Old Weil-Mclain Boiler No response.

Comments

-

I think i know what's going on now.

This is how the bi-metal switch looks when power off. With power on, the brown heating element heat up and the bi-metal arm gradually bend inwards.

5 minutes later it looks like this, side view, touching and pushing the white safety switch arm. However even after 15 minutes, it still doesn't bend enough to make the switch click. If i push it 2mm more, the boiler fire up.

I'm thinking the possible reasons are:

- Basement got too cold, right now about 50F, and the heating element is not powerful enough to raise the temperature to the needed point.

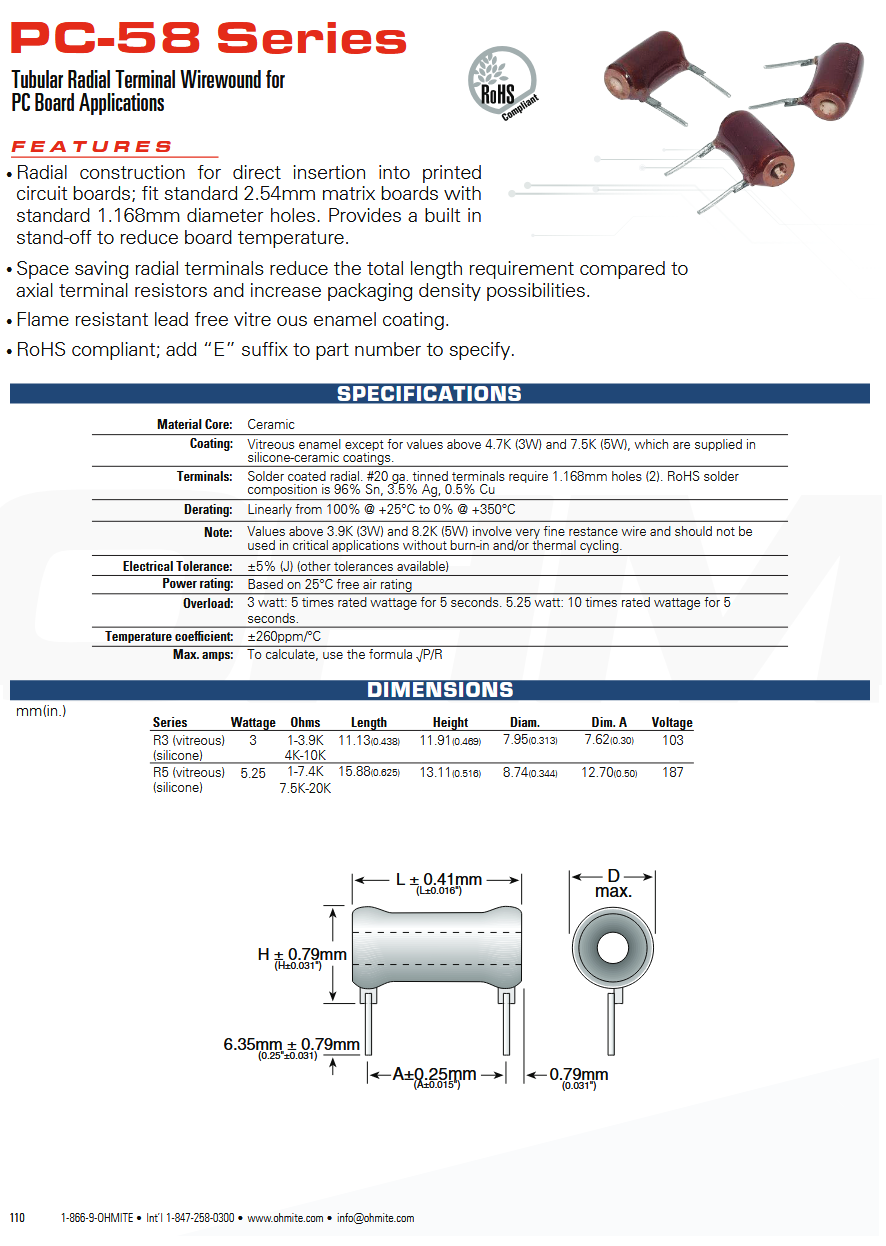

2. The heating element got weaker over the years. Not sure what the green rust is, on the connector between the wires and the heating element. Is there some kind of capacitor or anything there?

3. The bimetal strip got weaker or something. Unlikely though.

Whatever the reason, I'll bend the bi-metal strip 2mm more so it will make the switch click when heated up.

I tested the resistance of the heating unit an and it's 5000 ohm, with 138v on it when the electricity goes through probe to water, it's about 3.8W

The warning light is labeled 125v, 1/3w, and i calculated that is 47000 ohm. But with power off, the multimeter does not show it's resistance. Maybe it only works when electricity flow through with higher voltage?

When the wire is off the wingnut on the probe, and power on, 6-7 is 150v, 6-8 is 10v, 8-7 is 140v. This make sense that the probe in water can short the light route. When probe is dry, electricity must to go through the heating element then the light. The light has much higher resistance than the heating element so it's taking the majority of the voltage and light up, while the heating element cools down due to the big drop of the voltage applied on it

Any thoughts or advice on my plan to bend the bi-metal strip a little bit?

Any idea what's the green yellow buildup on the heating element connecting points?

0 -

oh, that's a little carborundum resistor with the screw through it on the left that just looks like a post?

don't move the bimetal strip, move the microswitch but make sure the connections to the power resistor are low resistance first

i think the green fuzzy thing is just a copper or brass crimp splice. it could have too much resistance and is keeping the power resistor from getting enough voltage because of its voltage drop. i doubt the value of the resistor drifted much. the corrosion is either just from moisture or possible from some flux that wasn't removed when it was manufactured combined with moisture. some wire insulation degrades and causes that too

there is or at least was a timer the manufacturer could order to their specification instead of rub goldburging their own.

the neon lamp will not conduct until the voltage is high enough to strike it which is usually in the 70-100v range or so

0 -

if you push the microswitch manyally does it kick over in to the has water mode? with the box missing over the power resistor and thermostat it isn't going to get nearly as hot as it does with the box holding the heating.

i will repeat again, that safgard has earned its retirement, replace it, you don't want to dry fire the boiler.

0 -

Not sure what you mean by "has water mode" but, warning light is off, vent damper start to turn and then ignition start to tick.

Good point about the cover and heat. I put it back on, also the outer casing just in case. Still won't fire after 15 minutes so something is going on in the bimetal unit.

I'll clean the corrosion and see what's under there.

I have another idea. Just thinking out loud here. The bimetal strip needs to bend another 2mm to trigger the switch. However, the boiler was working fine 10 days ago before this ordeal. Had the issue been corrosion, or weakened component or anything that's accumulative overtime, it's unlikely the failure will suddenly result in a 2mm gap. On the other hand, when the covers are on and heat more localized, maybe indeed it's just missing a hair to trigger. I can test this by a couple layer of tapes on the white arm. If it works then the issue was due to a gradual failing like corrosion. If it needs a lot more tapes like 2mm to work, then perhaps there was some thickness addon (for easier calibration maybe?) that finally broke and fell off.

I know lwco is a critical safety device but now that i see how it works. It really is very simple, without anything that can break except oxidation, and if it fails, it will just stop power to the boiler. It's impossible to fail in a way that would lead to dry fire. If i can fix it, i feel it's better than a modern lwco with 40 little electrical components.

0 -

did you check the resistance of the nearly corroded through wire and splices and the solder joints to the tabs of the power resistor? that is where i would guess the issue is, those are causing a voltage drop so the resistor isn't outputting as much power as it is supposed to. new wire needs to be soldered to that power resistor and connected to wherever the other end terminates.

mechanical parts of that system getting stuck closed is more likely than an electronic lwco failing closed.

0 -

You can do what you like but the reason for a low water cutoff is to prevent damage to the boiler, a potential fire or a potential boiler explosion.

Low water cutoffs were invented for a reason. Any boiler can develop a leak in the boiler or piping and loose water when you're not home.

Then if the control fails you have a problem.

1 -

The wire connections to the power resistor leads are probably crimped, probably just an un-insulated butt splice slid over both wires and crimped. Solder fails easily over time with constant exposure to heat, especially since the intent is to keep the heat in the area.

Looks to me like the metal that the micro-switch is mounted to is the 'calibration' adjustment by bending it. You may have to have a preload on the micro-switch's actuator level to get the change of state into the 'sweet zone'.

https://www.mouser.com/datasheet/3/132/1/res_pc58.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

" If i can fix it, i feel it's better than a modern lwco with 40 little electrical components. "

IMO Americans (maybe Humans in general) equate 'new' is better. What I see is new is just new, often 'new' is more complicated, harder or impossible to repair, costs more and does not last as long, it's like a contest to fill up land fills.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

i agree with that for the most part but on a safety control there are ways it can fail that you can't anticipate. if you are repairing it and making it up as you go along you could easily introduce an unanticipated failure mode.

it would be one thing if you were just fixing a solder joint or something like that, but this rube goldberg contraption had a bunch of things that were calculated that we know nothing about along with all sorts of opportunities for mechanical failures.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements