Hydronic retrofit - circ pump and low loss header sizing

Comments

-

Been using my meter and Δ T is 5° or less at the boiler supply/return throughout the heating cycle.

I was giving some thought to replacing the B&G monster pump with the Alpha when it arrives to see if it would handle the original system better than throwing a large flow volume around the monoflo system.

But now.........

Maybe I will open it to look at it before returning it. talked to the supplier this morning and it has already shipped so couldn't cancel the order

0 -

Has anyone calculated the head of this system? I know Taco has info for their 1.5 x .5 diverter tees. Just to get an idea where the VT might be operating.0

-

So, you're going to try and force these emitters down to about a quart per minute? I don't think it can be done without losing the imbalance created by the tee, that causes the flow.0

-

Very interesting about the difference between pressure change and temperature change and how it works within different types of heating systems.Hatterasguy said:

The Alpha can never work properly on a single zone system. It has no capability of varying the flow rate. You only get a single flow rate as you only have a single pressure (variations of pressure due to water temperature changes excluded).

The ΔT varies in direct proportion to load. Not desired under any circumstances.

After reading the responses in there I went out and found this informative article about ΔT and ΔP

http://flopro.taco-hvac.com/deltat_resources.html

I agree that the Alpha pump would not be appropriate for a monoflo where there is no change in pressure throughout the heating cycle as there are no opening/closing valves/zones for the pump to adjust to.

When the Taco gets here on Monday I may put it in the old system and see if slowing down the monoflo speed will make the old system more efficient. I should be able to raise the boiler temp back up to a level that works better if the water flow is not screaming around the racetrack. with the boiler set to 180 +/- the house heated too fast and the pump and boiler cycled at the same rate/time. Lowering the boiler temp to 160 kept the pump on while the boiler "rested" but the time to heat the house expended greatly. The room temp was maintained more evenly but this is no more than a kludge to an over large boiler and pump. I had thought about putting the pump on a reostat to slow it down, not permanently but just to see if this was the answer.

I am sure it will be interesting to run the system as is now (taking measurements of time and temp in/out) then with the ΔT Taco, and be able to compare, the 65 year old system as it stands to it with a modern (intelligent) pump then to the high efficiency boiler.

Gee I feel like I am back in science class once again.

OH....

The Alpha arrived late last evening. I don't think I should open it, just ask for a RMA.... BUT..... It is hard just looking at it sitting there all lonely..... PARTY TIME!!!!! 0

0 -

-

It would be interesting to try the Alpha for maybe a month, then the VT and compare the difference in operating and comfort conditions. I'm curious how ODR and VS/ DT get along.

Same question with mod con and VS/VT?

With a fixed speed as it has been running all these year, the system will find thermal equilibrium and the delta T throughout the system will vary somewhat based on load.

If both circ choices end up costing about the same $$ to operate a season, or for the pump's life expectancy, then comfort and performance may be the best way to select.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Can a ODR be retrofitted to a 65 year old cast iron boiler?Gordy said:There is an element missing in your observations. That is ODR. With that implemented your replacing btus as they are needed seamlessly. There is no 180 heats to fast, and 160 takes to long. It happens just right.

We have been using NSB because of the high heat loss of this older home. This makes the initial heat up in the morning rather slow as everything starts stone cold.

I have the thermostat set to start the boiler around 6:15. The house is "warm" by 7:30 and up to the set temp by 8:00. The system maintains the set temp extremely well over the course of the day until it sets down to 50° overnight.0 -

did not know you were using setback. You will have to get away from that with ODR, and new boiler.

How many degrees from non set back do you lose overnight?0 -

Operative word life expectancy here. How many of these new ECM circus with Logic will still be in the boiler room as original 20-30 years from now?hot rod said:It would be interesting to try the Alpha for maybe a month, then the VT and compare the difference in operating and comfort conditions. I'm curious how ODR and VS/ DT get along.

Same question with mod con and VS/VT?

With a fixed speed as it has been running all these year, the system will find thermal equilibrium and the delta T throughout the system will vary somewhat based on load.

If both circ choices end up costing about the same $$ to operate a season, or for the pump's life expectancy, then comfort and performance may be the best way to select.

0 -

House heating layout background:Gordy said:did not know you were using setback. You will have to get away from that with ODR, and new boiler.

How many degrees from non set back do you lose overnight?

There are two separate/independent heating systems in the house. One in each distinct part. Hydronic in the old/original house (cape cod). Carrier Infinity in the new/addition tight/insulated part (kitchen, dining room, den, library). No man's land between the two systems (kitchen/dining-room) is covered by both systems (forced air and baseboards).

We have the thermostats set back to 50° on the boiler system around 11:00 pm. We turn the Infinity system off at night.

The heat drops overnight in both parts of the house from the day time set temp of 68° down to 58° *as low as 50 on the coldest nights.

The boiler "auto-starts" in the morning before we get out of bed but the hot air system needs to be turned on at the thermostat as it is turned off at the thermostat (the Infinity only takes 10-15 minutes to go from the coldest overnight temp to 68°). The carrier Infinity was put in last hear and it is DA bomb. I can't describe how satisfied I am with that heating system. It maintains the set temp and the daytime temp does not change enough to be noticeable (variable output burner and variable speed fan in it). I want the hydronic to make me as comfortable and I believe that the Bosh and dual loop (LLH) should do this.

ODR & NSB:

the Bosch comes with ODR built in (oh boy more "homework)

I found this to be a good online article about NSB vs ODR. Informative and puts more into the little grey cells for use later on. I like articles written for the layperson, not directed to someone who already knows what they are reading.

http://www.comfort-calc.net/odr_vs_night_setback.cfm

0 -

Good article. When you get to the ODR setup though when properly tuned the thermostat ends up being nothing more than a high limit device.0

-

It would be interesting to compare both over time.hot rod said:It would be interesting to try the Alpha for maybe a month, then the VT and compare the difference in operating and comfort conditions. I'm curious how ODR and VS/ DT get along.

Same question with mod con and VS/VT?

With a fixed speed as it has been running all these year, the system will find thermal equilibrium and the delta T throughout the system will vary somewhat based on load.

If both circ choices end up costing about the same $$ to operate a season, or for the pump's life expectancy, then comfort and performance may be the best way to select.

I think my wife would end up killing me in the process though

This boiler retrofit has been going on for over a month and the only thing that has happened outside of a LOT of thinking and planning is the Bosch has left the pallet and migrated onto the wall and the basement has filled up with fittings, pipe, and tools.

http://i1066.photobucket.com/albums/u414/turtle-web/misc/HVAC/fittingsMore_zpsqgibhw7n.jpg0 -

Pipe them in parallel right next to one another and you could just switch back and forth by opening and closing valves. You already have the Alpha. We need some actual data not and feedback, not just manufacturers promises and hearsay.moosepucky said:

It would be interesting to compare both over time.hot rod said:It would be interesting to try the Alpha for maybe a month, then the VT and compare the difference in operating and comfort conditions. I'm curious how ODR and VS/ DT get along.

Same question with mod con and VS/VT?

With a fixed speed as it has been running all these year, the system will find thermal equilibrium and the delta T throughout the system will vary somewhat based on load.

If both circ choices end up costing about the same $$ to operate a season, or for the pump's life expectancy, then comfort and performance may be the best way to select.

I think my wife would end up killing me in the process though

This boiler retrofit has been going on for over a month and the only thing that has happened outside of a LOT of thinking and planning is the Bosch has left the pallet and migrated onto the wall and the basement has filled up with fittings, pipe, and tools.

http://i1066.photobucket.com/albums/u414/turtle-web/misc/HVAC/fittingsMore_zpsqgibhw7n.jpg

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I think that would be a good idea. A mono flo test bed.0

-

Yeah, micro-processors and heat are a concern, as is dirty voltage. I like the way Wilo moved the electronics off the motor. looks funky, but give you some temperature protection.Gordy said:

Operative word life expectancy here. How many of these new ECM circus with Logic will still be in the boiler room as original 20-30 years from now?hot rod said:It would be interesting to try the Alpha for maybe a month, then the VT and compare the difference in operating and comfort conditions. I'm curious how ODR and VS/ DT get along.

Same question with mod con and VS/VT?

With a fixed speed as it has been running all these year, the system will find thermal equilibrium and the delta T throughout the system will vary somewhat based on load.

If both circ choices end up costing about the same $$ to operate a season, or for the pump's life expectancy, then comfort and performance may be the best way to select.

Same with chilled water, I think Grundfos is one of the few that allows low temperature operation. Condensate or moisture is tougher to deal with, it seems. Here is the iced example they show at the Expos.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes, but read the fine print. A Taco SR-501-OR-4 will give you a partial curve that bottoms out around 130°F return temps. Full ODR will require a motorized mixing valve (like an iSeries-R) and (usually) an additional pump.moosepucky said:Can a ODR be retrofitted to a 65 year old cast iron boiler?

0 -

From what I have read a 1.5" monoflo main pipe will flow at between 20-22 gpm (that's a LOT of water flow). I've gleaned this info from the B&G site on their 1.5 x 1/2 and 3/4 venturi Ts and on the site I originally posted (pipe sizing flow rates)Hatterasguy said:

The "comfort" factor of the two pumps is identical. Both will provide sufficient flow to heat all rooms in the house.

That being said, the Alpha will operate with a smaller ΔT and flow more water. This results in less efficiency because the RWT to the boiler is higher and condensing is reduced. However, the fact that it flows more water means that the system pressure will be higher and you most likely will not have balancing problems. If you did, you always have the option of running the Alpha at its highest settings.

http://documentlibrary.xylemappliedwater.com/wp-content/blogs.dir/22/files/2012/07/GHS-619B.pdf

http://highperformancehvac.com/boiler-piping-flow-pipe-sizing/

The system (as it has been for the past 25 years has a ΔT of 5 and less which means that the existing/original pump is moving some water. Photo of the original B&G pump is in my first post. No flow info on the pump housing or motor plate so other than taking it off and measuring I have no idea what it is moving.

Both of the pumps I have ordered are variable speed/flow

Taco VT 2218 (18 gpm): http://www.taco-hvac.com/products/variable_speed_products/vr2218/index.html

Grundfos 15-55 F (21 gpm): http://us.grundfos.com/products/find-product/alpha.html

It's looking like I may need to try both of them until I can evaluate the performance of both

I'm thinking that I should install these pumps in the old system and see how they perform before committing to one pump or the other for the new boiler.

I can flush the system and while it is down, swap out one of these pumps with the B&G beast and see what happens.

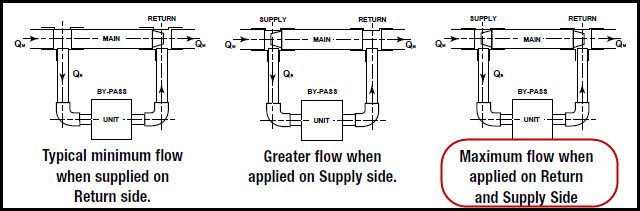

Am I going to run into issues with the 10 gpm hydraulic separator?

Now I am wondering if I should have gone larger there too. the boiler will more than likely be running 4-5 gpm but who knows what the race track on the other side of the separator will be running. Can a 10 gpm LLH handle the volume that the race track may need to flow? I can always get a larger one {sigh}. they come in 10-, 15 and 30 gpm and custom sized ones should that be necessary.

When I throw the pipe size and gpm for both sides (4 and 20) into their calculator, It comes up with 1.91 f/s which means %$#@*&!!!

http://www.spirotherm.com/products/quad/selection

What a choice?!?!?! That's almost as bad as....Hatterasguy said:The VT, is a completely different animal. It will maintain a ΔT that you set no matter how slow it must run (within operating parameters, of course). It's flow rate will be much slower than the Alpha for the majority of the heating season and it provides greater efficiency because of it. However, the fact that it flows less water means the pressure is less and the water might not want to go to your new rads that have some long runouts. You might have to do some homework to get it to run so that all rads are receiving a acceptable flow rate.

So, take your pick. One is easy and slightly less efficient because of it. The other is exactly the opposite.

"do you want a blindfold or not?"

On the longest run (2nd floor hall/bath) I plan on using 2 ventur Ts, the first reversed which should more than double the flow rate on that feed loop. That loop is double the distance of any of the other 2nd floor loops of of the race track

0 -

@moosepucky just because the pipe can handle that flow rate does not mean you need that flow rate. 10 gpm effectively gives you .67 gpm in each circuit if they were all identical pressure drops....which they are not. So some will get a little more some a little less.

1 1/2" pipe has the ability to carry 225,000 btus @22.5 gpm do you need that many btus? No. That is why your present delta is so narrow very high flow rates.

Honestly you can do two closely space t's ,and achieve the same result.0 -

My guess is if you cut your flow in half you will,still be a delta of 12*0

-

so if the previous system was running 18-20 gpm (which is pretty close based on the performance)... and working absolutely pitifully....Hatterasguy said:I'm sure you're correct. He's got to cut the flow by 75% to get in the ballpark.

Gordy said:My guess is if you cut your flow in half you will,still be a delta of 12*

The hydraulic separator of 10 gpm is going to be "goldilocks porridge" for me... sweet.

this will allow the boiler to be happy @ 4gpm and the venturis "should" work well at anything from 5 gpm and above.

Hopefully I can set a low flow of 4 and a max of 15 on the racetrack pump to start with and see what happens. Time to read the spec sheets and stop worrying. I still have no idea about whether the pump in the Bosch boiler is variable or if it is "user selectable" as far as the 3 speeds. All I have read just says 3 Speed Grundfos Integrated Pump, nothing more about the pump.

I guess it is about time I un-box that Grundfos Alpha pump....0 -

All of the old system operated pitifully?0

-

The on board pump,is user selectable. 3 speeds.

Remember the goal with the boiler for its rated efficiency is getting the return water sub 130* this may not always be possible at design day temps unless your emitters are abundantly sized for the load.

Otherwise your not doing much if any better than a ci boilers efficiency.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements