Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

pros and cons of the distributions system types for new mod-con install

Options

naphelge

Member Posts: 9

in Gas Heating

Hi gang,

I am planning to replace the electric baseboard heating system in my house this year with a NGas mod-con boiler setup.

What are the different system types and their pros and cons as far as plumbing from the boiler to the heat emitters goes (i.e. serially fed, tee-tapped mains, home run, etc.) ?

I will be installing 7 new cast iron rads throughout our small(ish), ~1400 sq. ft. house to provide the required ~35k BTUs determined to keep things warm and toasty inside our abode on the coldest day of the year.

My PEX runs from the boiler / manifold to the rads. should be:

(main flr) Bedroom 1: 27' x 2 (supply-return) (~3200 BTU rad.)

(main flr) Bedroom 2: 21' x2 (~3k BTU rad.)

(main flr) Dining area: 36' x 2 (~5.6k rad.)

(main flr) Living space: 28' x 2 (~5.6k BTU rad.)

(main flr) Sunroom: 30' x 2 (~5.6k BTU rad.)

(lower flr) Living space: 32' x 2 (~5.6k BTU rad.)

(lower flr) Laundry room: 21' x 2 (~5.6k BTU rad.)

Additionally, since I will run all the PEX myself, do you think PEX-Al is worth the extra $$$ vs potential added frustration running regular PEX solo?

Thanks in advance for suggestions, advice and shared experience.

I am planning to replace the electric baseboard heating system in my house this year with a NGas mod-con boiler setup.

What are the different system types and their pros and cons as far as plumbing from the boiler to the heat emitters goes (i.e. serially fed, tee-tapped mains, home run, etc.) ?

I will be installing 7 new cast iron rads throughout our small(ish), ~1400 sq. ft. house to provide the required ~35k BTUs determined to keep things warm and toasty inside our abode on the coldest day of the year.

My PEX runs from the boiler / manifold to the rads. should be:

(main flr) Bedroom 1: 27' x 2 (supply-return) (~3200 BTU rad.)

(main flr) Bedroom 2: 21' x2 (~3k BTU rad.)

(main flr) Dining area: 36' x 2 (~5.6k rad.)

(main flr) Living space: 28' x 2 (~5.6k BTU rad.)

(main flr) Sunroom: 30' x 2 (~5.6k BTU rad.)

(lower flr) Living space: 32' x 2 (~5.6k BTU rad.)

(lower flr) Laundry room: 21' x 2 (~5.6k BTU rad.)

Additionally, since I will run all the PEX myself, do you think PEX-Al is worth the extra $$$ vs potential added frustration running regular PEX solo?

Thanks in advance for suggestions, advice and shared experience.

0

Comments

-

How are you controlling the system? TRVs at the rads? One master thermostat for a single zone? Other?

Installing "home runs" tends to get sloppy and cumbersome with PEx. I'm a big fan of running a 2-pipe copper loop around the perimeter, or down the center, and making radiator take-offs from the supply and return mains.

You may not need aluminum in your tubing (Pex-Al), but don't use tubing without an oxygen barrier.Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes0 -

Manifolds will allow you to zone later if you want or have a single zone or TRVs . Pay attention to neatness or you'll end up with the slop John talks about . 2 pipe reverse return is another good alternative .

Pay close attention to head loss the circ will see whatever design you choose and match as closely as you can that circ to the head loss and flow rate . 1 gpm per rad is a good place to start . 1/2" will be sufficient to the rads .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

-

This may not interest, but just to offer it up if you hadn't considered: If you have access to the floor you're planning to heat from below I can't recommend enough doing radiant. It's more affordable than you might think since you're going to go through the install of a modcon anyway. Get extruded aluminum plates which you can install easily yourself, then drill and pull your Pex-Al. You'd need to plumb a manifold and obviously do some heat load and other calculations first but assuming it works out you will get extremely low-cost, very uniform and comfortable heat. We wear T-shirts in winter in a big attached house in the Northeast, which seems extravagant, but our max heating bill was 180 at outdoor temps in the teens and around $120 most winter months, including hot water (and like $40 in the offseason).0

-

Also whatever route you go I'd avoid doing it serial. We did on one floor and it means you can't adjust the heat room by room unless you install a bypass, which may not be easy depending on your setup.0

-

I'm a big fan of reverse return for radiators around the perimeter of the building when access is available from underneath. If they're CI rads and are fed across the bottom, I'd give serious consideration to copper or steel risers which will keep the vintage look. The runs are short enough that the cost and difficulty will be about the same for any pipe type, unless you have joists in the way and have to zig or zag your way down. The distribution loop is going to be hidden, so the type of pipe is less critical there. PEX will require about twice as many hangers as P-A-P and 3x as many as copper. Pick your poison

0

0 -

I recently did a very similar project at my house - installed mod con and retrofitted antique cast iron rads.

I went with a Uponor manifold and 1/2" pex-al-pex home runs. Each radiator has a TRV. For some of the more visible rads on the first floor I did short steel stubs to the basement, but honestly, PAP looks just fine.

Having a manifold allowed me to provision the system in stages. If you are doing the work yourself, that's a huge plus.

I definitely recommend against regular oxygen barrier pex(I used it at my other property for a similar project). It droops and expands just way too much. Plus without some sort of unwinder, installing it alone is not fun.

Pex-al-pex on other hand is super easy to make straight and the install looks very neat.0 -

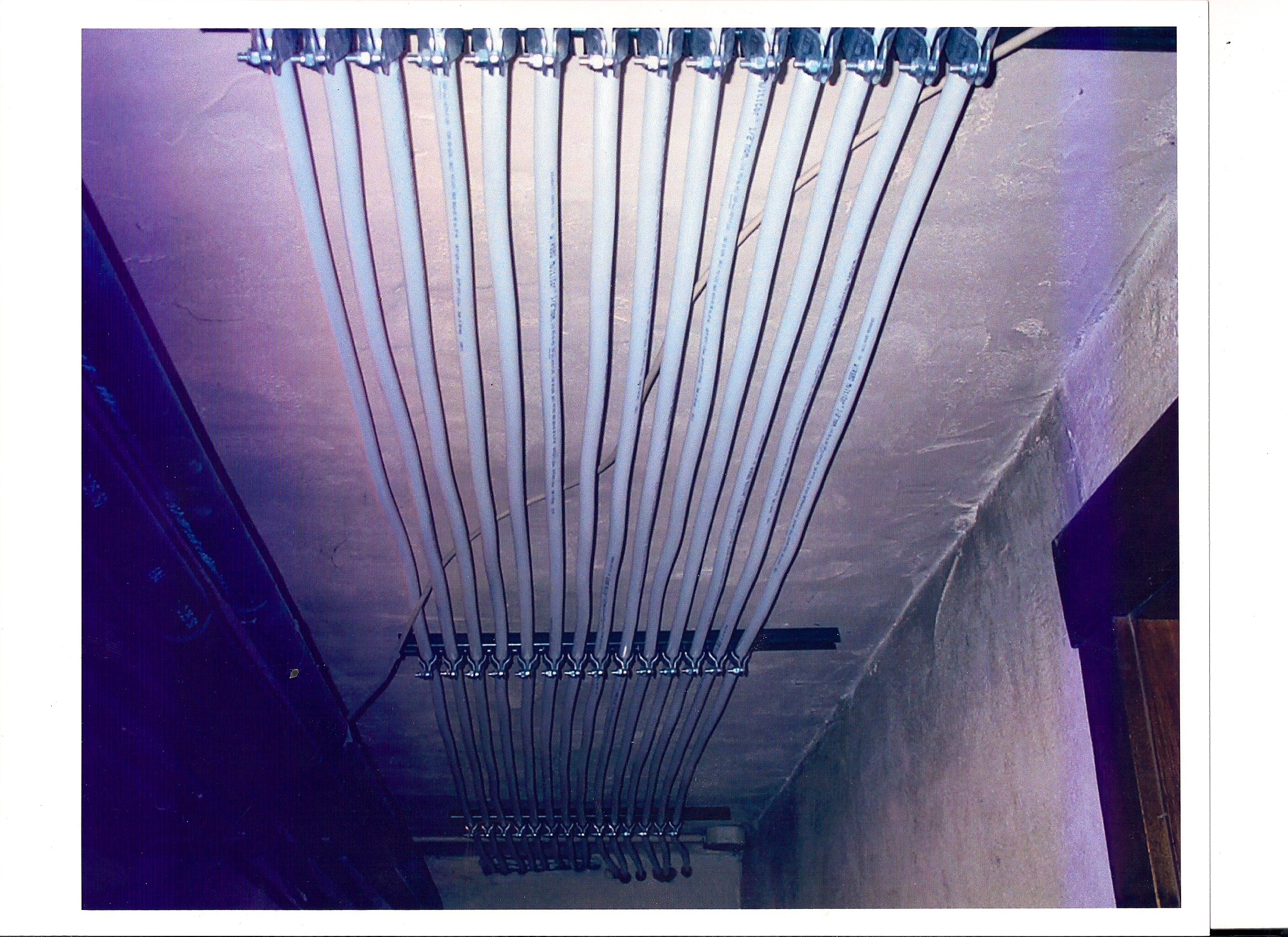

We've done a lot of these jobs. These pics are from one 14 years ago.

Steve Minnich2 -

On the radiation side, what was the supply water temps that you used to size the radiators?

I just installed a new baseboard system with modcon boiler and sized the radiation based on 130 degree supply temps at design to more fully utilize the condensing aspect of the modcon.

I ended up using copper in a split loop configuration, soldering a lot of copper is a lot of work.Hydronics inspired homeowner with self-designed high efficiency low temperature baseboard system and professionally installed mod-con boiler with indirect DHW. My system design thread: http://forum.heatinghelp.com/discussion/154385

System Photo: https://us.v-cdn.net/5021738/uploads/FileUpload/79/451e1f19a1e5b345e0951fbe1ff6ca.jpg0 -

As others have hinted at in earlier posts, each type of pipe has their pros/cons. There are a few differences you will have between using regular pex/o2 barrier and pex-al-pex, but I would suggest as a homeowner the main one is the expansion/noise characteristics:

Regular pex - droops when hot, expands and worms as it expands - also creaks when touching other things like joists and other pex runs.

Pex-al-pex - lower expansion rate, holds bends, easier to work with if you are a one person team.

0 -

Hey, thanks for all the awesome feedback. I haven't had a lot of time to reply since Spring time gets crazy at work.

Progress ensues: my boiler arrives this week and I got my rads last week.

I was somewhat disappointed to realize the "cast iron style" rads I bought are in fact rolled steel. My bad for not reading more closely all the details. I will just have to suck it up as shipping them back for a refund would cost about 30% as much as I paid for them. How less efficient do you think steel rads will be than CI? The maximum BTU output for each of the rads based on the heat analysis for each room in the house is what drove the decision for each rad ordered. So the BTUs for the coldest day should still be available when needed, but lower running temps the rest of the winter.

I will be ordering my primary loop components this week, but I am still on the fence about pipe layout. Our main goal is to keep the areas in each zone at a constant temperature throughout. Although we will keep the downstairs zone about 10 degrees colder than the upstairs, where 95% of our time is spent.

I thought if I run the rads in serial then the two (somewhat) short zones (upstairs and downstairs) would provide a decent load for the boiler that would help prevent/reduce cycling. But then I lose the ability to shut off any single rad if required.

But ultimately, I do think a trunk and branch reverse return set up might be the most flexible solution. The feed and return water tempos should be more even throughout, in addition I will be able to add shut off valves to each branch that will allow a rad to be isolated if required.

I am still considering the idea of a larger manifold (I will use a two position manifold if I decide to go T&B RR) and installing home runs to each rad. However, when I think about this set up, is it not essentially a T&B system, with the manifolds being the trunk and the home runs simply the branches, and then the returns can be installed in reverse order from the feeds?

One other question. I have seen set ups where the secondary circulator can be located on either the hot feed, pumping to the rads, or cold return, pulling from the rads, side. What might the advantages and disadvantages of either set up be?0 -

On the steel radiators vs. cast iron. The good news is they respond faster. The bad news is they respond faster. That is, if you call for heat, they heat up -- and start to radiate -- more quickly. On the other hand, when the call stops, they cool off more quickly. If you can run constant circulation with only slowly varying temperatures -- such as with a good ODR -- you won't notice any difference.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England5

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements