Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Radiant Heat (Closed System) - Why Do I Need 2 Expansion Tanks? (Domestic Supply and Radiant Side)

Options

cloves

Member Posts: 16

Hi all,

I am currently adding a radiant heating system to the auxiliary connection on my AO Smith Vertex to provide heat to my place. My radiant plans call for an expansion tank on the cold return part of the manifold. My first question is do I really need 2 expansion tanks if I already have an expansion take near the top of the tanks primary intake? Wouldn't that expansion tank take care of the all the expansion needs?

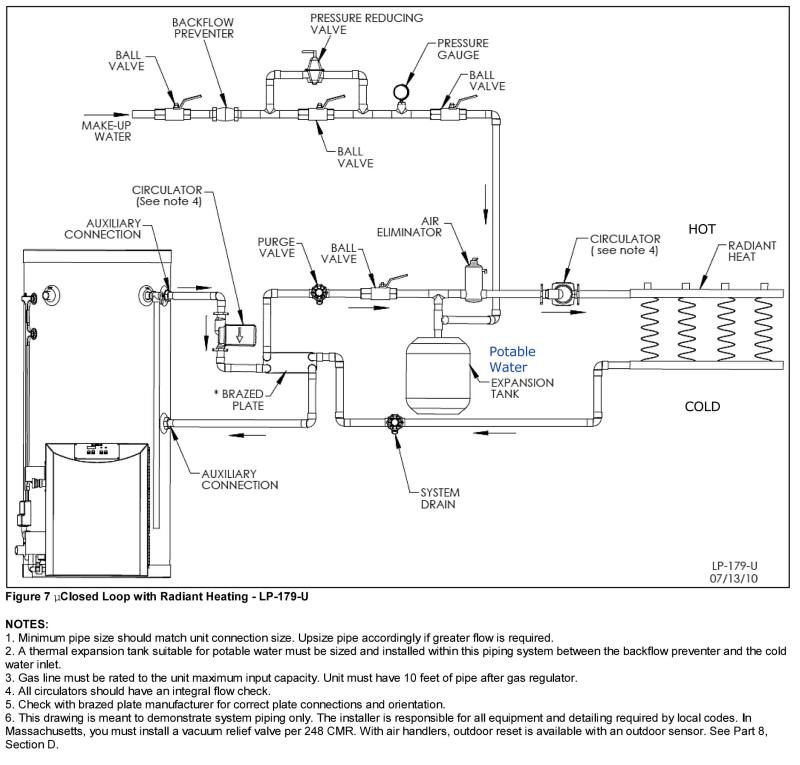

Attached are my plans and a sample of the finished project. The sample photo shows an expansion tank on the cold return line near the manifold but no expansion tank on the domestic supply line to top of tank.

Second question, what PSI should the expansion tank that is part of the radiant system be set to? My city water pressure is 60 PSI and that was what the expansion tank that provides water to the water heater is set to.

I am currently adding a radiant heating system to the auxiliary connection on my AO Smith Vertex to provide heat to my place. My radiant plans call for an expansion tank on the cold return part of the manifold. My first question is do I really need 2 expansion tanks if I already have an expansion take near the top of the tanks primary intake? Wouldn't that expansion tank take care of the all the expansion needs?

Attached are my plans and a sample of the finished project. The sample photo shows an expansion tank on the cold return line near the manifold but no expansion tank on the domestic supply line to top of tank.

Second question, what PSI should the expansion tank that is part of the radiant system be set to? My city water pressure is 60 PSI and that was what the expansion tank that provides water to the water heater is set to.

0

Comments

-

0 -

Good drawing. I like how you're adding antifreeze to your drinking water. That's one way to beat the winter!

But seriously, don't trust that ball valve to do the job. Back it up with at least a check valve, or an RPZ.Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes1 -

Nice drawing -- very easy to follow. Thank you!

Yes, you need two expansion tanks, since with any kind of luck at all there is no flow between the two systems. More on that in a moment. The expansion tank on the domestic side takes care of any possible problems with expansion from the water heater; you don't say whether there is a check valve (from a pump) or pressure reducing valve (from a street supply), which require it (if you had a pump the expansion tanks for the pump would do the job).

The radiant expansion tank doesn't have to be set as high. Like any hydronic system, though, it needs to be high enough to provide positive pressure at the highest point in the system -- half a psi per foot of elevation, plus 5 psi should do it. I would locate that tank, though, at the inlet of the Taco circulator, or very near it, rather than on the other side of the heat exchanger. That way you are sure to have enough pressure at the inlet to that pump.

Now on the connection between the two systems. You show a pressure reducing valve and a ball valve on the interconnect. I don't know what the code requirement in your area is -- but I wouldn't pass that. In my humble (?) opinion, you need a true reduced pressure zone backflow preventer on that connection. You would still have the ball valve (upstream of the RPZ).Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Hey guys thanks for the feedback. Never got an email about the topic being replied to.

JohnNY & Jamie you are both suggesting an RPZ between the Taco Pressure Reducing Valve (aka fill valve) and the ball valve. Would a standard check valve also serve this same purpose? Sounds like there is the possibility that the Pressure reducing valve (which flows only one way) isn't good enough?

I saw on the boards a huge discussion on the leaving the ball valve open versus closed after the system is filled but it was for a boiler not a water heater. Is the debate about leaving the ball valve open or closed after the system is filled also part of that debate?

Jamie thanks for the explanation on the expansion tanks.

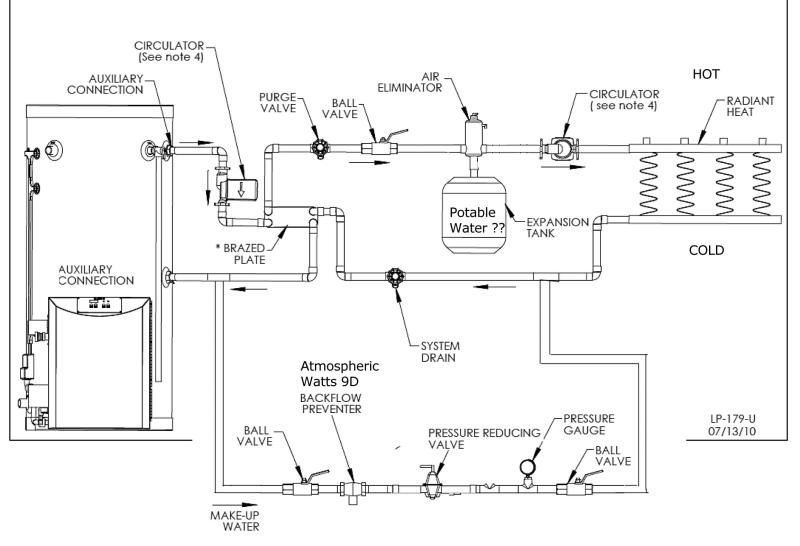

I have two check valves that lead into the mixing valve. I think that is what you were asking me right? (Pic Attached)

I am thinking of adding an air eliminator with an expansion tank after the heat exchanger and before the iron taco pump. I believe that is what you are suggestion correct Jamie?0 -

BTW any recommendations on back flow preventers? I know the big box store has a watts available but just looked at the specs and it says minimum pressure is 25 psi.0

-

Cloves ,

Remove any connection between the potable water and the heating system . You have a heat exchanger for separation between the potable and heating systems . Buy a watts RPZ and call it a day .

One other thing I noticed and have a question about . How many zones is this heating ? Even if it is more than one zone you do not require the differential pressure bypass valve . I recommend instead of that , using an ECM pump which will vary flow and pressure dependent upon system requirements . Did I mention they use 50 - 70% less electric ?

By the way . How the hell big are those loops that you needed such huge circs ? Good thing you're adding that expansion tank to the domestic side , that pump is huge .You didn't get what you didn't pay for and it will never be what you thought it would .

Langans Plumbing & Heating LLC

732-751-1560

Serving most of New Jersey, Eastern Pa .

Consultation, Design & Installation anywhere

Rich McGrath 732-581-38330 -

Sorry to be slow on getting back on this -- if you are still on! And no, neither a single check valve nor a pressure reducing valve can be counted on for prevention of backflow, since both of them have what are called single failure modes -- that is, a single failure will keep them from operating as they are intended to. Like if they get stuck open. Granted, with 60 psi domestic pressure and less in your heating, you would think that backflow couldn't be a problem -- but it can be, and you really don't want to be drinking the water which has been in your heating system. Hence the RPZ ("reduced pressure zone") backflow preventer, which is built in such a way that any failure will result in a leak (sometimes a downright flood!) rather than backflow.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

A listed dual check back flow preventer is plenty of protection for a system with non-toxic propylene glycol.

The bigger concern with connecting to a potable water source is diluting the glycol should you get a small leak, vent a large amount of air and add more water.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

We always make the heating system require a DuCAP. That's a dual check like hot rod said with with the added AP (atmospheric port) If Watts is what your store carries then it would be a Watts 9D. I've never check the minimum operating pressure on the 9D but you are going to have it installed upstream of the taco PRV so you would have your domestic pump pressure or city supply pressure actually going through the BFP - negating the min. operating pressure concerns.0

-

Here is a typical BFD for connecting boilers to potable water systems, know that some AHJs do require a BFD with test ports.

This brand will seal with a minimum 20psi inlet pressure if you have that need.

It would be very rare for this type of BFD to fail and allow fluid back into the potable side. Two checks and the center spool would all need to fail somehow. I'm not sure that has ever happened? If you use a Caleffi AutoFill there is also a check inside that fill valve, but not ASSE 1012 listed as a BFD.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Guys thanks for the reply and images. Learning a lot! I will be adding the watts 9D

As mentioned the side the RPV will be sitting on, will have city pressure and 25psi won't be an issue, totally missed that.

As mentioned the side the RPV will be sitting on, will have city pressure and 25psi won't be an issue, totally missed that.

I have over 10 zones the way the house is split up. Loops are all under 300 feet.

To up the antsy a few more questions are springing up. My plan calls for a "potable water" expansion tank near the cold out side of the manifold (As seen in my first post). The diagram attached to this post is from the phoenix manual. It is very similar to my heating diagram plan. Here the manual also states " A thermal expansion tank suitable for potable water must be sized and installed within this piping system between the backflow preventer and the cold water inlet".

Q: If the system is "closed" why is there a need for a potable water expansion tank? An atmospheric backflow preventer for example should stop any sort of backflow. The rest of the system to the right of the heat exchanger has no contact with the domestic water supply.

My manifold (rifeng) has air eliminator's built into the manifold, however I decided to get an Spirotherm Air Eliminator that has an expansion tank connection at the bottom. I will be placing it on the hot out of the heat exchanger before my taco circulator. This is where my next expansion tank question comes into play. Q: Is a "potable water" expansion tank still what I should be installing here? From my research, expansion tanks made for potable water purposes are not made to take hot water because of there construction.

I have attached a second drawing which shows the expansion tank below the air eliminator. The supply make up water coming off of the cold return line. A watts 9D atmospheric back flow preventer and then the fill valve aka pressure reducing valve (taco).

0 -

The expansion tank shown in your diagrams is on the heating loop. You absolutely have to have it. You set up and fill that loop through the makeup line and its valves, but those valves prevent any backflow. Now when tou heat the water in that loop, it is going to try to expand. The expansion tank keeps the pressure very close to constant. Without the expansion tank, the pressure will rise -- enough to pop the pressure relief valve on the heater -- you hope. Which you don't want to happen.

You may or may not have another expansion tank on the domestic water side. That depends on your water supply, and any check valves or pressure reducing valves on the domestic water. That's a separate tank.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thanks Jamie, that is case. I have an expansion tank on the cold incoming from the city that feeds the water heater. I also have to have an expansion tank in the heating loop.

Question I am trying to figure out is, 1. Can I have the expansion tank below the air eliminator as this is different from the original heating plan and 2. Why does the tank have to be rated for potable water if the system is closed indirect and also has a vented RPV.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements