In Power Venting, why does the 3" 45 deg angle have the same 5ft rating as a 90 deg angle

Hi All,

Installation with a Burnham Independance 5 Power Vented system, has 2 possible configurations for venting.

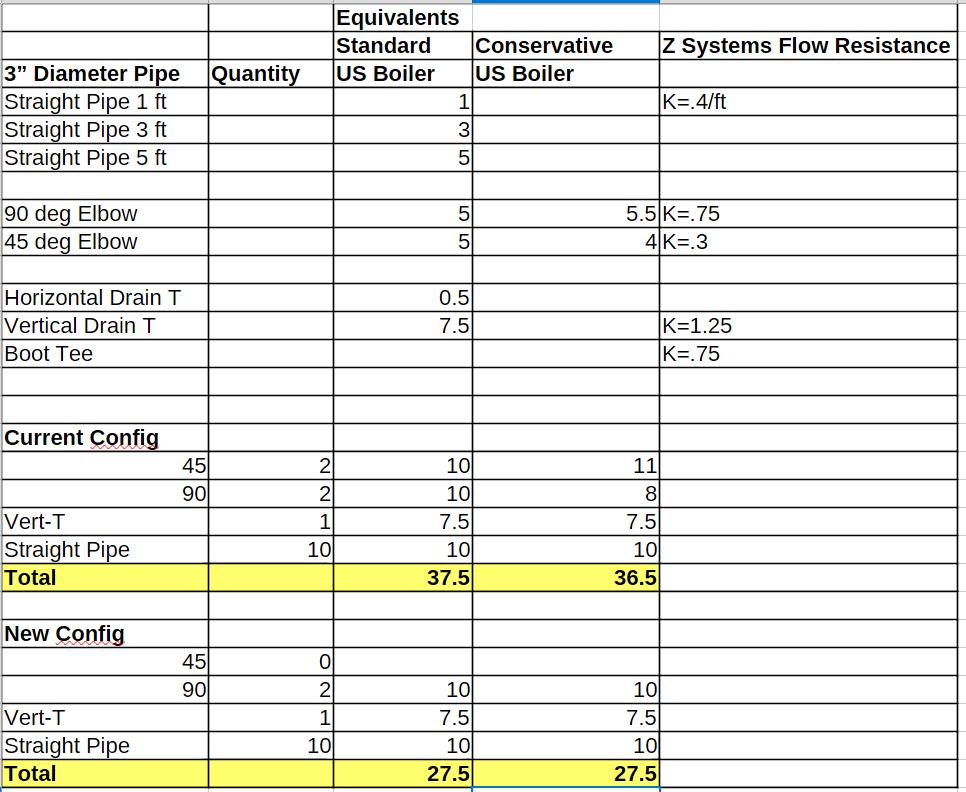

The first config: Six 45 deg angle pipes, with One 90 deg angle pipe. According to the documentation, 45 and 90 degrees have the same value, so, it is 7 bends, times 5 feet, equals a 35 foot run.

The second config: Three 90 degree angles, with a value of a 15 foot run.

The first configuration with 45 deg bends looks more gradual and it looks like it would flow better, but according to the Burnham manual it is the worst of the two.

Thanks for your help.

Best,

Peter

Comments

-

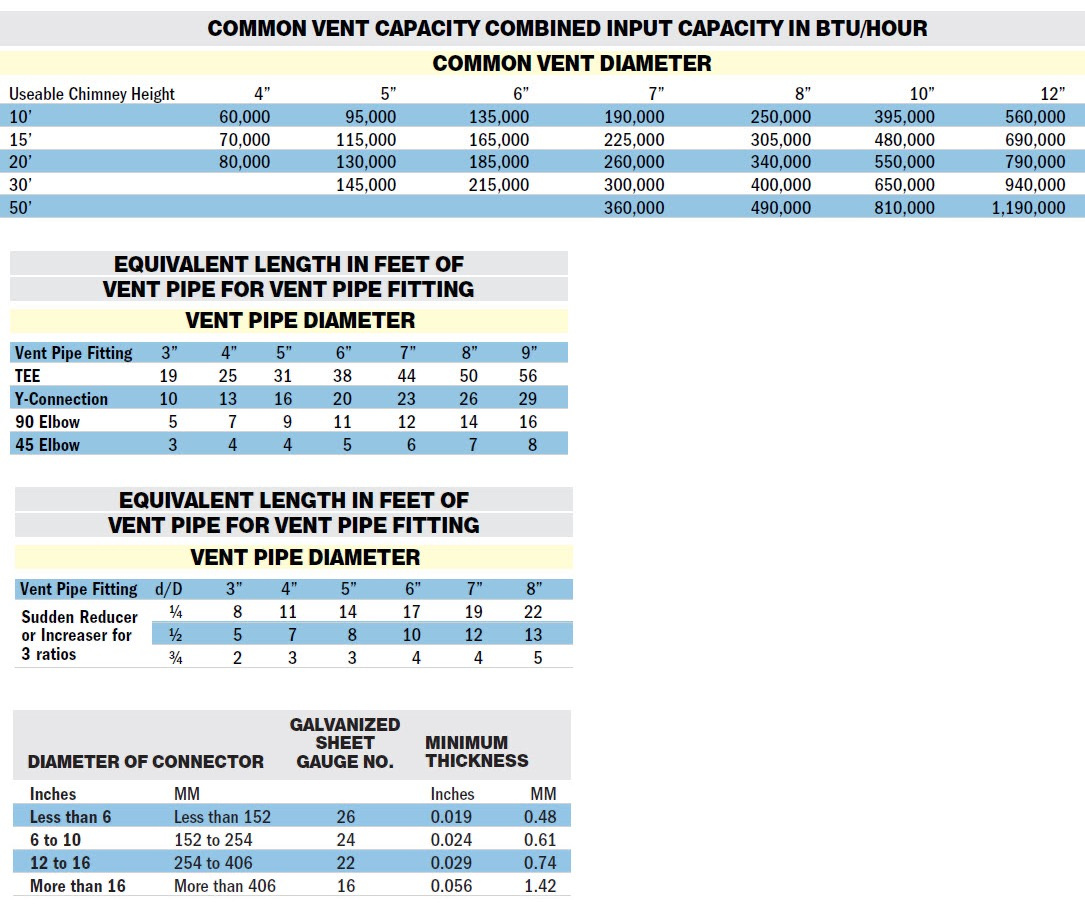

Where is this information? There is a difference in short radius and long radius bends (or elbows). Are you looking at a chart for short radius 45° and long radius 90° bends? I would like to see that chart.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

-

-

I think inspectors will go with what the manual shows, not a fitting EL chart?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

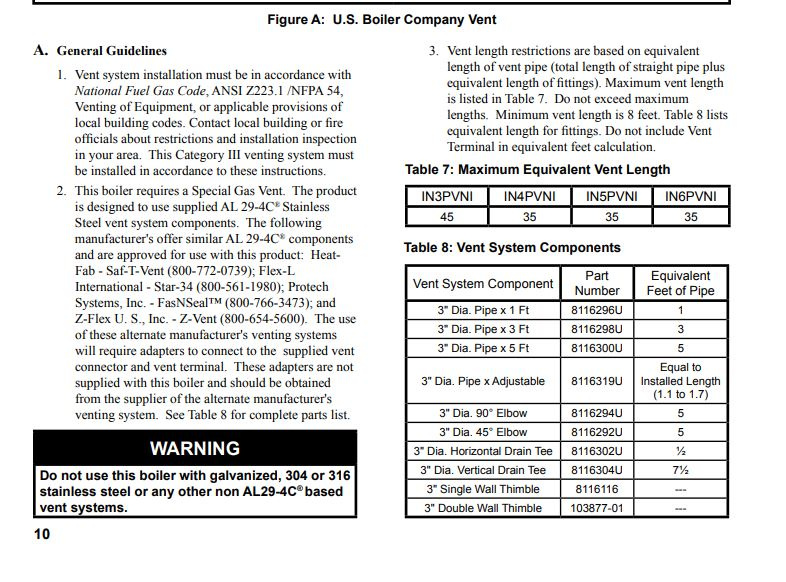

Type-O or not, that is what the manual states and that is what the inspector will go by. AL29-4C is in a different class of it's own when it comes to venting materials. Follow the instructions if you want to pass inspection. AND… I believe that the chart may be wrong for the 90° elbow. That equivalent length is supposed to be 10 feet

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

-

-

Hi All,

Thanks for the help. I was able to get tech support from US Boiler Tech and Z systems, which makes the stainless steel vents.

US Boiler said to go with the manual, which has 45 and 90 with the same value. I said it was odd that they would have the same value, so they then sent me a grid with an old conservative set of values, this had a 90 deg angle at 5.5 feet and a 45 deg angle at 4 feet.

Z-systems said that one had to go with the Boiler manufacturers values, because they depend on vent pressure and turbulence. However, they provided the Flow Resistance values, which are shown in the chart below. A 45 deg elbow is rated at .3, and 90 deg elbow has a value of .75 .

One online resource said that turbulence increases resistance and then turbulence eases with each straight run, but if you have a set of 45 deg angle pieces, the entire run may end up with a lot of turbulence and therefore a higher resistance. Here is my current chart with the values and my calculations with the old and new configuration. The new configuration has a better score because it has 2 90s and one Vert T, which is counter intuitive. You would think the one with more gradual angles would be better.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements