How would I drain possible airlock?

I have a possibly damaged PL-45 B&G pump that somebody installed wrong. It was installed vertically instead of horizontally, and apparently it was also installed backwards. I've successfully removed it and re-oriented it in what I think are the correct directions and there are no leaks. But now no heat is getting to 2 zones. I think I introduced an airlock by working on the pump. So now I need to drain the airlock, but am not quite sure which faucet to attach a hose to and which levers to shut and which ones to leave open, or anything else about releasing an airlock, actually. Maybe this isn't what you're supposed to do to solve this problem? Hoping to get instructions from somebody here.

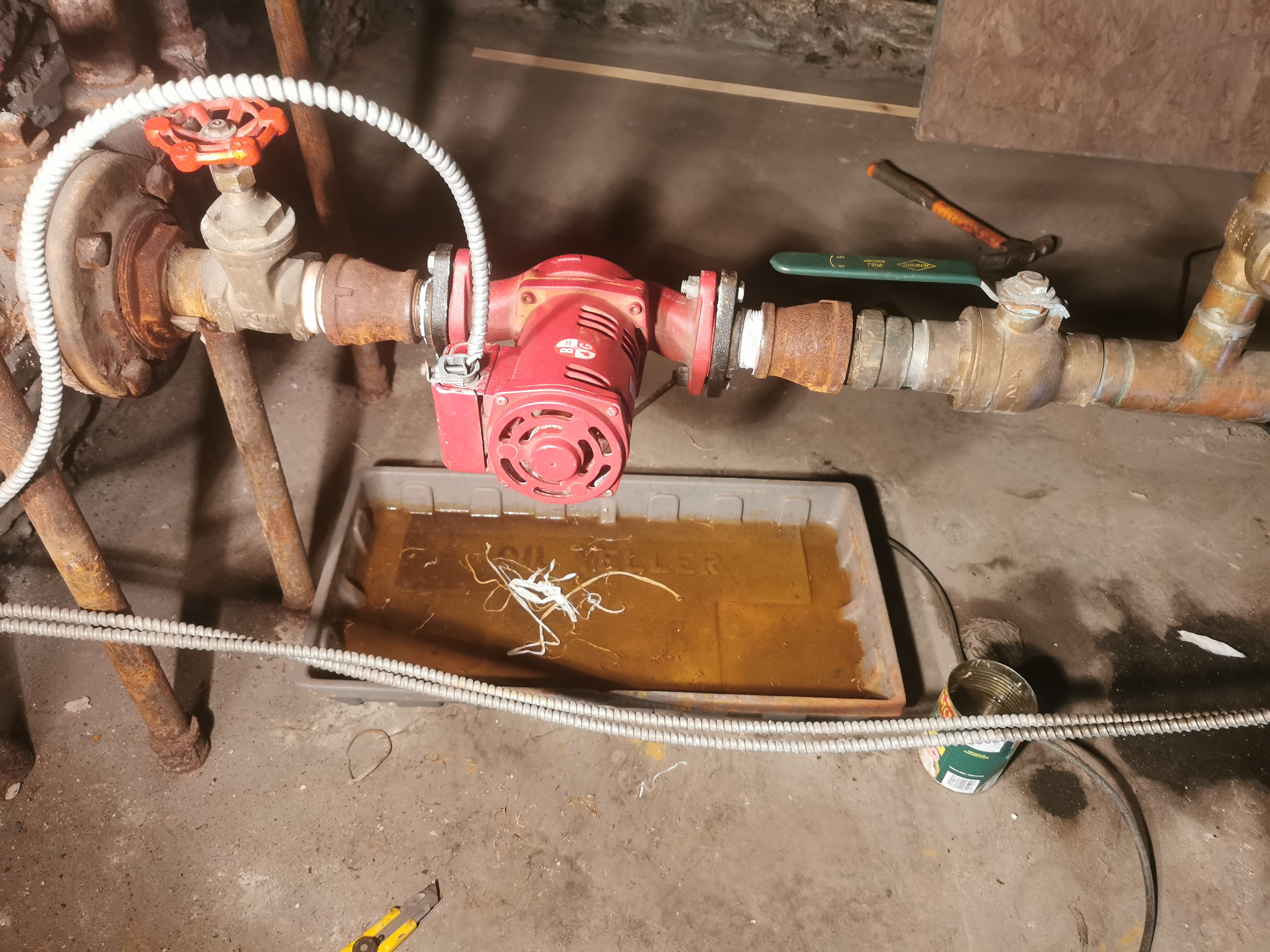

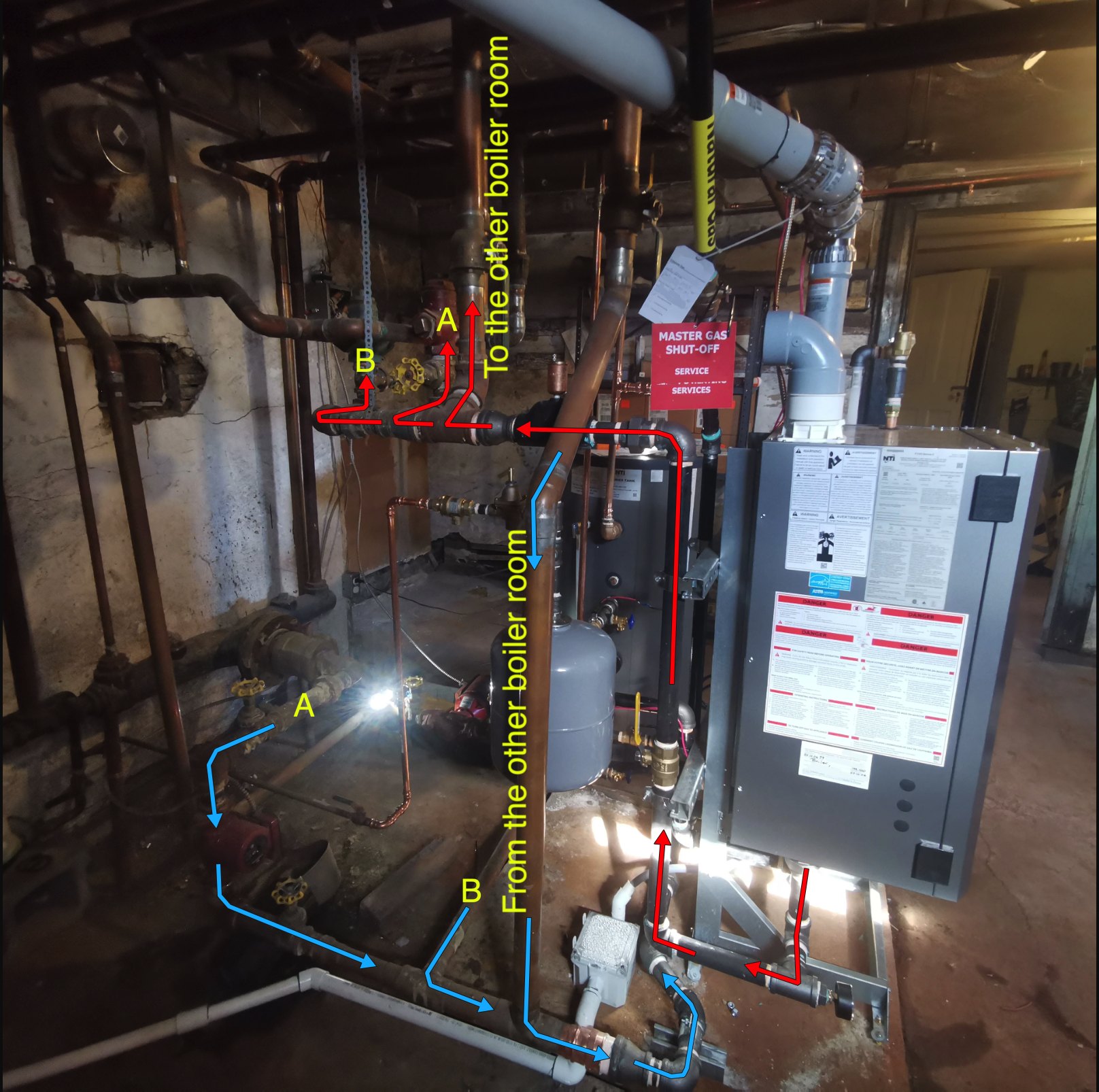

The PL-45, now pointing away from the hot pipes to the right of the frame and oriented horizontally:

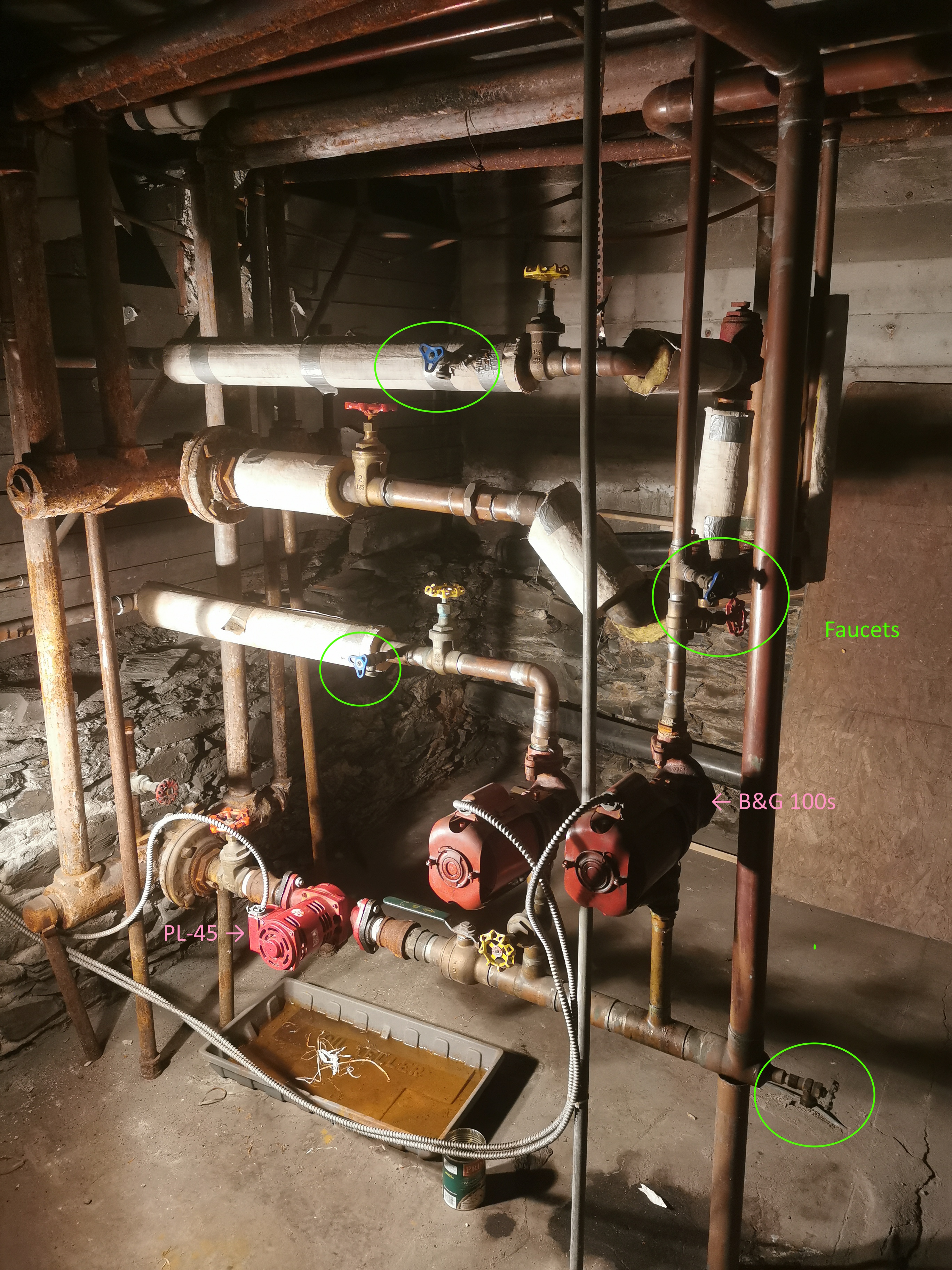

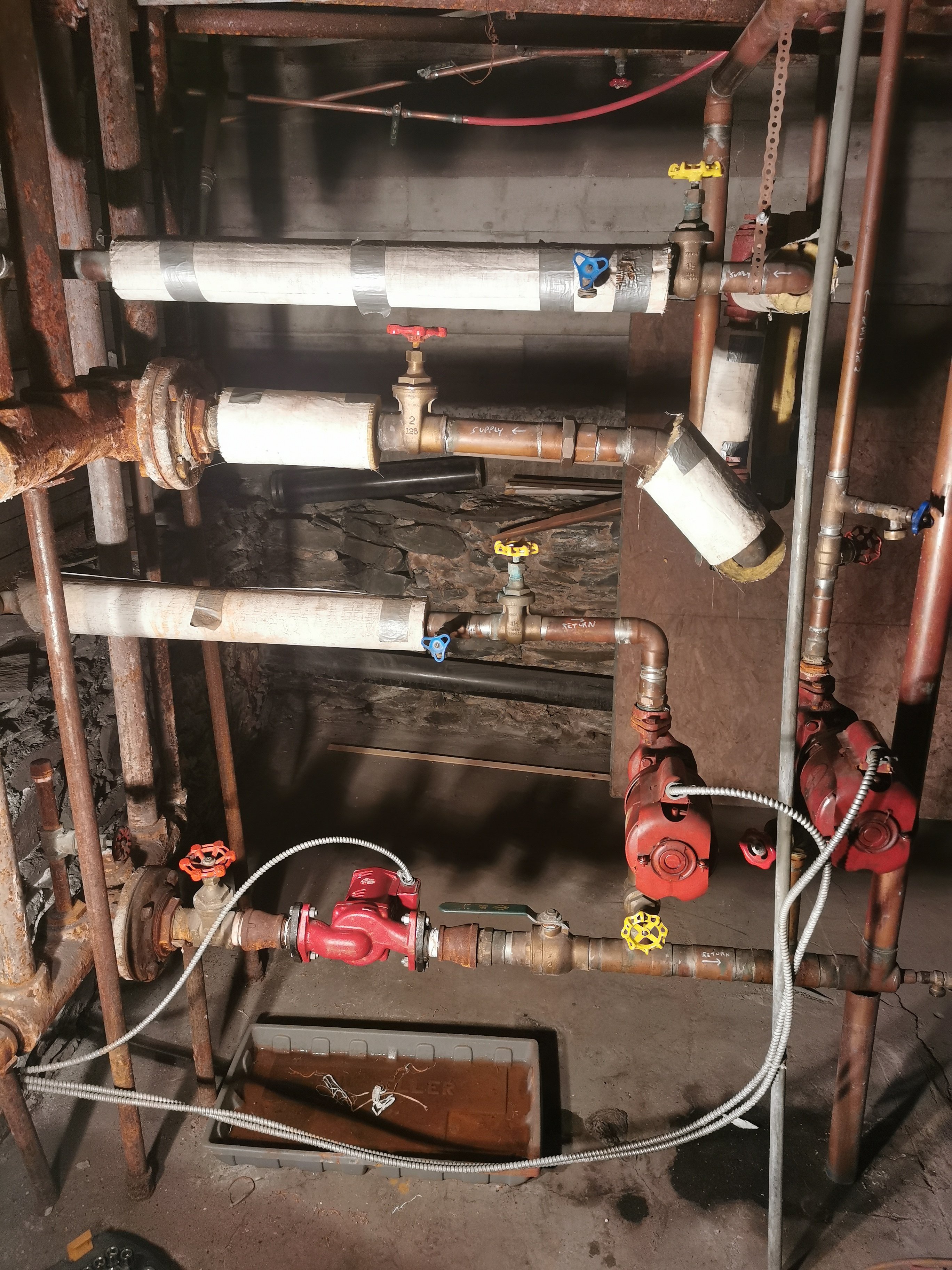

The area. There are several faucets to attach a hose to for draining, not sure which one I should use, or which levers and handwheels to close:

Alternate viewpoint:

Comments

-

What is the flow direction on the B&G 100's? Assuming those are pumping

g the correct direction?

The PL 45 is pumping right to left, so the 100's should be pumping up, correct. There should be flow arrows on the red flocheck valves also. Just to confirm everything is flowing properly.

Is there a boiler somewhere or is this a district or central boiler plant system? You need to know where the fill water enters the system, or have a pressure gauge somewhere to confirm pressure for purging,

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The B&G 100s are pumping down. See below - you can see the arrow pointing down on the pump on the left of this photo:

Since they are aiming down, towards the PL-45, and those pipes are hot, while the pipe on the other side of the PL-45 is cold, I figured the PL-45 should be pointing away from them. It was pointing towards them before.

The boiler is in another room at the front of the basement, maybe 25 feet away.0 -

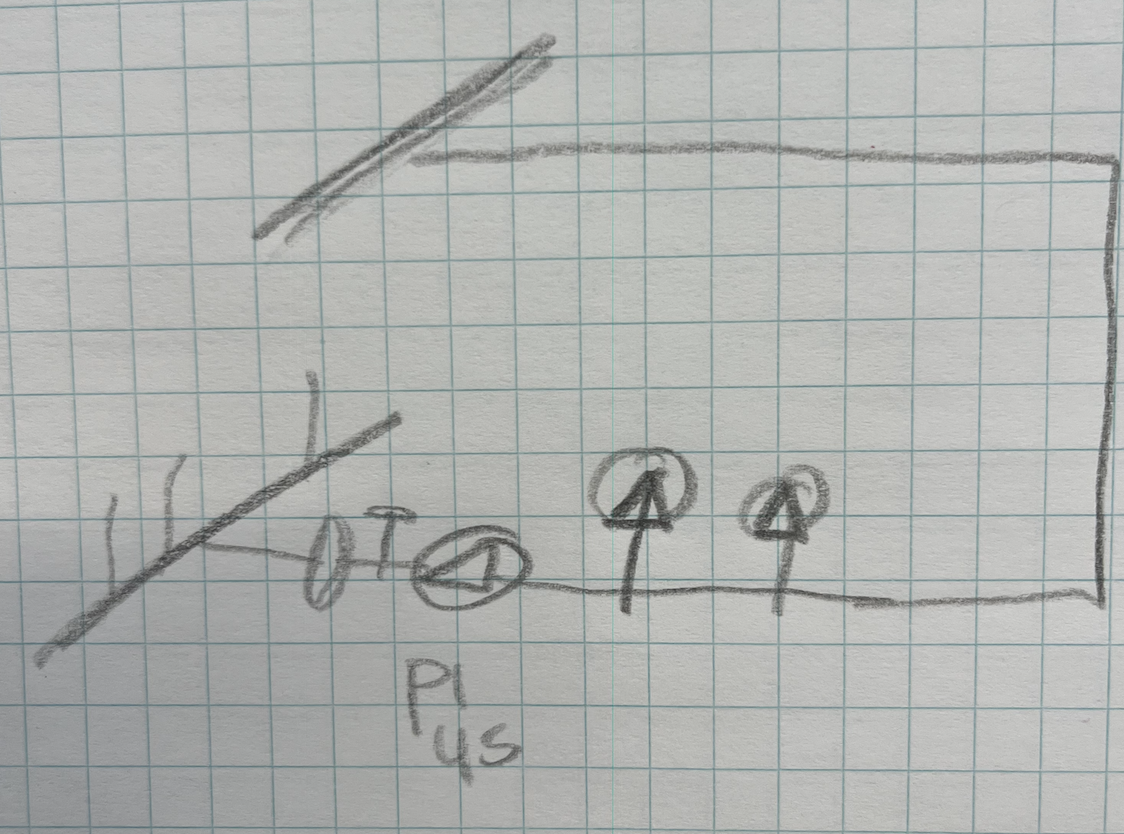

Maybe a sketch of the piping would help, where does the boiler tie into those

two headers.

From what I see the PL just loops the lower and upper header?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I don't think I can draw a sketch since it's too complicated and messy. But there's photos, diagrams, and detailed descriptions of the system in my other posts such as

0 -

I really don't think any sketch I could draw would be more useful than the photos, because in order to draw a sketch, I would need to understand the system, and what is flowing where, which I don't. That's why I'm asking for instructions, because I don't understand the system. If I understood it, I wouldn't need to ask. I can post more photos if you can use them to help me.

0 -

Hi @sjh , I'm thinking at least part of the reason for asking for a sketch is that it would be useful to get an idea where air might have risen to and be trapped in the system. Also, knowing where shut-off and purge valves are would make it clearer just how to move forward, using water pressure to flush out the air. Probably some mix of photos and sketch would do it. A sketch would just be to show how the pipes run and what valves or equipment is on them.

Yours, Larry

0 -

I'l attempt to draw a useful sketch. What do I start with? What do you need to see. There's too many pipes, valves, and knobs to draw, though. I started doing that with a 3D program but there's just too many of them and I can't see their full paths without ripping ceilings and walls down.

0 -

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

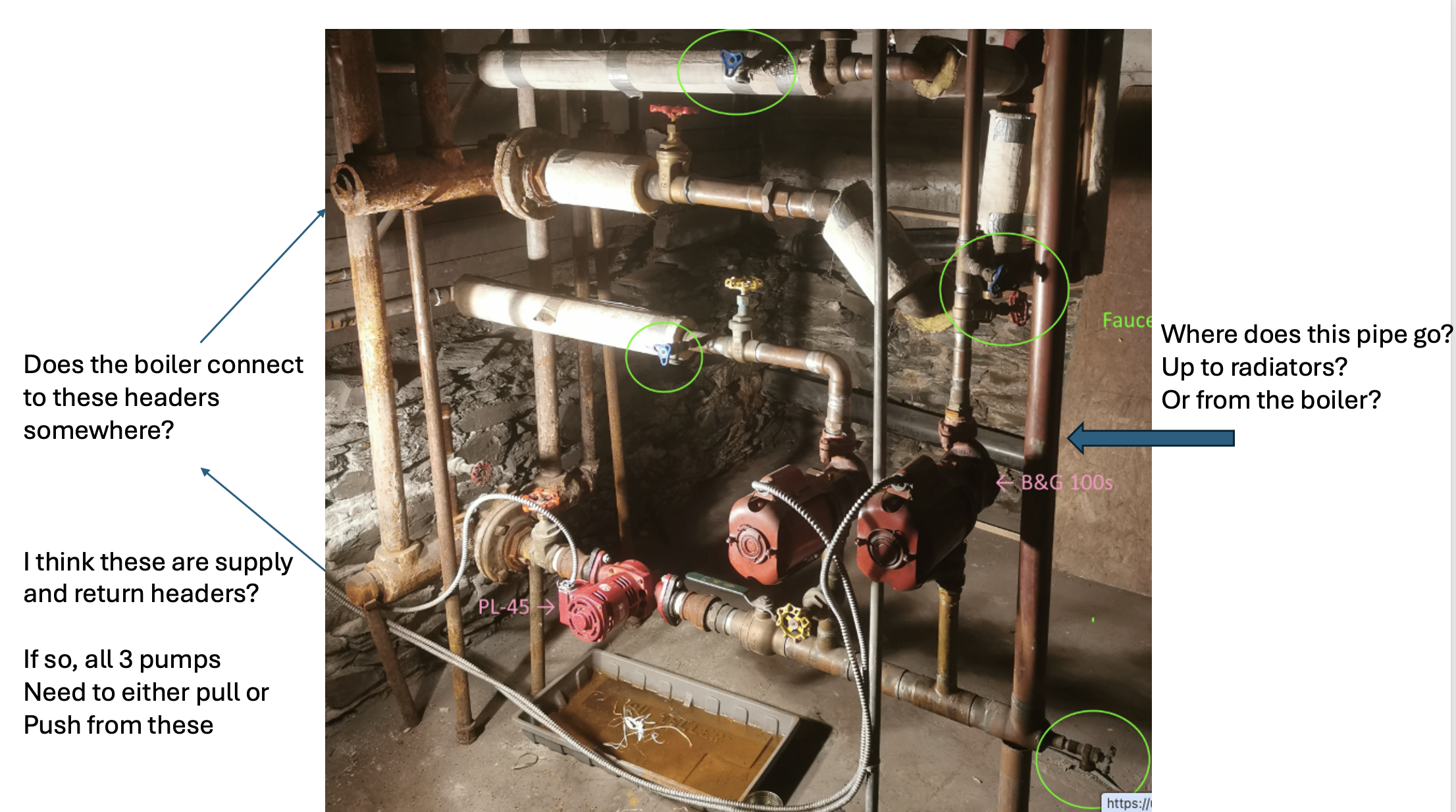

Q: Does the boiler connect to these headers somewhere?

A: Yes. Those upper headers are connected to what I believe is the Supply pipe.

The Supply does not directly feed the pumps. They are apparently on the Return side.

Q: I think these are supply and return headers?

A: I think you're correct, and the lower set of headers are apparently on the Return pipe.

Q: Where does this pipe go? Up to radiators? Or from the boiler?

A: It seems to go to the boiler, not from the boiler.

I don't know if my answers are correct. It makes no sense to me that on a day like today when it's below freezing, the Return pipes are scalding hot, the same temp as the Supply pipes, while the pumps they're feeding are cold and so are the pipes before the pumps. But all the pumps in the building (3 are shown) are apparently on the Return.0 -

I thought this looked familiar.

Here is the boiler that is in a separate room in the basement. There are two pipes from the boiler room that are labeled in this photo

Once those two pipes get to the other "Pump Room" that splits off into three other circulator zones. From the looks of things you have the PL 45 in the other pump room installed backwards.

The arrow on the PL45 is facing the wrong way

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Hi Ed,

I've got the PL-45 backwards now? I thought it was backwards before. It was also vertical before. But it was working better that way than it is now. Still making the same screeching noise as always though.

The arrows on those B&G100s are pointing down, into the pipe the PL-45 is on. So I figured they're feeding it, not the other way around.0 -

yes you could be air locked, so the new pump is not getting flow

Based on Ed’s drawing the pump is in backwards

It looks like you have valves to purge the 3 loops adequately

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@sjh, As I recall, You have 5 zones and it took me some time to understand that when you first posted back in October 2025. I needed to see the old system and the new system and with some comments from others I was able to see that the new boiler may not be pretty, however it is installed correctly.

At first I thought there were only 3 zones on one boiler and three zones on the other boiler, until you told me that there was only one boiler. Then I looked at all the photos as you posted them. In the new boiler photo above there are three pipes that leave the boiler room on the supply and three pipes that return to the boiler. Only two of the pipes have circulator pumps Zone A and Zone B. The third supply pipe leaves the boiler room and goes to feed three other zones in the other Pump Room. The second picture I have labeled the return to the boiler room and the three circulators that are connected to that Return pipe.

You already know that the pump is backwards because when it was installed in the vertical position, the zone worked. "But it was working better that way than it is now" Now that the pump is turned in the horizontal configuration the zone that pump feeds is not getting heat. DUH! That is because there is a flow control valve that prevents the water from flowing in the wrong direction. Your pump is pumping in the wrong direction. Believe Me. Your pump is backwards.

Look at the blue arrows on the drawing The two B&G 100 pumps are pumping down and to the left then up the return pipe and back to the boiler room. The B&G 45 is pumping so the water wants to go the other way. At the other end of the radiators on the supply side there is a flow check that is stopping the flow. As it is supposed to.

Ask yourself “if the pump was pumping in one direction and everything was working and now that it is pumping the other way and things are not working what did I change? Your answer should be the pump direction.

I might suggest that you get some type of marker and some white masking tape and start putting arrows on the pipes and I have done. Look at the most recent pictures because I got it wrong in the beginning until I knew you had only 1 boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

"The arrows on those B&G100s are pointing down, into the pipe the PL-45 is on. So I figured they're feeding it, not the other way around."

That would mean that two larger pumps are sending water to one smaller pump. To what end? You have 3 zones there. One thermostat for each pump. Each pump operates independently of the other pump. If all three pumps pointed down, would that make more sense?

Here is the same picture with less 90° elbows. this photo has the other zones, C D and E

Zones A and B are in the boiler room. Without actually knowing the home's layout I believe you originally had two coal fired boilers in that basement and all those large pipes were connected to a lot of cast iron radiators that were heated by a gravity flow or thermosyphon design.

At some point somebody may have said that you don't need two boilers and that one boiler alone can heat the entire building. When the boiler that replaced those two coal boilers was installed with pumps all those big pipes could be fed with smaller pipes using circulator pumps. That is when the two boiler rooms became one boiler room and one pump room.

Just photos of pipes without the context of the complete system, you will never get a proper answer to solve a problem. Your statements will be understood as truth even if they are incorrect. I was happy to remember this older discussion with all the photos that helped me to understand the boiler room(s) you have.

Once you get the zone E pump installed correctly in the correct direction it may stop making the noise. Only time will tell.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I switched the PL-45 back to pointing away from the rusty header, and it works now. So you're right.

I studied the setup and traced pipes for several days, still coming up with the incorrect answer. If it was pointing down, with the arrow pointing down just like the B&G100s, I might still conclude that they were sending the flow toward the rusty header. So any sketch I would have drawn would have been incorrect and might have led people in this forum to provide incorrect answers based on my incorrect assumptions. That's why photos were a better tool to use. Since I'm not a plumber or a hydronics expert, here's photos, let the experts see what's there, and advise me accordingly, like you have so helpfully done. I figured correctly that they were on a Return pipe but that didn't mean I could figure the correct flow direction. Same thing with the pumps in the main boiler room - even though I can see they're on the Return, You say they're going the opposite way from what I figured. I admit I suck at this and it's very confusing to me.

I've been labelling pipes, just the ones I know 100% for sure, because I don't want to wrongly label a pipe, then a year from now there's a problem I have to deal with, and I have wrongly labelled pipes preventing me from solving the problem, because I have them labelled wrong. In fact even after studying your edited photos, I still labelled a pipe with the arrow going in the wrong direction, and after 20 minutes of scratching my head thinking "how can this be?" realized "oh, the arrow has to go this way, not that way", and had to find something to erase it with. I had Supply and Return going in the same direction. Now it should be correct:

There is solid evidence that there was another boiler here a long time ago, probably in that 2ndary pump room. Several old rusty pipes are capped. There is what looks like coal boiler infrastructure at various places in the basement.

Is the PL-45 a zone pump, or is it boosting the other pumps? I've never been 100% positive what its role is. The answers I'm getting by searching online are, it's boosting.

What kind of setup do I have? Is it a Primary-Secondary System, or what?0 -

@sjh asked: "Is the PL-45 a zone pump, or is it boosting the other pumps?"

NO boosting. It is doing the same thing the other two pumps are doing. It is a zone pump

Maybe this will help.

This might be a coal boiler that could have been here a hundred years ago. There were no circulators on that old boiler because there may have been no electricity to operate them. Gravity or Thermosyphon technology was used to move the hotter lighter water in the boiler to the top of the system thru the supply pipes, and the colder heavier water in the radiators would go down to the boiler thru the return pipe. Those other two zone circulators were not there back then. Those pipes were connected to the ones that are capped off from that original flanged manifold.

Look closely at the flange at the top and the flange at the bottom. One is the supply and the arrow you have on that pipe is correct. The flange at the bottom is the return so you need to put an arrow on that pipe pointing in the other direction of the pipe on the top flange.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

In that photo going from top to bottom, the 4 horizontal pipes I've labelled are:

Supply ←

Supply ←

Return →

Return →

And I've added another "→" on the left of the left flange for the PL-45.I can see what you're saying about a former coal boiler in that space. I guess the capped-off pipe I have circled in green was connected to it? And the pipes the B&G100s are on weren't there?

0 -

@sjh Said: "I can see what you're saying about a former coal boiler in that space. I guess the capped-off pipe I have circled in green was connected to it? And the pipes the B&G100s are on weren't there?"

You are correct. the B&G 100 pipes were not there when the coal boiler was there. The pipes that are capped on the cast iron manifolds may have been connected to those pipes somewhere else before the pumps were added.

The fact that there are 2 capped off pipes on each CI manifold and there are two circulators is a good indiction that the radiators connected to the B&G 100 pumps were at some time in the past connected to the capped off pipes on the CI manifolds. But that is only a guess based on 40+ years of experience.

You can see how the PL-45 pump is a zone pipe now, Right?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan: You can see how the PL-45 pump is a zone pipe now, Right?

I would say it's a zone pump because it replaces a coal boiler, and that coal boiler was effectively a zone pump. It's not a booster pump for those B&G100s because they were probably installed, along with the PL-45, to divide the one big zone the coal boiler heated into 3 smaller zones. I imagine the reason a previous owner did that was because the coal boiler was old technology and being phased out of homes at the time, being replaced with cleaner and more efficient oil boilers, and instead of putting a new boiler there, it was probably cheaper to have 3 pumps installed, but not just cheaper - also more efficient and 'modern' in that it allowed for separate thermostats for each zone.

0 -

Booster is a term that was used by B&G over 75 years ago to sell pumps. It is like saying Jello™ even of your open a package of Royal Gelatin® and add it to the boiling water. You need to remember that over 100 years ago there were no pumps at all. Thrush was the first major pump supplier for the boiler industry. Bell & Gossett needed to tell the plumbers and pipe fitters of the time that their pump was better. You don't need a big pump. All you need is one of our "boosters" to get the job done. That way they sell more pumps than the other guy.

Remember you don't really need a pump back 100 years ago, so how do you get a boiler installer to add a pump. Call it something else and tell them you can use smaller diameter, less expensive pipes to get the heat where you need it.

So get the word "Booster" out of you head. It is an obsolete term and does not mean what you think it means in todays terminology. It is like saying this is a deluxe pump or a special pump or a space age pump, or a red pump. Even if you paint it purple or pink and you still call it a red pump. It does not make the pump any different. The name just sells more pumps.

The biggest thermostat manufacturer in the world lost a big market when the "think tank heads" at Honeywell called the software in their new thermostat "Intelligent recovery". Soon after the NEST thermostat became more popular because it was a "learning thermostat". Same idea inside the thermostat programing, just a different name makes one sell more thermostats than the other.

I better stop babbling on about trade names before I get too carried away.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements