Furnace cycles constantly, smells bad, and makes house shudder

The furnace is a New Yorker. I don't know the date of manufacture or the model number, it seems to be missing the tag. It was last serviced in Feb 2014, I have service records back to 2000. It is oil/hot water, with two zones.

Symptoms: Sometimes the furnace seems to behave normally enough and then other times it has periods where it goes crazy. These seem to be getting more frequent. The furnace will cycle on and off far too much, often in intervals of just a minute or two. When it runs, it seems loud (not like bearing noise in the blower though) and when it shuts off it is VERY loud and it shudders so violently that I can feel it throughout the house. The damper in the flu slams hard then too (maybe that's normal). Sometimes the damper slams hard even while the furnace is running. It also has a very strong bad smell, maybe like it isn't burning cleanly. I can smell it outside around the house too. Also, every once in awhile, we notice the house goes cold and when I check the furnace, the reset light is blinking. It does start up when I push the button.

I'm wondering what the problem(s) could be and if I can do anything to fix it. I'm not against calling a serviceman if necessary, but I'm handy and am open to saving money if I can!

Here are a few pictures to get an idea of the unit:

Thanks!

Comments

-

This sounds like a combustion issue and could be dangerous, it is also burning a lot of oil that it shouldn't.

If you don't get this serviced the best thing you can hope for is wasting money on oil because of poor performance, the worst thing is possible carbon monoxide getting into the house and making you sick - or worse.

The oil gun is not working right. It's going to take knowledge to troubleshoot the problem and a combustion analyzer to set up the oil burner properly.

I would call a service man asap.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Looks like an outside, or underground tank? It may be an air problem, plugged lines/filters, wrong nozzle and pump pressure, and those boilers are ticklish. A lining in the chamber area may be in it's future. No home inspection done before you bought?0

-

Also, if the air inlet damper is still in the burner, have it removed. I personally have never had a problem with them, but it is recommended to remove them0

-

FWIW:

Unless you have some special talents you haven't mentioned, you aren't handy enough to fix your problem. You need a Professional. And not the cheap one. One with a digital combustion analyzer.

New Yorkers aren't bad boilers for the cheap price they are. They come with that Beckett Burner. All Beckett's have issues with mis-firing on occasion that will get worse.

The first is the POS oil filter on the wall. It is probably plugged solid with sludge. Just as effective as that filter element, would be to take one of my old wool socks and stick it inside. Its almost as effective. Because you have such a POS and useless oil "filter", it passes sludge through the fuel system to the fuel pump, blocks the pump strainer, and clogs the nozzle strainer. The reason the burner is cycling rapidly is that the burner fires for a moment or few, then the nozzle strainer restriction stops the burner while running, the flame sensor senses no flame, and drops the control out. After a minute or two, the burner tries again, establishes flame and repeats the cycle. Until it will get so bad, you will need to re-set it. DON'T BE DOING THAT!!

You need to be having that oil filter changed and another one added. You need two. Spin-On types like Garbers. One to replace the one coming through the wall. Another at the burner.

Where are you located? Some/many States require an oil safety valve that will shut down the fuel if there is a fire, called a Firomatic Valve, usually direct connected to the fuel pump. You have none. The oil line where it comes through the wall, needs to be sleeved. If you live in Massachusetts, the oil line needed to be protected from the tank to the burner AND the Firomatic valve would have been installed. If not, it is an uninspected or un-approved installation. As far as the zone valves, they are probably original to the house and installation. They have probably 10,000 or more operations in their lifetime (opening and closing). How many brake jobs have you had done on your automobiles since that house was built. Replace the other valve. It will probably give you the same good service as the old ones did. The valve mechanisms can be changed without removing the valve body.

As far as the burner is concerned, someone has kept after it. It has a new electronic ignition transformer and a new burner controller. Probably installed because it was misfiring. Because the POS filter was passing fine micron particles through the pump and into the nozzle strainer. And when that happens, they spray oil on to the outside of the retention head/end cone and help the spark short out to ground. It has to be scraped off. Ignition electrode settings are critical on Beckett AFG's. Anyone not using the appropriate factory supplied gauges for the burner set up, and using a ruler, needs to have their rulers confiscated. with a heavy fine for doing so. IMO.

There's an old saying I once heard about oil and gas in relation to Carbon Monoxide.

With oil,

First you smell it, (exhaust)

Then you see it (smoke)

Then, you die

With gas:

You don't smell it (exhaust)

You don't see it (smoke)

and you die.

If you can smell exhaust smoke, there is Carbon Monoxide mixed in with the exhaust smell.

You are obviously NOT in Massachusetts. Where it is required by law that when a house is sold, there must be working smoke and carbon Monoxide Detectors in the house, on every floor, outside of bedrooms. Including the basement where the appliance is. And they have to be inspected by the Fire Department before completion of the sale. No inspection, no sale.

If you have them, and the alarms have been going off, you haven't removed the batteries to stop that annoying noise have you? If you live in a State that isn't requiring Combi units upon sale, do yourself a favor. Save a life. Go out and buy some. Or have them installed. The life they save might be your own.

And it is due for and needs a serious annual cleaning.

0 -

There is also no solenoid on the pump. As you described on shut down, it may be a pump cut-off problem. There is also another zone? I see the 2 Honeywells, which looks like a rat's nest of wires, and a take-off before the air scoop? The Genisys control would go into recycle if there was a flame failure, so I would say it would lock out after 2 of those. As Ice said, this setup would not fly in Mass. There needs to be more thermal oil valves. Also is that an exhaust fan to the left of the boiler? I see a grate or something.0

-

I would set this up for intermittent (constant) ignition to start with. This will tell you immediately just how well it is set up. You are most likely floating away after the ignition drops out. This unit originally had an 8184G that was constant ignition. The new control is a blessing in disguise, but when wired for interrupted ignition, everything must be spot on, and I would say that it is not0

-

A great feature on this control is that a trained tech can plug a contractor's tool in it and see what OHMs you have been running, and some other useful info0

-

@Billtwocase:

With that control like a Carlin 602000 electronic control, if the burner runs for a long enough period after a re-start, it cancels out the previous flame failure.

IMO, that control is a nightmare, disguised as a nice dream on an AFG with all the quirks they have being a fixed head burner.0 -

To add to the above stated comments, if as you said the unit was serviced in February 2014 (the coldest month of a horrific winter) it was probably repaired because it was broken and not "serviced". The unit should be checked out and cleaned by a pro. At least that way you will KNOW that it has been done.1

-

Gotta disagree Ice. I had more problems with the Carlin controls than any other. I like that control over the previous ones. I like the versatility. Carlin may have improved as of lately, but I still have a very bad taste that won't go away, and it was more of how warranty was handled, than what I had lost due to call backs on them. Beckett and Honeywell were always more of a stand up company when it came to a loss0

-

Thanks for all the input. First, I do have working CO and smoke detectors outside the bedrooms and I haven't pulled the batteries!

This is southeast PA, btw and I did have a home inspection for whatever it was worth. Not much as I've already learned in a few instances.

The second zone valve is already on order.

Was not aware that that filter type was so terrible, I will certainly add two Garber spin-on types.

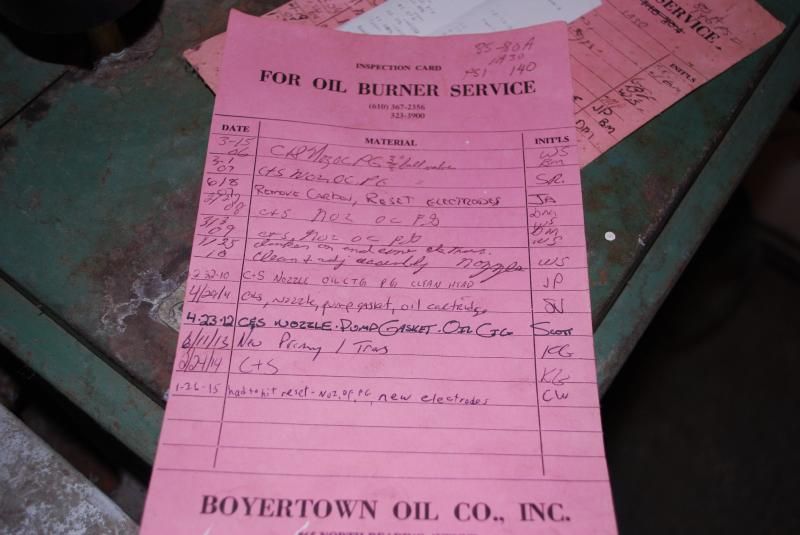

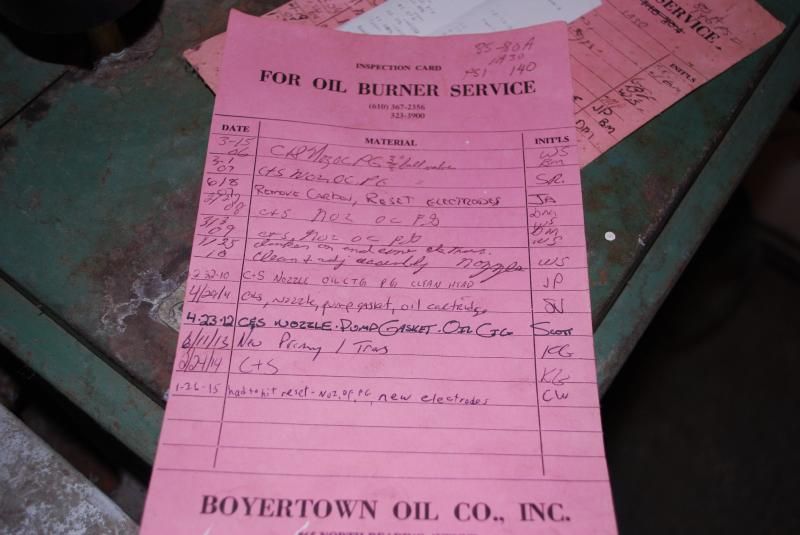

It looks like the filter cartridge was replaced last in 2012 going by the records.

I also have a test slip from the Feb 2014 service which says 5.5% 02, 4ppm CO, 462.7* F fluegas temp, 83.8% efficiency, 33.2% excess air, 11.58% CO2, and 6ppm undiluted CO. FWIW.

@billtwocase That's not an exhaust fan to the left of the boiler, just an accessory from the clothes dryer hanging on the wall.

It is an outside oil tank, right on the other side of the wall. The furnace/laundry room is a small '70s cinderblock addition on the rear of a stone farmhouse.

Anyway, your advice is taken, I will call a serviceman tomorrow. Now I'm new to the area, so I don't know who is good and who isn't. Is there anything I should be asking or saying to the serviceman to make sure that what needs to be done is getting done?0 -

That's not what I was referring to. I wasn't comparing the two controls. Only that they both recycle and have a specified time that they will remember to recycle. Once past that time, memory is lost as to the fact than it was coming up on the third time to fail and do a hard lock out.billtwocase said:Gotta disagree Ice. I had more problems with the Carlin controls than any other. I like that control over the previous ones. I like the versatility. Carlin may have improved as of lately, but I still have a very bad taste that won't go away, and it was more of how warranty was handled, than what I had lost due to call backs on them. Beckett and Honeywell were always more of a stand up company when it came to a loss

The biggest problem with the Carlin controls was that they had some bad boards. Wholesalers didn't rotate out their stock. Once the controls that were well out of the problem dates, how do you tell when some slug is just trying to get a new warranty replacement on a 6 YO control that he is going to mark it up from List Price anyway.

There is no level low enough that a slug will go to screw someone. W was in Lowes and saw a ISE Badger disposal on a sell quick table. For $50.00 I have never bought or installed one in my life. But there was a tired one in my Condo. It was missing the wrench, the drain and the instructions, along with the throat. I already had that so $50.00 was a good deal. I looked it over carefully. It didn't have any signs of wear. No water marks. It appeared to have never been installed. So, I bought it for when the old one died. And it was jamming up more and more.

Then, it died. I got out my new old replacement. Just before I ripped out the dead one, I happened to shine my flashlight inside. The Badger uses a heavy piece of galvanized sheet metal for a table that the hammers swing from. The table was completely rusted through in three places. Someone bought a new ISE, because the old dead one was in such nice condition, the replaced the old with the new, put the old dead one back in the new box, and brought it back for credit. Which they got. for it not working properly. No one looked inside. Lowes has a no questions asked policy about returns.

I had my receipt from over a year ago. They gave me a new one no questions asked when I showed them the plate.

Like I said, there is no level too low to screw someone.

0 -

Some things on the water side concern me:

First, the water pressure seems low. 12 psi or less on a hot 160* boiler is indicative of a low static fill pressure caused by a faulty fill valve. You should have at least 12 psi with the boiler COLD and not running. I can't see the fill valve in your pics.

Second, the copper line going straight up off of the supply on top of the boiler, what does it go to? If it's connected to an old expansion tank, then you have an issue. You shouldn't have that with a bladder expansion tank also connected. The bladder tank must have an air separator like it has, but a non bladder tank should not. It should be one or the other, but not a combination of both.

I also see not tempering valve with the tankless coil which could cause a scalding issue.

Also, NEVER close the valves to the tankless coil with the boiler hot or running: there's no place for the heated water to expand and the coil will rupture. It can be quite impressive if it does.

If you could post some more pics showing all of the boiler and it's near piping and accessories, that woul be helpful.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

In some Jurisdictions (like Massachusetts), they require a 75# Pressure relief valve on the cold water side of a tankless between the cold water shut off valve and the coil. So it won't do that.0

-

They do here, too. It should be done on all of them. It's just a good safety precaution.icesailor said:In some Jurisdictions (like Massachusetts), they require a 75# Pressure relief valve on the cold water side of a tankless between the cold water shut off valve and the coil. So it won't do that.

I would think that all manufacturer's instructions would require it.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

It sounds like a combustion issue. Could be related to flue flow. It also sound like you have issues with limit switches possibly roll out. This could be a dangerous situation for you and your family. I would call a professional this time around. Pick his brain while he does his service. Then maybe you will gain enough knowledge to safely service it next time.-1

-

Update: We were able to get a serviceman out today because my wife was home, though unfortunately I was at work. Therefore, I didn't get to ask any questions. All I know was what he wrote on the service record slip, which said: "had to hit reset, noz, OF, PG, new electrodes"

What does PG stand for?

He was here for 45 minutes.

Furnace seems to smell less, doesn't cycle as frequently, and shuts off less violently, so that's a positive.

@ironman I've taken a few more pictures for you. That copper line going up from the supply out of the boiler seems to head right out to the heating system in the house, I wish I could follow it after it passes through the wall. It does have an air bleed valve on it before it enters the wall. It does not lead to an expansion tank.

Tried to include pics of the fill valve, I had also considered that the system pressure was too low.

Unsure of what you mean when you say "Also, NEVERTHELESS close the valves to the tankless coil with the boiler hot or running: there's no place for the heated water to expand and the coil will rupture. It can be quite impressive if it does."

Also, any recommendations on where to set the Hi/Lo/Diff dials in the aquastat... or are they good where they're at? I've read about what function each performs, they're more involved than I'd have guessed.

0 -

One thing I think all will agree on is that the combustion issue is already critical in that the entire boiler needs to be cleaned (HX) then start from there. I fear the carbon build up is already causing a problem and before combustion tests can be performed, this must be cleaned. I notice on your tag that nobody has done a combustion analysis.... This should be done every year w/o fail. As stated above, you need a qualified tec. to check the combustion process and make necessary corrections. It blows my mind when a PM service is done on oil equipment with out performing the most critical test for that oil fired equipment.

Good luck and let us know how you make out.

Peace;

Mike T.0 -

PG must be their description of a pump strainer. I do see that someone has increased the pump pressure to 140, wise decision, but a solid nozzle will behave much better in that boiler. When you have it serviced again, have them verify that the baffles are still in it. Also, there must be another zone valve for the mystery pipe before the air scoop. I would say to follow the pipe that branches out just above the circulator to find it. On a zip loop system, zone valves can either be on the supply, or return. I would request a combustion test by them also0

-

"Never close". Stupid autocorrect.CutterComp said:Update: We were able to get a serviceman out today because my wife was home, though unfortunately I was at work. Therefore, I didn't get to ask any questions. All I know was what he wrote on the service record slip, which said: "had to hit reset, noz, OF, PG, new electrodes"

What does PG stand for?

He was here for 45 minutes.

Furnace seems to smell less, doesn't cycle as frequently, and shuts off less violently, so that's a positive.

@ironman I've taken a few more pictures for you. That copper line going up from the supply out of the boiler seems to head right out to the heating system in the house, I wish I could follow it after it passes through the wall. It does have an air bleed valve on it before it enters the wall. It does not lead to an expansion tank.

Tried to include pics of the fill valve, I had also considered that the system pressure was too low.

Unsure of what you mean when you say "Also, NEVERTHELESS close the valves to the tankless coil with the boiler hot or running: there's no place for the heated water to expand and the coil will rupture. It can be quite impressive if it does."

Also, any recommendations on where to set the Hi/Lo/Diff dials in the aquastat... or are they good where they're at? I've read about what function each performs, they're more involved than I'd have guessed.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

That's pathetic. Killing your business. That's another nail in the coffin of oil heat.

That thing is crapping out because that oil filter is passing fine sludge that is plugging up the nozzle strainer. The only way you can check it is if or when you change the nozzle. It then fires properly. Or, replace the old strainer on the old nozzle with a new one. Raise the pump pressure to 140#. All that does is make the higher pressure force more pressurized oil past the nozzle strainer obstruction. Until the 140# pressure can't push past the obstructed nozzle strainer. That boiler/burner has been serviced annually. Once, it looks like someone combustion tested it. No amount of combustion testing is going to show that crappy filter. Who owns Garber Filters, Ful-FLo Filters, and general Filters? General. They bought out all the better competition. You see those POS filters on Over The Road Diesel trucks? If that filter isn't changed, its just another nail in the coffin of the oil industry. Garbers will sludge up on the inlet side COMPLETELY and not pass oil. But they will never pass sludge. If you find ANY signs of sludge in a pump strainer, you will have a Non-Garber type filter. Once I had switched all my customers over to Spin-On's, I never had to ever take off a pump cover to change a dirty screen. I never ever had a clogged nozzle strainer.

I'll bet that if you disconnected the flare connection on the outlet of that filter and off the pump, and blew out the line with air, you would get a snot of sludge that would give a flue sufferer cause to ponder.1 -

Because a strainer is replaced, doesn't mean that is dirty or plugged. I always replace them, even if they are spotless, Garber in line or not. The pump will whine when it is squished, so just replacing the gasket and not the strainer is not wise. That was part of the reason the gasket was redesigned to fit between the strainer and pump face, and cover. Once you open the pump, replace the strainer. A vacuum gauge will do wonders here. As far as higher pump pressure, it is all about trying to better atomize the fuel we have to work with now. That's all. We fallowed suit with a European burner that ran about 160 on average

0 -

I would also have someone verify that white is line voltage here. At the least, B-1 and C=1 are white wires. Black should be line, white neutral. Cant see the line 1 and 2 coming in

0 -

and take no offense Ice. Filtration is usually key, but there is much more going on here.0

-

I never said that I didn't replace gaskets and strainers. I did.

When troubleshooting or servicing, replace the biggest creator of your problems. Oil filters. A vacuum Gauge or any pressure gauge made will not show you any nozzle strainer restriction. If you have 100# at the nozzle, you have 100# at the strainer. How do you know what the pressure is at the inside of the nozzle orifice? You won't. Because once the fluid passes the strainer, it can be whatever the restriction drops it to. If you raise the pressure to 140#, you don't increase the pressure after the strainer unless it clean and unrestricted. I think it is called "Pressure Drop". That you can't measure.

Or, explain why, when I found a recently cleaned and serviced burner by myself, running like a dirty dog, and I didn't have another exact new nozzle to replace it with, and the strainer was clean, so I swapped the strainer off another brand new nozzle strainer of the same GPH but different spray, the burner ran like it did when I serviced it. Then, it did it again after a week or two? The orifice pressure/flow isn't what it is rated for. Raising the pressure on a burner set up to 100# PSI and raising the pressure to 140#, just means that you made the nozzle effective at 100# orifice pressure.

The beauty of Digital Analyzers. Clean and service a burner and test it. I have a printout record at the moment I did the test. If a week later, it isn't running properly, so I test it again and the numbers have changed, so I change just the strainer on a week old nozzle, and the numbers go back to what they were a week ago, what could it be? A dirty, clogged nozzle strainer. Changing to two spin-on's and two months later, and it is still running fine, and the Digital Analyzer shows the same numbers, Its hard to blame it on smiling "Devils". Like a Jehovah's Witness guy I worked around used to do.

How I proved (to my satisfaction) that nozzle strainers were plugging up: When pulling the nozzle assembly out of the tube, I put my thumb over the hole. Held it there while inverting the assembly over a container. Removing my finger from over the hole, and taking note of how fast the oil ran out of the nozzle. Sometimes, it barely drips out (plugged strainer). Or how fast it runs out of a new nozzle under the same scenario.

That service call after a week or so is a freebie. My uncompensated time for a free service call would have paid for a Spin-On filter or two.

I also noticed that the boilers were cleaner after the same period. That's when I noticed that warm start boilers, set up properly, could easily go over two seasons without service. I don't recommend that, but for those that don't call, it gives the a break.

The Pure Pro ones that Webb sells are longer and you have to be careful that you have room to put a catch pan under the can. The gaskets also don't work as well as the garber ones do, The only ones I used were on my own house (emergency) and they both leaked oil all over my cellar floor.0 -

I use Sids, which is Mitco for spin ons. The reason for the vacuum gauge would be only for the supply, as in coming out of the tank, or supply line issue. It will do nothing on the pressure side of the pump, but blow the gauge. I would like to see pics of the tank here, and where the supply is connected. I will also say that if the I think the wires are crossed, and those controls do not like that

0 -

Also, I had them document that the Sids spin on gasket was ok for bio crap0

-

Where do you guys see that the pump pressure was raised to 140 psi?

Coming in, Line 1 is black, Line 2 is white. B1 and C1 are white, B2 and C2 are black.

Any thoughts on the Hi/Lo/Diff settings?

Also, there is definitely not a third zone valve anywhere else in the system, I have followed the whole system as best I can. That said, I think I figured out where the pipe goes that splits before the air scoop. Downstairs, just in front of the walk-in-fireplace two copper pipes come out of the concrete floor and are capped off. I don't know what their purpose was, but I'm betting that's where that pipe leads. If I grab it just a few feet downstream of where it splits off before the air scoop, it's cold to the touch, which tells me it is a dead end and not flowing through.

I'm also guessing the other pipe that's down at the fireplace returns into the side of the furnace. I took a picture of it.

0

0 -

-

Or someone planned in installing a wood stove with a coil in it. Or in the kitchen, planned on finding a stove with a coil in it and couldn't.

Good thing. Like Ironman said, "Leave it". Good advice.

Is that stove in the cellar? From the looks of some things, it appears that the previous owner was a DIY who might have read too many articles on how to MM things.0 -

Stove/fireplace are on the first floor. House is built into the hillside, there is no basement.

Curious as to why as a coil wood stove is a bad idea? Not disagreeing, just want to understand.

Any other thoughts on the questions I posed in the last post above the pictures? Thanks guys.0 -

They make steam about as often as they make hot water.CutterComp said:Curious as to why as a coil wood stove is a bad idea? Not disagreeing, just want to understand.

1 -

And for some strange reason, steam and hot water don't get along too well in the same pipe.SWEI said:

They make steam about as often as they make hot water.CutterComp said:Curious as to why as a coil wood stove is a bad idea? Not disagreeing, just want to understand.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

The real problem that is seldom mentioned here among the true Wet Head heaters here, is that the house water pressure raises the boiling point of the water. Water in a closed heating system at 12#, boils at 244F degrees. For those with handy devices that do Square Root Calculations (I've never run across a square root while playing my Earth Guitar in the Dirt Band), the formula is the Square Root of the pressure in PSI, X 14, + 198. Equals the boiling point. Normal street pressures can raise the boiling point of water well over 300 degrees. One cup of water expands to 1200 cups of steam as soon as the pressure is lowered to the boiling point. 50/50 solder has a melting point of 360 degrees. Well within the range of the pressure from heated water without relief valves. So, you can have that 1 cup of water, instantly convert to 1200 cups of high pressure steam. They used to run steam locomotives and ships on that principal.

+

Back two century's ago, (Nineteenth) they used to install those hot water storage tanks that were copper halves joined together with a soldered ring (50/50 solder) and when the solder melted, the pressure would drop, and the contents proved the above rule. And the stored heat energy was like a rocket. It launched the missile through floors and roofs. Truly spectacular.

Or, why all codes require a properly sized Temperature/Pressure Relief Valve in the top 1/3 of a hot water storage tank.2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements