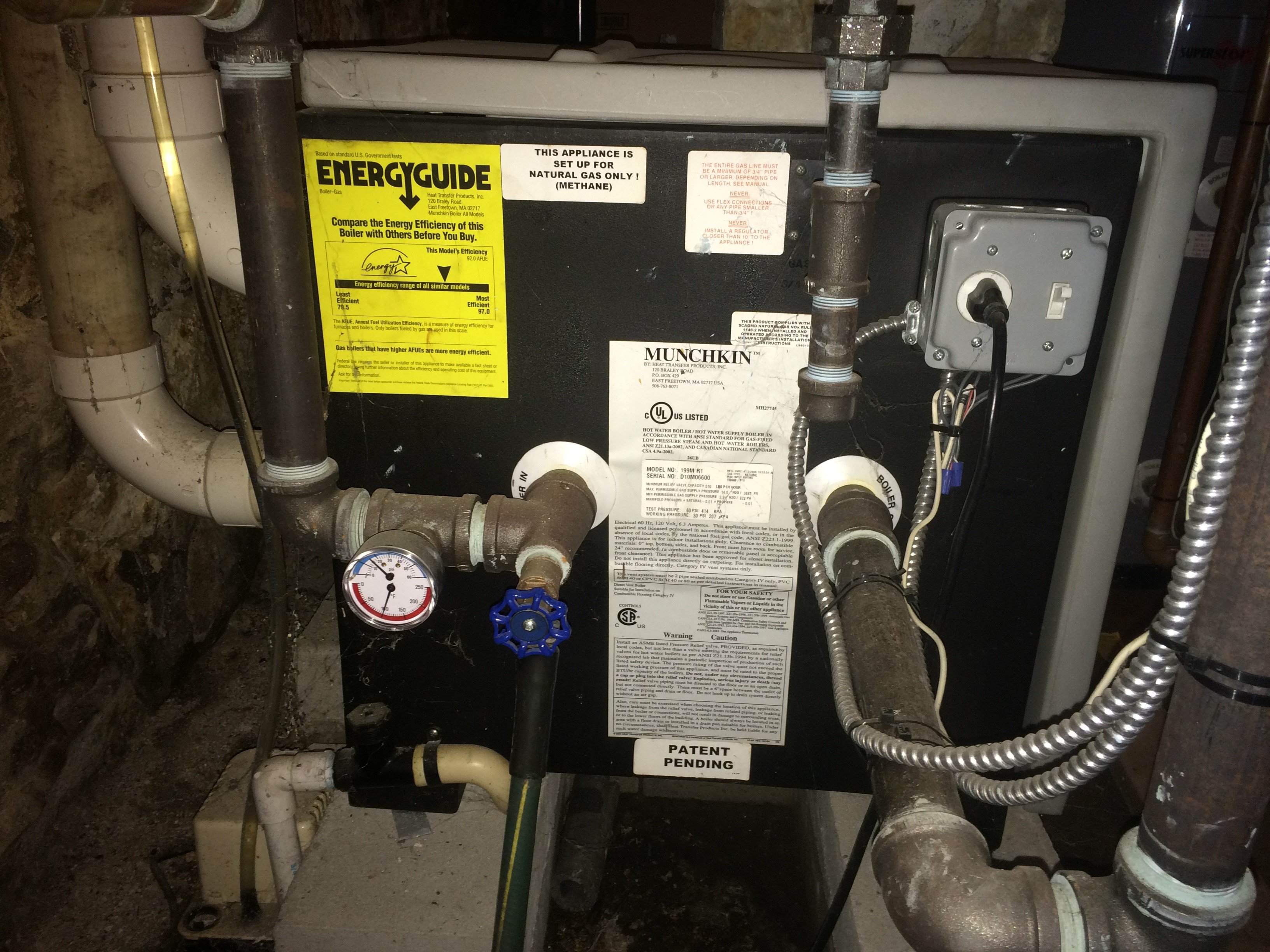

Munchkin boiler: P/S piping

Is this enough water mass to allow it operate correctly without P/S piping? Am I looking at flow problems that could cause an early demise for the HX? I would think a dirt separator and water treatment would be pretty key in this situation.

Pictures are shown below. Circulator is a Taco 0011

Comments

-

It's probably gonna get sufficient flow through the HX with those large pipes - assuming the circ is correct. On the flip side, the zones are probably over-pumped - particularly when one ZV is closed.

I agree that some type of strainer/dirt separator should have been installed. I would do a thorough water and fire side cleaning of the HX before taking it under contract.

Another note: over-pumping the rads can actually decrease their output. That may not be an issue since the house probably has a lower heat loss than it did originally due to window and insulation upgrades.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

That 199M Munchkin is probably way oversized for your application. Especially with zone valves. It's lowest modulation level is still higher than what you might often see, and if the second zone is smaller and the only one running, it could be overheating from a lack of flow. Here is the Munchkin Installation manual. In NO drawing, do they show any boiler NOT piped Primary/Secondary.

Does anyone ever read installation manuals and ask why things are described the way they are in there?

There's a learning experience between the front page and back page in every one.

http://www.htproducts.com/literature/lp-185.pdf2 -

You're correct on that one my friend. It's at least twice the proper size.icesailor said:That 199M Munchkin is probably way oversized for your application. Especially with zone valves. It's lowest modulation level is still higher than what you might often see, and if the second zone is smaller and the only one running, it could be overheating from a lack of flow. Here is the Munchkin Installation manual. In NO drawing, do they show any boiler NOT piped Primary/Secondary.

Does anyone ever read installation manuals and ask why things are described the way they are in there?

There's a learning experience between the front page and back page in every one.

http://www.htproducts.com/literature/lp-185.pdf

Good point. That's exactly what sparked my initial question. P/S examples only in the manual.0 -

That would certainly make an interesting marketing angle for your clients.0

-

As far as Magic, I saw a bumper sticker on a car with a lot of other stickers. Including ones in the shape of a fish.

The sticker said: "God said it, I believe it, and that settles that".

I think about that bumper sticker when I see something like that. Someone that does specific reading, not related to their job. And no other reading.0 -

So I'm back at the residence now. I had shut the make up water off overnight to gauge just what kind of state the distribution piping is in (it's an easy 100 yrs old) and this morning the boiler had a PR0 error (minimum pressure not met in the boiler).

At first I thought no big surprise due to the age of the piping. There is most likely slow leaks all over the place.

When I turned the make up water on and repressurized, the system went right back up and running. I did not have the purge anything and the radiators were back up and heating.

It seems the minimum pressure issue was in the boiler solely. As soon as the make up water was turned on the boiler bounced right back to 15 psi.

I may sound like a fool, but what kind of issue do you suppose I'm looking at here?

Some quick facts about the situation:

1. This customer is new to me.

2. They had no heat for a period of 4 days prior to my arrival.

3. A previous tech attempted to replace the expansion tank due to a dripping T&P valve. The expansion tank they used was much too small for the water volume and caused the system to over pressurize and blow down. They did not return and that's where I entered.

4. I replaced with larger expansion tank and replaced the T&P Valve. System fired and maintained pressure.

5. The boiler and near boiler piping is 7 years old. Distribution and emitters are easily 100 years old.0 -

When it does what you describe, it usually means that there is no thermal expansion area in the system. Either a compression tank with no air, or a bladder type with the pre-charge wrong or the tank not working.

If the system pressure through the Pressure reducing fill valve, is set higher or at exactly the same as the bladder tank, it will instantly go from zero pressure to what the fill valve adds. It can be as small as a teaspoon of water.

Drop the pressure to 0# and check the pre charge pressure on the bladder tank with a tire gauge. It should not read zero.

If the system is an old gravity system, you usually need a minimum of a #60 or equal bladder tank. Sometimes, two.0 -

When I had left this morning it was fired up to temp and working again. I currently have a #60 and #30 exp tank, both new, on the system.icesailor said:When it does what you describe, it usually means that there is no thermal expansion area in the system. Either a compression tank with no air, or a bladder type with the pre-charge wrong or the tank not working.

If the system pressure through the Pressure reducing fill valve, is set higher or at exactly the same as the bladder tank, it will instantly go from zero pressure to what the fill valve adds. It can be as small as a teaspoon of water.

Drop the pressure to 0# and check the pre charge pressure on the bladder tank with a tire gauge. It should not read zero.

If the system is an old gravity system, you usually need a minimum of a #60 or equal bladder tank. Sometimes, two.

I'll be back on site tomorrow morning with an HTP rep/trainer so I can learn more and see what he thinks about the current set up. Should be a fun day of learning.

0 -

Munchkins usually had a 10# minimum on their low pressure switch. Raise the system pressure to 14 or 16 #. It will keep it from cutting out if the pressure is too close.0

-

Easy and nice fix would be to add a properly sized circ for the boiler , throw a Caleffi Sep4 next to the boiler and change the circ on the system side to an ECM . This thing after a proper cleaning will work as intended by the manufacturer .

Who is your rep and what trainer will be there with you ?You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

The best nice easy fix would be to pipe it P/S like HTP wanted in the first place.0

-

Gee Ice , I pretty much thought that's what I just said . Of course simplifying it just a bit . A Sep4 is a hydraulic seperatorYou didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38331 -

Sorry.Rich said:Gee Ice , I pretty much thought that's what I just said . Of course simplifying it just a bit . A Sep4 is a hydraulic seperator

I don't think in codes. I had no idea that a "Sep4" was a Califfi Hydraulic Separator.

I personally think that everyone should use them when trying to go P/S. I did on every Veissmann boiler I ever did. Once I found out about them. They take any guess work out of tee spacing, and give a really nice chamber for the mixing to be done in.

Some installers I met don't understand the concept.

OBTW: My sister was born on Sep21.

0 -

Why the mention of September 21 Ice ? Just curious why you would refernec such a date .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Sep4 -- Sep21 Teehee.

Ford Master Technician, "Tinkerer of Terror"

Ford Master Technician, "Tinkerer of Terror"

Police & Fire Equipment Lead Mechanic, NW WI

Lover of Old Homes & Gravity Hot Water Systems0

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 167 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements