Short cycling+ unbalanced heat

Hey everyone (this will be a long read)

I'm reaching out for advice on two problems I have in the single family home I live in. I am a plumber and gasfitter by trade, residing in New England, but my particular plumbing journey has not given me much exposure to heating work until the last two or three years. Here are my issues:

1) Likely boiler short cycling

2) Unbalanced heat between 1st and 2nd floor

Details:

Boiler- Weil Mclain WGO-3 oil fired boiler, 100k btu max out

Piping- One heating zone, split loop between the first and 2nd floor. Copper fin tube convectors (slant-fin) used as heat emitters throughout home. Tstat on 1st floor

2nd floor total slant fin- 77'

2nd floor additional piping (to/from boiler) 45'

1st floor total slant fin- 67'

1st floor additional piping (to/from boiler and in between slant fin) 52'

2nd floor heated area- 650ft²

1st floor heated area- 800ft²

Basement unheated- 800ft²

Balancing issue:

The 2nd floor, which has 3 bedrooms, seems to get more flow of hot water than the 1st floor. I always feel very cold/uncomfortable on the first floor. The only thermostat is located downstairs, in the dining room. The 2nd floor will get very warm before the 1st floor is warm enough to satisfy the thermostat. I was initially surprised because the total piping is so close between the two floors. After thinking about it (a lot) more, I realized the first floor loop uses about 20 more 3/4" 90s to drop down into the basement and come back up for navigating throughout the space.

**Would that extra friction loss from extra fittings on the 1st floor alone contribute to the flow favoring the 2nd floor?

I have since attempted to balance the two floors using the 3/4" ball valves on the supply side. I have the 2nd floor valve about 70% closed and now the temperatures are more even. I do still feel cold/uncomfortable on the first floor.

**Would installing tacosetter inline balancing valves on both loops be the best first step to accurately monitor and balance flow? And if so, would they work best on supply or return side? (Boiler circulator is installed on return side, pumping into boiler)

Short cycling issue:

I've adjusted the hydrostat settings and have economy on (1) and thermal pre-purge on. Unfortunately there is no outdoor reset installed. In the last hour it has run about 6 times, or once every 10 minutes. This has been consistent this heating season. Older honeywell digital tstat is set to 66F, and I have no programming set. Anticipator on back of tstat is set correct. When boiler shuts down on high limit, temps are usually 193F- 197F.

**Does this seem like abnormal boiler operation for my particular set up?

I have an oil burner technician coming next week to service the boiler. I moved in (renting) the first of September so it's my first heating season here. I asked the landlord and he was not sure the last time it was serviced.

**Would a build up of soot and un-checked combustion at least partially contribute to short cycling issues?

Looking at the near-boiler piping, on both the supply and return, the installer reduced from 1 1/4" to 3/4" first, and then split the loop with 3/4" tees. In my mind, you would want to either use a full size 1 1/4" tee and then reduce, or use an 1 1/4" x 3/4" x 3/4" tee to promote more flow through the system.

**Could this contribute to the short cycling issue, if the pump can't move enough water through those sections of piping that may have been reduced too soon?

Lastly, using a few basic boiler BTU calculators and maps, it seems like this home only needs around 80,000 btus max (0F day, 68F inside).

**What can I do about the oversized boiler? Would adding outdoor reset be the best fix?

Ultimately I want to be as comfortable as possible in this home with the lowest heating bill, but I also want to use this as a learning experience. I would love any and all feedback, and can answer further questions you might have.

Comments

-

if you have 77’ and 67’ of fin tube x 500 btu/ ft the fin tube can move 72,000 btu/ hr if the load is 80K you are not far off. The fin at 180 supply probably get you to 80,000

Is the boiler 100, 000 output. The issue with that boiler is it cannot modulate, so if only 1 zone is heating, you balanced the other way down, then you have too much boiler and it will cycle. It will cycle more on mild days when the load is low.

In an ideal condition on a design day the boiler would run 24 hrs, adding exactly what the home is loosing.

Perhaps a better way to balance up and down levels is to close dampers instead of closing off flow?

10 minute run is not too bad, what is the off cycle?

A good number to know is the return temperature at the boiler at the 10 minute shutoff.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I might add that a 3/4" copper pipe can move about 40,000 BTU of heat. Your boiler can deliver 100,000 BTUs of heat, The WM WGO-3 has a Net output of 100,000 BTU. That is about 250% more capacity than the output of a 3/4" copper pipe can handle. You are correct about choking the piping down before it splits into the two different loops. Even if you had a smaller firing rate, the lowest recommended NET output would be 85,000 BTU. and that is still more than 200% oversized for the 3/4" pipe.

The first step is to get the near boiler piping correct. With two 3/4" loops from the boiler to the tee where they spit should be a minimum of 1" copper pipe. A 1" copper shared pipe can handle about 80,000 BTU and as @hot_rod indicated you have about 80,000 of heat emitters, so that would balance out just fine.

The next problem is the first floor being too cold. Well that is a matter of your thermostat setting. Set the thermostat where you are comfortable on the first floor. When the second floor gets too hot, you can close the air damper on each radiator unit to minimize the output of that particular radiator section. Some rooms on the second floor may get too hot and shutting off the air flow thru the radiator will cut as much as 70% of the radiator's heating output. There will always be radiant heat from that hot surface but the convection air flow is most of the output. Stop the air flow and you stop the heat flow.

EDIT:

Looking at the cycle timing of the burner seems to prove that the piping is too small. During a call for heat after the boiler is up to the high limit temperature, the run time to off time ratio is almost 2 to 1 Off to On. that bears out the fact the the pipe is too small by a ratio of 2 to 1. Get a bigger pipe and you will move more heat.

There is one other thing to look at. If your home actually needs 80,000 BTUh of heat on the coldest day or the winter (which it most likely does not), you may find that your radiators can not make the home reach the thermostat set-point on the very cold days. You may need 50,000 when it gets near zero outside but the thermostat will never go above 65° since you are only moving 40,000 BTUh of heat. That might be enough for a 65° temperature difference (∆T) when you actually need 70° ∆T. If it goes below zero to -5° then the home will only get to 60° inside … and so on. You need a bigger pipe

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

4 minutes is a pretty short on cycle. 10 or 15 on would be good, 20 - 30 off. The boiler and flue piping may not be warming up enough, getting above dewpoint. So you could be getting condensation in the boiler or flue.

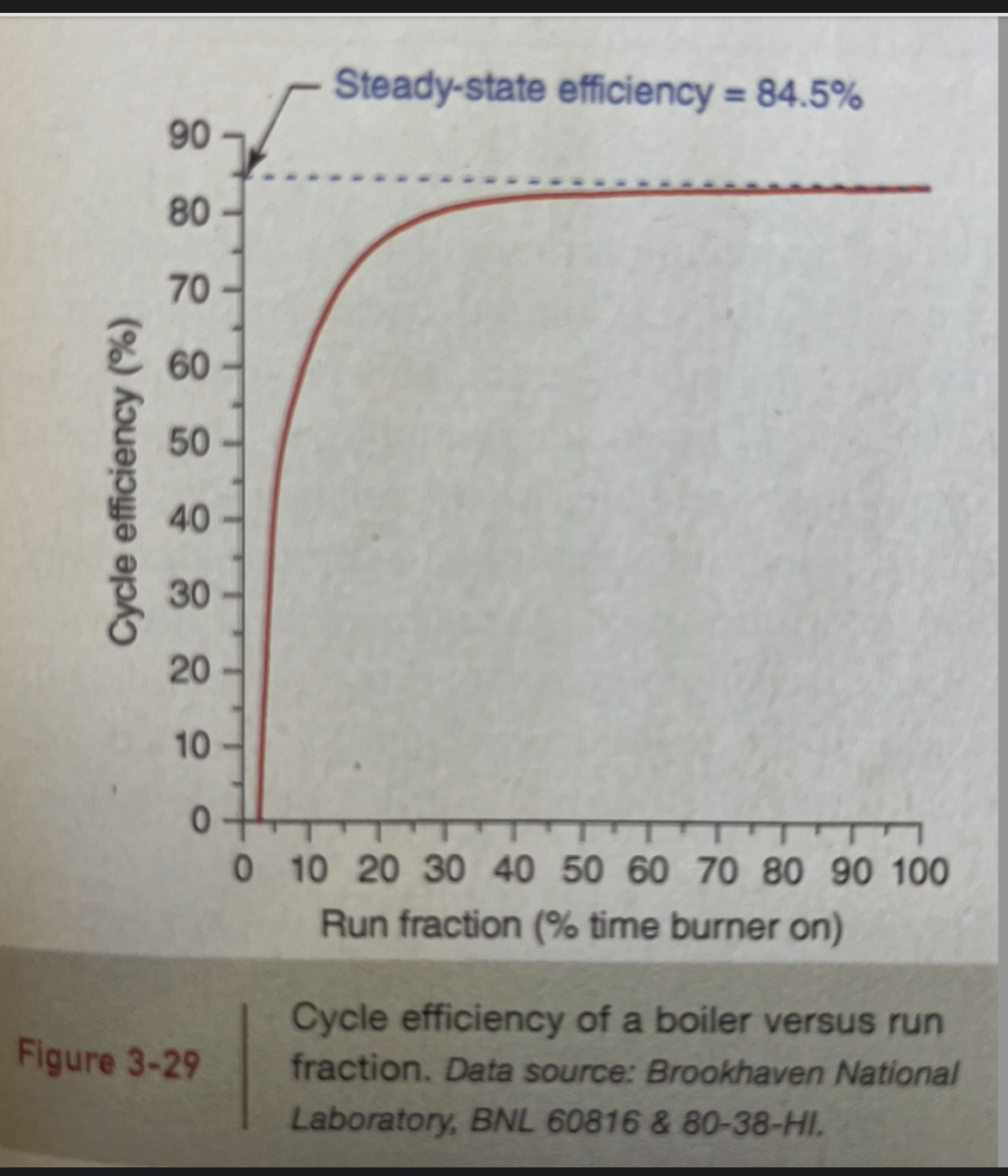

A run cycle looks like this 4 on 8 off over a 12 minute period so 4/12=0.333 or 33%

Plug that into this graph to get an idea of the boiler cycle efficiency. So perhaps 80% efficiency. I think that boiler could get up around 84- 85% This shows one of the problems with short cycles

15 on 20 off 15/35=0.429.42 or 42%, this gets you up close to the boilers max efficiency

You mentioned a soot build up?

Can you get a temperature on the return somehow?

The control may have some short cycle functions? There are other good better best options.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

What is your high limit set at? You can easily set it at 190 which should give you a 180 average water temp in the baseboard.

Taking supply and return water temps on each zone and look to get the same return water temp on each zone when both are heating

0 -

Only one zone. Only one thermostat. I believe there is a 1-1/2" supply opening that gets reduced to 3/4" before there is a 3/4x3/4x3/4 tee that splits to a first floor loop ad a second floor loop. Water will take the path of least resistance which must be the second floor loop since that loop is getting more heat than the first floor loop. Using a ball valve to reduce the water flow to the second floor can help to divert more flow to the first floor loop.

However, if you reduce the flow too much on the second floor, the heat there can become uneven. With very slow flow, most of the heat is released near the beginning of the loop, and the radiators farther along may not get enough heat because the water has already cooled down.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

if you have a multiple speed pump, you can squeeze a bit more output by increasing the flow(speed) of the water.

Fin tube output charts show 1 and 4 gpm. If you hear water hissing in the copper tube that is too fast, back it down a speed.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks to everyone who responded. After work I took my combustion analyzer and cooper kit in with me.

I opened the 2nd floor loop ball valve all the way and closed all of the slantfin dampers on the 2nd floor.

I took unit off of economy and turned up tstat to test combustion (180 high limit with 10 degree differential)

2.5% O², 19 co ppm, 84.4%eff,13.82%CO² 470F stack temp, 13.6% Ex air, 22 Co AF ppm.

I thought/think those were pretty good numbers as we don't know the last time it was serviced.

Reading temps on the return- I took measurements after closing the 2nd floor dampers and opening ball valve. Did this while doing combustion analysis so economy was still off and tstat calling.

2nd floor reading about 12-14 degree delta.

On the 1st floor I was averaging around a 22-23 degree delta.

This seems to make sense- 2nd floor heat has nowhere to go with the dampers closed, and the first floor has 20 more 3/4" press 90s than the 2nd, which must slow down the flow.

Tracking boiler on/off again while typing this, now that the boiler is back on economy setting (setting #1)

About 3 minutes on, 6 minutes off, 3 minutes on, 27 minutes off (tstat satisfied), 6 minutes on, 6 minutes off, 4 seconds on and then the t stat happened to satisfy.

I made a materials list to re-pipe supply and return so it is 1 1/4" and not choked down. Also on my list is the outdoor reset. Hoping I can pass off this good information to the landlord and see if he understands the value in making the corrections.

As far as the pump goes, it is unfortunately a basic taco pump that came with the boiler, and pumps towards the boiler. Wondering how worn down that may be if it's been trying to circulate water through inadequate piping for 11 years. I believe it's a 007 but the information on the front has been worn away over time.

I considered, and did buy, a better thermostat that can set limits for how many times the boiler can run per hour. I did not install it, as I feel like that's treating the symptoms instead of the cause.

Hopefully I can get this re-piped ASAP and see how it performs from there.

1 -

if we assume you are moving 4 gpm thru the 3/4 copper

490x4gpmx12 delta= 23,520 btu/ hr

490x4x22 delta= 43,120 btu/ hr

Added together you are moving 66,400 btu/hr

Some pressure readings across the pump would be one way to know IF in fact you are moving 4 gpm. If you had that exact gpm number to put into the above formula you would get a more accurate picture

One thing to know, when you take the delta temperature you want the system to be at thermal equilibrium the fin tube extracting what the boiler can add. To know that condition measure supply and return, when those readings stop moving, up or down you are at thermal equilibrium point to get an accurate delta reading.

This could involve some bucket time to get to the point of getting accurate readings. With an oversized boiler you will probably keep bouncing off the high limit, which makes the data collection a bit more time consuming.

The heat emitters drive the operating condition of the boiler, not vice versa.

It would be interesting to see what the second floor would show with dampers open?

If it jumped to 40 k and the lower is 40 k that is about reasonable. I don’t see a repipe at the boiler changing what the zones can move with 3/4 tube if your moving 4 gpm which that pump is capable of. Maybe the pump impeller is worn or damages as you suspected?

But if the heat load at design is 80K or less you should be fine other than some balancing.

The short cycling is not as easy to eliminate. A 100k boiler, even at design is too large.At less than design day, probably 80% of the heating season the boiler appears even more “oversized” to the smaller load conditions

Has the system ever worked properly over the 11 years? 1450 square feet of home even at a fairly high 30 btu/ sq ft is 43,500 btu/ hr load. Your current piping and pumping should easily cover that. Your fin tube installed can move 72,000 at 500 btu/ ft.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements