Where to tap into secondary loop?

Hello,

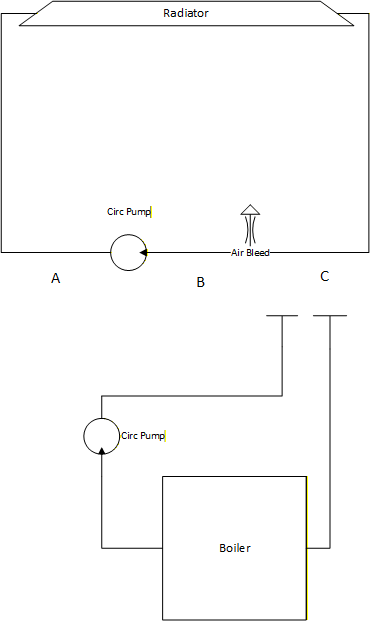

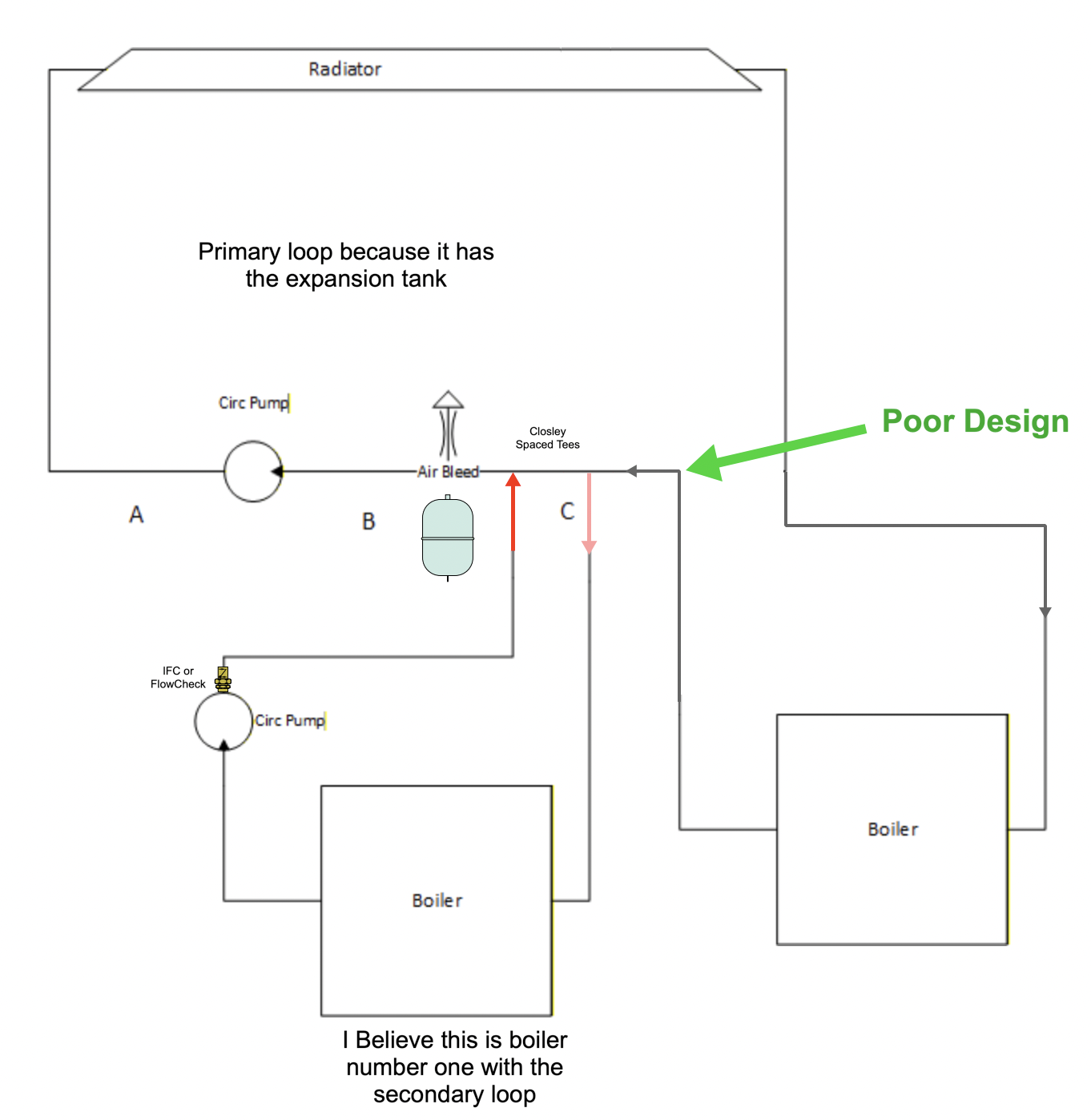

I have two boilers: one already has a secondary loop with its own circulating pump and the other has a single loop which uses just the boiler's circulating pump. I am wondering at which point I should tap into the secondary loop. The pre-existing one is tapped at "C." I just didn't know if that was best practice and what I should do.

Why create a secondary loop you may ask. The boiler was built in 2004 and has weak flow even after running descaler through it. Thought perhaps I could get some more years out of it and that the newer boiler with secondary loop might be a better design, one that I should mimic.

Thank,

Jay

Comments

-

If your expansion tank is where the air bleeder is shown I would tap the two lines in between the expansion tank and the circulator in the "B" section of pipe

0 -

expansion tank under air purger, tie in at C, boiler pump on the return side of the boiler

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Let me know if I got this wrong. I believe you have only one boiler in your drawing. I also believe it is the boiler with the secondary piping and boiler circulator you referred to in your first line above.

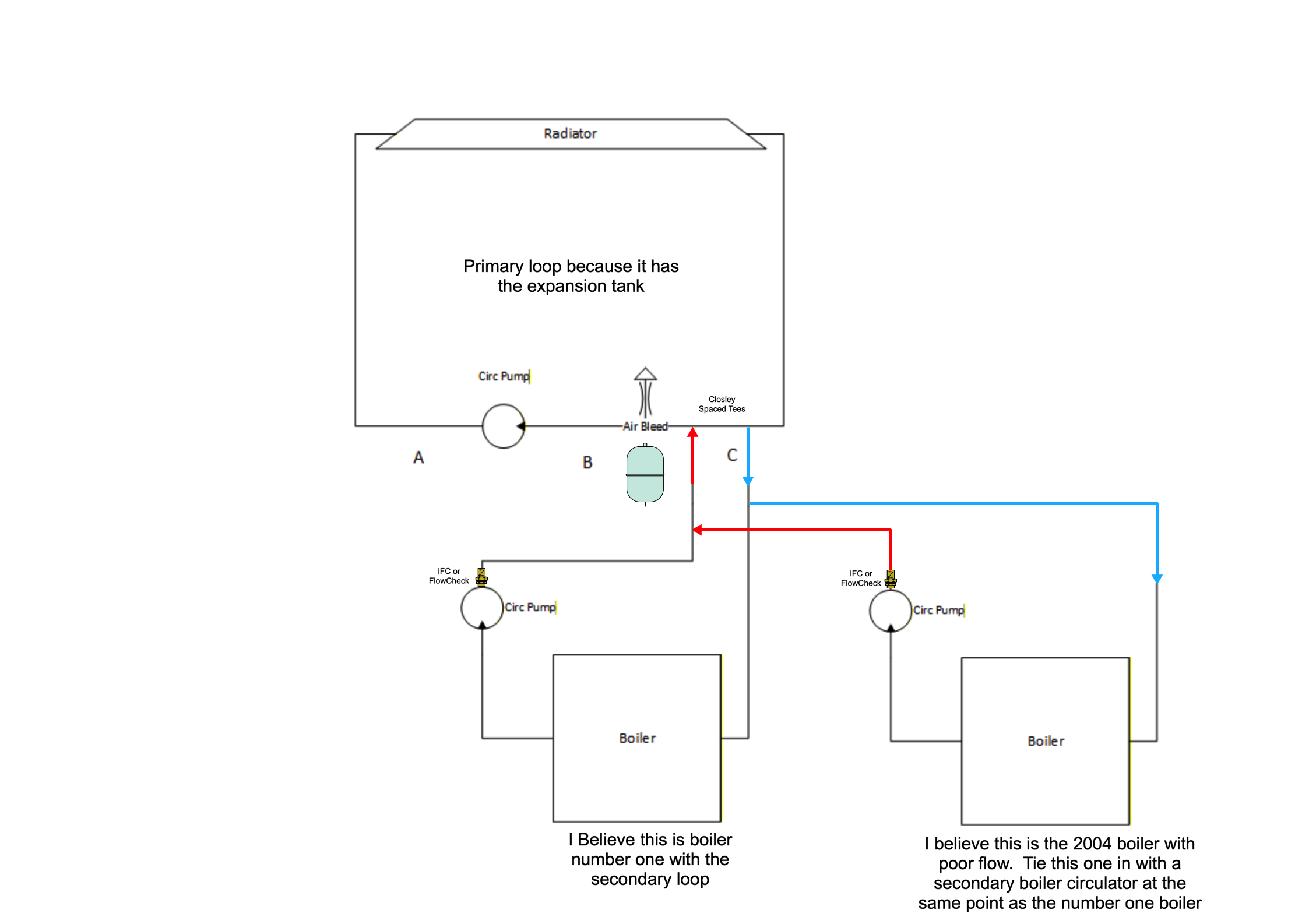

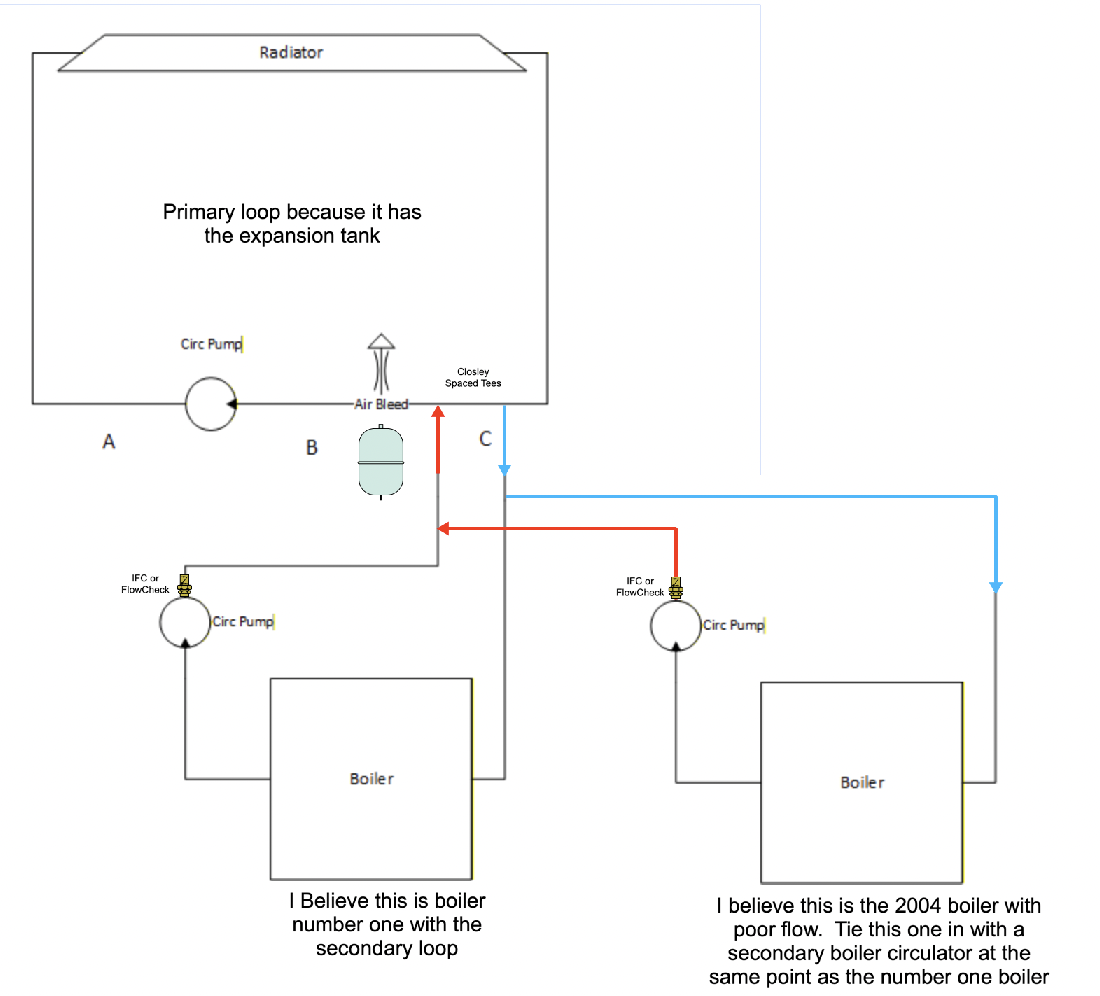

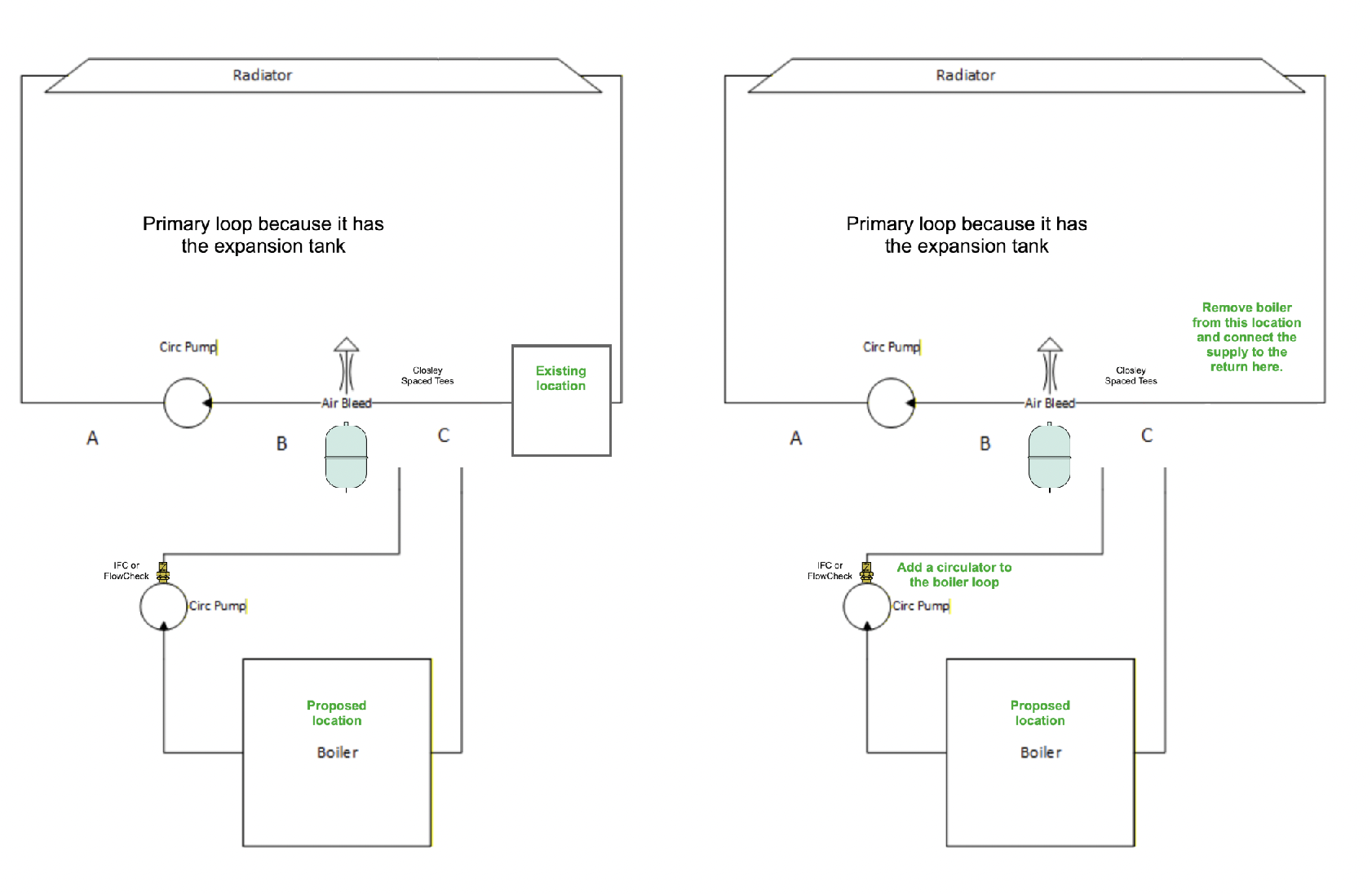

If you add secondary piping for the 2004 boiler then it should be added at the same point in the primary loop as the first boiler. This way both boilers have the same introduction point (Supply) to the primary loop and the returns have the same inlet point from the primary loop.

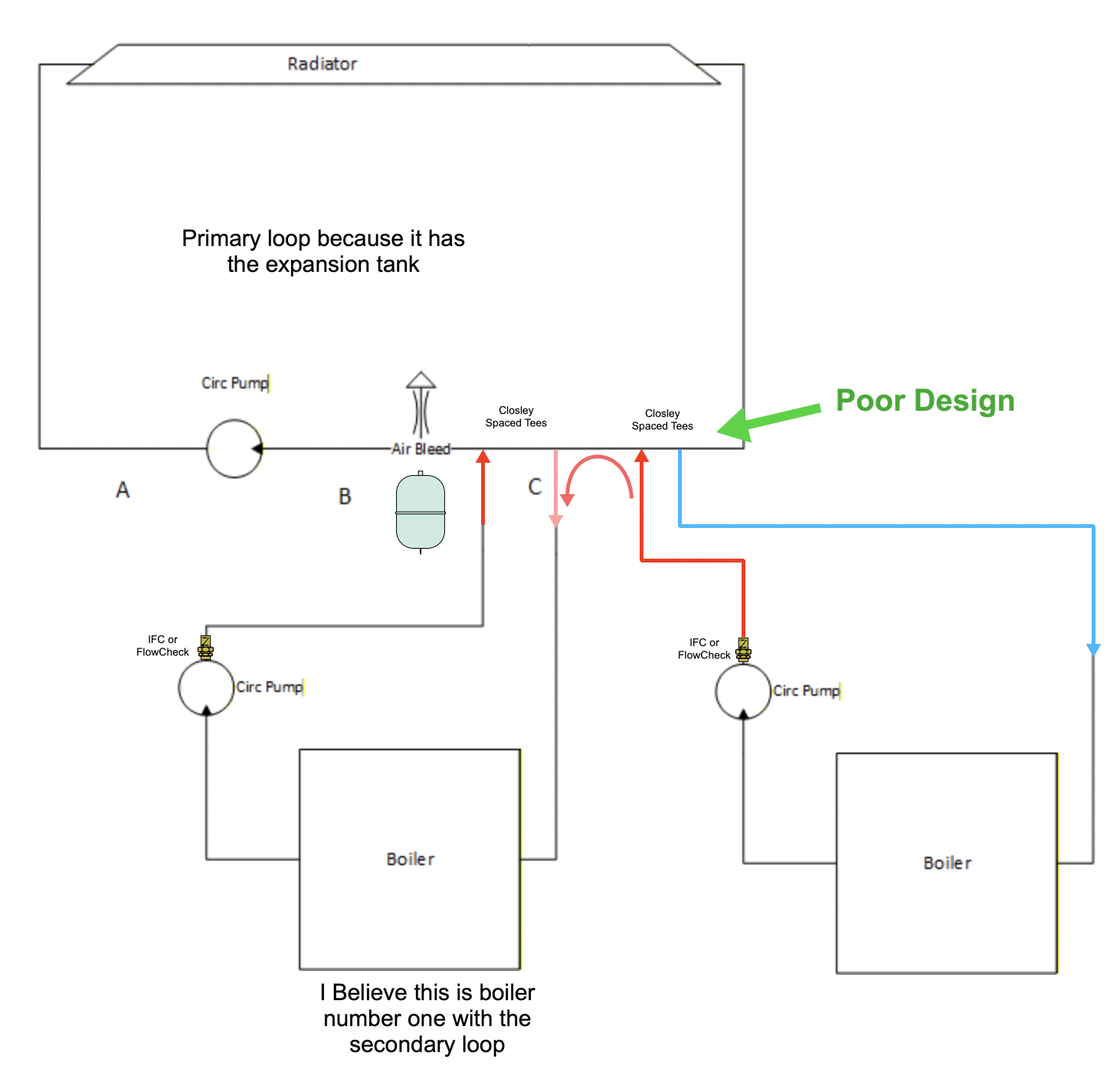

If you try to add a boiler to the primary loop at different locations then you will be getting heated water from the supply of the first boiler on the primary loop to feed the return of the second boiler if both boilers operate at the same time.

Can you see how the 2004 boiler is heating the water entering the return pipe of the secondary loop boiler if done separately? That boiler can not be as efficient with such high temperature return water. If you leave the 2004 boiler in the system somewhere without a secondary piping design, then one of the boilers hot supply water will be entering the return of the other boiler making that boiler less efficient.

So you have a good idea to make both boilers part of a secondary loop, you just want to put them both in the same location like my first illustration.

Hope this answers your query

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

why do you even need a primary loop, just parallel the two boilers?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes, the expansion tank is right under the air purger.

0 -

Each boiler serves a separate part of the building. They share no common plumbing other than where they connect to get city water.

0 -

Apologizes to @EdTheHeaterMan for not being more clear in my OP. My drawing is what I want to create and not a drawing of the boiler that already has a working secondary loop. It seems the consensus is that boiler was correctly configured and that I should build mine out to connect at "C."

Thank you all,

Jay

0 -

what type of boilers do you have?

Condensing or basic cast iron

What type of heat emitters, cast rads or low mass fin tube?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If you have one pipe already connected to the "other boiler" that is not in your diagram and you want to know where to connect the other pipe, and you selected C for that other pipe then one of the boiler supply pipes will be feeding the return of the other boiler at some point. Your point of no pressure change will play havoc on how the two different pumps interact and you may not get the result you are looking for.

Whenever you have 2 boilers in one system, you should connect both boilers in the identical way or one of them will bully the other boiler's pump and one of the boilers will not be able to offer you the same ∆T increase from the boiler's return to the boiler's supply.

I will draw a diagram of what might happen. Please let me know if I have the boiler not shown connected as you intend? BRBEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I get it now. you have two separate systems and you want to make the older boiler operate like the newer system.

C is the correct location. Remove the boiler supply and return from the system and connect those pipes with the shortest pipe you can. Leave the original circulator pump to pump away from the Expansion tank and connect the boiler with a secondary loop at C. that will put the lowest pressure and the highest temperature water in the primary system at the location of the air purger. Exactly where you want it.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Yes, exactly. Thanks so much,

Jay

0 -

I'd offer another version, showing both pumps "pumping away" from the expansion tank PONPC.

Or the tank could be on the boiler loop just before the boiler pump.

Depends a bit on the boiler. If it is a restrictive type HX like a mod con, you always want to pump into the boiler away from the exp tank. If it is a wide open cast, with little pressure drop, not as much a concern.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements