Relay 90-293q re-wiring question

Hello

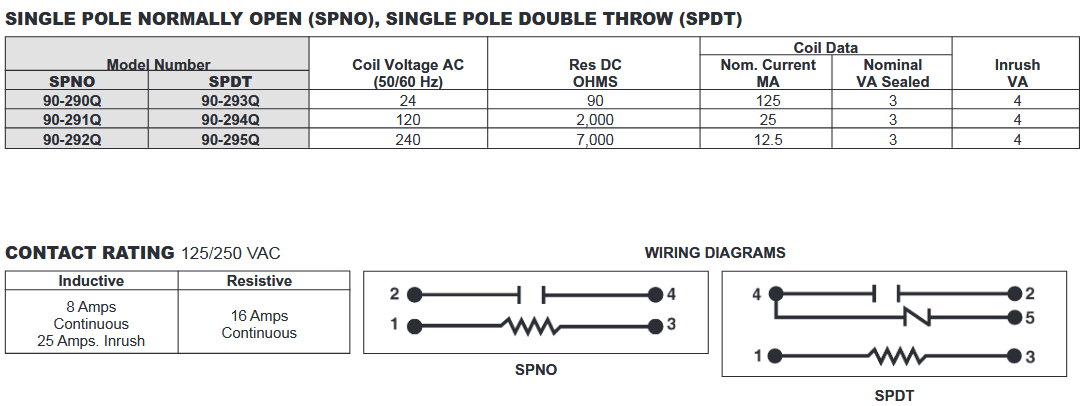

I am using Emerson 90-293Q Enclosed Fan Relay below

They are installed on WM CGM Series 9 CGM-4-PI with two zones, and are wired as follows:

#1 goes to white thermostat wire

#2 goes to the other relay, and also to the main transformer inside the boiler

#3 goes to green thermostat wire

#4 goes to the high limit temperature control

#5 is not being used.

I'm going to be replacing these wires and their connectors and was wondering if these terminals require specific wire gauge or color coding.

I'm pretty OCD when it comes to this stuff, so if the run to the high limit needs to be a certain gauge or color, that's what I want to do. If there's a specific quick connect to be used, that's what I want to use.

Thanks in advance everyone

When you see hoofprints think Zebras not Horses

Comments

-

Why do you want to do this ?

Anyway;

Same color (to match the wiring diagram), same insulation type (material, voltage rating, temperature rating), same wire gauge, same length, proper connector(s) and if they are crimp on connectors the proper crimping tool, which no one usually has because they can be expensive, and thus resulting in poor workmanship.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks for taking the time to respond.

When you see hoofprints think Zebras not Horses

0 -

Circling back to why.

#3 connector has two different color wires of two different gauges. I'd like to remedy that.

The condition of the connectors is an issue as well. Here's a close up pic of #3 zone 1. It goes to the white thermostat wire. I'll be replacing it.

As to length, I'd like these wires to be about 12" so I can relocate the relay itself. It's in a bad spot. That doesn't seem unusually long to me but maybe 12" is really long to you? LOL sorry man I couldn't resist.

This sucks, but I don't have a wiring diagram. I bought the house as-is and the last guy spilled something on it. It's illegible. I reached out to WM to see if I can get one. There's a part number on it says 550-224-040/382 but having trouble locating.

As far as my craftmanship, you don't need to worry. I swear. Tell me the best crimper to use, the best connector to use, and what else you would do if it were you

Thanks again

When you see hoofprints think Zebras not Horses

0 -

Is this the boiler wiring or the thermostat /zone valve wiring or both ? There is a wiring diagram on the inside of the cover ?

Color changes and wire gauge may be intentional and do not need to be remedied, hard to say from here. If in doubt use the heaver gauge if you want wire gauge consistency.

If there is no wiring diagram for a troubleshooting reference they all could be black wires, however color helps to trace things out if needed.

Crimping tools, that is, the actual manufactures recommendation are usually product specific. You would have to look at the data sheet for the product you are going to use. In your picture I already see two different styles of connector. So it appears someone was there before making a mess of things, but it probably worked well beyond the warranty period so no one usually cares much. Finding manufacturing quality crimps in field wired equipment is very rare.

Well if you are relocating things the wires will be longer.

Folks usually make a mess out of wiring and leave to the next gut to figure out.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

For now, I want to replace the wires that come off the relay posts #1 through #4.

I'd like to use 16 AWG for posts #1 and #3 which go to the thermostat wire. I was thinking white and green respectively, because the thermostat wires they meet in the wire nut are white and green.

I'd like to use 14 AWG for post #2. Post #2 goes to the other relay, and to the main transformer/relay. I was thinking black, because the transformer/relay wire it meets in the wire nut is black.

I'd like to use 14 AWG for post #4. Post #4 goes to the high limit temperature control. I was thinking of using yellow, because the high limit temperature control wire it meets in the wire nut is yellow.

I'd like to make these new wires up to 12" long because I'm very particular about how wires are run, bundled, isolated, identified, etc. I don't like where these relays are mounted. I don't like that nothing is labeled. The 'next guy' is me and I'm figuring it out now, before it becomes a problem.

I do feel like you're talking down to me about the crimping, for the second time, so I will ask you again. Tell me the crimping tool you would use. Tell me the connector you would use. You don't see manufacturing quality crimps in the field? Tell me how to make one.

TIA

When you see hoofprints think Zebras not Horses

0 -

14 Ga. is fine, probably overkill unless you are powering a circulator through that wire. No, not talking down to you, although I think you don't understand the vastness of what you are asking. This is just one example;

Let me put it this way, I don't like crimps, they fail way too often and sometimes it is hard to find the failed connection. Most folks use the inexpensive 'Kit' from the big box store or their favorite electrical supplier and it gets the job done. I've seen crimps that look good to the eye and feel secure that are a total failure under load when viewed with a IR thermal camera.

The industry uses crimps since they are quick, inexpensive, generally last beyond the products warranty period and over thousands or millions of crimps the cost of the tooling is almost nothing. Some tools are over $100 and don't include the dies.

For myself (when forced to use that type of wire termination) I often use un-insulated or I remove the insulation from an insulated crimp on connector, crimp it with a generic crimping tool and then solder it, once it cools a bit I remove the flux and put a layer or two of heat shrink tubing to strain relief it and it also helps seal it. Usually the heat shrink tubing is slid over the wire before the termination is crimped on. For automotive or harsh environments I use the heat shrink tubing with the intermelt (hot melt adhesive). I've had zero issues with this method, however it is more time consuming, need to be able to solder and have heat shrink tubing.

Also I find it awkward and/or maybe just silly to recommend an expensive tool that may do an exceptional job when used correctly for a dozen wire terminations.

At work they have so many crimping tools it is often hard to find a suitable one. And I am not the guy that buys them so I rarely look at the make and model, just look at the die to see if it matches the terminal I am trying to crimp. If I don't like the crimp I get, it gets cut off and redone and/or redone with a different tool or just soldered depending on the application / situation.

The proper way is to decide on the wire termination you want that suits your needs / application, look up its data sheet and procure the manufacture's recommended crimping tool for that wire termination. I would venture to say that never happens for wiring repair in the field in the HVAC industry. Maybe it does in the aviation industry, I don't know.

However there nothing saying you can't go above and beyond the typical field wiring repair quality. For me crimp, solder, heat shrink, some folks won't like that method for various reasons.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Awesome.

When you see hoofprints think Zebras not Horses

0 -

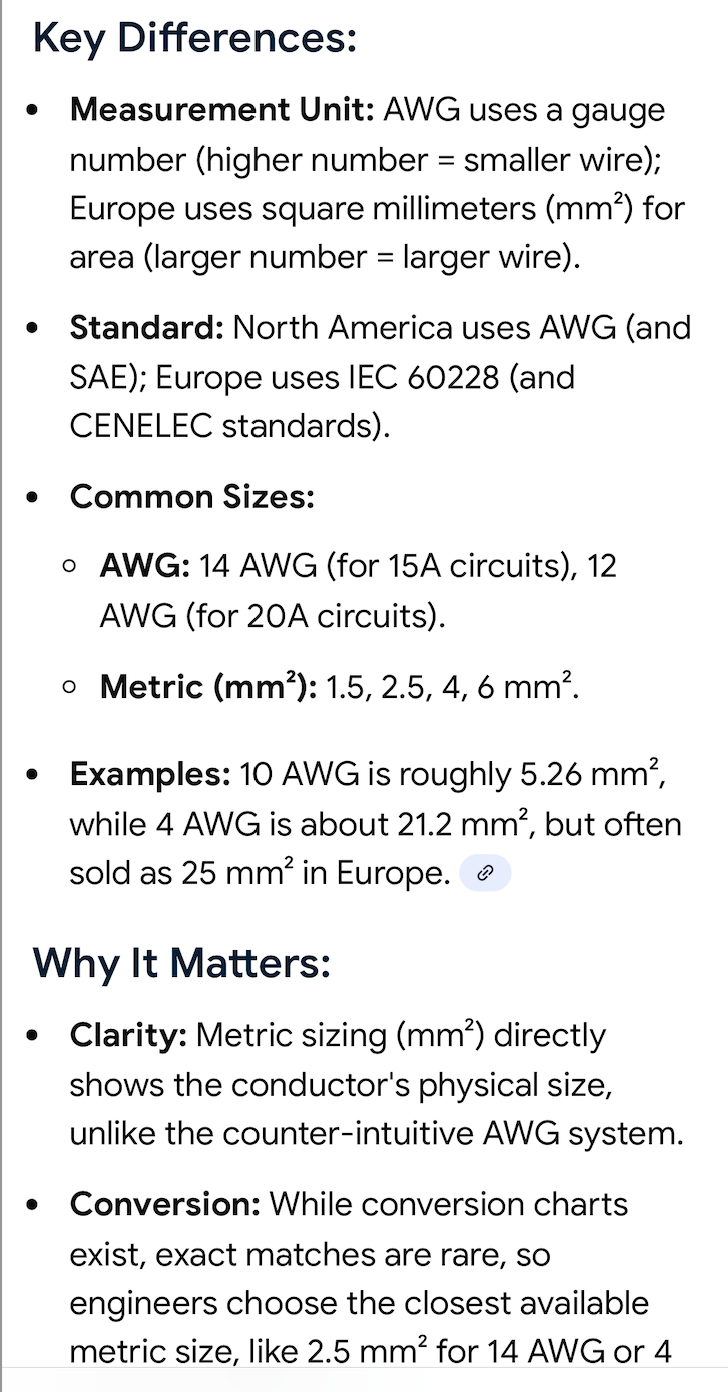

I started using wire ferrules on stranded wire after visiting a few control manufacturers in Germany, years ago. They are used on control and line voltage wiring.

The crimper I bought squeezes 6 sides and does not release until it is closed all the way, so no issues with under-crimping.

I believe DIN certified ferrules are required to get CE certification on wired components.

I also learned wire gauge in Europe are metric sized so you may notice European wiring terminal strips don't always accept AWG wire size without some wrestling , especially stranded control wire.

So the ferrules help when working with Euro based control, most mod cons wiring in general. They look professional also.

Basic kits from ferrulesdirect.com

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Depending on the situation Wire Ferrules are nicer that 'Tinning' stripped wires. Like when poking stripped wires into Phoenix Connectors.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Ferrules are quick and easy and you can color code the various wires with your ferrule selection.

Not many plumbers carry soldering irons or pencils :) Tinning wires with a torch takes some practice.

The white ones in the assortment allow you to write on them

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for weighing in.

FWIW, I've been to Germany and it leaves an impression.

They are not messing around.

When you see hoofprints think Zebras not Horses

0 -

109A_5 I'm going to review these new connections under load with an IR camera like you suggested.

When I used my IRC for air sealing, every single leak stood out dramatically . . . there was no guessing at all.

Should that be my expectation here? A bad crimp under load is going to get much hotter?

Thanks man

When you see hoofprints think Zebras not Horses

0 -

Well at the power levels found with boiler control circuits, a poor crimp may take some time to heat up a bad connection. The heat generated by a load may cause a false positive if not scrutinized carefully. If your crimps look good they will probably work fine. Connections can degrade with time and oxidation.

Another verification test is the overall voltage drop from end to end of the wire, it should be low millivolts or even hard to get a measurement, depending on the meter.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It's nice to know that some of us are still doing "Rocker Surgery" on the HVAC systems in out homes. And I like to use tiny wire nuts with different gauge wire twisted together after twisting them the wrong way because I'm left handed. Now that is what I call "Perfect"

There is a story that goes with "Perfect". Read this one:

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Here is an example, my old 1989 Chevy Astro Van. I've had it for maybe at least 12 years, it is very close to retirement now. I believe the former owner sold it since his mechanic could not repair some simple issues. One was charging system issues. I put a new alternator in it. While changing the alternator I found this crimp on the output wire. I believe the old alternator had issues but this non-OEM crimp was not going to stay and give me grief down the road. I did the wiring repair as I explained above and have not had any charging system issues since. This is an example of the obvious poor workmanship found out there. Other crimp defects can be more subtle. Fun fact, the Walmart (Johnson Controls) battery I put in lasted 9 years and 11 Months.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I saw this and started down the rabbit hole.

Now they're all perfect, like perfect perfect.

Ed I was going to suggest a LH wire nut, but nobody in their right mind would by them . . .

When you see hoofprints think Zebras not Horses

0 -

My low voltage thermostat is sending 27v to the relay

Is this acceptable?

Thanks in advance especially @109A_5 who must be tired of telling people to get the meter out by now. I'm a parts cannon kind of guy but I'm changing my ways.

When you see hoofprints think Zebras not Horses

0 -

@tonynap I'm not the only one that promotes the use of a meter here. It often just makes troubleshooting so much easier. Parts cannon can work, often it is expensive and time consuming and may not repair the issue. Many folks don't know how to use a meter or are afraid of electricity. Yeah never know. If a meter can be used it is usually a benefit.

27 VAC is fine, 24 VAC is a nominal voltage. If you have a 40 VA transformer that is not loaded to 40 VA (fully loaded) the transformer's output voltage is more often than not higher than nominal.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

👍️and thanks again

When you see hoofprints think Zebras not Horses

0 -

If this was a chainsaw forum I'd tell you (with 100% certainty) not to bother with the amazon carburetors, and to get yourself a ZAMA or WALBRO carb. Pay now or pay later.

In that spirit, is there a better relay besides the Emerson 90-293Q I installed? I bought two and they both act like amazon carbs when I want a WALBRO.

Thanks,

TonyP.S. I'm not the luckiest person so if there's a 1% chance of a relay being garbage off the line I'm the guy who ends up buying it.

When you see hoofprints think Zebras not Horses

0 -

There are thousands of relays . . .

Do you know what the purpose of the relay is in the system ?

Do you know if the Coil of the old relay is AC or DC ?

The Emerson 90-293Q has an AC coil.

If that original relay has a DC coil, a relay with a AC coil may not work so good.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I'm pretty sure it is AC . . . It replaced an interstate electric 90-293 pictured below.

It's completing the circuit to the circulator (a TACO 007-F5) via terminal #2 and the high limit switch (WM 10-312-250) via terminal #4.

Everything is back in good working order except it buzzes, and I'm not sure if that's par for the course. If that's a quality control issue because I'm using an inferior part, I'd like to replace it. If not, I'm content to leave it as.

Thanks man

When you see hoofprints think Zebras not Horses

0 -

OK, so it is not the relay pictured earlier in the thread. The wires going to the contacts of that relay were not appropriate to be controlling 120 VAC power to a circulator. Sometimes AC coil relays buzz, but function correctly, it's annoying.

And the old relay did not buzz ? Just did not function correctly ?

Supplyhouse.com (for example) has 58 relays that would probably work for a reasonable replacement, kind of depends on the mounting and the wiring and what you like.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It's all good so I can live with the buzzing. Thank you sir.

When you see hoofprints think Zebras not Horses

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements