Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Duct design

Options

mburg

Member Posts: 48

in Gas Heating

I am new to hvac and have found that I haven't found a good resource that discusses duct design. Can anyone give me a step by step process or point me in the right direction. Thanks.

0

Comments

-

Are you asking how to size a duct system? If so, you can get a "ductulator" from almost any HVAC supply for about $5. Understanding how to use is a little more in depth. I would look in the online book store on this site for something. There are also programs and apps, but they don't tell you how they do it.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Keep your eyes open from supply houses. They usually have classes for that. We have it in MA, I'm sure you do too! A typical two day seminar is likely or an all day Saturday. Usually $100-$175 but related classes to your job most. Employer are more than willing to pay for but may deny reimbursement if you score less than a B or go on a go no-go test that usually occurs with most instructors...

Good luck

0 -

If you want to learn proper duct design for residential you have to read Manual D from ACCA.org, If you can read it and understand it you will be way ahead of the game, it is the only right way to go, they also have training DVD's on manual D presented by Jack Rise, he is one of the best Hvac trainers out there....1

-

-

Appreciate the input guys I have a ductulator but honestly I don't know how to use it and can't seem to find someone to show me. I will look into the manual d also.0

-

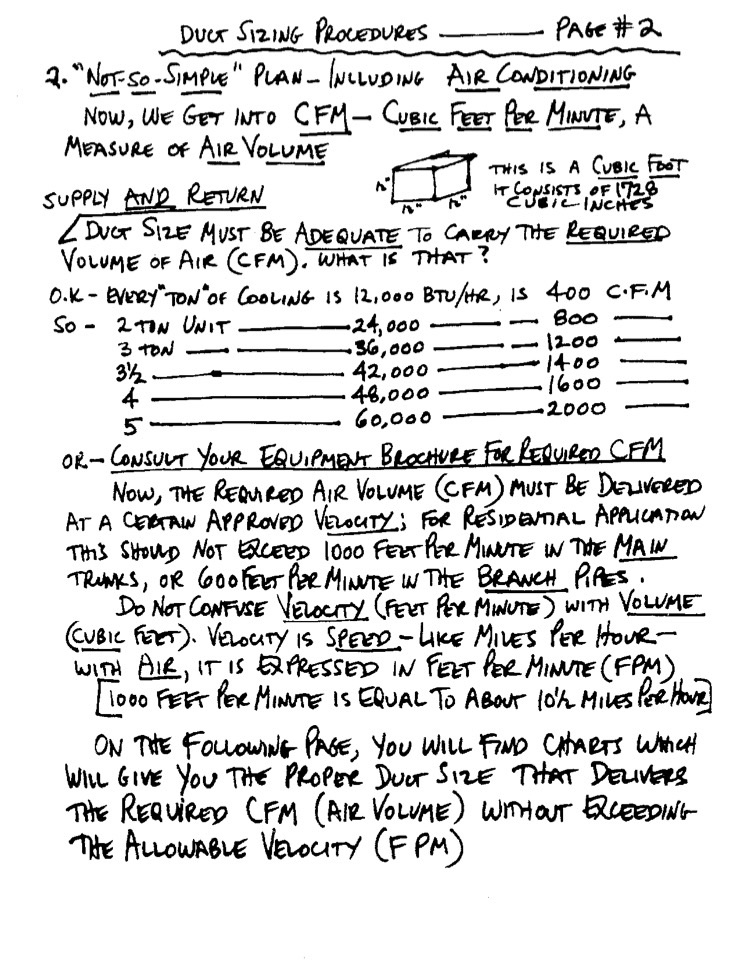

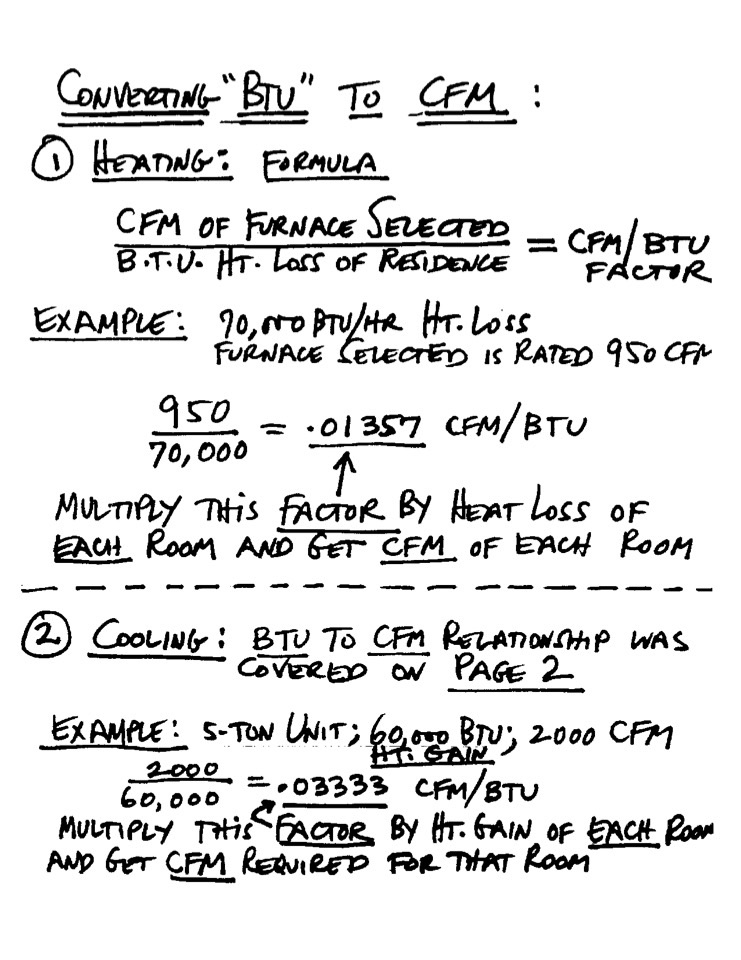

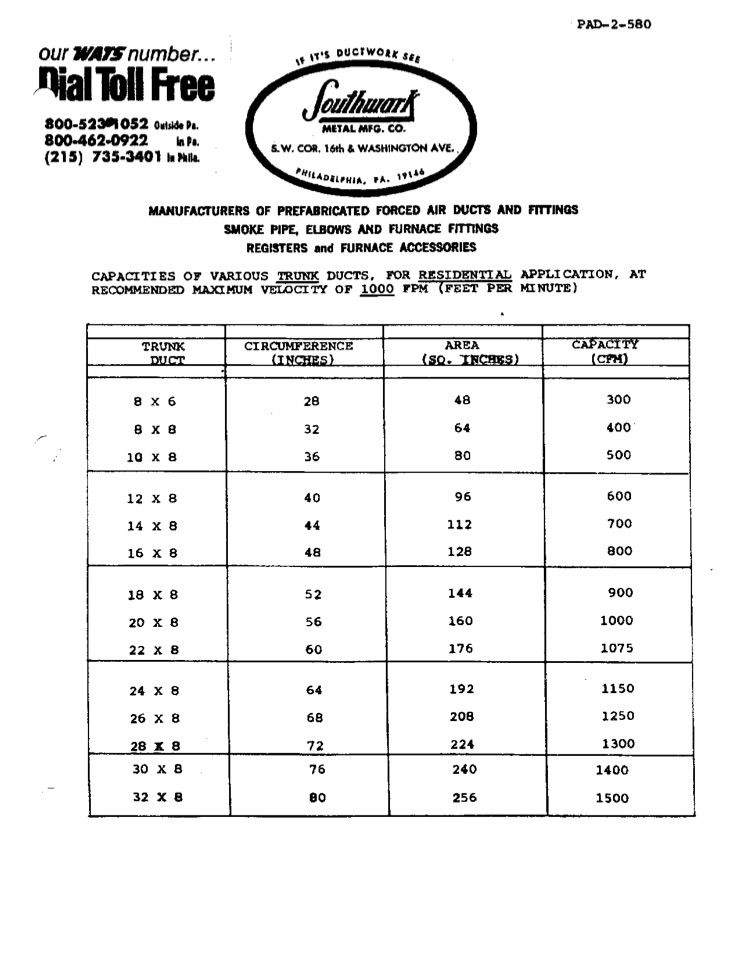

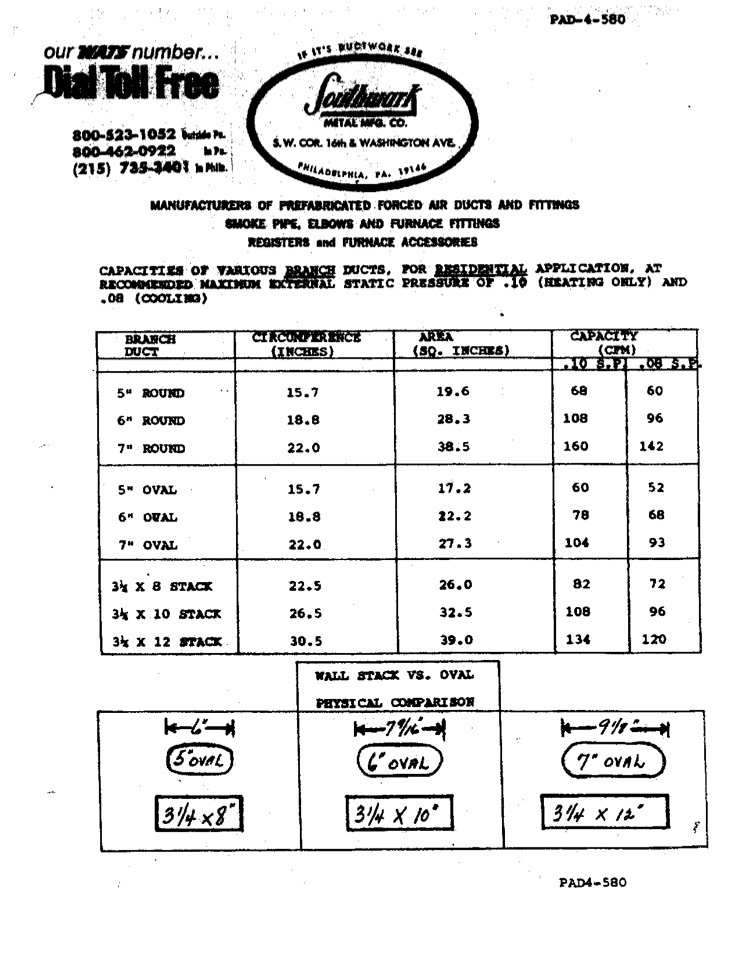

Here's a handy cheat sheet that will help. I don't agree 100% with everything on it, but you won't go wrong using it along with a ductulator.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Thanks, Bob. I'm pretty sure I have all the parts, but there appear to be two duplicate pages uploaded and I want to be sure there isn't a missing page.0

-

Thanks Bob...I looked at all the attachments without reading your post and thought "I'm not in complete agreement with everything", and then I read that you're not either.

The one thing I've always struggled with is plugging in a static pressure of .1 when we don't know the static pressure yet and we won't know until we stick a magnehelic on it.

Furnace manufacturers typically rate the furnace cfm based on an external static of .5, but it's not unusual to have a static higher than that once you consider an A-coil, high MERV filter, and duct work.Steve Minnich0 -

I'm gonna reload it just to make sure every pages is there.

Also, it should be note that page1 applies to 8" rectangular duct only. I'm not a fan of this method.

Sorry, but the pages aren't loaded in order.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

I stand corrected. I believe the .1 is being used in order to keep velocities down and not at all reflective of the total external static pressure.Steve Minnich0

-

Stephen if I read your question correctly you are having trouble trying to figure out why a design pressure drop doesn't jibe with what you measure in the field . None of the rule of thumb/cheat sheet methods take into account the total EQUIVALENT length of the run. As a result ducts are undersized and pressure drops exceed design. When you set your design pressure drop opposite the cfm you need on the ductulator and think that is the size duct required you are assuming the total EQUIVALENT length is 100 feet or less. If you add the equivalent length of all the fittings from the a-coil through the register you will seldom find a run less than 100 feet.

You should divide the design pressure (.1") by the total equivalent length times 100. Let say the measured length plus the equivalent length of the fittings is 150' .1/150 x100=.0667 or.07 . If you needed 100 cfm and set your ductulator at .1 it shows you need a 6" duct if you set it to .07 you need a 7"duct . If ducts are sized correctly the total static pressure will not exceed design.There was an error rendering this rich post.

1 -

Thanks Bob...that is helpful. The cheat sheets that Ironman shared were great too. For some reason, my mind was locked in on total loss and not just the duct losses that were being referred to.Steve Minnich0

-

Bob's got it.

Equivalent length of fittings is a big deal. For example, You have the plenum on top of the furnace going straight up into the bottom of the main trunk, hard 90° turn, no turning vanes. This equals 120' equivalent length of duct. If you run your plenum up and cap the top, bring the top of the main trunk down a couple inches from the top of the plenum and miter the bottom of the trunk into the plenum; you now have an equivalent length of 10'.

Making those changes is a fairly easy way to reduce the esp.

Another biggie is the filters. Normally, the filter racks native to the equipment don't provide enough surface area for an acceptable pressure drop across the filter. This typically means an external filter rack needs to be put in. If you can't get enough real-estate in your return plenum, you can switch gears and go with a 4" pleat. A lot more surface area in those. Hence, lower velocity air traveling through the media and a lower pressure drop, provided you don't go with a high merv rating.

Manual D is the only way I know how to build duct systems. Even then, some stuff is left to intuition.0 -

Yup, I agree with all of that. We've been making our own plenums with offset starters forever and take extra care to size the filter to the blower cfm. I see too many guys sizing filters based on the cut-out on the side of the furnace.

I took the HVAC Save class and certification a few years ago and that was quite an eye opener. It's not uncommon to see a 95% AFUE furnace connected to a duct system that's only 40-50%. The results are quantifiable.

Manual D - took the class in the 80's but keep the manual nearby for reference.

Steve Minnich0 -

With that said, I rarely do forced air anymore and I don't miss it. Boilers and high velocity AC is our bread and butter. Some ductless splits but the application has to be just right for me OR an there has to be an insistent customer. I have trouble getting past the aesthetics.Steve Minnich0

-

Hello: If you're in PG&E territory, they are having a class taught by Dan Perunko on Optimizing Residential HVAC System Performance. He knows how to get tight ductwork that flows well. Here's a link. https://pge-web.ungerboeck.com/classcalendar/Results.aspx

Yours, Larry0 -

Another great resource for duct design are the guys from NATIONAL COFORT INSTITUTE0

-

If you want to look also into computational fluid dynamics simulation for duct designs this project is free to use as template: Duct Design Flow Analysis0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements