Weil McLain EG boiler keeps needing new pilot burner / flame rod assemblies

I have a Weil McLain EG-75 boiler serving a one pipe steam system. I have a problem where the burner won't stay lit. When there is a call for heat, the pilot valve opens, the pilot igniter lights the pilot, and sometimes the main burner will light and sometimes it won't. The pilot lights every time, but you can tell that the flame detection rod is not always convinced, because sometimes the igniter keeps clicking away even though you can see the pilot flame.

When the burner lights, it will light normally (first at low fire, then high fire) but it will only stay lit for a few minutes. Then the burner cuts out, and the pilot ignition sequence restarts. But usually it won't relight until it has cooled down for a bit. As such, the boiler only runs for long enough to make steam in the closest radiators; the upstairs doesn't get any heat. (it was 46 in the bathroom yesterday morning!)

This is the third straight heating season I have had the same problem. Each of the previous times, the problem was easily rectified by replacing the pilot burner assembly, which has the flame detection rod as an integral part. Once this is replaced, the boiler seems to operate normally for the rest of the heating season. So the assembly that is acting up now was replaced just about a year ago.

I'm wondering if there is any cause that would make these assemblies only last for about one year. I tried cleaning the rod on this one to see if that would help, but nothing changed. There really wasn't any corrosion or build up to speak of anyway, on this rod or any of the previous ones, so I am not sure if that is the issue.

Any ideas before I head out to the distributor to buy yet another pilot burner assembly? (At least today, it's about 50 degrees. last time it happened, it was about 10!)

Thanks

Comments

-

OK, so here is a new bit of info. I replaced the pilot burner assembly. Once I got everything put back together, it seemed to work great. Until it stopped again and now seems just like it was before. Starts, runs for a few minutes, cuts off, and then can't relight the pilot.

I'm wondering if the UT 1003-611A controller might be the issue? Or perhaps there is something else the matter. Any help would be greatly appreciated.0 -

Yes, I've seen this behavior with a bad ignition control.Alec said:I'm wondering if the UT 1003-611A controller might be the issue? Or perhaps there is something else the matter. Any help would be greatly appreciated.

0 -

Somewhere you might find listed the μA range for the ignition module, if you're inside that range then the control is bad. After several times of replacing flame rods first & then ign modules, I always check now.

I just found a flame rod cleaner at Johnstone, it's just like one of those wire brushes for cleaning the outside of pipes, just sized for a flame rod. Be interesting to see how well it works, it looks like it might be pretty aggressive.

0 -

I always thought that coating was a bit fragile and you had to be a little gentle with cleaning.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Sounds like you have an underlying problem with either the control module or faulty wiring connections. The first thing you should do is go through the wiring harness and make sure you have sound connections. If it's corroded, redo the connection. Don't neglect the ground wires.0

-

So I replaced the ignition module and now it seems to work. Prior to doing that, I cleaned the rod again with 00 steel wool. I also tried testing the current, but according to the Weil McLain control supplement manual, the range is supposedly less than 1 microamp, lower than my meter could read.

I wonder now if the problem was the ignition module all along. But if that were the case, then why would replacing the flame rod have temporarily (for a year) fixed the problem on the prior occasions where the boiler wouldn't stay on?

Thanks to those who replied for their input

0 -

It's my suspicion that, especially on tiny currents or voltages, a super thin layer of oxide on the connector is a reoccurring problem. It "goes away" when the connection is disturbed, but comes back after a while. It's just a pet theory, but it explains a lot if true.

WRT factional μA, I've had good luck with this. It'll allow you to read down to tenths of a μA, it can be left in-circuit without tying up your meter, & it's a lot cheaper to replace than a meter if something goes wrong.

0 -

Microamps are normally in the range of 2 to 10, normal is 3 to 5. Many systems list the minimum as 1 microamp or slightly less but remember that is the minimum.

I always clean flame rods with a soft clean emory cloth or a jewlers burnishing tool.

When you have a pilot flame and the spark still continues then you have lost burner ground. It is not a good idea to keep changing expensive parts when just running a new burner ground from the pilot bracket over to the gas valve can many times solve the problem.

I have been busy this week in court so I will take some time tomorrow and look at the manual on the EG and also the United Technology 1003-611A board.

2 -

Tim, when you say to run a "new" ground wire, you mean one that wasn't there before? Or replace an existing wire? Sorry to belabor the distinction, but there does not appear to be an existing ground wire that takes the path you describe. The pilot burner assembly has a wire for the spark, and a wire to the "sense" terminal on the ignition module. The ground path appears to be through the burner tube that the pilot bracket is on, back to the burner manifold. Or it could also be via the aluminum tubing that carries the gas from the gas valve to the pilot module. I measured the resistance of that ground path with my multimeter and it seemed ok- maybe 1 ohm or in that range, anyway.

The other thing that was weird this time vs. last year was this time the boiler would light normally if cold, and run for a five minutes or so before shutting off. But it would not relight when hot- it had to cool down for a bit. Last year, it wouldn't light at all, hot or cold.

Thanks for any more clues you may uncover!

Alec0 -

Yes sometimes the ground through the pilot tubing seems to mal function. Simply loosen one of the screws that holds the pilot bracket to the burner and strip the end of the wire and wrap it around the screw and tighten up. Put some sort of clip on the other end and attach directly to the gas valve. Some like Honeywell and Robertshaw actually show a ground symbol on the valve and provide a place for such a hookup.1

-

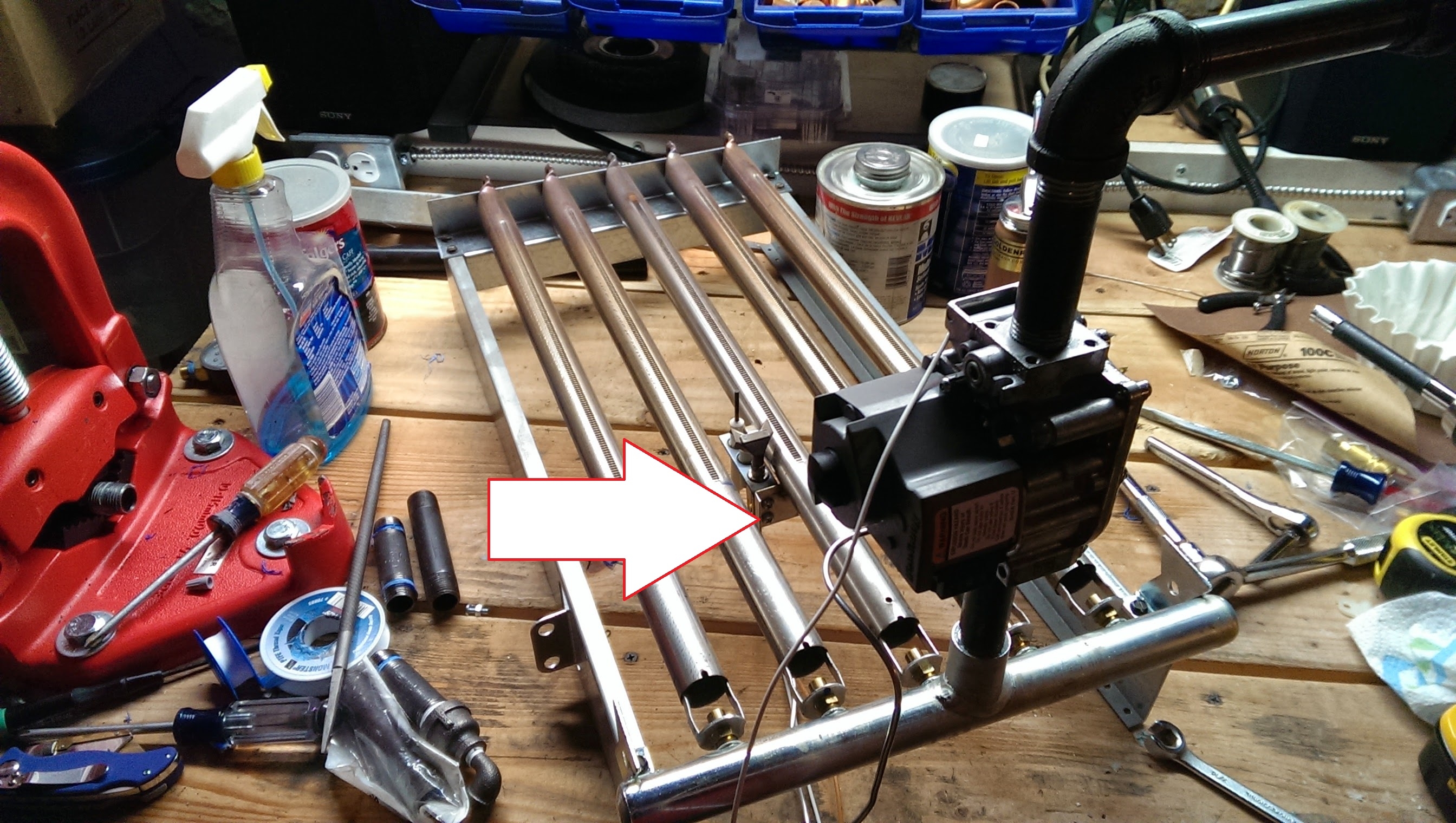

I recall the CGV on my EG series having a place for a ground. The next time I have the burner tray out I'll probably add a ground wire just for good measure.Tim McElwain said:Yes sometimes the ground through the pilot tubing seems to mal function. Simply loosen one of the screws that holds the pilot bracket to the burner and strip the end of the wire and wrap it around the screw and tighten up. Put some sort of clip on the other end and attach directly to the gas valve. Some like Honeywell and Robertshaw actually show a ground symbol on the valve and provide a place for such a hookup.

I assume any wires that travel under and near the burners like this should have a Teflon or silicone insulation?

Single pipe quasi-vapor system. Typical operating pressure 0.14 - 0.43 oz. EcoSteam ES-20 Advanced Control for Residential Steam boilers. Rectorseal Steamaster water treatment0 -

Silicone and teflon wire both are good to 200C but silicone would be best because Teflon can emit phosgene gas if over heated enough.. i would also sleeve it with spun glass sleeving for extra protection.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

-

Would the added ground wire be best connected to the ignition module also in addition to the gas valve? The module is the brain box looking for flame sensing.0

Categories

- All Categories

- 86.1K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 52 Biomass

- 422 Carbon Monoxide Awareness

- 85 Chimneys & Flues

- 1.9K Domestic Hot Water

- 5.3K Gas Heating

- 96 Geothermal

- 155 Indoor-Air Quality

- 3.4K Oil Heating

- 62 Pipe Deterioration

- 907 Plumbing

- 6K Radiant Heating

- 380 Solar

- 14.7K Strictly Steam

- 3.3K Thermostats and Controls

- 53 Water Quality

- 41 Industry Classes

- 47 Job Opportunities

- 17 Recall Announcements