Piping methods of EC variable speed pump and zone valves

I am stuck at the correct plumbing/piping configuration and controls for a system like this. I have read through (and talked to a few contractors) all the discussions on 1 pump per zone, or 1 pump per system + zone valves, P/S loops, etc., and have really run out of time to figure this out. While I have a pellet stove that we are using for heat, I really need to get this system up and running before winter sets in.

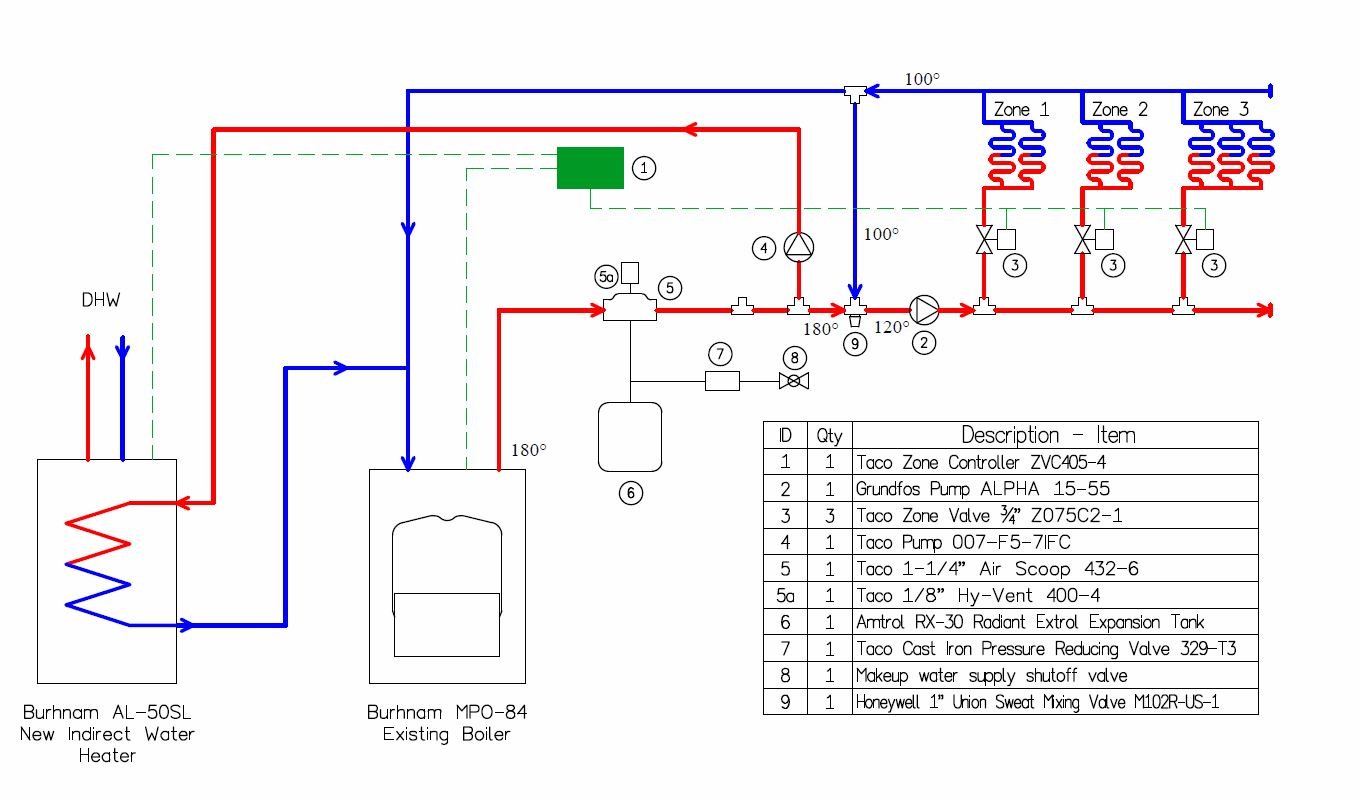

What I would really like to do is use 1 Alpha EC variable speed pump, and then 3 zone valves for the floor heating. I also am planning to install a Burnham AL-50-SL indirect water heater, fed from a Taco 007 pump. Because I need the water temperature to the heating zones to be less than the boiler feed (designed for 180deg boiler water, and 120 to the heating zones), I know I need some type of mixing valve.

Can I just use a thermostatic 3-way mixing valve, or do I need some type of modulating/electronic mixing valve?

Here is a schematic of the system I would like to install.

Comments

-

A smart mixing valve like the taco I series with ODR. You will need a valve for boiler protection from low return water temps also.

I notice you have a 20 delta for the radiant. 10 is more exceptable for more even floor temps.0 -

I agree with Gordy on the smart valve. It will give you outdoor reset and boiler condensation protection. Absolutely the way to go.

Your drawing is pretty good. You will need flow checks on the circulators and you need to think through how you purge the air.

How long and how many loops do you have. The alpha is great for this application as long as the loops are not crazy long."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

For air purge, beginning at the air scoop and working backwards, install a full port ball valve, then a 3/4" drain/purge cock. And there you have it. I noticed the IFC on the 007, but as Zman pointed out, ALL circs must be checked. Simple basic and functional.0

-

When it comes to the circulators being used, I don't know the flow and head of the radiant zones. Some guys like to use zone pumps instead of zone valves because it could be hard to undersize. Take a look at the math.

I was looking at the indirect tank and flow requirements are 6 gpm at 9.6 foot of head (just for the coil). Add the piping to it and the head loss can be higher.

The 007 is close, but the 008 or the 0015 set on medium speed would be a better choice.

Would the 007 work and has it in the past, most definitely yes however, you lose some of the capacity of the tank and "run" out of hot water.

Also the ratings of that tank is based upon a boiler that can deliver 110,000 BTUs/hr, so make sure the number are adjusted for the smaller boiler.

Or get a bigger tank, or add a mixing valve to the domestic side to increase the capacity.

Dave H.Dave Holdorf

Technical Training Manager - East

Taco, Inc

0 -

The Alpha pump comes with a plastic IFC that can be installed in its output flange. As far as using the Alpha or any pump, you start by calculating head loss. Since the "zones/loops" are in parallel, calculate the head loss of each "loop" (separately) and use the highest value you calculate. Then cross that head loss on the chart and see what the GPM output is. If it satisfies the total GPM (all zones open), then your good to go.0

-

Thanks for all the feedback. To answer a few of the questions and provide some more information.

Gordy; thanks for the suggestion on the Taco i Series. I looked into that today, and they seem to indicate that I will need to use a P/S loop system. I was trying to stay away from adding an additional pump. Do you know if I could get away with using a 3-way i-series in place of the thermostatic in my original design? Also, I am still trying to understand the boiler water protection. Are you suggestion to add some additional valve, or use the feature in the i-series?

Zman, Mark, Dave; maybe I underestimated the features of the Alpha pump. I know with fixed speed I had to be very careful for head loss and gpm flow. I thought from my understanding of the Alpha, that it covered a wider range.

Anyway, here is the information on the hydronic design

3 total zones using 1/2 Pex-Al-Pex tube (~1700feet total)

Zone 1: 480 feet of pex, split in (2) circuits with ~240 each

Zone 2: 760 feet of pex, split in 3 circuits with ~230-270 each

Zone 3: 530 feet of pex, split in 2 circuits with ~ 265 each

With the heat load calculations for each room, and a 20deg Delta, I had calculated that I needed a ~6gpm flow total.

My zone with the maximum flow and longest length, had a head calculation of <0.5ft for the tube. I am planning for the zone manifolds to be away from the boiler area, but that max distance will be 25ft, with only 4-5 elbows, and run in 3/4" pex.

Thanks for the advice on the purge areas and the checks. I will work on the diagram in the next week to add some details of where those items will be installed.

0 -

Your head in a 270' loop plus piping to, and from loop is considerably more than .5 feet. More like 8.5 ft at 1 gpm plus piping to and from loop.

Yes the I series R feature for boiler protection, and the benefit of ODR. Need to keep the boiler return water above 130*. Your radiant floors will benefit from the ODR feature.

With zone valves you need to use constant pressure mode due to the changing flow characteristics with zones opening, and closing.0 -

You can put the I valve in place of the one drawn. With a cast iron boiler the minimum flow rate is not a concern so primary secondary is not needed.

It looks like with the I valve with a cv of 4.0 and the alpha set to constant pressure 3, your shortest loop will flow about .90 gpm and the longest .83 gpm. This is a good thing."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

@dms369

Gordy; thanks for the suggestion on the Taco i Series. I looked into that today, and they seem to indicate that I will need to use a P/S loop system. I was trying to stay away from adding an additional pump. Do you know if I could get away with using a 3-way i-series in place of the thermostatic in my original design? Also, I am still trying to understand the boiler water protection. Are you suggestion to add some additional valve, or use the feature in the i-series?

Although Taco's manual shows the I Series valves in injection loop & P/S configurations you DO NOT REQUIRE P/S piping to use the valves successfully . The circuit pump will pull supply and return water through the valve whether or not that water has a pump on the other side or not . I have spoken with Taco about these manuals yet , they remain the same , losing out on quite a bit of sales I would imagine .

You would want to use the 4 way valve for boiler protection , also pay attention to the Cv rating for the valves . You will want the smallest valve possible for your anticipated GPM , even if it is smaller than the piping it will be connected to . Targets temps will be reached faster this way .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

The 1" he has drawn has a cv of 4. I would not go any lower.Rich said:@dms369

Although Taco's manual shows the I Series valves in injection loop & P/S configurations you DO NOT REQUIRE P/S piping to use the valves successfully . The circuit pump will pull supply and return water through the valve whether or not that water has a pump on the other side or not . I have spoken with Taco about these manuals yet , they remain the same , losing out on quite a bit of sales I would imagine .

You would want to use the 4 way valve for boiler protection , also pay attention to the Cv rating for the valves . You will want the smallest valve possible for your anticipated GPM , even if it is smaller than the piping it will be connected to . Targets temps will be reached faster this way .

A 4 way valve would be useful if there was a circ on the boiler side and/or the boiler had minimum flow requirements.

I believe the 3 way model will do boiler protection as drawn. Maybe I am missing something? (edit) I was missing something, not enough coffee...

I don't understand what target temps have to do with this, the boiler size, emitter size and system mass will be factors, I don't see a system like this taking long to come up to temp with a boiler sized for the heat loss.

As long as the mixing valve is sized for the system flow, life should be good."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Target temps would have to do with the fact that there is floor heating and maybe the OP would like to use odr feature but yet protect the Cast iron boiler . A pump is not required on the boiler side .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

I've not used that valve but it seems to me that without primary / secondary and a boiler pump the three-way i-series valve would see the 100 degree water coming back and close - right? So there would be no / very little flow in the boiler loop and it may take a very long time to bring the loop up to temperature? So a four way valve would solve that problem.1

-

-

This valve would be the Outdoor reset type for best performance . When lower temps are required this would also sip out of the mass in the boiler while holding out the burner lessening firing time .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

My bad, I wasn't seeing it clearly. A 4 way is needed for boiler protectionRich said:This valve would be the Outdoor reset type for best performance . When lower temps are required this would also sip out of the mass in the boiler while holding out the burner lessening firing time .

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

Thanks for all the great feedback and suggestions. I am realizing that when I tried to go with a more "progressive" and new technology system, it is getting overly complicated. I need to think over this this weekend. I am going to look at installing a more traditional system of 1 fixed speed circulator per zone, and use a thermostatic mixing valve. I talked to my local contractor today that is helping me, and he said that all these discussions about EC variable speed, modulating mixing, etc. are nice, but for a small residential system, the design/install headaches, higher upfront costs, future maintenance, and reliability issues point to not using any of that. He is highly recommending that I use a simple/conventional system. So I need to rethink what I was trying to do. If anybody has some basic feedback on a conventional versus progressive system, I would appreciate it. I realize both will need to be designed and installed correctly for both comfort performance, proper operation, and boiler protection, but it seems that I was way over complicating what I am able to do from a DIY perspective.0

-

Sorry to hear that and that your contractor is leaning that way .

Your system will work perfectly (almost ) for roughly 2% of the heating season , your boiler will short cycle itself to death . All this while you spend more money on gas and electricity but you certainly will have spent less money up front .

Nothing mentioned here is exotic or not immensely worthwhile . Shame we were not able to persuade you or made it sound difficult . Is there anything we can do to make it easier to understand .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

Watch out for that indirect.Its coil is only 3/4 and if you plan on maintaining 140 in tank with a mixing valve recovery takes some time.BTW Burnham does not make it is is made by Vaughn I believe but for an extra $200 you get a Burnham jacket.

0 -

I really don't see the complexity in the recommendations. It's all pretty basic stuff.

Why zone with 3 Circs instead of one, and zone valves? The I series valve may be pricey but it serves three purposes. ODR, boiler protection, and radiant mixing. Price that stuff out seperatly.

Seperate components.

ODR

Mixing valve for radiant

ESB valve for return water boiler protection.

I would highly recommend a higher DHW storage temp, and a mixing valve for domestic.

You will get more hot water.

Do you understand the functions of the mentioned components? If not more than happy to help you understand.

You need to protect the boiler.

You need radiant mixing

ODR is not a must, but for your wallet, and comfort it will be worth it.

5 -

Thanks everyone for the guidance and support. I have tried to take all the feedback and work on an updated diagram as posted here. I have added the iSeries 4-way with ODR so I can get the mixing and boiler protection.

Few additional questions:

1. Is that the correct install for the 4-way with ODR? I am still concerned about the 1-pump only solution, so I want to make sure I have the correct location of all the items.

2. There was a note about not oversizing the mixing valve. A 1" 4-way has a very large Cv of 9.3. I have <6gpm flow, so I was thinking of going down to the 3/4" size (the smallest Taco has in 4-way).

2. Purging: I added the 1 purge boiler drain and ball valve as noted. Where else do I need to have valves and drains? I have seen a type of valve that has an integrated drain. Are they worth it, or should I just stick with full port individual ball valves, and add tees and boiler drains as needed? Also, I have seen some system designs with other float vents at high points in the main supply or return lines, or even on the distribution manifolds. Are they needed?

3. I received a suggestion from another source for using a TF1 Magnetic filter in the system; particularly because of the Alpha pump. Thoughts on using those, or specifying a different brand or solution?

4. Distribution manifolds: I was thinking of using a nice distribution manifold like a Caleffi or similar with individual circuit shut-off valves and flow meters, and supply/return main valves and vents. However, that seems overkill for my simple 2 and 3 circuit zones. Is it really necessary to have circuit flow-meters, and if so, any suggestions on brand/model that I could just plumb into the circuit with little ball valves?

5. My old system had a big 1 1/4 Taco flow-chek in the system. Do I need anything like that in my system, or the check valves in the pumps accomplish the same?

0 -

The 3/4 I series with a Cv of 7 will be a better choice for your particular arrangement .

Flow meters are always helpful and allow easy adjustment of each individual circuit . Air elimination can never be too much as long as it is placed where you think it will remove the most .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

Looks good. All though I would put an isolation valve at the boiler return. I see two on supply before the air separator. Maybe one was suppose to be on return.0

-

I like it...."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements