Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

why does the triangle tube require a P/S pumping system

Options

keyote

Member Posts: 659

I have a question

i can see why the indirect hot water would need a second pump to pull water off the internal tank pump which is a primary loop [a tee inside the boiler exits with a dedicated nipple to IHW supply]

But it occurs to me to then add another pump outside the tank essentially inline with the internal pump both on the primary loop is redundant [without even getting into circs v zone valves on a secondary loop for each manifold].

I was thinking about using a alpha ecm pump and zone valves.

Then I started thinking why even have a secondary loop then a tertiary loop for each manifold.Why not replace the internal pump with an alpha or abandon or remove it and put the alpha outside the unit. then have zone valves to each of the four manifolds as the secondary loop. wouldn't the alpha if sized sense the zone valve s and actuators opening and closing and do its thing.

My system is i think fairly well balanced i did it in loopcad its four almost identical floors 1150sf each, three above ground and the basement where the boiler is.totals are 52 kbtu, 15.7 head loss 11.6 gpm 124 water temp DT 10 degrees.

The top floor has a slightly higher load and the basement slightly lower so required water temp gets down to 110 there, i thought i could handle that and other individual room/loop discrepancies with actuators on the loops and zone valves on the 1" copper risers to each floors manifold, Each floor has four loops totaling about 1000' per manifold, though a few loops are are close to 300' and a few as low as 180' since every room has its own loop and because occupancy issues i want to control rooms/ loops individually anyway.

The flow/ head loss differences starting in basement are 2.6 gpm/15. hd,, 2.17 gpm/12.3hd,, 3.21 gpm/13.8 hd,,3.6gpm/10.7 hd

Hope this isnt a stupid question I dont want to re invent the wheel but electricity in NYC is expensive and part of the fun is really dialing in the efficiency i did spray foam triple panes LED lighting w occupancy sensors and other energy saving procedures so.

I have read or at least skimmed seiggy and holorans books and am in a related field sheetmetal on big jobs done a lot of plumbing so i have a passing knowledge of the concepts. But honestly even the triangle tube 110 book has about five piping scenarios that could be used but no explanation of why Id prefer one over the other, so simplicity and efficiency is whats guiding my thinking and these full port zvalves and ECM pumps seem to change the game.But perhaps not as much as I think.

I know that internal pump is partly to maintain a minimum flow through boiler but couldnt a alpha outside the tank do the same.,weather valves were open or closed.

Thanks guys

i can see why the indirect hot water would need a second pump to pull water off the internal tank pump which is a primary loop [a tee inside the boiler exits with a dedicated nipple to IHW supply]

But it occurs to me to then add another pump outside the tank essentially inline with the internal pump both on the primary loop is redundant [without even getting into circs v zone valves on a secondary loop for each manifold].

I was thinking about using a alpha ecm pump and zone valves.

Then I started thinking why even have a secondary loop then a tertiary loop for each manifold.Why not replace the internal pump with an alpha or abandon or remove it and put the alpha outside the unit. then have zone valves to each of the four manifolds as the secondary loop. wouldn't the alpha if sized sense the zone valve s and actuators opening and closing and do its thing.

My system is i think fairly well balanced i did it in loopcad its four almost identical floors 1150sf each, three above ground and the basement where the boiler is.totals are 52 kbtu, 15.7 head loss 11.6 gpm 124 water temp DT 10 degrees.

The top floor has a slightly higher load and the basement slightly lower so required water temp gets down to 110 there, i thought i could handle that and other individual room/loop discrepancies with actuators on the loops and zone valves on the 1" copper risers to each floors manifold, Each floor has four loops totaling about 1000' per manifold, though a few loops are are close to 300' and a few as low as 180' since every room has its own loop and because occupancy issues i want to control rooms/ loops individually anyway.

The flow/ head loss differences starting in basement are 2.6 gpm/15. hd,, 2.17 gpm/12.3hd,, 3.21 gpm/13.8 hd,,3.6gpm/10.7 hd

Hope this isnt a stupid question I dont want to re invent the wheel but electricity in NYC is expensive and part of the fun is really dialing in the efficiency i did spray foam triple panes LED lighting w occupancy sensors and other energy saving procedures so.

I have read or at least skimmed seiggy and holorans books and am in a related field sheetmetal on big jobs done a lot of plumbing so i have a passing knowledge of the concepts. But honestly even the triangle tube 110 book has about five piping scenarios that could be used but no explanation of why Id prefer one over the other, so simplicity and efficiency is whats guiding my thinking and these full port zvalves and ECM pumps seem to change the game.But perhaps not as much as I think.

I know that internal pump is partly to maintain a minimum flow through boiler but couldnt a alpha outside the tank do the same.,weather valves were open or closed.

Thanks guys

0

Comments

-

-

I have read a lot and looked at a lot of designs but I think they leave something out. Imagine i first go in and out of the TT S/R with a Primary loop, all the designs ive looked at show a primary pump on that loop outside the boiler [ but they never really show the internal pump which is part of that same first loop] so when you add that second circ you now have two primary loop circs one inside the boiler the other outside.so we now have a primary loop with double pumps,Whats the point of that?

Now the indirect water heater is fed in this case from the TT dedicated IDHW supply stub which is nothing more than a tee upstream of the inside pump so its a tee of the primary loop that happens inside the cabinet that gets piped into the supply of the IDHW this is a secondary loop and it requires its own pump to pull supply water away from the primary loop into the IDHW, then back out the indirect and ties into the return side of the primary loop, If the triangle tube didnt have the dedicated IDHW out, both S/R to the IDHW heat would come off the primary loop outside the cabinet. Either way the IDHW is a secondary loop with a pump of its own That would be a routine install up to this point. Then also coming off the primary loop would be tees to the zones in my case risers to a manifold for each floor. also normally at this point we would discuss the reletive merits of putting zone valves or zone circs on those risers. Each of those riser pairs would like the IDHW loop be its own secondary whether circs or valves were used. Correct? Since my zones are quite similar and have fairly low flow and head Im thinking I dont need additional circs for each riser pair but could save electricity using zone valves instead. What I think I understand and may not is that ECM pumps solve a lot of the problems that used to be solved with zone circulators and piping methods.At least if your system is small enough and fairly well balanced.

Maybe Im making this sound complicated Im not really suggesting not having a primary secondary obviously if i have the IDHW and Tees to manifolds theres a primary and several secondary zones. and i dont think zone valves over circulators is controversial. It really mostly the question is why an internal and and external primary pump. My guess is the internal one may not be big enough even for my system and its not ECm only 3 speed but imaging i could swap it for a large enough ecm why wouldnt then use only the one primary pump?

Sure Im also asking a bit about using zone valves vs zone circs in my specific install but its kind of saeparate except i use it to demonstrate i indeed have secondary piping coming off primary piping.

0 -

are you saying to remove the grundfos internal pump in the 110....and installing an alpha in its place? or installing the alpha on the outside with no pump internally? can you draw a diagram?ASM Mechanical Company

Located in Staten Island NY

Servicing all 5 boroughs of NYC.

347-692-4777

ASMMECHANICALCORP@GMAIL.COM

ASMHVACNYC.COM

https://heatinghelp.com/find-a-contractor/detail/asm-mechanical-company0 -

dont know why this is so hard to visualize Im saying when you pipe a primary loop with a pump from a TT you are putting a second pump in the primary loop because TT has an internal pump that is by definition part of any primary loop. I see no need for two in line pumps in a primary loop and would want my pump to be an alpha which TT does not use. whats to be done? I ask can it be replaced with an alpha or can it be removed and pipe put in its place and an alpha added outside the cabinet . or can it simply be not used without it restricting flow? **** good is it if its an inferior pump and cant be replaced0

-

The purpose of p/s, or any form of hydraulic separation, is to maintain separate flow rates in each circuit while allowing the circuits to mix with each other to transfer heat. Think of it as being like a heat exchanger except there's no physical barrier between the circuits.

The boiler REQUIRES a constant minimum flow rate through it when it's firing. Without it, the water in the boiler will almost instantly flash to steam - an experience not soon to be forgotten if you're in close proximity.

You CANNOT use an Alpha (delta P) circ on the primary through the boiler. And, delta T circs don't work well unless their speed is controlled by the boiler itself.

I assume you're referring to the Solo 110 since that's the only TT that comes with the circ built in. That was the first size offered and the circ was built in to assure proper flow through the HX since many American plumbers didn't understand p/s at that time. A lot still don't.

It's not an "inferior circ"; it simply has a different function for this application. Because an Alpha uses less energy, that does not make it superior if it's not correct for the application.

Actually, you could use the Alpha if you kept it on one of the constant speed settings. The cost of the pump would be more than you'd realize in energy savings over its average life span. But you'd still need a separate circ for the indirect because it's a separate circuit and the boiler pump drops out during a domestic call.

Also, please notice that in TT's piping diagrams (or any others) that there are NOT two circs 'in line" with each other. Meaning they are NOT in series. They are hydraulically separated by proper p/s piping or the use of a low loss header. It doesn't matter if the circ is inside the cabinet or outside of it. You still only use one primary circ.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.3 -

The boiler manufactors piping recommendation is all about flow rates through their boiler. Most importantly minimum flow rates.

They have no idea what system their unit is being strapped into. Let alone the systems flow requirements. With zoned systems it becomes more critical. So with P/S, and their pump insures that their boiler will get the required minimum flow rate. There should be charts in the I/O manual.

Now if you know the appliance well, and the system there are many cases where direct piped will work just fine. You have to do the math on the required system flow rates though. Minimum possible, and maximum possible.2 -

I kind of knew it was for minimum flow and was thinking there would always be flow if heat was called for but can see now how at times less flow could be called for than the boiler requires at a minimum, so are ECM pumps only used on zone or are they set up as a second loop then the zones come off that as a third third, I guess i dont see how ecm pumps help then if they cant be used as primary pumps0

-

As mentioned, there are two basic types used in residential hydronics: delta P and delta T. The former operates based on pressure differential, the latter on temperature differential. The application determines which is better suited.

For instance: panel rads with TRV's would be an application where a delta P circ would be well suited because the circ would respond to the pressure changes in the system as the TRV's modulate. A single zone or loop would be better suited to a delta T circ which would modulate based upon temperature because nothing in the circuit changes its pressure.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

i posted my loop cad drawings for the floors which has all the hd temp flow etc both by manifold/floor and system total loop cad allowed me to play around untill at delta T 10 and 124 max temp they were all pretty close to right so if im understanding my system is fairly well balanced in all parameters flow temp head and i thought i would put an actuator on each loop so each room gets a tstat to balance out any minor fluctuations or personal preferences.I am guessing youre refering to pump types and i would think i would want a alpha which adjust deltaP as the zone valves and actauators open and close while the boiler monitors temp at 124 the highest required the lowest was 110. well i put up a couple of near boiler sketches which oi think represent what you guys are saying i need0

-

They don't require primary/secondary piping, but they do recommend it in order to prevent clueless installers from causing damage. If you keep reading, you will see:System Piping - Through Boiler

In new or retrofit applications in which primary/secondary arrangement is not utilized, the PRESTIGE Solo allows this flexibility due to a lower boiler pressure drop0 -

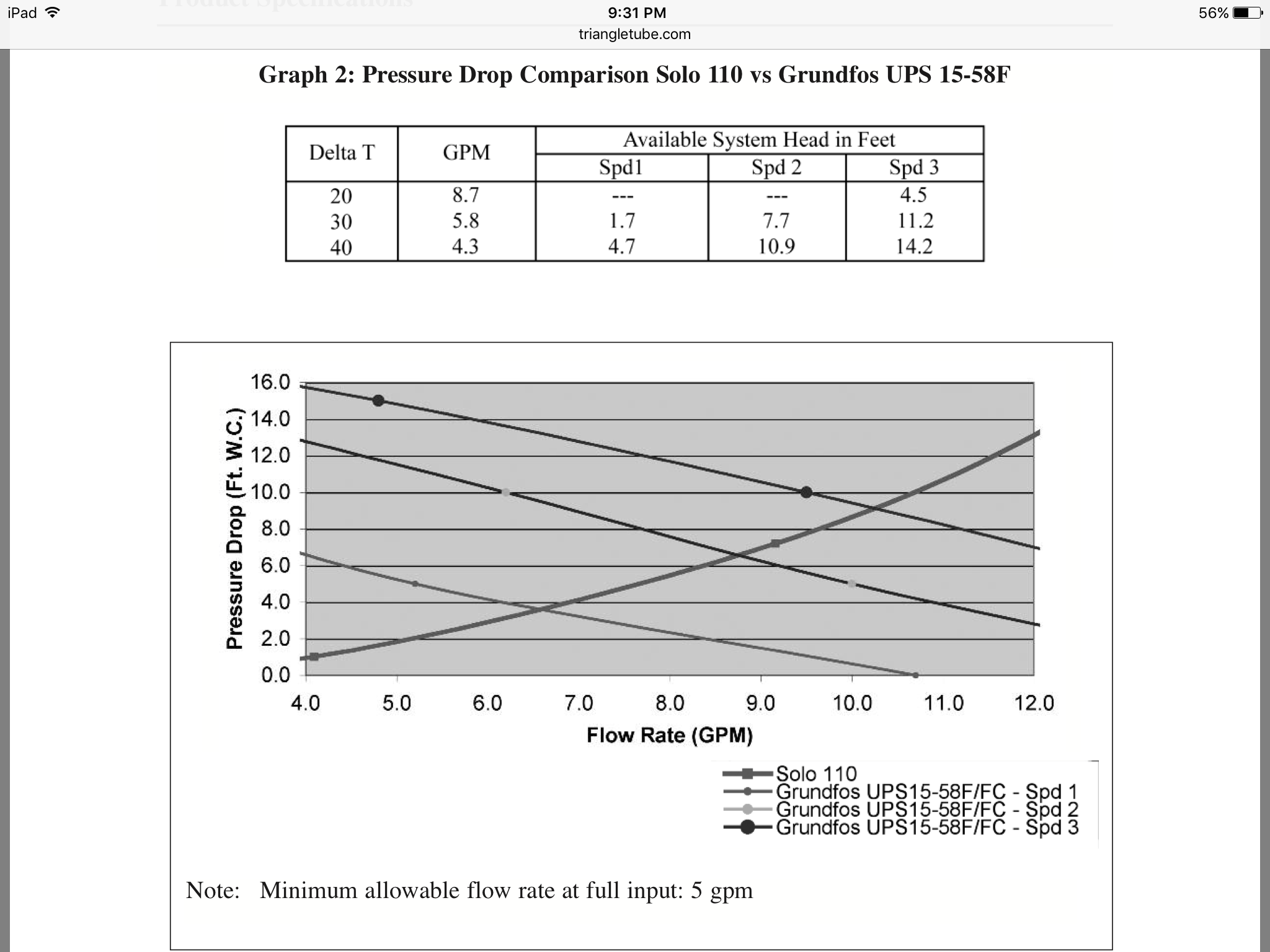

Check out page 84, and tell me if you can run a 40*DT through that boiler..... http://www.triangletube.com/documents/1/Prestige 110 TriMax Manual 020614.pdf0

-

The book says that circ at DT40 On third speed is 4.3 gpm at 14.2 ft hd the pressure drop at that speed across the boiler looks like about 10.5 gpm /9 ft hd so i guess the answer is no.

at DT 10 degrees my total or highest hd is 15.7 and total flow is 11.6 id have to recalculate the flow at DT 40 but its a radiant system so i wouldnt want DT that high. But that might be unimportant on the primary loop huh? I guess you are saying even if i could swap pumps i would want to but with p/s pumps i get there? i put my loopcad stuff and a proposed p/s design up in a different post a hour ago which may make all this less confusing sorry im such a newbie thought i had this well look and tell me what you think0 -

Very Generally speaking a zoned radiant system will not play well piped direct. With that boiler...... A single zoned radiant system yes.

You also have to look at the btu requirements for the smallest zone, and the lowest modulation of the boiler. This one around 30k. So short cycling becomes an issue. So adding features to prevent that becomes more cost.1 -

Gordy....Your screenshot cut off......minimum flow rate of 5gpm at maximum input. Why do they show a flow rate of 4.3?0

-

i have posted a P/S separately design in another post. i see why without p/s i have several problems starting with boilers min flow, the idhw needing a primary and as you say multizone not being ideal for direct .

I too am also a bit worried about the short cycling particularly because for now only zone four is going on line and the indirect. it says it modulate 5.5 to one so that about 20% 20kbtu ? my top zone is only about 16kbtu plus hot water i actually have a copper fintube loop in the basement which isnt currently being used i could flush it and put that online andi have an extra TT indirect as a buffer? For now the other floors are being renovated and heated with a 100 year old rusty 2-3"' pipe system dont want to run through this system.

i probably ought to go with a smaller boiler eventually i picked this up on craigs list for a song with a brand new smart 50 and a slightly used smart 30 and a bunch of trim and pumps so my plan is to use it till im finished renovating the other floors.then swap out the boiler0 -

my smallest zone is 2.2 gpm and 12.2 ft hd0

-

Look at HTPs UFT 80.0

-

The 4.3 gpm just correlates to the example DT at given system heads that the GF 15-58, and its speeds are capable of. Hence go by the note of the minimum flow rate requirement.

0 -

actually that was the minimum flow /head of smallest heat zone i dont know what the indirect needs i could look it up but

But honestly Im not sure what we are getting at here; are we still considering whether only the internal pump could be used? Because i thought my short answer was for safety the boiler needed to maintain a minimum flow that is at times higher than the minimum flow the zones may require and so two loops are are a must. I suppose this could be gotten around since TT shows such a setup but i also assume it would be a on off only setup and not an alpha almost asleep.

Or are we considering it in conjunction with a secondary pump.I have uploaded the four zones in loopcad with all the figures as well as several possible P/S near boiler proposals in another comment

0 -

There are ways to make it work, even with a ΔP pump. A pressure bypass valve and/or a bypass zone can be used to ensure minimum flow.0

-

Swei I dont know if you looked at my loop cad uploads in my other comment but I havnt meant to argue until a work around is found im only trying to ascertain the absolute best design. Actualy i was erroneous when i first posted that a secondary pump would be inline with internal TT shows a simple single loop using the internal pump only or with a IDHW pump also but the P/S schemes are recommended for multizone and do in fact clearly show the second pump in a secondary loop upstream of zone valves or multiple zone circulators.

I got into this wanting to cut back on electric use with alpha pump[s] and zone valves and i guess what i was muddilly thinking was an alpha could replace the internal pump and since it self adjusts could ramp up and down under all circumstances.

I thought though my system is a four floor/manifold and IDHW it was so typical floor by floor and what i thought was low flows and heads temps btus that in my case this might work be simplest and most efficient. it seems not.My fall back is whats next best an alpha secondary and zone valves? I apologize I thought i undestood more than i did i guess.Just a dumb tinknocker huh?0 -

If you're only using the TT till the renovations are done... don't sweat the minuscule increased electrical cost (compared to your renovation co$ts) for the system pump.

Once you're ready to choose your new permanent boiler- go with one that is direct piped vs. PS... like the HTP UFT-80W that was mentioned above. That boiler has no issues with an ECM Alpha for space heating.1 -

well i had hoped to get the piping right now and assumed i would end up with a smaller TT but but im going to look into that it seemed TT was the favored boiled here when i started the reno and did my initial research0

-

It won't be difficult to change your P/S piping to direct down the line if you engineer it with that in mind for the future.... just cut and cap between the tee's.

In addition to direct piping (one less pump)... the HTP UFT-80W has a 10:1 turndown vs. the TT's 4:1 turndown so it can fire down to 8K BTU's.1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 52 Job Opportunities

- 19 Recall Announcements