Closely space tease primary secondary

From boiler is hooked up with closely spaced tease boiler is working and running fine. Got to looking at it and noticed that on the left coming down into the is the supply and on the right which the pump is on coming out of the is the return that makes a circle through the boiler primary loop, now on the left and right side of the where the secondary hooked up on the left the return water is and on the right the supply is going out to zone pumps, it is opposite, but the boiler is running and doing what it’s supposed to and heating. Is this a problem?

Comments

-

Can you post a sketch? I think what you are saying is the return and supply from the boiler is reversed. You have to look at the boiler pump closely to see which way it is pumping. Or post a picture.

0 -

no the return and the supply from the boiler right the boiler pump is pumping up into the boiler and then out down into the bullhead of the tee, the problem I’m seeing is on the left, which is the supply from the boiler. The return comes in to the left side of the tee, and then on the right, which is the return the supply from the secondary which is multiple pumps is pumping out on that right side. The boiler is running at 120 and it is running good from what I can tell right now there is hot water going out to the floor, with that said, I know it is not right, but will it work just don’t know the dynamics in depth on hydraulic separation and the way it pumps through the closely spaced tease

0 -

0

-

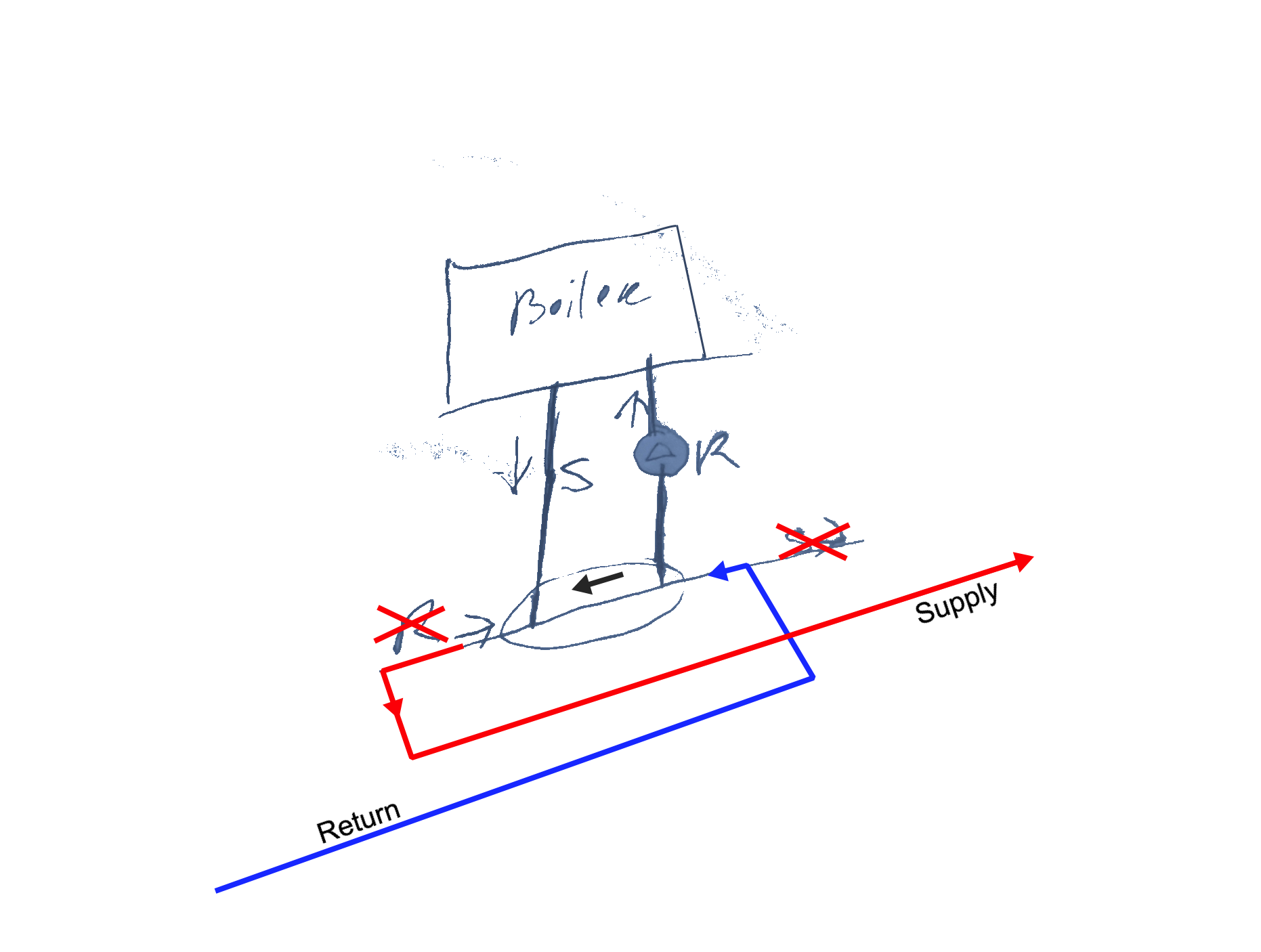

That drawing is backwards. Here is the easy fix:

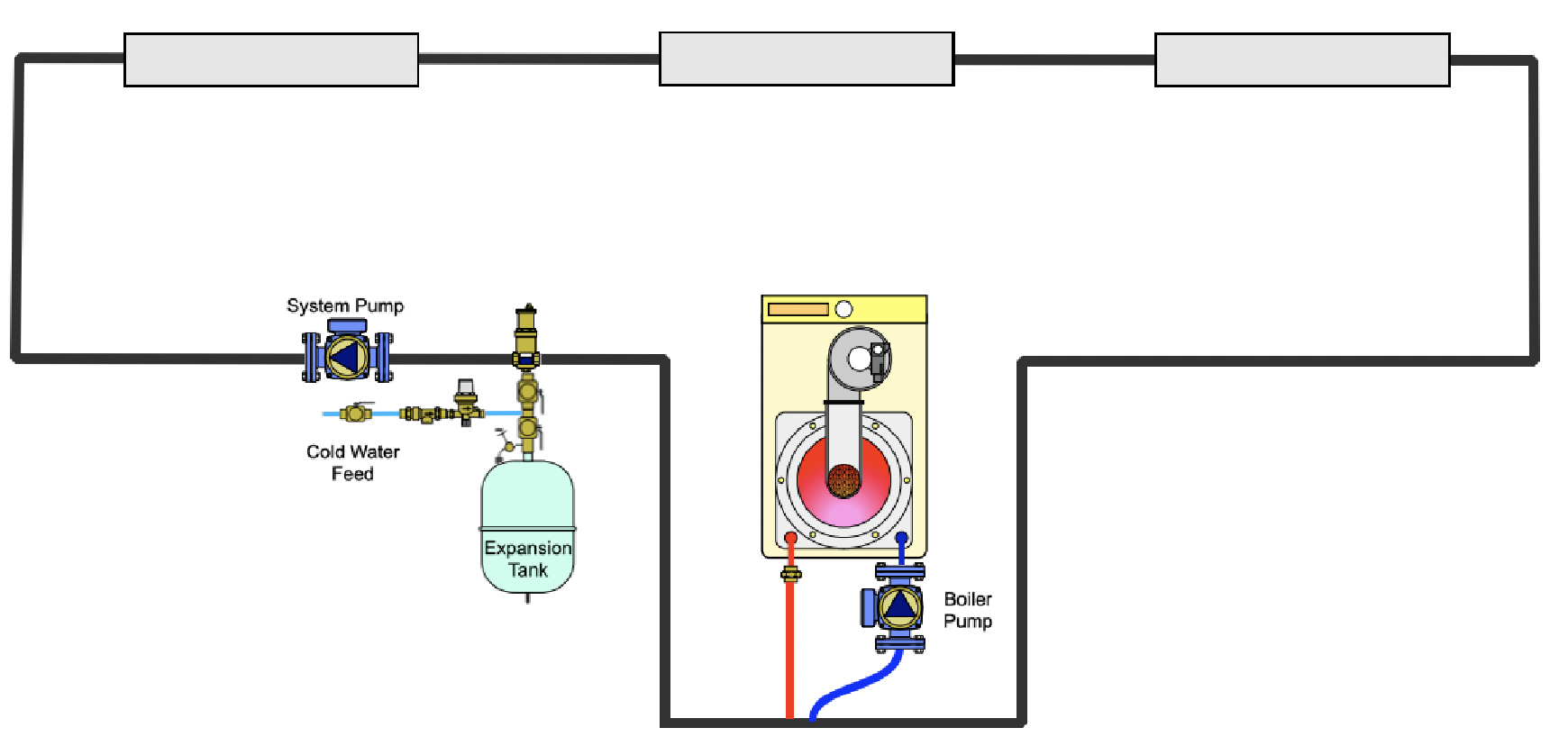

So you know how to use the term primary secondary loops properly, the loop with the expansion tank is the primary loop. and that is most likely the system side of the closely spaced tees. The secondary loop is the boiler loop. with the boiler pump on it.

The best place for the expansion tank in this system is just after boiler supply pipe somewhere on the red supply line of the primary loop. The next thing on the primary loop is the circulator pump so the circulator is pumping away from the expansion tank.

If you need to drain everything down to repipe the near boiler piping you may as well make all the necessary corrections all at once. Here is a good diagram for you to follow.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Oops, I forgot to include the diagram of the system I mentioned above:

See the direction of the system flow, The hottest water does not go past the return to the boiler. The hottest water goes to the system and the return gets fed to the boiler return.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I understand all of what you guys are saying and thank you, but will it ever work piped the other way

0 -

-

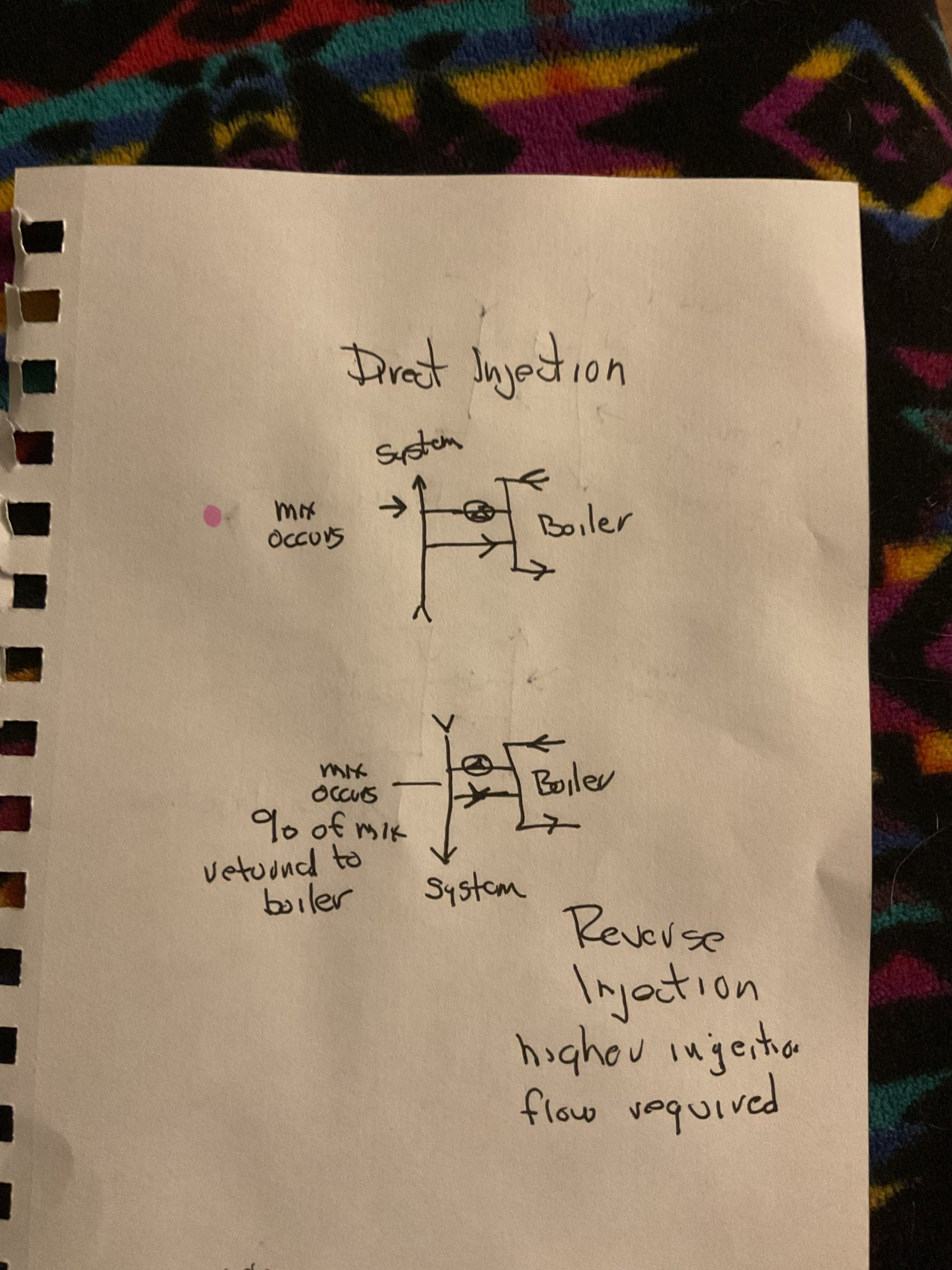

what you show is known as reverse injection, it will work. The boiler flow would need to be much higher as a % of the boiler supply Is being returned to the boiler.

With direct the mix point is downstream of the close tees.

With reverse the mix is between the tees.

For your type of system it would be worth making the switch to direct

Change flow direction on the horizontal line in your drawing and you have direct

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

thank you I appreciate all your guys advice

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements