Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Multistage, multizone wiring of thermostats

Options

djohn

Member Posts: 93

Well, the AC I was planning to use for last couple years ended up being an old, low seer unit. Should have checked the model/serial number sooner. Even though the coil was much newer, I decided to bite the bullet and invest into new 18 seer, 2 stage heat pump and matching coil by Goodman.

Here is the composition of what I have, and how I intend to use it:

- Heat Pump stage 1 (running at low speed of Trane XV95 blower)

- Heat Pump stage 2 (running at high speed of Trane XV95 blower)

- Furnace stage 3 (100k BTU Trane XV95 furnace with stage 1 and 2 via time delay)

- Boiler stage 4 (Lochinvar Knight with 3 zone valve relay board)

I use in-floor exclusively about 4 months out of a year and don't need stage 4 to fall back to 3, except for breakdown/emergency. Also don't need or want stage 4 to go on to help lower stages. HP 1 and 2 would handle fall and spring months and go to furnace heat based on outside temp. I do plan on installing ERV for the air quality. I also use XV95's CleanEffects and slow ECM circulation all the time.

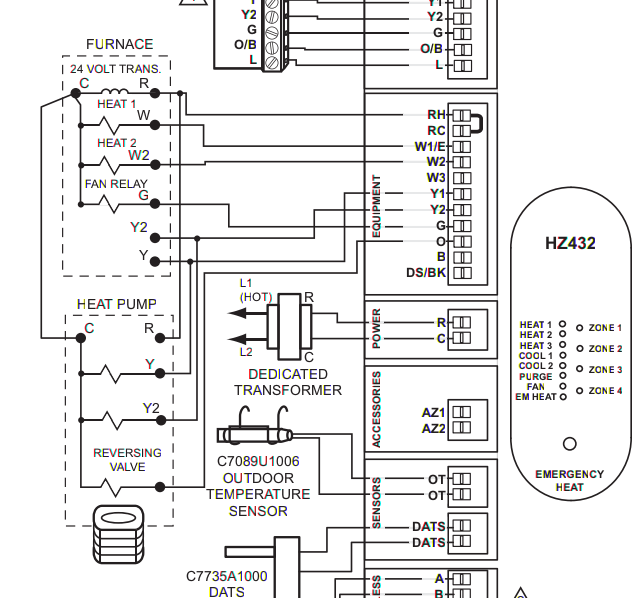

Ducting is all zoned through dampers and wired to HZ432 panel (with bypass damper too). In-floor zoning is done through zone valves and runs thanks to Zman's (famous single pump system, haha). HZ432 looks like 3 heat, 2 cool device, so boiler zone wiring will likely bypass it and go straight to thermostats, unless for some reason I end up with HP stages time delayed too, like furnace and fit all 3 appliances on HZ.

I originally planned to use Ecobee thermostats but I was grossly disappointed with the way the company evolved, moving towards Nest crowd and making thermostats for not-so-smart people (sorry, couldn't resist myself). I am doubting Ecobee 3 is for me and now it looks like Ecobee Smart won't be developed anymore. Too bad.

It looks like it will have to be Honeywell Prestige IAQ 2, as I really don't see other options right now. Any suggestions here?

Here is the composition of what I have, and how I intend to use it:

- Heat Pump stage 1 (running at low speed of Trane XV95 blower)

- Heat Pump stage 2 (running at high speed of Trane XV95 blower)

- Furnace stage 3 (100k BTU Trane XV95 furnace with stage 1 and 2 via time delay)

- Boiler stage 4 (Lochinvar Knight with 3 zone valve relay board)

I use in-floor exclusively about 4 months out of a year and don't need stage 4 to fall back to 3, except for breakdown/emergency. Also don't need or want stage 4 to go on to help lower stages. HP 1 and 2 would handle fall and spring months and go to furnace heat based on outside temp. I do plan on installing ERV for the air quality. I also use XV95's CleanEffects and slow ECM circulation all the time.

Ducting is all zoned through dampers and wired to HZ432 panel (with bypass damper too). In-floor zoning is done through zone valves and runs thanks to Zman's (famous single pump system, haha). HZ432 looks like 3 heat, 2 cool device, so boiler zone wiring will likely bypass it and go straight to thermostats, unless for some reason I end up with HP stages time delayed too, like furnace and fit all 3 appliances on HZ.

I originally planned to use Ecobee thermostats but I was grossly disappointed with the way the company evolved, moving towards Nest crowd and making thermostats for not-so-smart people (sorry, couldn't resist myself). I am doubting Ecobee 3 is for me and now it looks like Ecobee Smart won't be developed anymore. Too bad.

It looks like it will have to be Honeywell Prestige IAQ 2, as I really don't see other options right now. Any suggestions here?

0

Comments

-

This looked pretty easy until you through the infloor and the erv into the mix.

If it wasn't for the ERV you could just have a seasonal switch and keep the systems separate. The ERV will blow cool air on you in winter mode unless you get the velocities way down.

How is this thing ducted?"If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

It's a basement and 2 stories above it. Lots of decentralized and high returns. Flows really nice. Plenum off the furnace splits 3 ways:

- 2x 14x8s taking care of 1st floor, dampened

- 1x 14x14 taking care of 2nd floor, dampened

- 4x 8" rounds coming off 14x8s close to plenum for the basement (had no other way to do it unfortunately), all 4 dampened

- bypass damper

I already have the HZ432 panel. It technically is 3 heat, 2 cool device, but the way the wiring diagrams are, with 2 stage heat pump and 2 stage fossil fuel (assuming HP and my furnace), it still has W3 terminal available. But no idea if that could be configured in HZ and then via Lochinvar (assuming zone valves would be wired to thermostat)

From what I read, Honeywell Prestige 2 IAQ is the way to go for controls, since it does things like ERV, dehu and humidifier. Its 4H2C thermostat.

So the burning questions would be:

1. Can Boiler/zone valves be wired to thermostats directly, bypassing HZ panel

2. If not, can I use W3 on HZ panel for hydro and still have 2 stages of HP and 2 of furnace

3. If not, I can sacrifice furnace staging through thermostat (ending with HP1, HP2, F1, B1) and possibly even HP heat staging through thermostat (ending with HP1, F1, B1)

(assuming furnace staging through the furnace itself would be time delayed and possibly the same would pertain to HP)

4. Your idea of a switch can be awesome. HP is unusable in Wisconsin winters, so in December HP1, HP2, F1, F2 would be switched to B1, F1, F2 (last 2 being emergency heat). That would involve reconfiguration of HZ and thermostats though, twice a year.

Here are couple docs that might be useful:

HZ panels wiring with hydronics:

http://s3.supplyhouse.com/product_files/HZ311-Wiring.pdf

HZ432 install manual:

https://www.forwardthinking.honeywell.com/related_links/zoning/truezone/install/69_2070_01.pdf

Prestige install manual:

https://customer.honeywell.com/resources/Techlit/TechLitDocuments/69-0000s/69-2758EFS.pdf

and

https://customer.honeywell.com/resources/Techlit/TechLitDocuments/69-0000s/69-2739.pdf0 -

Follow the instructions carefully on the wiring of the furnace. You don't use Ylo and Y for an unloading scroll. Follow the instructions for using Y and BK for that technology. Otherwise you'll have airflow issues on low cool.0

-

Can you be more specific? I had it wired without using BK on thermostat and furnace blower ran way too fast in ECM circulation mode and both HP stages were running in high speed, so pretty bad especially for dehu.0

-

Here is the way I have it wired right now, between Heat Pump (DSZC18036), Furnace (XV95) and Thermostat (TCONT402). It seems to be working, although it might have been cooling quicker when it was wired with both stages of cool in high speed (BK was unhooked on thermostat, bad circulation speed though - that Trane thermostat needs BK for VS). That might be obvious.

O - O - O

W1 - W1 - W1

C - B/C - B

R - R - R

Y1- Y/lo - Y/Y1

Y2 - Y - Y2

N/A - W2 - W2

N/A - G - G

N/A - BK - BK

L on HP not attached

W3, H1, H2 on thermostat not attached0 -

Trane shows hooking Y1 on the stat to Y on the furnace board then to Y1 outside. Then Y2 on the stat goes to BK on the board and Y2 outside. You need to cut jumper W14 to allow this. O then needs to be connect to the furnace board so the furnace knows whether the heat pump is heating or cooling.

The Ylo runs the blower at 50% speed for the dual compressor models. The unloading scroll like your Goodman is closer to 80% on low so you are running way too little airflow on low. If you use the BK method, the blower slows to 80% which is more appropriate for your scroll.0 -

Trane board shows 800cfm in 1st stage and 1,200cfm (full speed) in 2nd stage, using my way of wiring.

Goodman coil flow table starts at 800cfm and goes past 2,000cfm.

If I dip switch it to 450cfm per ton, it would go up to around 900cfm and 1,350cfm. Low stage flows faster than nominal 60% (should be 720cfm in 1st) likely because of CleanEffects flowing better than average media filter.0 -

Dipswitched to 450cfm per ton it now flows 600cfm in circulation mode and 900cfm in 1st stage.

I believe BK has to be connected between thermostat and furnace to achieve 60% nominal speed in 1st stage. If BK is disconnected, it's 50% as John mentioned and also circulation mode runs really fast.0 -

Just a thought to all. Did you know that when you receive your res. furnace they are,.......(in the lab) specing it out to .5 static/blower performance? Just my .o2, but you can take off the ducting/filter/coil ect after that. As a result by the time it's properly designed the system, it should be close to desired performance by us. This is not of corse for extended or zones designs as they require Longer branch duct or funky and excessive bends. Not law, but Res. supply duct just because on possible noise is recommended at 1000FPM and ret. @ 800. Like the Matrix some rules cane be bent/ Others can be broken.

My.020 -

Empire, that was my thoughts too. Bet Trane spec'd it with regular media filter and fairly restrictive ducting (not new construction).

Question to John - would my new numbers satisfy your concerns?0 -

djohn can I ask you 1 or 2 Q;? 1). In all your specs. I have not seen a plan as to the space you are heating and or cooling? Fair enough? 2;) How have you or will you let us know what your climate is, location, Average degree days/ structure exposure etc.... How in all good conscience can I or anyone give you a honest recommendation? Really? If you give me a million "bucks" meaning deer, because there is no price discussed here, I can also have your system recover enough hot water to actually Ionize the crud on your dishes so you will not even have to have a dish washer. NOW! I digress..... sorry Had to do it. You have a lot of nice wants but no and I repeat NO SPECS. for me or others to look at. Not a big deal just saying I can go as many stages as the equipment allows, give back up and worse case scenario, full load demand.

I know you have a HP. and Lockinvar boiler which by the way covers your parameter loss, heat wise...... Was it sized for the house or half to 3/4 of the loss of heat. If it were my CO. My boiler would cover your total loss, unless the home owner stated otherwise,plus It's my **** on the line when it doesn't seem to cut the mustard. I hope you see where I am coming form. Your Q:? are general and nonspecific.....

Peace;

Mike T.

Mike T.0 -

Mike, it's not like I can change anything - it's all installed and we live here, in SE Wisconsin. I can't locate my heat loss calc right now but remember it was below 70k BTU.

Walkout basement with 2 floors above it, about 1,600sqf per level. 3in of closed cell spray foam + 2in of polyiso outside, taped and staggered. R-38 + 2in of taped and staggered polyiso for cathedral roof. Good low-e windows and doors. Overall pretty well insulated and airtight.

Trane XV95 is a 100k BTU version, easily does entire house (was existing to the old house before remodel so we kept it. It was leaky 1,700sqf house)

Lochinvar is WHN-110, 89K BTU version, sized for the house, 2in of foam under slab and then R-19 under joist traks.

HP is 3 ton 18seer, 2 stage version with matching TXV coil.

That helps?

To make things simple, right now I am leaning towards wiring it as:

- HP 1st stage of heat

- HP 2nd stage of heat

- Boiler 3rd stage of heat

- Furnace wired to single separate thermostat set at 50F, as emergency heat (in case we are traveling)(dampers are power close and HP wouldn't be running in the winter anyways)

My original question pertained just to thermostat wiring, so in all consciousness I don't think above info is that necessary, but if it helps, that's great.0 -

Ylo is 50%, if you use the BK route for the unloading scroll compressor, 1st stage cool is 80% of set cooling speed.0

-

John, with BK not being used in thermostat wiring, I have no control over slow circulation speed for CleanEffects - is there a walkaround for that? I also have no control over 1st stage low speed)

With BK I can set circulation speed between 35% and 100%.

I can also set the 1st stage low speed between 35% and 60%.

Without BK circulation speed goes full speed (crazy) and 1st stage low speed is the same as 2nd stage high speed (crazy, no dehu)

So of 2 options reviewed, here is what I can set the speeds to using existing Trane thermostat and Trane blower dip switches:

- 800cfm/1,200cfm (using BK, dip switched to 400cfm per ton medium speed), with 500cfm circulation speed

- 900cfm/1,400cfm (using BK, dip switched to 450cfm per ton high speed), with 600cfm circulation speed (running that setting right now)

I am just guessing that Honeywell Prestige IAQ will give me similar if not better control over the speeds.

Can I get some help with actual solution to my problem and wiring diagram? I have 2 stages of heat pump, 2 stages of furnace and 1 (modulating) stage of boiler that has to be wired using 3 heat - 2 cool HZ panel and 4 heat - 2 cool Honeywell thermostats.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements