Lochinvar WHN055 Direct vs. P/S Piping

Is it true that the boiler needs a constant flow rate (thru boiler) to be able to modulate accordingly? I read a thread on the forum that suggested the boiler relies on constant flow and its "logic" varies the firing rate depending how quickly the supply temps rise.

My "current" plan for the home is to use panel radiators throughout the main portion of the house, TRV'd, running off a single manifold and a delta P circulator (Grundfos Alpha). In the near future I'll be converting a slab-on-grade, three season room to an entry/entrance hall, mudroom, 2nd bathroom and closet. I have to raise the current slab, 8-12 inches and was thinking of running radiant floor heating if possible. If not, I'd use more panel radiators.

The radiators I've selected for the main portion of the house are slightly oversized for design day with 160/140* (supply/return) temps. If I plan on running radiant floor heating in the "addition" it'll probably need to run at lower temps.

Can a system with 2 zones be piped direct to the boiler? First zone would be panel radiators, TRVs and delta P pump. Second zone would be radiant floor, mixing valve (to lower boiler supply for other zone) and constant circ.

Comments

-

You need to pipe the trv panels primary/secondary. Otherwise you will not meet the minimum flow requirements of the boiler.

If you add a second zone with mixing, you should get the mixing valve controller from lochinvar and let the boiler control the second zone. This way the boiler will only fire to the temp needed for the zone calling."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

I agree with Zman. Your going to have varying flow rates with a trved system.

As proportional valves (trvs) close with delta p pumping, or delta t for that matter flow rates will vary. Probably not meeting the minimum flow requirements of that boiler.

I would use a hydraulic seperator verses the closley spaced t's. Makes for a tidy mechanical room. The Hydro sep is multi functional giving you dirt removal, air removal, and a X tank location.0 -

As far as "constant flow rate" it is going to offer the best system performance, comfort, and boiler performance. Constantly matching loads is the best it can be for comfort, and efficiencies.0

-

CoolZman said:You need to pipe the trv panels primary/secondary. Otherwise you will not meet the minimum flow requirements of the boiler.

If you add a second zone with mixing, you should get the mixing valve controller from lochinvar and let the boiler control the second zone. This way the boiler will only fire to the temp needed for the zone calling.

I read this thread: http://forum.heatinghelp.com/discussion/106576/constant-circ-for-dummies

So if I understand correctly… the "zone" circs will run continuously (24hrs/day), but the boiler (and boiler circ in a P/S setup) will only fire when called upon by a thermostat.

I'm curious about setting up two "constant" circ zones. How do I prevent say the lower temp zone (radiant slab) from receiving higher SWTs for the panel zone? Is it just matter of turning OFF a particular zone's circ? If so, then it won't be constant circ and only circulate when there is a call for heat… like a bang-bang system, right?

Seem the Lochnivar controller mixes all three zones… I thought I could just set boiler to higher temp zone and let the mixing happen only on the second zone.0 -

your radiant zone is still going through the mixing valve.0

-

-

Like this from uponor

Seemed simple to lochinvar controller + 2 mixing valves, plus added cost.0 -

The last paragraph in your post is what happens. Maybe I'm not understanding your question, the boiler is set for highest temp emitter, and the radiant zone is mixed down.0

-

null

With the lochinvar multi temp controller? As far as I can tell each zone needs a mixing valve. The controller tells the boiler to fire at the temp with the highest set temp calling for heat, if more than one zone is calling for heat.

I was hoping to reduce the number of mixing valves and just fire the boiler at the hottest temp needed for the panels and mix down when the radiant floor calls. All the while having constant circ.

Maybe that's asking too much.0 -

The idea is to have constant circ for comfort, performance, right? And only fire the boiler when the circulated "zone" water no longer satisfies the heat loss/room set temp.0

-

You only need the mix valve for the radiant. The higher temp emitters will take priority, unless the low temp zone is calling. You really don't have to make it complicated. Under constant circulation zones will circulate the water until the water temp gets so low then the boiler fires heating the water back up based on the reset curve. The high temp zones will be set with the boiler temp output.1

-

That's what I thought…Gordy said:You only need the mix valve for the radiant. The higher temp emitters will take priority, unless the low temp zone is calling. You really don't have to make it complicated. Under constant circulation zones will circulate the water until the water temp gets so low then the boiler fires heating the water back up based on the reset curve. The high temp zones will be set with the boiler temp output.

So what kind of mixing valve and controlled by… A thermostatic mixing valve would only maintain a single temp. I think I would need a way to be able to mix so that the radiant zone is always say -40* less than boiler supply temp (along the reset curve).0 -

I read an excerpt from John Siegenthaler's Modern Hydronic Heating book… he talks about proportional reset and its advantages vs. disadvantages.

Sounds like there are a few ways to do it. Boiler SWT set to higher temp zone, ODR and mixing of lower temp zone via: manual, thermostatic or "intelligent mixing valve.0 -

Now you got it.0

-

null

That's what I figured, but I'm racking my brain as to the "best" way to accomplish the mixing.0 -

see Zmans post above.0

-

I talked to a tech at Lochinvar… I think I have a better understanding of the MTLC. You were right, only need one "intelligent" mixing valve if I go that route. Something to think about in the future.

Also shed some light into the boiler controls, wrt ODR, WWSD and ability to set system pumps to constant circ.0 -

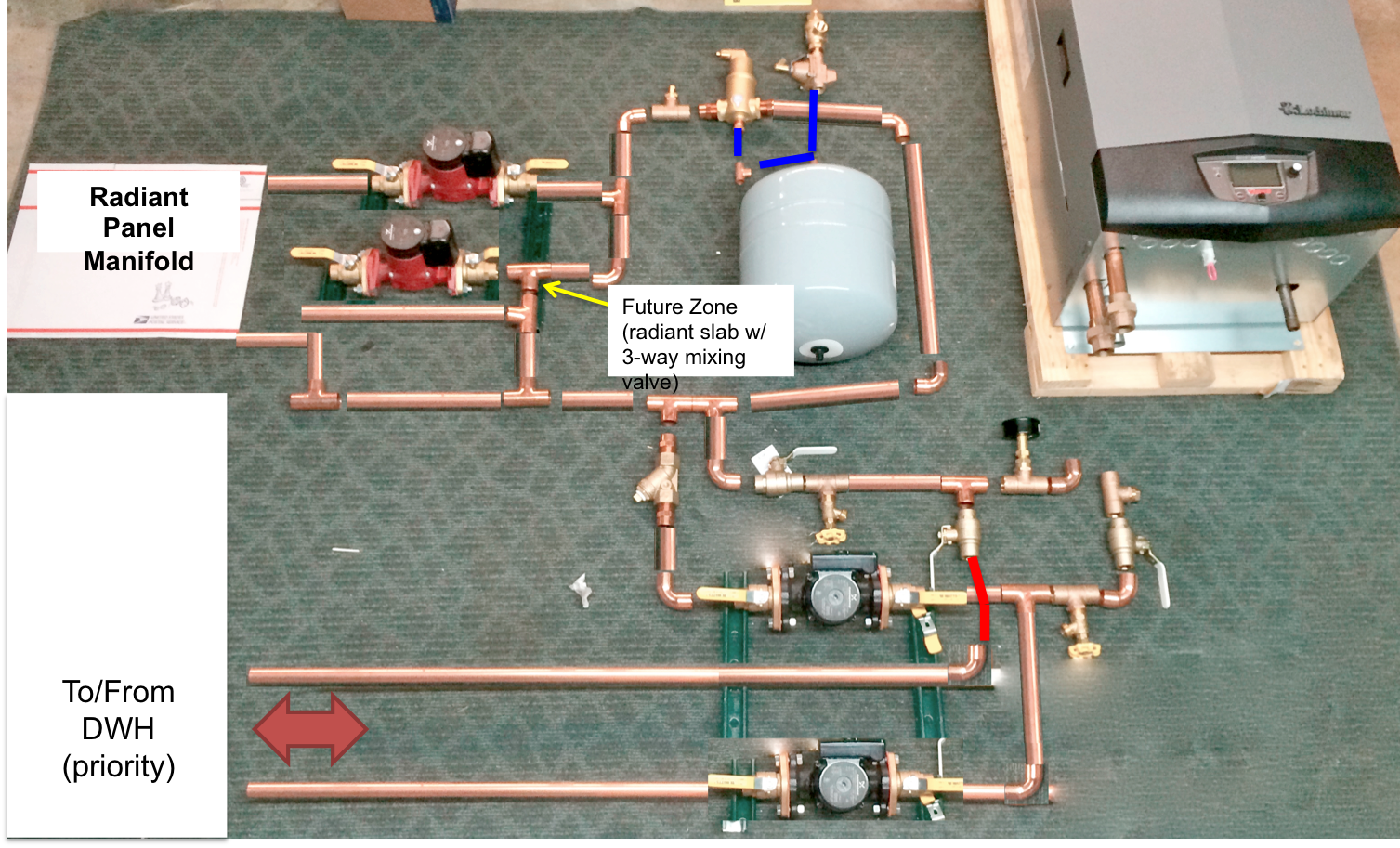

Here is my rough layout: P/S, 2 zones (radiant panel & radiant slab) and DHW Priority. For reference the green carpet is ~5'x8'.

Zone 1 (upper red pump): Radiant panels (TRV'd), constant circ, Grundfos Alpha, 150* SWT

Zone 2 (lower red pump): For future addition, manifold will be ~ 30' away, radiant slab, motorized 3-way mixing valve, constant circ, ?* SWT

All circs will be IFC. All near boiler piping 1" (P/S and DHW). Thoughts on pipe distances:- Closely Spaced Tees (CSTs): 4x 'D'

- Upstream of CSTs (run): 8x 'D' (min)

- Downstream of CSTs (run): 4x 'D' (min)

- Upstream of Circ: 10x 'D' (min)

- DownstreamUpstream of Circ: 4x 'D' (min)

- Pipes entering CSTs (bulls) in my case the boiler secondary?

- In/out of air separator?

- Spacing of supply and return tees on primary loop/header (zones)?

0 - Closely Spaced Tees (CSTs): 4x 'D'

-

Thanks, I used those guidelines… so the others I mentioned are insignificant?Gordy said: 0

0 -

Where is the panel rad manifold tieing in to all this?0

-

Not more than 4 times pipe diameter between ts0

-

You need to know how you're going to set up your (future) radiant slab, to make provisions for it, now.

http://www.caleffi.com/sites/default/files/file/idronics_7.pdf0 -

Gordy said:

Where is the panel rad manifold tieing in to all this?

This should show it better (basically a line drawing of above pic):Paul48 said:You need to know how you're going to set up your (future) radiant slab, to make provisions for it, now.

http://www.caleffi.com/sites/default/files/file/idronics_7.pdf

Radiant panel manifold is that white USPS box in the upper pic. The Slab manifold will be located approx. 30' away from the circ and mechanical "panel". I anticipate having to run it at a lower temp, so I can put in a mixing valve (say a tekmar 3-way with electronic control) upstream of the second circ controlled by a Lochinvar Multi-Temp Loop Controller.0 -

where is the mixing valve going. Also you may need two different radiant supply temps. One for future concrete in slab, and one for over the top in bath/walk in closet area.

0 -

closely spaced tees, right? Not tees on a common supply or return header? I have a steel header and the tees are about 7" apart (3/4" bulls on a 1 1/4" common).Gordy said:Not more than 4 times pipe diameter between ts

0 -

Okay that's what I thought let's call it panel rad manifold instead of radiant panel manifold.0

-

Right. So as it's not more than 12"bmwpowere36m3 said:

closely spaced tees, right? Not tees on a common supply or return header? I have a steel header and the tees are about 7" apart (3/4" bulls on a 1 1/4" common).Gordy said:Not more than 4 times pipe diameter between ts

0 -

Right, with closely spaced tees.Gordy said:

Right. So as it's not more than 12"bmwpowere36m3 said:

closely spaced tees, right? Not tees on a common supply or return header? I have a steel header and the tees are about 7" apart (3/4" bulls on a 1 1/4" common).Gordy said:Not more than 4 times pipe diameter between ts

I'm referring to a header when multiple circs are attached to a common supply or return (not P/S). Like a lot of CI boilers have installed.

Is the spacing between the tees/circs important?

Fix my diagram 0

0 -

Where is this header going?0

-

Not using a steel header per se, but something like this:

Tee spacing on the supply (circs) and returns, circled in yellow?0 -

I guess im confused with all that copper you got chopped up on the floor. Expensive way to experiment.0

-

The spacing of those tees has nothing to do with P/S. There is no hydraulic seperation on the zones as pictured.0

-

Photoshop… I just laid out the components and fittings. All the pipes are photoshopped, I haven't cut any copper yet…Gordy said:I guess im confused with all that copper you got chopped up on the floor. Expensive way to experiment.

1 -

That's what I figured, I just wasn't sure if there was some "best practice" as far as spacing, if it makes any difference. Or can you just jam those circs side by side.Paul48 said:The spacing of those tees has nothing to do with P/S. There is no hydraulic seperation on the zones as pictured.

Based on John Siegenthaler's book, "common piping" to multiple circs should be sized so as to reduce head loss. That way, each circ operates "almost" independently. Common piping or header should be sized so flow rates are 2 fps or less [to reduce head loss in common piping].0 -

Correct you are. We try to show this graphically with "large" lines on the piping schematics. Spacing is not so critical as long as the header provides sufficient flow.

From Idronics 15Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

So I finally got the boiler hung in the basement and I've been thinking about DWH circ sizing… which then led me back to the boiler pump. The pump included with the boiler is a UPS15-58 (3-spd). Even at its slowest speed, it'll provide way more GPM then I need (on the boiler-side loop).

Loch's manual lists a minimum of 3 - 5 GPM (35-20* delta) with a head loss of 0.1 to 0.27'. Based on my rough layout, I figure the equivalent length of 1" copper pipe will be 50' or so. That translates into 1-2' head in the boiler loop… Seems their recommendation for 1" pipe and pump is a bit conservative, unless you do some crazy boiler piping.

Since I already have a Grundfos Alpha for the system side, I was wondering if I could use another Alpha (on fixed speed) for the boiler pump. On its slowest speed it should be able to provide about 4 GPM at 2.5' head… which even then is a bit "oversized". However a lot better than the 15-58, which I think I can use for my DWH.

Sounds reasonable?0 -

My rational is that the heating load will be a greater % time-wise vs. the DWH (recover as quick as possible). Thus use a more electrically efficient circ for the boiler side.

And an obligatory pic: 0

0 -

Yes, that Grundfos pump is to big for use as a boiler pump. Do yourself a favor, and pick up a Taco Viridian 1816. You can slow this little pump down to the correct speed. Even on low, the Grundfos is going to give you velocity noise, and maybe air issues.0

-

By Grundfos pump, you mean the 15-58 that comes with the boiler, right?ced48 said:Yes, that Grundfos pump is to big for use as a boiler pump. Do yourself a favor, and pick up a Taco Viridian 1816. You can slow this little pump down to the correct speed. Even on low, the Grundfos is going to give you velocity noise, and maybe air issues.

I already have a Grundfos Alpha for the system side and looking at its min speed, its pretty similar to the Taco 1816. So I was thinking of getting another Alpha for the boiler pump.

Then use the 15-58 for my DWH.

I'd have to find out if my supply house can get the Taco... was just trying to keep the pumps in the same "family" for replacements issues down the road.

0

Categories

- All Categories

- 86.8K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 56 Biomass

- 425 Carbon Monoxide Awareness

- 109 Chimneys & Flues

- 2K Domestic Hot Water

- 5.6K Gas Heating

- 105 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 966 Plumbing

- 6.3K Radiant Heating

- 385 Solar

- 15.3K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 47 Job Opportunities

- 18 Recall Announcements