Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Is my new Burnham Independence Steam boiler not running properly?

KG21

Member Posts: 5

In October, my 30+ year old steam gas boiler was replaced (had corrosion and leaking gas) with a Burnham Independence Steam boiler. I have a few concerns about how it's running.

1)This November was warmer yet it consumed the same amount of gas as the old boiler that was leaking gas and constantly running a pilot (new boiler only has a lit pilot when operating) did last year. Also, I have a programmable thermostat that is set the same as last year.

2) Shortly after it turns on, there's loud banging for ~30 seconds and periodically while running. Is it possible to stop the banging? The banging seems to be coming from the return pipe. There was some banging with the old system but not as bad as it is now.

3) It takes longer to warm up my house. It takes 45 minutes just for all the radiators (old school cast iron ones) to get warm (1500 sq foot house, radiator in each room, 9 total with 7 on the first floor and 2 upstairs) and 2 hours to raise the temp 4 degrees in my house. Old system took less than an hour to warm the house the same amount. I also feel like the radiators don't get as hot now as they did before.

For the pressuretrol the Diff and Main are set to .75 PSI (was 1 plumber suggested drop to .5 but it didn't help so we tried .75 and it didn't seem to make a difference) & when running the internal syphon reads 0 psi. I've also replaced all the steam vent valves on the radiators.

Any thoughts would be greatly appreciated!

1)This November was warmer yet it consumed the same amount of gas as the old boiler that was leaking gas and constantly running a pilot (new boiler only has a lit pilot when operating) did last year. Also, I have a programmable thermostat that is set the same as last year.

2) Shortly after it turns on, there's loud banging for ~30 seconds and periodically while running. Is it possible to stop the banging? The banging seems to be coming from the return pipe. There was some banging with the old system but not as bad as it is now.

3) It takes longer to warm up my house. It takes 45 minutes just for all the radiators (old school cast iron ones) to get warm (1500 sq foot house, radiator in each room, 9 total with 7 on the first floor and 2 upstairs) and 2 hours to raise the temp 4 degrees in my house. Old system took less than an hour to warm the house the same amount. I also feel like the radiators don't get as hot now as they did before.

For the pressuretrol the Diff and Main are set to .75 PSI (was 1 plumber suggested drop to .5 but it didn't help so we tried .75 and it didn't seem to make a difference) & when running the internal syphon reads 0 psi. I've also replaced all the steam vent valves on the radiators.

Any thoughts would be greatly appreciated!

0

Comments

-

Post some photos of the boiler and nearby piping, preferably from at least two angles.0

-

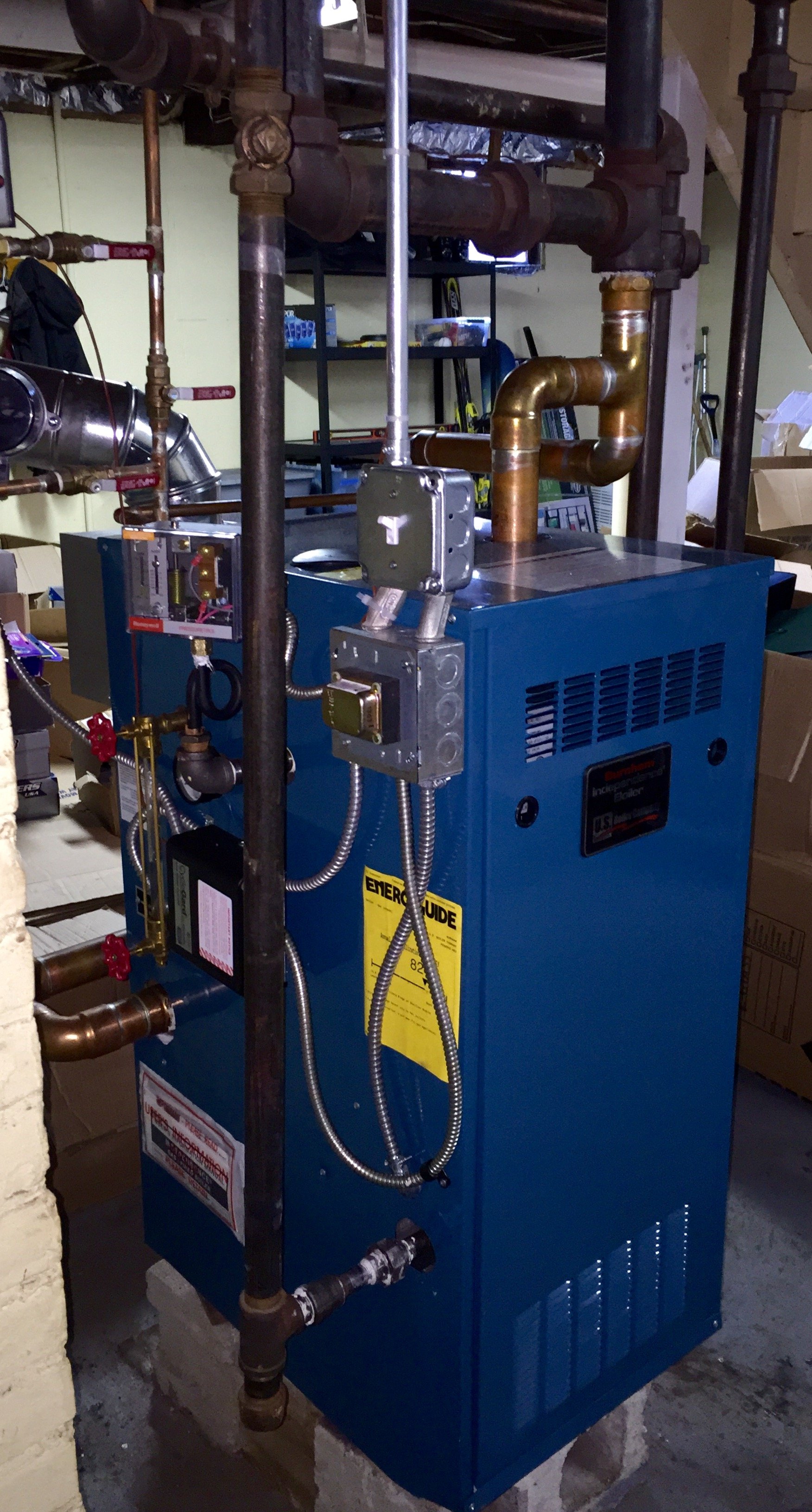

Do these pictures help?

The last one shows where the pipe is banging.

Thanks!

0

0 -

Nice solder job.

I guess he didn't own a power drive and threading equipment.0 -

Beavis and Butt-head strike again. That steam piping around the boiler is completely wrong, and will have to be re-piped. Compare it to the diagram in the manual and you'll see how it should have been done. Bad piping will allow water to get up into the steam pipes, where it will bang and cause the steam to condense long before it should.

Go here to see some boilers that are properly piped- I think at least one is an Independence. You'll notice that the risers leaving the boiler are taller- this helps keep water from getting that high. The risers drop into a horizontal (but slightly sloped) header which then feeds the steam mains. The header pipe size is larger then either the risers or the steam mains- this slows the velocity of the steam and allows any water that made it this far to drop out of the steam and flow back to the boiler.

https://heatinghelp.com/systems-help-center/what-is-a-drop-header/

The systems at this link heat up quickly, quietly and efficiently. Yours can too if it's properly piped.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

HG, the only thing I can figure is- you have to be able to actually READ.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

There is no allowance in the price for time to read the I/O manual. Besides, they usually claim that they have been doing it this way for years and years. Sometimes, before the owner was born.Hatterasguy said:Amazing.

Why is RTFM so difficult?

Scary.

0 -

You got some good info here…from the posts…Like they said it must be repiped, period….I also feel any steam guy that has to read the book on near boiler piping is a phony…..It is simply amazing what you see and what you hear out here….I am sorry that that happen to you….I recently got a friend of mine who recently posted here a full complete refund…from the install co…The new boiler was grossly oversized and piped if you can believe it worse than yours…6

-

Yes have met a lot of guys like this. Thing is they haven't a clue themselves, some guys pipe it just to manufactures specifications, and then tell me I'm spending unnecessary money and doing unnecessary work. My question to them is does your system heat quietly and efficiently, usually that can't answered either.icesailor said:

There is no allowance in the price for time to read the I/O manual. Besides, they usually claim that they have been doing it this way for years and years. Sometimes, before the owner was born.Hatterasguy said:Amazing.

Why is RTFM so difficult?

Scary.

Moral of the story, if you don't know what your doing, at least do copy the I/O manuals instructions.DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......0 -

-

Is there a Hartford Loop?0

-

It would have been SO easy.......that system is an absolute NATURAL for a pretty drop header.........even I could have done that one......0

-

Icesailor, you're so spot on. I had a couple of guys to hook-up my burners last year scrambling to read the I&O manual while trying to figure it out. It would have been funny if it weren't so sad and my house wasn't 32deg at the time. I had actually sent the owner of the co. a pdf so they could review it before coming. And that was only the wiring! They left saying it was too difficult and they didn't have the time. They only allotted so much for each job and apparently that didn't include reading the manual. Makes me made just thinking about it, but at least I didn't have to deal with having someone comeback to REDO what they didn't do right in the first place. ColleenTwo-pipe Trane vaporvacuum system; 1466 edr

Twinned, staged Slantfin TR50s piped into 4" header with Riello G400 burners; 240K lead, 200K lag Btus. Controlled by Taco Relay and Honeywell RTH6580WF0 -

That's our competition.

There's never enough time to do it right. But always time for someone else to do it over.0 -

Behind the copper in the third photo on the bottom. Connected to the last vertical tee.John Mills said:Is there a Hartford Loop?

0 -

Drop header?Don said:It would have been SO easy.......that system is an absolute NATURAL for a pretty drop header.........even I could have done that one......

Smash those two 2" cast ells up where it goes from the horizontal to the vertical, and you have all the room to do whatever you could imagine.

Even Roscoe The Wrencher could come up with a nice idea for that.

I know. It takes a lot of energy and ambition to swing a 4# hammer and crack a 2" CI fitting.

Nice solder job though.

0 -

Thanks everyone for taking the time to comment! Seems my gut feeling was right.

In the picture below, is the red line I added the way the piping should be for a drop header? Or is there more to how the system needs to be re-piped then I'm understanding? Only the user info manual was left, not the installation one. So I'm going off the pictures from the link steamhead gave. The pictures in the link didn't show a pipe that comes around the boiler like I have in the third picture above so I wasn't sure if that needed reworking too.

Also, is having the pipes soldered a bad thing? And are any of you near Boston?

Thanks! 0

0 -

Hatterasguy, thanks for the detail explanation. Is the diagram I created correct and are the other pipes, like where the hartford U is, ok as they are? I'm trying to make sure I understand everything before having it redone.

Also, has the way piping is done for steam units changed over the years, or did the original plumber from eons ago do it wrong in the first place?

Why black iron and not the copper?Hatterasguy said:

All that copper needs to be replaced with black iron.

And, the most critical point: The height of the risers off the top of the boiler need to be a minimum of 24".............or 36" above the waterline.............way above what you currently have.

And how do you tell where the water line is? If it's where the water line in the glass tube is, then the current riser is only about 26" above the water line. If someone could explain why that would be awesome. I'm trying to understand everything so I can make sure it gets fixed correctly.

Thanks again for all the help!0 -

You mentioned being near Boston -- if "near" is somewhere west of Boston, you could do much worse than call Charles Garrity in on the job... garrityplumging@gmail.com. He's busy, and he's not inexpensive -- but he's one of the best.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Hatterasguy, thank you for all the explanations. I really appreciate the time you've taken to help me understand my problem and how it should be fixed.

Jamie, I'm slightly south of Boston but thanks for the recommendation.0 -

South of Boston call True Heating in Stoughton. He's one of the few plumbers I got estimates from that knows steam.0

Categories

- All Categories

- 86.2K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 52 Biomass

- 422 Carbon Monoxide Awareness

- 90 Chimneys & Flues

- 2K Domestic Hot Water

- 5.4K Gas Heating

- 99 Geothermal

- 156 Indoor-Air Quality

- 3.4K Oil Heating

- 63 Pipe Deterioration

- 913 Plumbing

- 6K Radiant Heating

- 380 Solar

- 14.8K Strictly Steam

- 3.3K Thermostats and Controls

- 53 Water Quality

- 41 Industry Classes

- 47 Job Opportunities

- 17 Recall Announcements