leak in pex tubing in concrete slab

Currently building a new house which we layed pex tubing runs in the concrete slab that got poured right before winter hit late this past fall. It seemed to hold pressure through the pour and also for a couple weeks after. Currently all the framing is done, and ive gotten back to checking the manifold to see if its holding pressure. Put in around 40 psi of air pressure and that dropped within a week. Ive found the smallest leak off the manifold but havent had the chance to fix that yet. Im worried the framers ran a nail too far through the concrete slab and hit a tube. Not sure where to start with this issue. Located in south dakota.

Comments

-

fix the discovered leak and air it up to 80 psi. It will drop as the air from the compressor cools down. But if it drops to zero, time to start looking.

Any framing that was anchored down is the first places to look. Check the gauge with spray soap also, if it ever had moisture in it maybe it froze?

It is repairable once you find it. Is the slab the final finish? Or are you going over it with tile or wood?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I found the leak with soapy water right by the pressure gauge, but it seemed to be very slow. I'll fix that soon. Nothing has been in it yet. Plan to lay vinyl flooring as we progress, so I'm not sure how to find the leak in the floor without getting a broiler going.

0 -

The higher the air pressure the easier to hear or see them leak with soapy water, around nails, etc. 100 psi is acceptable in pex tube.

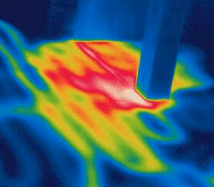

By far the easiest is with an infrared camera, but you need to connect the tube to a boiler or other heat source.

Possibly on a cold day, warm air from the compressor may show on the camera, worth a try.

Do you have manifolds attached to the loops with individual shut offs?

If so you can do a loop by loop air test.

Did you take pics of the loop layout or have a drawing? That helps narrow down the area to investigate.

Maybe it was just the leak at the gauge, start there.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Don't overlook the possibility that sometimes the gauges themselves can leak.

0 -

@hot_rod did you, or anyone ever think to try testing radiant tubing with nitrogen like AC lines, at a much lower psi, of course. Then one could easily calculate pressure drop or rise, based on line temperature (decay test) to determine if there is an actual lea

Just wondering.0 -

I've used Leakbusters a few times. They have a bunch of different tricks they use.

With air pressure they have a headset and a heavy flat steel mic that they slide across the slab. That was successful on one indoor greenhouse slab job.

On another, a snowmelt, he used a fill tube with a venturi and orifice like pressure washers use. So it sucked air in as it pushed water into the various loops. He was able to detect the noise better with the water/air blend and the listening device.

For indoor use he has some gas that could be injected and he would use a sniffer.

In both cases he marked a few spots on the slabs with a piece of masking tape and sure enough the leaks were within inches of his marks!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements