Variable speed air handler settings

Comments

-

You need to wear less clothing in the homestead.0

-

I am all for it. Note I can not see @chrisj from my house.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating3 -

Nice.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

81F 64% outside right now.

Nothing has had a break, first floor is 76F.

I can't wait for winter.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Not exactly. I like 70 and keep the bedrooms around 64f using TRVs. The wife likes 72f likely due to cold floors in the kitchen and cold walls and windows everywhere.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

That certainly is Kurt.0

-

I think I may have found what I've been looking for, but I'm confused. Why would a 14 SEER unit have such a huge difference between high and low output while a 16 SEER doesn't?

I assume these are all sensible cooling numbers?Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

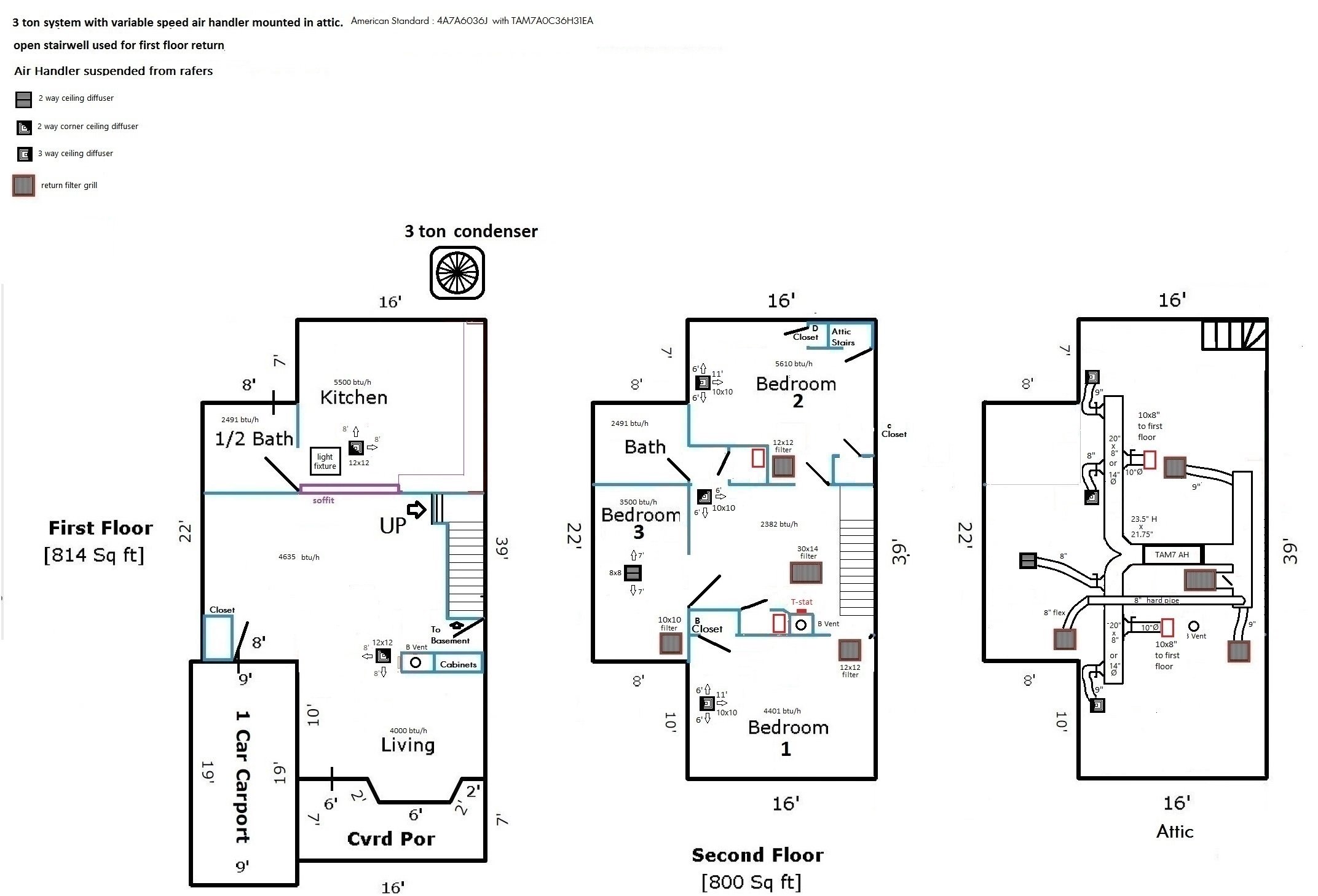

How's it look?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Wait you added a furnace to the equation? That makes me sad.1

-

-

I'm over here spending weeks trying to get my runs of flex as short and straight as possible, meanwhile that disaster pops up on my facebook.

Right now it looks like most of mine will be 2-3 feet and likely dead straight. I don't want any longer than 5 feet if I can avoid it.

Also considering R8 fabriflex for it's acoustic properties.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

ChrisJ, my friend, What system has ONLY 5' of duct run? My mind's eye is fuzzy here? Are you using "dampers" on each and every takeoff?0

-

@TechmanTechman said:ChrisJ, my friend, What system has ONLY 5' of duct run? My mind's eye is fuzzy here? Are you using "dampers" on each and every takeoff?

5' or less of branch run which will be R8 nylon flex duct pulled tight and fairly straight.. The trunk is to be hard piped, I believe 14" round and about 15 feet in each direction. Dampers at each branch, I'm hoping for bell mouth connectors, but we'll see what I can find and the cost etc.

I expect the trunk and any steel ducts to be made from 20 gauge galv sheetmetal which a friend is helping me with. We're using 20 gauge because that's what he buys in bulk. I've got two 10" round runs to the first floor which will be hard piped as well as an 8" return that I need made primarily metal (about 10' run) with a short flex connection at the ceiling box.

Everything is being done with ceiling diffusers and all returns will have filters.

Oh, and I'm planning on plumbing a Megnahelic into the return so I can monitor my filter life. The steam system has one, so why not, right? The wife already OK'd a panel mount version in the wall.

The steam system has one, so why not, right? The wife already OK'd a panel mount version in the wall. Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Stuff is finally starting to come in. Nice!

So far, the two 10" 3 way diffusers for the two large bedrooms, the 10" diffuser for the middle area and a 10x10 filter grill for the small bedroom are here.

Feels kind of odd buying air conditioning stuff as fall sets in, but I'd rather be doing it now than in the spring.

Next will be two 12x12 filter grills, a 14x30 filter grill, 8" 2 way diffuser and two 12" two way diffusers.

All rectangle duct a friend is helping me fabricate from 20 gauge steel.

Here's my plans after many many changes. They're not perfect, but I'm happy with it overall. Thermostat location isn't finalized yet. The btu/h listed is from the heat gain survey and I don't necessarily agree with the numbers. For example, I feel a few are too low, and others are too high etc.

All flex connections are short and will be made using Hart & Cooley F218 flex, fairly straight and tight with 90 and 45 metal elbows were required. I tried to get nylon flex acoustic duct, but had issues. My duct losses should be reasonable as most of it is oversized, for example I expect 9" flex to carry 175-190 cfm. 8" 120-130 cfm etc. The system should flow fairly nice.

The 10" 2 way diffuser is actually on the large side for the middle area on the second floor, but I didn't want to be launching cold air at the big return any further than I had to. The 10" will only throw 5 feet or so. All other diffusers will be operating at a higher velocity.

I also want rubber duct isolation at the air handler, which isn't shown in my drawing.

I also have a Magnehelic coming to permanently plumb into the return for filter monitoring. The boiler has one, so why shouldn't this?

Like I said, it's not perfect but I think it's the best I can do at a reasonable cost for my family's wants and needs.

@JUGHNE Thank you for recommending using closets for duct work etc, before that I had never even considered it.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

Still going to disagree with such statements.JUGHNE said:IMO using a little extra length of flex helps to reduce the noise of air flow. FWIW

We are probably anxious to get the reports next summer on humidity control in your house.....with the over sized capacity and all

Since my operating temps are always lower, my system will be no more oversized than anyone else's. Not to mention the air handler has a dehumidify setting that will run it on it's lowest speed setting.

Also just ordered one of these bad boys. I've already got a 0 - .25" but I'm thinking this one will work nice piped across the air handler permanently.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I service the HVAC for 4 phone "switch" buildings. These were formerly owned by the Bell/AT&T system. I can see the remains of their air filtering monitoring system. They used a pre filter before the main filter. Pressure transducers would see the difference as the pre filter plugged. Also they could see if the indoor fan was running. The Midwest area was monitored in Denver, (600 miles from me), I think they got a good deal on dedicated long distance lines. This was all done thru an "Andover" system.........all this technology has been replaced by me

.

.

Your filter grills will only handle a 1" filter?? You could put a high Merv 5" filter right at the AH also. If your blower had the stones to handle the increased static that is. You could monitor the drop across that mega filter to see change as the 1" plugged.

General Filters has a whistle to install and adjust to tell you when your filter needed attention. Have some but never tried them.1 -

I've thought about running a filter at the air handler as well, but I'm concerned it would just be too much load on the blower?JUGHNE said:I service the HVAC for 4 phone "switch" buildings. These were formerly owned by the Bell/AT&T system. I can see the remains of their air filtering monitoring system. They used a pre filter before the main filter. Pressure transducers would see the difference as the pre filter plugged. Also they could see if the indoor fan was running. The Midwest area was monitored in Denver, (600 miles from me), I think they got a good deal on dedicated long distance lines. This was all done thru an "Andover" system.........all this technology has been replaced by me

.

.

Your filter grills will only handle a 1" filter?? You could put a high Merv 5" filter right at the AH also. If your blower had the stones to handle the increased static that is. You could monitor the drop across that mega filter to see change as the 1" plugged.

General Filters has a whistle to install and adjust to tell you when your filter needed attention. Have some but never tried them.

I'm planning on MERV 8 filters in all of the return grills.

Besides the 0 - 1" Magnehelic, I also picked this one up. I think it may be too sensitive though, but may work to monitor a single filter, such as one back at the unit?

It came with the Dwyer case, the hanging standing bracket and 2 lengths of hose which is nice.

I've got an issue with buying these things, I'm up to three now.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@ChrisJ that gauge you have pictured is the one we use to measure the differential pressure of the finished product handling rooms that have multiple filters.Very nice gauge. Our spec to use the room is a difference of 0.05 in or higher. They usually sit around 0.1 to 0.4 with a short length of 1/8" inch tubing. I'm sure you could set it up to put on your manifold that will house your steam gauges too

You can have it good, fast or cheap. Pick two1

You can have it good, fast or cheap. Pick two1 -

So,

To continue this where I'm at now, I've found Carrier (actually, Tempstar in my case) gives a hell of a lot more information on their products which is nice. I ended up looking at Tempstar because a local distributor in our town that I deal with a lot sells them.

I'm a bit confused on why they list several different size air handlers for each size outdoor unit. Meaning, a 3 ton outdoor unit coupled with a 2.5 ton, 3 ton, 3.5 ton and 4 ton air handler, or as they call it, fan coil.

It looks like the 3 ton and 3.5 ton indoor unit running at 3 tons both provide identical results? Is this the case, or is there far more to this story?

The units I have highlighted aren't variable speed, but rather use X13 motors.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

May be a stupid question but I'm having a brain fart.SWEI said:The different coils are going to give you different SHRs.

Isn't S/T on the chart for sensible vs total? Meaning they're all 0.74 so they claim there's no difference.

25,308 sensible, 8,892 latent if I understand correctly.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Larger evap area = different temps. I'm a bit outside my knowledge envelope here, but Harvey will know the correct term to use.0

-

True,SWEI said:Larger evap area = different temps. I'm a bit outside my knowledge envelope here, but Harvey will know the correct term to use.

Larger evap area, but still moving the same CFM so the temp should remain constant.

What I don't see, is what CFM is used for those results, perhaps 1200? Not sure if 400 cfm per ton is the standard for SEER ratings or not.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements