Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Ignitor issues?

Options

Canucker

Member Posts: 723

in Gas Heating

I have been having some issues with my boiler lighting(not helpful during this cold spell) I can hear the ignition click then the burners light up, followed by it shutting down less than a second later. It retries to light after this and usually is successful, and runs until the heat call is satisfied. Sometimes I can hear it attempt to light for upwards of 15-20 seconds before the burner fires. The burner does not always light, and goes into a lockout, I assume. It will light after the power is cycled. This is the part that concerns me. (I have had the pleasure of coming home after night shift to a house that was 13C during this cold spell) The boiler is a Raypak E-105, copper tube HX, Honeywell control(not sure the model #)

Is there something simple I can do to repair this or should I schedule a service call before it dies? (I know my limitations, rather not be playing with the gas train)

If you need anymore info, I can provide it. Thanks in advance.

Is there something simple I can do to repair this or should I schedule a service call before it dies? (I know my limitations, rather not be playing with the gas train)

If you need anymore info, I can provide it. Thanks in advance.

You can have it good, fast or cheap. Pick two

0

Comments

-

My first guess would be flame sensor needs cleaned. If you have spark igniter the flame sensor may be part of it. If hot surface igniter than probably separate flame sensor. You don't usely try to clean a HSI.0

-

I'm not sure what I have. Is it easy to identify from a picture? I'll see if I can get one, if it is.You can have it good, fast or cheap. Pick two0

-

What do you actually "hear" when it attempts to light for 15-20 seconds before burners light? Is a tic-tic or buzzing sound?

If you have owners manual or download one it would explain the ignition sequence of operation.0 -

I wish the manual was easy to find online. I've looked, I never find a match(probably not looking for the right equipment)

As for the sound, I think it's closer to a rapid series of tic tic tic sounds.You can have it good, fast or cheap. Pick two0 -

That is what spark ignition would sound like. The spark and the flame sensor may be the same device. It may be part of the pilot burner. Usually to remove to clean you will have to disconnect the pilot tubing and remove the whole assembly from the main burner. The pilot burner should be cleaned also. It is possible your gas pressure drops and there is not enough for good pilot lite.

There are several different designs.

Some one may come on who is familiar with that boiler and give a better answer.0 -

Give us some control numbers and we can help you out.0

-

The only number I can see on the Honeywell is a sticker that reads S8600H1022(1) Is there anything else you need?You can have it good, fast or cheap. Pick two0

-

What you have is an Intermittent Pilot System that uses a spark to light the pilot and then proves the flame through a flame rod. The pilot should be pulled and cleaned and the sensing rod cleaned with a soft clean emory cloth. It may also be the case that you have lost the low voltage system ground from the pilot to the module (S8600H). Try this and see what happens, it would be good if you knew how to measure and test microamps, if not a professional should be able to do that.

Because you have a Raypak it would be a good idea to have a professional come in and clean it and check the heat exchanger condition.0 -

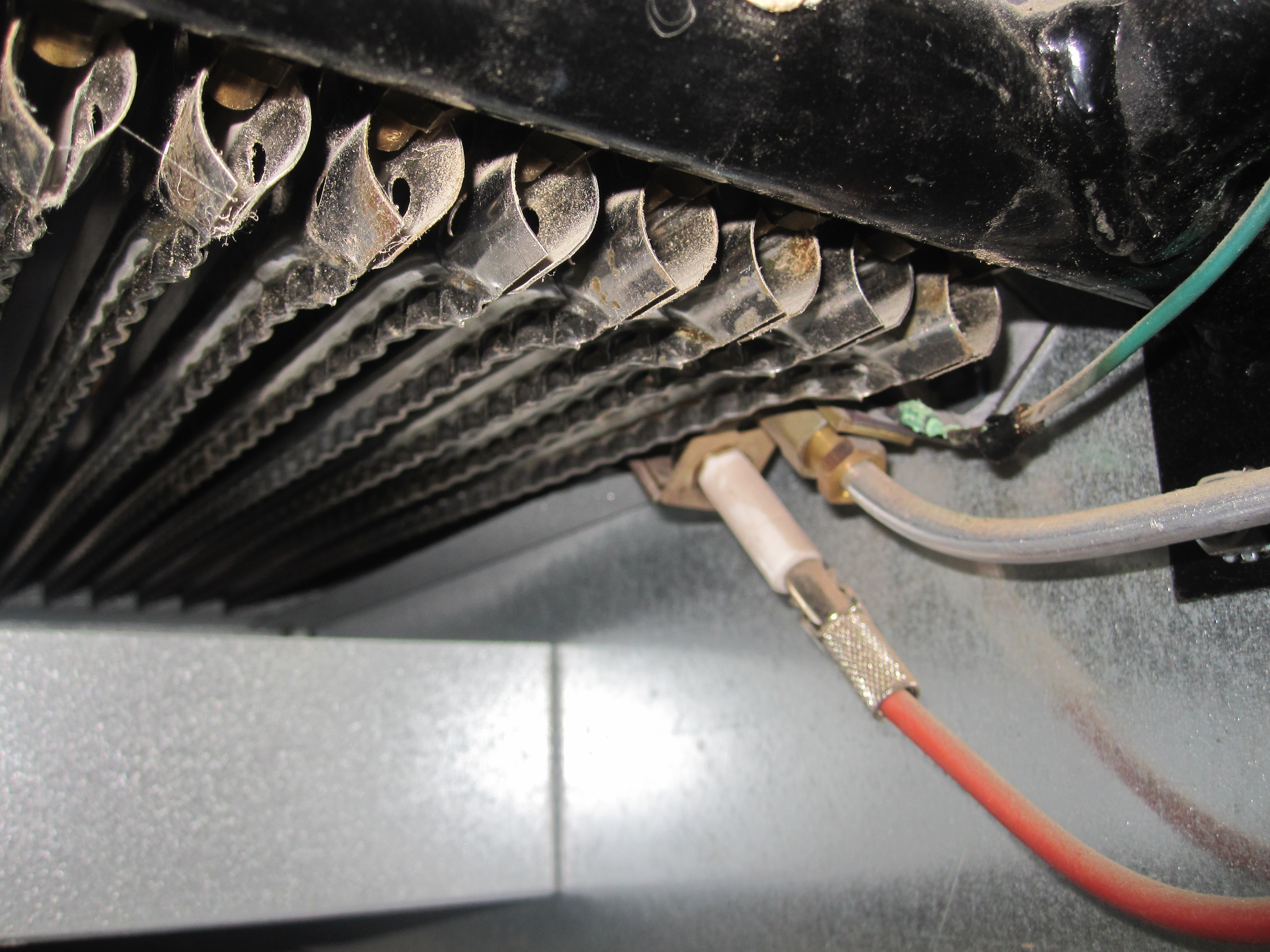

Thanks @TimMcElwain , @JUGHNE Here's what I'm looking at, not sure how it comes apart. It's been firing fine today but it's been warmer too.

You can have it good, fast or cheap. Pick two0 -

Looks like that ground wire may have some issues. The pilot assembly is attached to one of the burner tubes.0

-

That ground wire that looks baked out is essential, it tells the HW module that there is fire, (proves flames) and to stop sparking because there a pilot flame and turn on the main gas valve. If when the main valve opens the bad ground loses its continuity the HW shuts off all gas and tries the relight sequence.

So what is your skill level.....a man's got to know his limitations.

To fix this you must disconnect the pilot tubing at burner, remove the pilot assembly from burner. Clean pilot, spark/sensor, redo ground connection at both ends.

OF course you shut off the power and gas first.0 -

You have to pull that whole burner rack out to get to the pilot. It's something a pro should do. You have to disconnect wires and the gas line at the union. Also if that boiler hasn't been cleaned, when the burners rack is out is a good time. Takes a few hours if the copper fins are dirty and they may be if your melting that ground wire.0

-

I have never seen one of this type. Uncle John obviously has.

I would call a pro familiar with a copper fin boiler. But you now have an idea what to expect as the problem. You know all the major parts probably work alright.0 -

When its running are you seeing a bit of a flame coming out at the pilot tube connection at the pilot assembly….That could be a cause for the burnt ground wire…0

-

Thanks guys. It sounds like this is getting beyond my skill level, @unclejohn I'm not that comfortable playing with gas without training. @ja There doesn't appear to be any flame coming out of the pilot tube connection.

I'll have schedule a service call, hopefully they can get over here before it has bigger issues. I had it serviced in October, so the melted wire must have happened recently.You can have it good, fast or cheap. Pick two0 -

you're a smart man0

-

The green wire is the ground and the system uses the spark wire as the flame sensor. If not the pilot would be facing out not in and the spark would be behind the flame. When the tech comes out be there and watch, he has to strip that boiler down to clean it right, the copper tubes should look like copper not green like pennies in the rain.0

-

I have noticed it doesn't want to light if it's had a few calls for heat in a short time frame. (I have 3 zones and an indirect.) Is it possible that a dirty heat exchanger is letting it get too hot around the ground wire?You can have it good, fast or cheap. Pick two0

-

Yes it is. There should be a flame roll out switch on the opposite side from the pilot thats a manual reset type. So if you don't have that issue, and it hasn't already been pulled up out from it's proper position it isn't totally blocked but might be getting close. It could also be that you have a slight leak at the compression fitting going into the pilot that burned the wire and you just need to clean the flame sensor.0

-

Don't see many if at all raypacks up here...do they really have a manual reset type flame roll out sw. Not seen that. Manual resets are mostly spill sw. Flame roll outs must be replaced...After of course u find the reason....usually not good. Lack of TLC.0

-

This troubles me. I have it serviced every year but I've never seen any of them take it apart for cleaning. Just a look up at the heat exchanger with a mirror while the burners are out for cleaning. They do a combustion analysis, tag it and go.j a said:Lack of TLC.

You can have it good, fast or cheap. Pick two0 -

Well spill or flame roll out. I think of spill switch from out of the flue, as in blocked chimney or vent after the furnace or boiler. And I think flame roll out any time the flame comes out of the heat x. And yes the ones on the ray pacs and others I have seen are reset-able. Canucker; when they do a combustion test they use a meter not just the eye-ball test. If they are using a meter and the co is ok it's most likely just a flame sensor cleaning issue.0

-

That's good news then, the last CO reading was 3 ppm. Hopefully it's a simple fix. Thanks for the helpYou can have it good, fast or cheap. Pick two0

-

Just posting as a follow up. Had the boiler serviced today, and the ground was shot and needed to be replaced. The tech did note that the gas valve itself may need to be replaced in the future as it shut down once immediately after ignition, but the long attempts to light seems fixed, no leaks in the pilot tube. As a side note, this tech is the only one who's asked me to turn on my fireplace, dryer and bath exhaust while he did a combustion analysis.You can have it good, fast or cheap. Pick two1

-

Thanks for advising on the out come.0

-

I've been continuing to have intermittent ignition problems. This will be the 4th time the the service guy will have been here, when he arrives today.(Essentially the only thing left to change is the Honeywell control or the wire to the ignitor) Now, being the curious fellow that I am, I found the test procedures for intermittent spark ignition and ran through them. What I have found is that the ignitor and wire have resistance when it's at ambient temp. It's very small at the tip(around .5 ohms and changes slightly as you slide the probe up and down the rod) Now after the burners shut down(which they are doing before the end of the call and will not re light until sometime later), I shut the power off and checked the wire again. At this point the assembly has a very high resistance at the tip(same as if I stuck the leads into the ground) Does this point to the wire being a problem and probably not the Honeywell? (I'm asking because I don't want to pay for another service charge if the control is swapped out and I have the same problem, which is what I'm being told the problem is now)You can have it good, fast or cheap. Pick two0

-

At this point you may want to replace the pilot and the control and the valve just to get it over with. I don't like throwing my hands up and taking a stab at a problem especially since it's a expensive repair. If the tech stays long enough he should be able to catch the issue. Although if the gas controls and valve are over 20 years they should be replaced anyway IMO.1

-

That's exactly what direction I ended up going. New board and new pilot assembly, runs like it used to again. The original control died while he was testing the system.You can have it good, fast or cheap. Pick two0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements