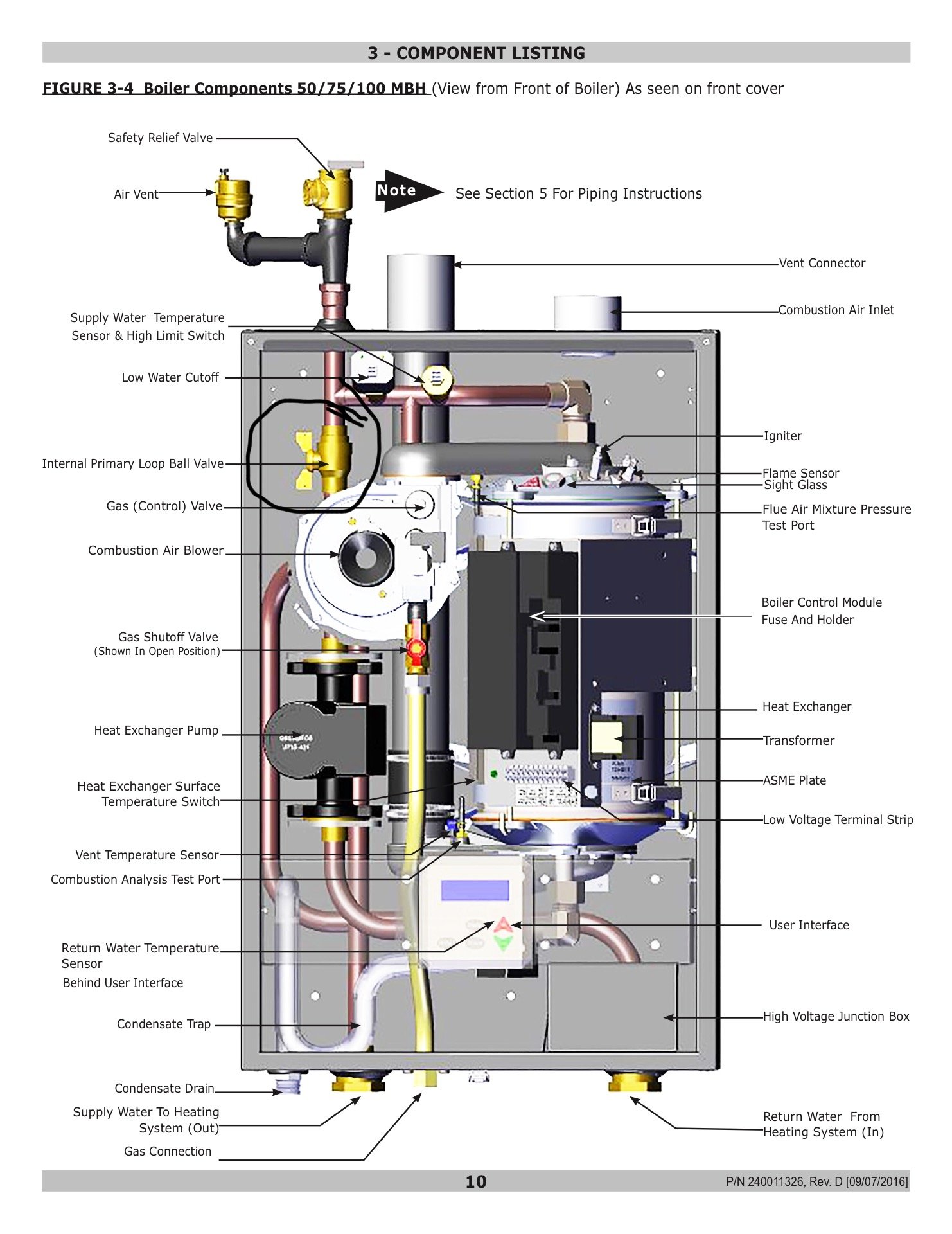

There's an internal ball valve in the boiler that should be open with the type of piping arrangement that you have. See the attachment.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

So it looks as though the internal ball valve is open. Picture below. Picture of Taco model number and Dunkirk model number below as well. Is there a way that I can check if he circulator was removed or do I absolutely have to ask the contractor?0

-

-

a 0014 circ is much too big. Was this a gravity hot water boiler?0

-

That circ comes with a check valve installed. If he didn't remove it, that's probably your problem.

The other thing would be to make sure that the pump is programmed to stop when the zone valves close. It should NOT be set to post purge.

Zoning up a mod/con is poor design, especially with six zones. The boiler is gonna short cycle a lot when only one or two are calling.

Also, the 014 Taco is excessive when only one zone is open. You'd be better served with a delta P ECM pump that will modulate with the demand.

You need to consolidate those zones as much as possible or install a buffer tank to prevent short cycling.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Hello,

Just got a Dunkirk DKVLT-075 installed and keep getting error code E36 - low water cut off (lwco). Purged the system and we know it's full and really never hear any pressure being released. The lwco device is sitting properly between 5 & 15 degrees up/back. After many tests, resets, and checking over the system we've come to the conclusion the lwco device needs replacement. I've gone ahead and disabled it in the configuration menu for now as I am not fearing the water is low. A new lwco device is on order but I was wondering if anyone out there has run across this issue or has heard of this lwco device being an issue?0 -

I would not recommend disabling a safety - particularly a LWCO.

Is the knob open on the auto vent on top of the boiler? You may have air trapped in the top.

What's the static fill pressure?

You should start a new thread.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Pressure has been good 18/20. The high vent was open for airflow but after reading your message we checked it and there was some debris. Cleaned that and the lwco probe - kept the zones isolated and flushed boiler real good again. Seems there may have been some little junk still hanging around in there? It was acting right so we enable the lwco device and it seems to be running good. Time will tell and the new lwco device may end up in the stock box of misc parts for the house! Thanks for your feedback. Right now all seems good. I will post another update should the status change.... and I'll try to figure out how to start a new thread then!0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements