Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

balancing heat distribution

Options

Comments

-

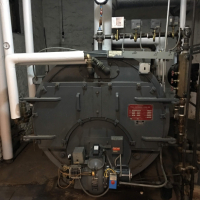

manuals

Thank you! That manual is much more useful. By the way, does anyone know where to get an installation and operation manual for our A. L. Eastwood boiler, model FST-40? I have the spec sheets from a previous post.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Pro in Brooklyn NY

Arches,

Can you recommend someone who can help me do the same Hi/Lo modification to my Carlin or did you do that yourself?0 -

vacuum valves

So, I read the Hoffman pamphlet How To Lock Out the Air Thief (1928) from another post (http://www.heatinghelp.com/files/articles/1310/128.pdf) and it makes me wonder if our system was designed to operate with a vacuum. Scanty evidence: The building was built in 1928, a year later. There is only one vent on a main. I've found a number of these Hoffman vacuum valves (or at least they look that way to me) on riser vents and one on a radiator. I'm wondering if this would explain the lack of vents in a system that seem pretty well designed.

Is it possible that the system was designed to work with a vacuum and then fell out of repair with switched valves and leaks? If that were the case, would it be possible/desirable to take it back to a vacuum system? This seems nearly impossible, considering the places where leaks can occur. Is this system practical only for new systems? Or maybe it was never practical. The pamphlet is an advertisement.

This strategy seems to be the opposite of the vent the mains fast approach. With that approach, you still have push the air out whenever you build up steam.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Hoffman vaccum vent?

I forgot to post this photo. Is this a vacuum vent?Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Coal heat

From what I understand from the Wall, the buildings in NY built around that time were originally coal heated. The slow and steady steam generated required little or no venting as the pipes were never completely empty. This is thrown out the window with the cycling of oil burners.0 -

60 minutes may be too short

I use 90 minute cycles...longer cycle is helpful with an oversized boiler (which it sounds like yours may be, if its able to heat the building on low-fire only). Not sure if the cycle time is adjustable on all heat timer models (we have a MPC platinum). Where is your heat sensor located?0 -

DIY

I did the vaporstat and low/high/low controls by myself. Probably best to go with a pro, unless you a pretty comfortable with electrical work (and have a lot of time to read operating manuals!).0 -

Times they are a changing

The article you read is accurate and truthful for steam heating when it is solid fuel powered, be it wood or coal. With modern systems the fast vent for mains and risers method will save more fuel and create more even of heat. In a building your size the risers also need venting added. If those are your radiator vents I think it is time to work on them too. As to the mention of venting far radiators faster, that is not as true as it was once. The radiators need vented according to size not distance from the boiler. This is why the risers are vented to get steam to the radiators fast. The idea of orifices may also be considered as Boiler Pro does in his boiler sizing method.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating0 -

did I screw up?

So, I was trying to make sure that our heat timer was set to 60 minutes and I'm wondering if I messed something up. I thought the cycle time indicator was for setting the cycle time. 55 was displayed. I turned it until just before 0.

Now, I'm wondering it's actually an indicator of how much time is left in the cycle. This seems like a stupid question. Should I not have touched it?

Maybe it's a coincidence, but our temperature has dropped in the last couple days.

Thoughts?Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Carlin 801CRD burner manual?

Does anyone know where to find a manual for the Carlin 801CRD burner?Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

cycle times factory set

the manual states that the cycle time is factory set (not adjustable) on those units...if you turned it manually you may have broken something ...uh oh1-pipe Homeowner - Queens, NYC

NEW: SlantFin Intrepid TR-30 + Tankless + Riello 40-F5 @ 0.85gph | OLD: Fitzgibbons 402 boiler + Beckett "SR" Oil Gun @ 1.75gph

installed: 0-20oz/si gauge | vaporstat | hour-meter | gortons on all rads | 1pc G#2 + 1pc G#1 on each of 2 mains

Connected EDR load: 371 sf venting load: 2.95cfm vent capacity: 4.62cfm

my NEW system pics | my OLD system pics0 -

Heat timer cycle time

If you have a mechanical EPC or EPU heat timer, you won't do any damage manually turning the timer dial through the hole in the panel. All this will do is manually advance the cycle, not actually change the programmed cycle duration. The total cycle length is not adjustable and is either 30 or 60 minutes depending on the timer motor installed. The cycle firing time is set by the letter heat setting knob and the outdoor temperature. As JPF mentioned there is a chart in the manual which indicates the cycle firing time vs. letter dial setting and outdoor temp. If properly calibrated, the times indicated should be pretty close. Of course it also depends on how well the outdoor sensor is placed. If it doesn't accurately indicate the actual outdoor temperature, then all bets are off.

Are you sure you have a return pipe temperature sensor? In one of your photos. I noticed that you have an additional pressuretrol marked HT (heat timer?). Sometimes a pressuretrol or other pressure sensor is substituted for the return temp sensor. The pressure sensor performs the same function in that the system pressure starts to rise when all the radiators are filled with steam. When pressure exceeds the setpoint the timing cycle is started, as it would if the threshold temperature was detected at the return sensor. If the pressuretrol marked HT is actually being used for this purpose, then the return temp setting on the panel will have no effect. The pressuretrol setting will then determine when the cycle actually begins instead.

If the pressuretrol is actually being used for starting the cycle, then the indoor sensor dial must be set to X+2 to work properly. See the top of page 3 of the manual for details.0 -

Heat timer

Thanks for the info. It was dopey of me to try to change the cycle time indicator. We're getting heat so I'm hoping I didn't break anything. We did have a bit of a temperature drop and I had to adjust the settings, but maybe it was a coincidence. The cycles seem to be working fine.

The heat sensor was installed about three years ago, about ten years after the boiler. It was originally installed with a pressuretrol. It seems that the pressuretrol is no longer connected but I'm not positive. The sensor control definitely works. It has a large effect on the temperature of the building. When I looked at the heat timer manual, it seemed that it can be wired to either a sensor or pressuretrol, so my guess is that it isn't connected there.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

replacing and adding main vents

So, I'm slowly moving towards replacing and add main vents in our system. JP came by a week ago and gave me a ton of information. The work is starting to feel doable, but I'm a little overwhelmed.

I took advantage of the snow today to map out the mains in the basement. The drawing is below (ElmoSteamMap.pdf).

The plan:

A - replace current vent with antler (one #2, three #1s) -- this is the only main that has a vent currently. it's very undersized., 79 ft., 1.817 cf

B - tap and add antler (one #1), 14ft., .322 cf

C - tap and add antler (one #2 or four #1s), 45ft., 1.035 cf

D - tap and add antler (one #2 or three #1s), 42ft, .966ft

? - (vent A's pipe joins another pipe with a connection below the water line. I didn't show this connection. The picture is below. Since the connection is below, I'm wondering if this pipe needs to be vented at the end as well. This is the 10' pipe below A.) I'm not sure how this works, but I think we need to vent the 40' and the 10' pipe - (one #2 and one #1), 50ft, 1.15cf

JP, I used your worksheet and checked it by hand. (I didn't measure every radiator connected to the mains so didn't fill out each column. I plan to find the radiator load after I know the mains are vented properly). The goal is to vent the mains in one minute, right? Also, I sized all this at 1oz, since that will be the pressure we will ideally run at.

Does this seem right to everyone?

EricSingle-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

Venting Capacity

The Gorton # 2 is the equivalent of three Gorton #1's and will cost you a bit less. So save some money and extra effort mounting all those #1's and just use the #2's on the big returns.0 -

agreed...

the gorton #2 box actually says that the #2 = 4pcs of #1 .. so that's how my spreadsheet is set up .. but you will have a much cleaner time of it if you stick with #2s ONLY in places where you were going to mix or where it called for 3pcs #1. you cannot OVERVENT .. and the time and effort and fittings saved will make up for the slight difference in cost.1-pipe Homeowner - Queens, NYC

NEW: SlantFin Intrepid TR-30 + Tankless + Riello 40-F5 @ 0.85gph | OLD: Fitzgibbons 402 boiler + Beckett "SR" Oil Gun @ 1.75gph

installed: 0-20oz/si gauge | vaporstat | hour-meter | gortons on all rads | 1pc G#2 + 1pc G#1 on each of 2 mains

Connected EDR load: 371 sf venting load: 2.95cfm vent capacity: 4.62cfm

my NEW system pics | my OLD system pics0

This discussion has been closed.

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements